Depending on the operating mode, the electric motor rotates at different speeds. Control over the process of converting electric current into mechanical movement is carried out using a special device - a speed controller.

Modern production of industrial and household appliances implies the presence of some kind of drive to activate actuators. The motor for operation is usually electric. The working body can be a separate part: for example, the design of a vibrating plate includes a moving component that interacts with the surface being processed. In this case, the load level can vary up to 3 kW or more. Some industrial systems use a 220 kW or larger electric motor, which requires additional tuning. To adapt the system to the selected operating mode, a 220V electric motor speed controller is used.

The main advantage of a speed controller for electric motors is a smooth change in the rate of rotation of the driving shaft. This is not the only benefit of using a tuning system in units rated 3000 watts and above; The regulator also cuts off voltage surges in the power supply complex, protecting the engine and peripheral electrical circuits from overload. Thanks to this, the launcher and all associated devices serve reliably throughout the entire period of operation declared by the manufacturer.

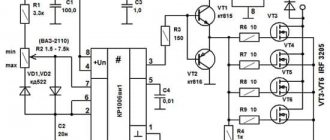

Speed controller circuit for an electric motor

Of course, a 220V electric motor speed controller can be bought in a store, but:

- It is difficult to find boards for mains voltage in stores (the main part of the market is regulators up to 35 volts).

- Those sold for network engines are of mediocre quality. They do not support power and speed, so they are not suitable for machine tools (for example, lathes) in principle.

- Industrial controllers that maintain speed and power are very expensive and difficult to purchase.

Why not collect it then? All parts are sold at any radio store, and you won’t need to program or flash anything, although you will need a microcircuit.

Controller Specifications

The circuit will have the following characteristics:

- Operating voltage - from 110 to 230 volts.

- Adjustment possibilities – 9 – 99%. In general, this indicator depends on the chosen dimer.

- Load – up to 2.5 kilowatts.

- Operating power – 300 watts without radiator. If you install good cooling, you can increase it by 20-25%.

This speed controller circuit for a 220V brushed motor is quite quiet and has a smooth start. Assembling it is quite simple.

What is an asynchronous motor?

AC electric motors have found quite wide application in various spheres of our life, in hoisting, processing, and measuring equipment. They are used to convert electrical energy that comes from the network into mechanical energy of a rotating shaft. Most often, asynchronous AC converters are used. In them, the rotation speed of the rotor and stator is different. A structural air gap is provided between these active elements.

Both the stator and the rotor have a rigid core made of electrical steel (composited type, made of plates), acting as a magnetic circuit, as well as a winding that fits into the structural grooves of the core. It is the way in which the rotor winding is organized or laid out that is the key criterion for classifying these machines.

Squirrel-cage motors (SCR)

Here, a winding is used in the form of aluminum, copper or brass rods, which are inserted into the grooves of the core and closed on both sides by disks (rings). The type of connection of these elements depends on the engine power: for small values, the method of joint casting of disks and rods is used, and for large values, separate production is used, followed by welding to each other. The stator winding is connected using delta or star circuits.

Wound rotor motors

The three-phase rotor winding is connected to the network via slip rings on the main shaft and brushes. The “star” scheme is taken as the basis. The figure below shows a typical design of such an engine.

The simplest regulator circuit

Refer to this diagram. To reduce the speed of the electric motor, you need a PWM modulator, also known as a triac. This is a microcircuit that modulates a PWM signal, which allows you to set its own frequency.

In this circuit, the role of a modulator is played by the U2008B chip. This inexpensive board is designed specifically for adjusting the speed of an asynchronous motor.

According to the Electrical Systems company website, you will also need a diode and a resistor to reduce the voltage. In the diagram they are shown with signs D1 and R1. Also, to filter the incoming electricity, a power capacitor, designated C1, is needed.

P1, R5 and R3 are voltage dividers designed to regulate voltage. The second resistor is needed to synchronize the internal motor blocks with the triac.

To keep the frequency regulator safe, it is recommended to install a regular 1.5 amp fuse.

If you want to make a professional board, grab this printable circuit:

All that remains is to transfer it to foil PCB and etch it. You can view the instructions here. The asking price for such a regulator is 200 rubles.

Selecting a device

In order to select an effective regulator, it is necessary to take into account the characteristics of the device and its intended purpose.

- Vector controllers are common for commutator motors, but scalar controllers are more reliable.

- An important selection criterion is power. It must correspond to that permitted on the unit used. It is better to exceed for safe operation of the system.

- The voltage must be within acceptable wide ranges.

- The main purpose of the regulator is to convert frequency, so this aspect must be selected according to the technical requirements.

- You also need to pay attention to the service life, dimensions, number of inputs.

Triac device

The triac device is used to control lighting, power of heating elements, and rotation speed.

The controller circuit based on a triac contains a minimum of parts shown in the figure, where C1 is a capacitor, R1 is the first resistor, R2 is the second resistor.

Using a converter, power is regulated by changing the time of an open triac. If it is closed, the capacitor is charged by the load and resistors. One resistor controls the amount of current, and the second regulates the charging rate.

When the capacitor reaches the maximum voltage threshold of 12V or 24V, the switch is activated. The triac goes into the open state. When the mains voltage passes through zero, the triac is locked, and then the capacitor gives a negative charge.

Factory regulators

In some cases, it is more profitable to take a speed controller of a commutator or asynchronous motor if you are going to modernize industrial equipment.

The most common models:

1 Motor Speed Controller 400W. Inexpensive (1300 rubles) PWM controller with simple controls. The main panel has an on/off button and a 10-step dimmer. It has high performance and is capable of driving motors up to 400 watts. There is a good cooling and protection system inside. Connection instructions for it will be described below.

2 KLS 4000-A1. Perhaps one of the most powerful Chinese rotation controllers. No connection required as such. Simply insert the plug into the socket on the case. There is a screen where the revolutions per minute are displayed. Perhaps this is the most convenient way to adjust the speed of a brushed motor without loss of power. The price starts from 2400 rubles from China. In Russia it is sold at a 1.5 times premium.

Thyristor speed controllers are in particular demand among Russian home craftsmen.

In appearance, they are similar to conventional rheostats, but have a large power reserve. However, you can do them yourself using this scheme.

There are a lot of disadvantages to this type of regulator:

- Omissions of half-wave waves. In this regard, the engine will constantly make noise during operation. This will not affect the operation of the engine, but the ease of operation is questionable.

- In principle, they are not suitable for high-power engines. They are convenient for starting small motors, such as fan motors. You can forget about washing machine motors.

- Power stabilization is quite low; it is advisable to install an additional capacitor to smooth out voltage surges.

But there are also advantages:

- Price. You can literally buy them for 150-200 rubles in any radio store. You can order from China for 75 rubles.

- Small size and compactness. They can be hidden, they do not take up extra space on the table and fit in your pocket.

Frequency regulation

Just recently (10 years ago), there were a limited number of frequency controllers for motor speeds on the market, and they were quite expensive. The reason was that there were no cheap high-voltage power transistors and modules.

But developments in the field of solid-state electronics have made it possible to bring power IGBT modules to the market. As a result, there is a massive appearance on the market of inverter air conditioners, welding inverters, and frequency converters.

At the moment, frequency conversion is the main way to regulate the power, performance, speed of all devices and mechanisms driven by an electric motor.

However, frequency converters are designed to control three-phase electric motors.

Single-phase motors can be controlled by:

- specialized single-phase inverters

- three-phase inverters with the exception of the capacitor

Converters for single-phase motors

Currently, only one manufacturer announces serial production of a specialized inverter for capacitor motors - INVERTEK DRIVES.

Optidrive E2 model

For stable engine starting and operation, special algorithms are used.

In this case, frequency adjustment is possible upward, but in a limited frequency range, this is prevented by a capacitor installed in the phase-shifting winding circuit, since its resistance directly depends on the frequency of the current:

f – current frequency

C – capacitance of the capacitor

The output stage uses a bridge circuit with four output IGBT transistors:

Optidrive E2 allows you to control the motor without removing the capacitor from the circuit, that is, without changing the motor design - in some models this is quite difficult to do.

Advantages of a specialized frequency converter:

- intelligent motor control

- Stably stable engine operation

- Huge capabilities of modern inverters:

- the ability to control the operation of the engine to maintain certain characteristics (water pressure, air flow, speed under changing load)

- numerous protections (motor and device itself)

- sensor inputs (digital and analogue)

- various outputs

- communication interface (for control, monitoring)

- preset speeds

- PID controller

Disadvantages of using a single-phase inverter:

Using a state of emergency for three-phase motors

A standard frequency converter has a three-phase voltage at its output. When connecting a single-phase motor to it, remove the capacitor from it and connect it according to the diagram below:

The geometric arrangement of the windings relative to each other in the stator of an asynchronous motor is 90°:

The phase shift of the three-phase voltage is -120°, as a consequence of this - the magnetic field will not be circular, but pulsating and its level will be less than with a power supply with a shift of 90°.

In some capacitor motors, the additional winding is made of thinner wire and therefore has a higher resistance.

When operating without a capacitor, this will lead to:

- stronger heating of the winding (service life is reduced, short circuits and interturn short circuits are possible)

- different current in the windings

Many inverters have protection against current asymmetry in the windings; if it is impossible to disable this function in the device, operation using this circuit will be impossible

Read also: Oscillator op 240 circuit

Advantages:

- lower cost compared to specialized inverters

- Huge selection of power and manufacturers

- wider frequency control range

- all the advantages of the inverter (inputs/outputs, intelligent operating algorithms, communication interfaces)

Disadvantages of the method:

- the need for preliminary selection of the inverter and motor for joint operation

- pulsating and reduced torque

- increased heating

- no warranty in case of failure, because Three-phase inverters are not designed to work with single-phase motors

The engine speed controller is needed to perform smooth acceleration and braking. Such devices have become widespread in modern industry. Thanks to them, the speed of movement in the conveyor, on various devices, as well as when the fan rotates, is measured. Motors with 12 Volt performance are used in entire control systems and in cars.

Ways to connect the speed controller

How to connect the speed controller? Let's consider Motor Speed Controller 400W for 3 reasons:

- This is the most popular speed controller.

- There are problems connecting it due to the markup in Chinese.

- The connection is almost no different from having assembled it yourself.

To begin with, it is worth studying the connection diagram printed on the side of the regulator or the device passport.

Now you need to use the pinout on the back panel. You will need to select the necessary conclusions. The CCW and COM pins are always shorted and should not be touched. To connect you will need to use the 3 bottom contacts. AC ~ AC is zero and phase (the wires are installed arbitrarily, but the current is alternating). The ground wire, if present, is inserted into the FG.

In general, the preparation is complete. All that remains is to insert the plug from the regulator to the motor terminal block.

It is recommended to place a capacitor in the gap in the phase wire.

It will help smooth out incoming tension. It also wouldn't hurt to install a ferrite filter. It will help smooth out interference during work.

Single-phase frequency converter

The compact frequency conversion device is used to control single-phase electric motors for household equipment. Most frequency converters have the following design capabilities:

- Most models use the latest vector control technologies in their design.

- They provide improved torque for single-phase motors.

- Energy saving is set to automatic mode.

- Some models of frequency converters use a removable control panel.

- Built-in PLC controller (it is indispensable for creating data collection and transmission devices, for creating telemetry systems, and integrates devices with various protocols and communication interfaces into a common network).

- Built-in PID controller (monitors and regulates temperature, pressure and technological processes).

- The output voltage is adjusted automatically.

Fig. No. 7. Modern Optidrive converter with basic functional features.

Important: A single-phase frequency converter, powered by a single-phase network with a voltage of 220V, produces three linear voltages, the value of each of them is 220V. That is, the linear voltage between the 2 phases is directly dependent on the output voltage of the frequency converter itself.

The frequency converter does not serve for double voltage conversion; due to the presence of a PWM regulator in the design, it can increase the voltage value by no more than 10%.

The main task of a single-phase frequency converter is to provide power to both single- and three-phase electric motors. In this case, the motor current will correspond to the connection parameters from a three-phase network and remain constant

Washing machine motor speed controller

Connecting the electric motor speed controller for a washing machine, first of all, it is recommended to disassemble and check the presence of a triac - a power element. It should be on the radiator. If it is not there, it should be additionally installed so that the regulator does not overheat. The radiator is lubricated with thermal paste for better thermal separation.

After this, the regulator is assembled and connected to the engine according to the diagram shown on the housing. This makes it possible to regulate and stabilize the speed, increasing the voltage amplitude. At the same time, the power of the device increases.

Measurements

It is clear that the number of revolutions needs to be determined somehow. Tachometers are used for this. They show the rotation number at the moment. You can’t simply measure speed with a regular multimeter, except in a car.

As you can see, on electric machines you can change various parameters, adjusting them to the needs of production and household use.

DIY birthday decor

Close…

Pointed-toe cowboy bootsThe principle of operation of a homemade lock is as follows. In one half there is a permanent magnet. and in the other there is a metal plate. One of them is attached to the door. The second, with the metal plate removed, is equipped with a KEM-1 reed switch and attached to the door frame. If the door is in the closed position, the two parts of the lock are pressed, the magnet acts on the reed switch, closing its contacts. If the door opens, the magnet goes away and the reed switch contacts open.

The battery, the computer system unit, even the power supply for a laptop are all best friends. I’m already silent about such good hot water bottles as my husband and I.

Take the filler and stuff the doll. When the stuffing is completely evenly distributed, sew the product up. The handles must be sewn to the body almost near the neck.

From one pallet, sanded, impregnated and varnished, you get a garden table like a coffee table, on the left in Fig. If you have a pair in stock, you can make a wall-mounted work desk-rack out of them in literally half an hour, in the center and on the right. You can also weave chains for it yourself from soft wire, covered with a PVC tube or, better, heat-shrinkable. To fully raise the tabletop, small tools are placed on the shelf of a wall pallet.

Well, if you fill a glass bowl, vase, candy dish, punch vessel or ordinary glasses with water, scattering sea pebbles on the bottom, and let the candle-tablets float freely, you will get magical lighting for a romantic New Year. For a more interesting and unexpected effect, you can experiment with the color of the water. How are studs installed on rubber?

Handmade toys for children are beautiful, cheap and enjoyable. Every child needs original and educational toys, but it is not always possible to purchase them. Today we will show you 5 examples of fun toys that you can make yourself. They can be made from cardboard, paper or wood. In general, be inspired and make your children happy more often.

For the base of such a structure, you can use thick plywood, and for its upper part - polycarbonate. Finding solar panels online today is also not a problem.

Attention! When joining panels, do not use too much force, as you may damage the joint. This is exactly how many knives a housewife should have in her kitchen so that the cooking process is always simple and enjoyable.

This is exactly how many knives a housewife should have in her kitchen so that the cooking process is always simple and enjoyable.

To make a feeder with your own hands we will need:

Timber calculation. The boards, called staves, have biconvex sides to give the cooperage product a convexity. To make them like this, you need to take the lower part of a tree trunk and split it, similar to chopping wood. If you cut it carefully, the natural integrity of the fibers will be disrupted, which is bad for such a product. You shouldn’t start figure sawing right away - the logs need to be dried for 2 months. Moreover, dry it not under the scorching sun, but in a dark, cool room.

How to weave bracelets from laces

The fact that most New Year's costumes for preschool children are easily sewn on the basis of overalls can significantly narrow and facilitate creative search. If you learn how to sew a jumpsuit - the basis for a New Year's costume and come up with (draw from) and make decorative elements for it with your own hands, then you can make amazing and quite interesting models of New Year's outfits for children. The main thing is to think through everything in advance to the smallest detail, arm yourself with knowledge on the topic - so that the result of the work will pleasantly surprise and delight everyone.

Wardrobe design

Images

DIY birthday gift for mom photo instructions

Similar news

.

With the ever-increasing growth of automation in the domestic sector, there is a need for modern systems and devices for controlling electric motors.

Control and frequency conversion in small-power single-phase asynchronous motors, launched using capacitors, allows you to save energy and activates the energy saving mode at a new, progressive level.