Types of saws based on operating principle

Power saws can be divided into three types depending on the principle of their operation: tools with a reciprocating mechanism (jigsaws, reciprocating saws, alligator saws), circular saws and chain saws. Each type is designed to solve its own range of problems. Jigsaws allow you to make complex, curved cuts in almost any material - wood, plywood, chipboard, OSB, MDF, other composite materials, plastic, non-ferrous metals, steel, ceramics, rubber, foam rubber, cardboard, sandwich panels, profiles, etc. (except for asbestos-containing materials). A jigsaw will certainly come in handy at the stage of finishing work: cutting a hole for a sink in a countertop, making holes for ventilation grilles, cutting laminate in place when laying, cutting a hole in ceramic tiles - this is not a complete list of options for its use.

Jigsaw Makita 4329

- Tools

Instructions for craftsmen: how to cut smoothly with a jigsaw

Reciprocating saws

Reciprocating saws were originally created as a tool for dismantling construction projects - and in this regard they are very convenient. This compact tool allows you to cut wood, metal, lightweight foam and aerated concrete, and in difficult conditions of limited space. A cordless reciprocating saw is simply indispensable for roofing work when sheathing is being installed. This tool is also very convenient for trimming twigs and thick branches in the garden.

BoschBosch Low Vibration technology reduces vibration levels in Bosch cordless reciprocating saws.

Greenworks

The Greenworks G24RS cordless reciprocating saw is powered by a 24 V battery, which is suitable for all 24 V Greenworks tools.

When working, the reciprocating saw should not produce too much vibration, which when purchasing is best assessed by turning on several tools for comparison.

Saw Hammer LZK 800 B

When choosing a reciprocating saw, be sure to take into account the nature of the future work with it in order to choose the right tool in size and weight. To dismantle a shed or reinforced concrete wall, you will most likely need a powerful tool with comfortable handles for both hands. And the weight of the instrument (3-4 kg) does not play a special role here. And if you are going to trim apple tree branches while standing on a stepladder, it makes sense for you to choose a reciprocating saw that is as compact and lightweight as possible (and of course, better with a battery) - models such as, for example, Makita JR100DZ, Metabo ASE 10.8 0 or Bosch Keo , which weigh 1-1.3 kg. The cost of such saws will be 5-10 thousand rubles, and heavier and more powerful ones, powered by the network, cost less, 3-5 thousand rubles.

AEGReciprocating saw BUS 18BL (AEG), 18 V, with PROFLUX brushless motor

Bosch

Cordless reciprocating saw Bosch AdvancedRecip 18

Leroy Merlin

Reciprocating saw Makita M4501, 1010 W (RUB 7,920)

Reciprocating saws, like jigsaws, are equipped with files with a standard shank. Files can be for different quality of work and for different materials. Moreover, the cost of some models of files can be quite high (500-1,000 rubles or more)

RyobiBrushless reciprocating saw R18RS7-0 (Ryobi), 18 V. The pendulum mode allows you to increase the cutting speed by up to 40% compared to the straight stroke.

Black & Decker

Reciprocating saw Black & Decker RS890K-QS (RUB 5,200)

Which company is better to choose a jigsaw?

A good jigsaw can be bought at any large hardware store, but most craftsmen are interested in the best device that can make precise cuts, can cut thick wood and can easily handle metal. To choose the right tool, you will have to learn a little about popular manufacturers, the cost of their products and features.

- Bison is a large domestic manufacturer that began operations in 2005. It is focused on the production of electric and hand tools in the household and semi-professional niche. If we compare it with global brands, the product from Zubr belongs to the mid-budget segment. The range includes everything: screwdrivers, drills, jigsaws, tools for car repair and woodworking and much more. Their advantages are moderate cost, long warranty and wear resistance.

- Whirlwind is a Russian company that began producing electrical devices in the 70s of the last century. Since 2000, production from Samara has been moved to China, which has expanded the range of products. It produces tools for both household and professional use. Its price niche is budget. The main advantages of the product are affordable cost, good build quality, high strength of the body and internal elements.

- Metabo is a renowned European manufacturer of pneumatic and electrical repair tools. The country of production is Germany, the headquarters is in Nürtingen. Professional products are valued by construction companies, but you have to pay for quality, since the company is focused on the premium segment. The advantages of Metabo devices: high power, durability of all components, ergonomics, large selection and the possibility of use in industry.

- Interskol is one of the leaders in the domestic niche of power tools, which also produces small-scale mechanization devices. It is one of the ten largest manufacturers in the world and offers construction, gardening, and snow removal equipment. The catalog includes jigsaws for DIYers and professional devices. Its price niche is average.

- Bosch is a good company for the production of various electronics and all kinds of electrical tools, which appeared back in 1886. To this day, the company’s equipment is valued due to its high consumer qualities: durability, power, performance and ergonomics.

- DeWalt is the fastest growing company, and it is also one of the best in terms of the quality of any product. The company was founded in the 40s, but gained the greatest popularity after its acquisition by the large manufacturer Stanley Black & Decker. Today the plant produces hand tools: tile cutters, impact wrenches, jackhammers, grinders, jigsaws.

- Makita is a Japanese brand that has been producing professional electric and gasoline tools since 1915. This company is one of the leading manufacturers in the repair equipment market, which develops devices for working with wood, concrete, metal and other materials. Today it has 8 factories - in the USA, Japan, China, Germany, Great Britain and Romania. He has amateur and professional level products.

- Military is a company owned by the German concern Hammer Werkzeug GmbH, which creates inexpensive power tools. The products are aimed at home craftsmen, for whom over 50 models of jigsaws have been produced. There are also professional devices, but their list is not so rich - about 20 varieties. The company is physically located in China. It entered the domestic market recently, but has already managed to establish itself well by producing durable, efficient and convenient jigsaws. All products are guaranteed for 1 year from the date of purchase.

- JET is an American company producing wood and metalworking machines, which is distinguished by the active integration of advanced technologies into its products. It produces circular saws, milling machines and stationary jigsaws. The price of all products is high, which pays off in the reliability, safety and reliability of the tool under intense loads.

- Dremel is a brand that produces both small tools for working on cars and large attachments for working with materials. Since 1993, the company has belonged to the Bosch concern. Most electric tools are used in construction and are valued due to their convenience and ease of use. Jigsaws are not the company’s core purpose.

The best electric planers

Circular saws

A circular saw is used for precise and long cuts of wood and all types of materials based on it, and with special saw blades, the saw can easily cope with sawing plastic, non-ferrous metals, and aluminum alloy profiles. This tool is used at all stages of construction, from sawing boards to carpentry and furniture work.

Circular saw Interskol DP-190/1600M

Circular saws differ in the diameter of the blade that can be installed on the saw, as well as in the diameter of the mounting hole. In everyday life, saws are used with a working blade diameter, usually from 120 to 250 mm, and with a mounting hole of 16, 20, 22, 30, 32 mm. Some size options are more common (for example, 165/20, 185/20, 210/30 mm wheels), while others are less common. In any case, make sure that you can easily purchase the right size disks at any time.

6 photos

AEG

Brushless circular saw BKS 18BL (AEG).

Leroy Merlin

Working with the guide plate.

Greenworks

Cordless circular saw Greenworks G24CS 24 V (RUB 9,690)

Greenworks

For precise and accurate cutting, the circular saw is equipped with a laser cutting line indicator, a guide plate and markings. Cordless circular saw Dewalt DCS391N, 18 V, 165 mm (RUB 11,735)

ShutterStock/Fotodom.ru

For cutting longitudinal grooves, a circular saw is perfect, on which special adjustable groove saw discs are installed for this operation.

Makita

Compact cordless circular saw Makita HS301DZ (RUB 5,600)

Circular saws provide the highest precision when cutting wood. For construction work, this is perhaps one of the indispensable tools with which you can make split cuts, making boards of the required width. When longitudinally sawing thick beams and logs, high power of the tool is required, so if the volume of work is large, you should not skimp on this characteristic. It is better to choose a model with a power reserve (1,500-2,000 W) rather than burn the tool in the middle of work. To work with thermoplastic plastics, it is advisable that the circular saw be equipped with a speed regulator (thermoplastic materials are cut at low speed).

Circular saw BISON ZPD-2000

Discs are available for different types of wood and are also designed for rough or fine work. The diameter of the disc determines the maximum cutting depth, which is approximately 30–40% of its value. The tool should be selected so that the maximum penetration depth is sufficient to cut thick boards. Therefore, say, saws with a blade diameter of 130 mm and a cutting depth of 42 mm are not suitable for cutting boards of fifty (50 mm). On the other hand, such models are very convenient for work due to their compactness and low weight (the weight of such a saw can be 2.5 kg, and the weight of a saw with a 210 mm blade can be more than 5 kg). Perhaps, with a large volume of work, it makes sense to arm yourself with two models of circular saws with large and small working diameters of the disks. Fortunately, the cost of circular saws is not very high: for 4-5 thousand rubles. you can buy a tool of quite decent quality.

To cut boards with great precision, removable guides are used, which in some models are included with the saws, and sometimes are purchased separately. If there is a large volume of such work, it makes sense to purchase a sawing machine, since now you can find models for quite affordable money. Thus, models of Interskol, Ryobi, Bosch, and Einhell machines can be purchased for 10–25 thousand rubles.

Manufacturing technology of decorative and openwork products

To work you will need the following:

- Plywood or wooden blank.

- A template, drawing or drawing of a future product.

- Manual or electric jigsaw.

- Files and needle files of various configurations.

- Wooden square and ruler.

- Skin of various grain sizes.

Cutting drawings

To begin work, you need to determine what should happen at the end of the work. To do this, you will need a drawing or template of the future product. You can come up with it and draw it yourself, or use ready-made solutions. There are many collections containing drawings and diagrams of crafts. The Internet is also replete with a variety of interesting ideas. And for almost everyone there will be an interesting diagram or drawing.

Typically, diagrams of small crafts are printed on A4 paper. To create drawings of decorative and stylish furniture or other large household items, whatman paper in sizes A0 and A1 is used, however, other paper and cardboard media, for example, pieces of unnecessary wallpaper glued together, can also be used for this purpose.

After the drawing is selected, it must be transferred to the material from which the craft will be made. There are several ways to do this:

- Transferring a design using a stencil. To do this, the drawing is cut out of paper - a stencil is prepared. Then this stencil is applied to the plywood and carefully traced (it is better to trace with a simple pencil, so that if something happens, the drawing can be corrected).

- Drawing a drawing on a workpiece using carbon paper. This paper is applied to the workpiece with the glossy side, the drawing is placed on the copy and traced with a sharp object (pencil or knitting needle). It is better to use dark paper so that the drawing on the workpiece is better visible.

- Drawing by thermal method. To do this, you need an inkjet printer; the selected pattern is printed with a large amount of printer ink. Next, this drawing is applied with the front side to the plywood and processed with an iron. A few seconds of ironing is enough for the design to be completely imprinted on the surface of the workpiece.

- The easiest way is to directly glue the drawing onto a wooden piece. The glue can be used as stationery glue or PVA glue. However, with prolonged sawing from plywood with a hand jigsaw, the drawings may stick strongly, which will increase labor costs during further processing and sanding of the product.

Technology

After applying the drawing to the workpiece from which the future craft will be made, they begin to cut it out. Sawing begins with the internal elements of the workpiece and only then the outer contour is cut out. This procedure is more convenient - holding the workpiece is much easier.

Holes for the jigsaw blade are drilled in sharp places on the internal contour, which also makes work easier. You need to drill holes carefully, as chips may form on the back side.

To avoid this, you need to follow a simple rule - do not drill holes completely. For example, if the thickness of the plywood is 3 mm, then the depth of the hole to be drilled should also be set to 3 mm. This is easy to do if you limit the depth of penetration of the drill into the plywood using electrical tape - wrap it around the drill, leaving only the 3 mm long tip without electrical tape. After drilling, turn the workpiece over and use an awl to make holes.

After the workpiece is cut, it needs to be processed and sanded . If the outer contour is not difficult to process, then grinding the internal elements is sometimes difficult, especially in sharp corners. It is difficult to sand such places with a file or needle file. Therefore, ingenuity can come to the rescue. You need to cut a thin strip of sandpaper and insert it instead of a jigsaw and then it will be much easier to process hard-to-reach places.

The principles of sawing with a manual or electromechanical jigsaw are similar, but there are also differences.

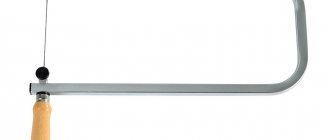

Working with a hand jigsaw

When working with this tool, you need an additional device - a sawing machine . It must be equipped with a clamp for attaching to a workbench or table. This device serves as the base on which the workpiece is sawed. This addition can either be purchased at the store, or you can make it yourself from a piece of thick plywood.

When working, the workpiece should be secured at chest level - this will make work more comfortable and maintain posture.

When working with a hand jigsaw, you need accuracy and patience . The files of this tool are quite fragile, so you need to avoid sudden movements and distortions of the blade, and also not allow the file to overheat during operation; to do this, you need to pause work every 10 seconds and let the cutting blade cool.

When sawing, the jigsaw file should remain in one place, that is, it should not be moved forward or backward, the movement of a hand jigsaw is vertical, reciprocating. They only move the workpiece, turning it smoothly, without stopping the forward movements of the manual jigsaw.

Sawing with an electromechanical tool

The operating principle is very similar to a hand tool. The difference is that a manual jigsaw does not require additional equipment (a machine with a clamp). And also when sawing, the shaped movement is produced not by the workpiece, but directly by the tool itself. The wooden workpiece is firmly pressed or attached to the workbench, and all curly movements are made directly with a jigsaw.

A jigsaw has an advantage over a hand saw - it is the thickness that it can cut in shapes. A wooden blank 50 mm thick is inaccessible for processing with conventional, non-electric tools. So, if you need to decorate elements of a porch or furniture, then you can’t do without a jigsaw.

You need to be very careful when choosing a power tool, since not all tools allow you to perform high-quality figure sawing of great depth.

Saw alligators

The alligator saw is an interesting type of tool with a reciprocating mechanism. It uses two cutting blades at once, moving in a support rail in counter motion to each other.

Saw BOSCH GFZ 16-35 AC

Thanks to this, the tool works easily, without jerking and vibration typical of, say, a reciprocating saw, the sole of which must be pressed tightly against the surface being processed. The alligator saw is a fairly powerful and productive tool; in terms of the range of tasks it is close to reciprocating saws.

DeWaltAlligator saws are used to cut a wide variety of materials.

Bosch

The long bar allows you to cut thick logs.

FAQ

Sometimes the jigsaw stops cutting in a straight line - it keeps turning and the cut turns out crooked. Why?

+

There may be several reasons:

- Strong horizontal pressure - you are trying to do everything quickly, but at the same time the workpiece itself is thick.

- Perhaps the blade itself is not selected correctly (for example, sawing thick plywood with a blade with fine teeth).

- The file is simply dull - you need to replace it with a new one.

Does the pendulum stroke greatly affect the quality of the cut?

+

It does, and not for the better. These jigsaws have a higher cutting speed, but the file may tend to leave the line. It is generally not recommended to make curved cuts with the pendulum turned on.

Jigsaws

When choosing a jigsaw, pay attention to the design of its body and especially the sole. It is desirable that it be designed in such a way as to prevent its deformation during intensive work (a slightly curved guide leads to defects during operation). It’s good, for example, if the sole is cast from an aluminum alloy with stiffening ribs. The body of the instrument must be balanced so that it can be held suspended with one hand without any effort. The handle of an electric jigsaw can be of two types - closed and open. The closed handle is considered the most universal. At the same time, jigsaws with an open handle are considered more suitable for figured cutting.

RyobiJigsaw RJS1050-K (Ryobi). A good overview of the cut is achieved due to the narrow contour of the gearbox, LED lighting and the sawdust blowing function.

AEG

Electric jigsaw: BST 18BLX (AEG), battery 18 V, 4Ah

Electric jigsaw: G24JS (Greenworks) cordless, 24 V

Electric jigsaw: “Interskol MP-85/700E”, “Home Craftsman” series, power 700 W

The main technical characteristic of jigsaws is the number of saw strokes per minute. The greater the number of “stitches”, the higher the speed of work. Most modern models have the ability to adjust the speed (just as it is possible to adjust the shuttle speed of an electric sewing machine). For a less experienced user, it is better to choose low or medium speed (1,000–2,000 strokes per minute). Many jigsaws have a pendulum mechanism (the file makes not only translational movements back and forth, but also oscillatory movements, like a pendulum). This mode of operation increases productivity several times, but reduces the quality of the cut, so it is good to use for rough work.

Jigsaw Kolner KJS 500

Jigsaws in general are relatively inexpensive tools. For 3-5 thousand rubles. You can purchase models from such well-known manufacturers as Bosch, Makita, Metabo, Ryobi, Interskol. Most modern jigsaws use files with a T-shank; other variants are very rare (and it is better not to choose such a tool, so that later there will be no problems when finding the necessary files). Saw blades are available for different materials (hard and soft wood, metal, plastic, etc.), so choose a file according to the type of material and the nature of the work.

Bosch

The design of the handle and a good view of the cutting site are important when cutting shapes.

Bosch

The Bosch Electronic system allows you to adjust the stroke frequency using a push switch.

Leroy Merlin

Cordless jigsaw Dexter, Li-ion, 18 V (RUB 3,654)

Leroy Merlin

Jigsaw “Fiolent PM 3-650E”, 650 W (RUB 2,700)

Rating of the best jigsaws

To determine which electric jigsaw is best suited for certain areas of operation, the following was taken into account:

- Maximum thickness of material for processing;

- Power;

- Functionality;

- RPM;

- Product weight;

- Durability;

- Availability of backlight.

Also during the review, the combination of price and quality, the presence of a large number of positive reviews and expert opinions were of considerable importance.

Benefits of cordless tools

Cordless models are now found in almost all types of power tools, including in categories that were previously considered not very suitable for batteries, such as circular saws (for example, the Ryobi R18CS-0, Makita HS301DZ, Bosch UniversalCirc 12 0, Greenworks G24CS 0) or, say, chain saws (models Greenworks G40CS30, DeWALT DCM565P1, Husqvarna 120i). This happened thanks to modern battery models that are capable of operating at any intensity mode, especially if you have a spare battery. Their high cost is the main disadvantage (several thousand rubles apiece). In other respects, battery technology is much more convenient: it is more compact, lighter and much quieter when compared with models with internal combustion engines). And, of course, no fuss with power cables.

The main parameters of canvases and what do they affect?

All main parameters are described above. Briefly about what determines each of the main parameters.

Shank types

The shape of the shank must match the model; for example, a file with a U-shaped shank cannot be mounted in a jigsaw designed for T-shaped files.

Sometimes it happens that thick files with a suitable shank do not fit into the fastening groove. This occurs on models with an auto-clamp (without threaded fastening). In such cases, take a thinner file, or slightly sharpen the shank on both sides.

Dimensions

The length of the files is divided into 4 groups from 75 to 150 mm. Each group is marked in the marking with a number from 1 to 4. When selecting the length of the file, proceed from the thickness of the material. At maximum reach, the end of the file should come out of the workpiece.

The longer the file, the more prone it is to move to the side. As a result, the cut may end up crooked. Short, thick files are less prone to bending and cut more accurately.

Saw blades of maximum length - 100-150 mm are used for cutting large-sized wood, soft and light materials such as polystyrene foam.

Tooth shape

Most teeth are shaped like a triangle with sharp corners. Their sizes, layout, and inclination may be different. In addition, there are blades with a wave-shaped cutting edge for soft materials and blades without teeth, with super-hard coating for ceramics, bricks and other hard materials. Here, a layer of diamond chips or tungsten carbide acts as a cutting surface.