It is believed that cinder block is excellent for the construction of residential buildings and other buildings, due to its availability and compliance with the required characteristics.

To further reduce the cost of the material, many begin to produce it themselves.

This can be done either using improvised means or using a special machine. The device is not cheap, but you can also build it yourself.

Features of the material

Cinder block is a building material that has proven itself to be one of the most durable and unpretentious.

It has considerable dimensions, especially if you place an ordinary brick next to it. You can make slag blocks not only in a factory setting. Some craftsmen undertake this work at home. If you strictly adhere to the technology, you get high-quality and strong blocks from which you can build a house or any outbuilding. If a decision has been made to independently produce such products, then a number of its features should be taken into account.

- Cinder block is a fireproof material. It does not ignite itself, and does not intensify an existing flame.

- Really good quality blocks make long-lasting and sustainable homes/outbuildings. Such buildings will not be harmed by harsh climatic conditions, hurricanes, or constant gusty winds.

- Repairing cinder block buildings does not require extra effort and free time - all work can be completed in a short time.

- Cinder blocks are also distinguished by their large sizes, thanks to which buildings made from them can be erected very quickly, which pleases many builders.

- This material is durable. Buildings built from it can stand for more than 100 years without losing their previous characteristics.

- Another feature of cinder block is its soundproofing component. Thus, in dwellings made from this material there are no annoying street noises.

- The production of cinder blocks is carried out using various raw materials, so it is possible to select the optimal products for any conditions.

- What distinguishes cinder block is that it is not subject to attacks by various kinds of parasites or rodents. In addition, it does not rot, so it does not have to be coated with antiseptic solutions and other similar compounds designed to protect the base.

- Despite their decent dimensions, such blocks are light in weight. This feature is noted by many masters. Due to their lightness, these materials can be easily moved from one place to another without calling a crane. However, it must be taken into account that some types of such products are still quite heavy.

- Cinder block is not afraid of low temperatures.

- These blocks are distinguished by their high heat capacity, thanks to which they make cozy and warm homes.

- Temperature fluctuations do not harm the cinder block.

Cinder block buildings are usually decorated with decorative materials to give a more aesthetic appearance.

However, it is very important to remember that the cinder block cannot be covered with ordinary plaster (any “wet” work with this material should not be carried out). You can also use a special decorative block, which is often used instead of expensive cladding. When working with cinder block, it is important to take into account one important feature - this material is characterized by high water absorption, so it must be protected from contact with moisture and dampness. Otherwise, the blocks may collapse over time. Unfortunately, the geometry of the slag blocks leaves much to be desired

That is why, when laying floors from such material, you will have to constantly adjust individual elements - trim them and saw them. Cinder blocks have a relatively low cost.

Otherwise, the blocks may collapse over time. Unfortunately, the geometry of the slag blocks leaves much to be desired. That is why, when laying floors from such material, you will have to constantly adjust individual elements - trim them and saw them. Cinder blocks have a relatively low cost.

Cinder concrete blocks - properties of building materials

How to build a house from expanded clay concrete blocks with your own hands?

Cinder concrete blocks are a building material produced using vibration pressing technology. Along with cement and sand, the following types of filler are used for production:

- slags, which are waste from metallurgical enterprises;

- granite and crushed stone screenings;

- brick waste;

- river crushed stone;

- expanded clay particles.

Brick waste is one of the components for cinder concrete blocks.

The production of cinder block products can be carried out in various ways:

- using industrial technology, which involves heat treatment and steaming;

- at home using a homemade block machine.

By producing cinder blocks on a block making machine, you can obtain products that have the following advantages:

- increased thermal insulation characteristics. Slag concrete has low thermal conductivity and retains heat well;

- increased dimensions. They allow you to quickly build a cinder concrete building, outbuilding or garage with your own hands;

- resistance to microorganisms and damage by rodents. This is ensured by the filler used and the structure of the cinder block mass;

- reduced cost. A homemade cinder block is cheaper than, for example, a foam block used for construction purchased in a retail chain.

In addition, slag concrete material is fireproof, easy to process and dampens external noise.

Along with its advantages, slag concrete has a number of disadvantages:

- limited service life. The durability of a slag concrete structure does not exceed two and a half decades;

- reduced strength properties. Only one-story and two-story buildings are erected from cinder concrete;

- cracks when sheared. During the shrinkage of the box, cracks do not occur along the seams, but directly along the blocks.

Cinder concrete has low thermal conductivity and retains heat well

Slag concrete also has an unpresentable appearance and requires exterior finishing. In addition, cinder concrete cannot be used for foundation construction.

Creating a Form

First of all, you need to decide what kind of machine you need. If you want to build a garage or temporary shed, then a machine with two or even one mold is enough. If you are going to organize a small business, then you will need a more productive machine, at least for 3-4 matrices.

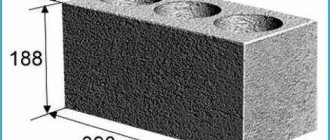

Cinder block dimensions

The most important part of the machine is the shape. The remaining parts and assemblies are additions that allow you to perform various manipulations with this form.

For example - filling, lifting, compacting the solution, moving, etc.

When producing cinder blocks, the plant uses standard iron molds, as well as professional equipment that presses concrete into a mold under a weight of several tons. Do-it-yourself cinder block molds are most often made from wood. There are many types and designs.

In essence, the form is a container into which concrete is poured and where it remains until it hardens completely. It should be noted that the forms must be collapsible so that the finished cinder block can be easily removed. In most cases, they are even made without a bottom, and a plate of material to which concrete does not stick is placed under the bottom.

The easiest way to create voids in a block is to immerse plastic water bottles or glass champagne bottles, which is preferable, into soft concrete at the desired location. But, if you want to set up a small production of cinder blocks with your own hands, then the void formers must be fixed in the mold.

Sketch of a wooden mold

Made of wood

First of all, you will need planed boards, the width of which will correspond to the height of the cinder block. Then it is necessary to make the outer cross members, which will be connected to the longitudinal boards with “sliding grooves”.

Then cuts are made from the inside of the longitudinal boards at a distance equal to the length of the cinder block. The transverse grooves should have a depth of 7 - 8 mm. The width of the cut corresponds to the thickness of the separating plates, which can be made of iron, getinax, textolite.

Sketch of a form filled with solution

The plates can be made from other sheet material, the main thing is that it is smooth. The drawing above shows how to make wooden molds for cinder blocks with your own hands. It is advisable to open the mold details with any oil paint. This will make it easier to remove the cinder blocks from the mold.

Please note that the sketch shows smaller dimensions than a standard cinder block requires. Before creating the mold, you can make your own cinder block drawings

This procedure will not be superfluous and will not require much work.

The above forms are used without a vibrator. The solution in them should be poured into a softer solution with a higher water content. However, with a little effort, you can create a more advanced vibrating machine.

Form-stretcher

The molds for the vibrating table look a little different. Handles must be attached to the sides so that two people can lift them and place them on the vibrating table. There should be two cones at the bottom of each cell.

You should not make a mold with a large number of cells, as such a stretcher will be very difficult to lift. Such forms cannot be disassembled, and the cinder blocks from them are shaken out by tipping them over. The internal surfaces of the mold must be smooth so that the products can be easily removed.

The photo shows a metal form

Made of metal

When creating a machine for making cinder blocks with your own hands, you will need a steel sheet 3-5 mm thick. Shape elements should be cut out of it based on the size of the cinder block. The standard is 190x190x390 mm; in accordance with these dimensions, do-it-yourself cinder block drawings are made. The height of the form should be 5 mm above the block so that you can pour the concrete mixture and press it on top with a plate

Since the cinder block must be hollow, it is important to make the void formers correctly. The easiest way to use pipes for these purposes is

Please note that they need to be given a conical shape. Thanks to this, the product will be easily shaken out

Blanks can be ordered from a turner so that he can remove a few mm from one side of the pipe. Sometimes rectangular void formers are made. Their shape doesn't matter, the main thing is that they are conical. Keep in mind that the cinder block should be no more than 30% hollow.

A wooden or rubber seal should be made at the bottom of the mold along the perimeter to avoid deformation of the edges of the matrix. You can also weld metal plates 20 mm wide along the edges.

Vibrating table of the simplest design

Homemade vibrating table and its application

A vibrating table is a movable table with a vibrator attached to it - the already familiar electric motor with an eccentric.

Its purpose is the production of paving slabs, figures, statues, etc. by vibration casting method, as well as from composite blocks. To make building blocks, molds filled with mortar are placed on the table surface. The process of forming blocks is approximately the same as on a vibrating machine. Champagne bottles are sometimes used to form voids.

When producing paving slabs and other building and architectural elements using the vibration casting method, appropriate forms are installed on the table. The concrete recipe for making colored paving slabs is as follows:

- sand – 1 part;

- cement M500 – 1 part;

- crushed stone with a granule size of 10-20 mm – 2 parts;

- dye – 5%;

- plasticizer – 2%.

The technology of its production was described above.

We hope that the descriptions given will help not only to make a homemade vibrating machine or vibrating table, but also to organize the production of the necessary concrete products with their help.

What is the best way to fill the forms?

If you are setting up the production of cinder blocks at home, know that there is no universal composition; each master selects his own unique recipe, which is more suitable for a particular bathhouse and which depends on the existing slag. But the standard cinder block recipe is as follows: 7 parts slag, 2 parts sand and 2 parts gravel, 1.5 parts good cement (grade M400) and from one and a half to 3 parts water. The accepted dimensions of a cinder block are 39x19x20 cm, but dimensions of 40x20x20 cm are also used in private construction.

In addition to the slag itself, ash, other coal combustion waste, gravel, processed sawdust, perlite, stone and granite screenings, gypsum, broken bricks and the like are used as fillers for such blocks. For greater plasticity of the blocks, a plasticizer is also added - this is 5 grams per block, during vibration casting. For what? It is this substance that significantly increases the strength of the block, its frost resistance and water resistance, and eliminates cracks.

You need to measure the amount of water especially carefully: the blocks should not spread during removal. You can conduct the following test: if the solution crumbles when it falls to the ground, but comes together in your fist, this is what you need. By the way, concrete for the construction of a small bathhouse can be prepared manually, but for a more serious structure it is better to initially acquire an electric concrete mixer designed for a volume of 0.2-0.5 cubic meters.

What can you make a cinder block from?

What cinder blocks are made of is clear from the very name of the building material. One of the components of the cinder block solution is slag, which is formed as a result of coal processing.

Additionally, the blocks may include other materials: sawdust, crushed or old brick, metallurgical waste or products of coal combustion in boiler houses. All these materials will not interfere with the production of cinder blocks, as they will give them good thermal insulation properties.

The mixture also includes coarse sand, water and cement. To increase density, you can add concrete strengthening mixtures.

The standard composition of the mixture for blocks includes sand (2 parts), cement (1.5 parts), gravel (2 parts), slag (7 parts), 1.5-3 parts water. But in fact, not all craftsmen adhere to the standard recipe, preferring to make the composition depending on the available slag and the parameters of the future structure.

To ensure plasticity, when making cinder blocks at home, you can add a plasticizer to the composition (5 g per block). This component allows you to improve the strength of the block, its frost resistance and water resistance, and prevent the appearance of cracks. A plasticizer is added during vibration casting.

Feasibility of use for the production of cinder blocks

The need to have a brick making machine at your disposal is far from obvious. Especially when it comes to private construction. Therefore, we will provide justification for those cases when the presence of a vibrating machine (vibropressing unit) is really necessary:

if the construction of a house, cottage, country cottage is carried out independently, and the time factor is not subject to limitation, and the first place is the desire to reduce the cost of the process as much as possible, then in this case a vibrating machine will be the most optimal solution;

When producing cinder blocks at the plant, standard iron molds are used.

- environmental issues are held in high esteem today, and if you want to be insured against the use of building materials in the manufacture of which components of unknown origin were used (this applies not only to cinder blocks, which are usually made from various industrial wastes), then using your own equipment will allow you to control this issue;

- Our own vibrating machine makes it possible to form the required amount of building materials with an accuracy of one product. There is no need to buy building blocks in excess or rush to the store when a shortage becomes obvious.

The ability to sell the equipment after construction is completed is another reason not to give up using your own vibration machine. You can rest assured that there will be people who share the same views as you on the principles of construction work.

The following factors can force you to refuse to purchase a vibrating machine and produce block building materials on site:

serious time investment. To make cinder blocks, foam blocks or other block products, you will have to “sweat”, even if you use a concrete mixer. The time factor is equally important: keep in mind that about a month should pass from the moment the cinder block is made to the possibility of its use. This will not suit everyone;

The forms must be collapsible so that the finished cinder block can be easily removed

additional energy consumption. Vibrating machines for the production of building blocks, like concrete mixers, are powered by an electric motor, and electricity is now expensive. This point must also be taken into account in preliminary calculations.

The last question that will have to be resolved is whether to buy a brick press for making cinder block products or try to make the device yourself. If the scale of construction is small, it is obvious that it will be much cheaper to assemble the unit yourself, since the design of the simplest models of such devices will not pose any major tasks for you.

How to make a block mold?

In production, the molds are made of iron or steel so that they can handle large volumes of solution, up to several tons. To produce such blocks with your own hands, you can use a wooden mold. In essence, you should get a formwork into which the cinder block mixture will be poured.

It is necessary to take into account the thickness of the wooden sheets when measuring, so that the dimensions of the future cinder block are the inside of the mold.

As a rule, to make it easier to remove the cinder block, the mold is made without a bottom, placing a film underneath. But it is necessary to ensure that the surface of the base is level, as are the wooden parts. The surface can be a flat table, a concrete surface or a sheet of iron.

To build load-bearing walls, hollow blocks are used, for which they use hollow bottles that form voids; they are pre-filled with water so that they do not float out of the solution.

Types of building blocks

Brick is still the main material in the construction of high-rise buildings, but for low-rise construction it is cheaper to use other building materials. If you exclude wood, which is now expensive, the choice will still be varied. Modern wall materials are made from:

- foam concrete;

- slag concrete;

- aerated concrete;

- expanded clay concrete.

Block characteristics comparison table

As a filler for cinder blocks, a variety of and sometimes exotic materials are used, which are industrial waste: screenings, broken glass and bricks, sawdust, wood chips.

Let's first consider how expanded clay blocks and cinder blocks are made independently, as the most budget-friendly among all the above building materials.

Homemade machines with a vibrating device

Homemade machine diagram

Vibrating machines for making cinder blocks are more advanced equipment. Making blocks using them is faster and more convenient, since you don’t have to wait for the solution to set. In this case, the concrete solution is prepared more rigid and thick, it should have a slight shrinkage.

Technically, this is implemented in two ways:

using a vibrating table;

Vibrating table

equipping the mold itself with a motor, on the shaft of which an eccentric with a displaced center of gravity is installed.

A machine with an eccentric is more convenient for producing large quantities of material, since it allows you to obtain a finished block in one go without turning over.

Homemade machine according to the “laying hen” scheme

Machine – “laying hen”

The given drawing of a machine for making cinder blocks is one of the simplest.

Its design includes the following basic elements:

- molding box - matrix (it has no bottom);

- vibrator on the side wall;

- drawer handles designed for easy removal without damaging the impression shape;

- replaceable sets of pressure plates;

- void formers for various void shapes.

The current standard provides for the established dimensions of one such block - 39 x 19 x 18.8 cm. In this case, the voidness should not exceed 30%.

Matrix manufacturing

- Sheet metal is taken (from 3 mm);

- A shape is cut out of the sheet to the size of one block (5 cm is added to the indicated dimensions for compaction);

- A through box is formed (no bottom);

- Special strips welded at the ends give the box greater stability. For this purpose, profile pipes with a small cross-section are used;

- The base of the matrix is upholstered with sheet rubber, which will serve to protect the lower edges of the matrix from deformation;

- An apron is formed for the edging, which will prevent the solution from spilling when filling the mold;

- Handles are attached.

Manufacturing method of a vibrating machine

Making a vibrating machine with your own hands is not a difficult task for an enterprising performer. Using a drawing, use a grinder to cut a steel sheet and, using welding, form a shape consisting only of side walls (if you plan to produce two, three or four blocks per cycle, take care of constructing partitions, which can be made from thin-walled material, 1.5-2 mm). If you adhere to current industrial standards, the size of a cinder block will be 190x188x390 mm, but no one forbids making blocks according to your own dimensions. From below, strips are welded to the shape of the vibrating machine, making the device stable (in case of strong vibrations, this is a mandatory requirement).

Manufacturing hollow products allows you to significantly save on cement and other components of the solution.

For this purpose, the matrix design provides for the presence of removable or rigidly fixed conical void formers. Since it is highly desirable to produce cinder blocks with exactly repeatable geometric dimensions, to ensure a standard height of the finished product, make a limiter below which the press will not fall.

Vibrocompression - compaction of a semi-dry concrete mixture when the latter, while in a mold, is subjected to pressure from above

The press is a plate with cutouts for void formers, to which handles are welded. It is with the help of a mold (and a vibrator, of course) that the mortar is compacted.

The motor is installed on the side face of the concrete block mold; the motor is turned into a vibration unit by an eccentric - this is an additional weight rigidly mounted on the motor shaft.

Minor design improvements will make it easier to form building blocks with your own hands. By providing the device with a simple lever system, you will reduce the physical effort expended when lowering the press. Equipping the brick making press with small wheels will make it possible to produce cinder blocks directly on the construction site, without the need for stacking.

Homemade machine for making blocks

This device will make it possible to obtain more reliable building materials, as well as speed up the production process itself. Assembling it does not promise any special difficulties in manufacturing, however, such equipment will be able to compete even with factory analogues.

The most basic version of a vibrocompression machine consists of a matrix, a hand press and a vibrator. To minimize physical stress, the “press” can be easily improved - use a lever system.

Materials, tools

To assemble a machine for making blocks, you need to prepare and/or purchase:

- sheet metal, minimum thickness - 3 mm;

- pipes for voids, diameter - from 8 to 10 mm;

- channel, metal strip (3 mm);

- electric motor (up to 1 kW);

- grinder, metal disc;

- welding machine;

- metalworking tools;

- vice;

- cotter pins;

- fasteners: bolts, nuts, washers.

The dimensions and shape of the matrix are chosen independently, since these parameters depend only on the scale of block production.

How is the equipment made?

The manufacture of a homemade vibratory pressing machine occurs according to the following scenario:

- Using a grinder, blanks are cut out of sheet metal for the walls of the mold, as well as for internal partitions. An extra 50 mm is added to the height; it will be necessary for compacting concrete.

- The pipe is cut into as many sections as necessary for the voids of all bricks made at the same time. Each of them must have three holes. The length of each element is less than the height of the matrix: the difference is 3-5 mm.

- Cylindrical segments are converted into conical ones. The pipes are first cut to the middle, then the blanks are crimped in a vice. Now it’s time for welding work: this is connecting the sides of the crimped pipes, tightly welding the elements on both sides.

- The next step is to connect each three blanks with metal plates. Then a plate is added from both edges of the “tubular” row for fastening to the walls. Holes are made in them for fixing to the eyes.

- Cuts are made in the middle of each compartment. Eyelets are welded on the outside of the mold. They make it possible to temporarily attach pipes to obtain voids. In this case, by removing the cylinders, you can make solid cinder blocks.

- By welding the outside of the long (or transverse, it depends on the size of the machine) wall, four bolts are welded to fix the electric motor-vibrator. A metal apron is welded on top, and blades are welded along the edges.

- A press with handles and holes for limiter pipes is made from a thick plate. Their diameter is slightly larger than that of pipes: the press should go 50-60 mm deep into the matrix, but no more.

- Mount the engine. Eccentrics are welded onto the shaft. These are bolts that are fixed parallel to the shaft, leaving room for the nuts. The axes of the fasteners must coincide. Nuts are screwed onto the bolts; they will make it possible to change the strength and frequency of vibration.

- The machine is cleaned, polished, primed, dried, and then painted. The last necessary operations are cotter pinning (locking) of threaded connections and grounding of the electrical part.

Performance

This unit will not be able to guarantee large volumes of production, however, such goals are not usually set in the household. They say that by working together with a matrix of several cinder blocks, you can make dozens of stones in a day. The numbers here vary greatly, so it makes no sense to cite them as an example.

Classification of vibration machines

This subtype of construction equipment is practically unfamiliar to the mass consumer, but brick making machines are manufactured by many domestic companies. There is no single standard regarding the principles of structural calculations, but a classification of such units exists, even if only conditionally. Vibrating machines are divided according to the following characteristics:

- by control method (from manual to fully automated);

- by the number of blocks produced per one working cycle;

- by type of product produced (hollow/monolithic);

- according to the degree of convenience and practicality in operation.

From the point of view of the last factor, industrial brick making machines are divided into three subclasses. The simplest and most structurally primitive equipment involves mainly manual labor; with its help, one cinder block can be produced per working cycle. This productivity is relatively low, because you can only make 50 building blocks per work shift.

The most important part of the machine is the shape

A professional block vibrating machine can produce more than three finished products per cycle. Being equipped with many additional devices and accessories, a high-performance vibrating machine significantly facilitates the work process, requiring the use of minimal amounts of manual labor.

The cost of such devices can vary greatly, because they are aimed at different categories of consumers. Budget category machines have such a simple design that some experts prefer to make such units themselves. At the same time, the technical characteristics of homemade vibrating machines are not inferior to factory ones in terms of important operational characteristics.

Preparing a solution for cinder concrete

A concrete mixer is the best option.

Before we talk about how to make cinder blocks at home, let's consider preparing a solution for them. The solution for slag concrete blocks includes a filler, preferably slag remaining after the combustion of coal in the furnace, in an amount equal to seven parts by volume.

Coarse expanded clay sand - two parts, gravel, fraction 0.5 - 1.5 cm - two parts, cement, grade M500 - one and a half parts and water - three volume parts. But not only slag can be a filler; gypsum, expanded clay, ash, gravel, screenings of crushed stone, sand, brick waste and even processed sawdust can be used as such.

When using blast furnace slag as a filler, no unnecessary additives should be present: wood chips, earth or unburnt coal. Therefore, the slag must be sorted in advance and sifted using a special sieve.

If the filler is gypsum, then the components of slag concrete are taken in the following proportions: gypsum - one part, slag mixture - three parts and water. The solution is thoroughly mixed and used almost immediately.

This mixture is prepared within a maximum of six minutes. The slag mixture is pre-moistened. To prepare one cubic meter of solution, about 350 liters of water are used.

In order to make high-quality slag concrete blocks at home, a special plasticizer is added to the solution. As a result, the mixture becomes very plastic, and the blocks are strong, waterproof, frost-resistant and not brittle.

In addition to hollow ones, blocks can also be made solid. They are the strongest and most durable, and most often they are used to make the foundation. In contrast, hollow blocks are lightweight and have excellent heat-insulating and soundproofing properties.

Well, one more important property: cinder blocks can be colored if dyes are added to the solution, which can be chalk or crushed red bricks

Vibration pressing and vibration casting

Diagram of a vibrating table and sand sifter.

Vibrocompression is the compaction of a semi-dry concrete mixture when the latter, while in a mold, is subjected to pressure from above and, at the same time, vibration loads. Production using this method is easily automated. The production process itself is as follows:

- a semi-dry concrete mixture is placed into the mold (matrix);

- the punch, vibrating together with the frame, begins to put pressure on the mixture;

- after the mixture is completely compacted, the vibrations stop;

- the punch and then the die rise up, leaving the finished product.

This method was the impetus for the creation of a wide range of construction products. This is not a complete list of these products: building blocks, paving slabs, panels, columns, bricks, curbs, pillars, etc. All of these products have the following positive properties:

- strength;

- wear resistance;

- high structure density;

- frost resistance;

- resistance to external influences.

Vibrator table diagram.

Vibration casting is the production of construction products by vibrating the concrete mixture on a special device, a vibrating table. The concrete mixture is poured into a rubber or plastic mold and placed on a continuously vibrating surface of a vibrating table. To prevent knocking from the walls of the mold, the vibration amplitude must be constant. It is necessary to strictly monitor the filling of the molds with the mixture, otherwise marriage is inevitable.

After vibration treatment, the molds are removed and sent to a warm place to stand (dry) for 46-47 hours. Then the process of stripping begins: the products in the molds are placed in a water bath, and then the products are knocked out of the molds using special devices. The process is very difficult to automate. To increase frost resistance, it is necessary to add plasticizers and modifiers, and increase the amount of cement.

Vibratory casting is more often used in the production of paving slabs, especially colored ones, and paving stones. It is used for paving squares and sidewalks, and laid on pedestrian paths. Such products have a presentable appearance, but do not have very high performance qualities. In winter, they are covered with a thin layer of ice and can crack under the influence of frozen water. In contrast, the same qualities of tiles made by vibration pressing are much higher.

Features of homemade machines

Types of equipment for the production of expanded clay concrete blocks:

- Manual vibration machines.

- Mobile mechanized machines.

- Vibrating tables.

- Vibrating presses.

Manual vibrating machines

Consist of an electric motor and a vibration stand. The mixture is placed into molds. The equipment allows you to produce solid or hollow blocks. Technical equipment has stationary or removable void formers.

The disadvantage is low power and low productivity. All processes take place with the direct participation of humans. The equipment power does not exceed 2.0 kW.

Mobile mechanized machines

Equipped with vibration equipment for expanded clay concrete blocks with a power of 2 to 10 kW. Trailed or removable casters are used for movement. To perform additional functions they are equipped with modular systems.

The advantage is the ability to move freely, small dimensions, low cost.

The disadvantage is the low productivity and energy consumption of the equipment.

Vibrating tables

They are a spatial structure with an electric motor and a vibration device. The table surface consists of a steel tray. For its manufacture, galvanized steel sheet with a thickness of 3 mm with sides is used.

The molds filled with the mixture are placed on a pallet. Under the influence of vibration, the solution is compacted and takes the required shape. After this, the products are sent for drying.

The advantage of vibrating tables is their simplicity of design, maintenance, and minimal equipment cost.

The disadvantage is low productivity and a large proportion of manual labor.

Vibrating presses

Used in industrial enterprises. They have a power of up to 500 kW. Equipped with automation and non-destructive testing devices for finished products.

The equipment operates in automatic and semi-automatic mode at all stages of production. Productivity reaches 150 or more cubic meters of products per shift.

Classification of brick making machines

Vibration equipment for the production of blocks is manufactured by many large companies and small firms, many of which introduce a number of improvements to the design, which makes a clear classification of these devices difficult.

However, based on a number of criteria, it is possible to identify the main classes of brick making machines.

Mobile brick making machines are well suited for warm climate zones where they can be operated outdoors

By type of formation of block products:

- mobile;

- stationary.

The bed of a mobile concrete block press with the help of a wheeled chassis makes it possible to form cinder blocks directly on the surface of the construction site, which becomes part of its structure. In mobile vibrating machines, which are popularly called “laying hens,” the matrix, on which the punch presses, is pressed directly to the floor. After completing the manufacturing cycle, the matrix rises, leaving the manufactured product on the surface, moves to the required distance, and the process is repeated.

Mobile brick making machines are subject to a number of requirements that narrow their scope of application:

- To deploy a vibrating machine, a construction site with an area of 300 square meters is required. meters;

- the working surface of the vibrating machine must be flat, since it is responsible for the formation of one of the sides of the product;

Depending on the tasks assigned to the brick making machine, the design of this machine may differ significantly

- the use of a dispenser and mixer for mobile vibrating machines is a complex engineering task;

- If the product is intended to be exported outside the existing construction site, it is necessary, in addition to manufacturing, to organize its storage.

Structurally stationary vibrating machines are divided into devices that use pallets and those that do without it. Vibropress machines with a pallet, which is the formative element of the unit, are considered more universal. They are characterized by fewer restrictions on use (the only drawback of vibrating machines with pallets is the need to have a sufficient supply of pallets of the required configuration).

Based on the type of drive, vibrocompression machines are divided into devices with:

- automated drive;

- manual drive.

To organize production and achieve full productivity, it is necessary to have large production areas

In manually driven designs, excess pressure is created using muscular force using a system of levers. It is precisely these machines that are popular when manufactured independently, but they have a significant drawback: limited assortment. Other factors limiting the use of manually driven vibropresses are considered to be insufficient quality of products (due to the inability to achieve the required compaction of the mixture), as well as heavy physical stress on operating personnel.

Do-it-yourself cinder block manufacturing technology

Cinder block is a modern building material that is very popular in the construction of various structures. It is distinguished by its strength, reliability, and ability to retain heat. All these characteristics will be transferred to the buildings and structures that you are going to build. This building material is distinguished by its low cost, which makes it even more popular. But despite this, it can still be made cheaper in a simple way. Today we will tell you how to make a cinder block at home.

The composition of cinder block is unique, and at the same time very simple. Cinder block is a very affordable building material that you can make with your own hands, and then take and build a wall from cinder block, also with your own hands, even without experience in the construction field. Compared to brick or other building materials, you can make a cinder block at home, without having any special equipment (except for a cinder block machine) or skills. Now we will tell and show you how to do this.

STEP 1: materials. To start producing this building material, we need to decide what materials we will need for this business. If you want to get reliable blocks, then you should not skimp on materials, because this can play a cruel joke on you in the future.

Sand. Clean sand, without unnecessary inclusions. Large faction.

Slag. To make a cinder block, you must take blast furnace slag, because it has the necessary strength characteristics and does not collapse under the influence of moisture.

Gravel. It is also necessary to increase the strength characteristics of the cinder block.

Cement

The main attention should be paid to cement. After all, the further formation of the block depends on it

To form reliable blocks, you need to use grade 400 cement. The best building materials are made from this cement, which can withstand absolutely any weather conditions, loads, etc.

Above we have presented a list of necessary building materials that you will need when creating a cinder block. In addition to all this, you will need water, a cinder block machine, and a concrete mixer. You can do without a concrete mixer, but without a machine it will be difficult. If you are going to make cinder blocks without a machine, then you may end up with them, just the wrong ones. The vibrating machine promotes uniform distribution of the solution in the mold. Due to this, the strength of the block increases.

STEP 2: proportions. If you don’t know how to make a cinder block correctly, it’s not a problem. Each master has his own proportions, but there is one, standardized instruction that will suit you. And so, to prepare the correct solution we will need:

- 7 parts slag;

- 2 parts sand;

- 2 parts gravel;

- 1.5 parts cement;

- 1.5 – 3 parts water.

This is the most optimal recipe for making cinder blocks, which has been used for decades. We will act on it.

STEP 3: prepare the mixture. Next, all materials need to be mixed in the required proportions in a concrete mixer. You can do this manually, but it is better in a concrete mixer. We pour all the materials strictly in proportion into the concrete mixer, fill everything with water, and start the engine. After the mixture is homogeneous (this is easy to determine with the naked eye), we begin to pour it into molds or into a machine.

In this article we will tell and show you how to make a cinder block with your own hands at home, without any experience in construction. We assume that you have a vibration machine available, but if you don’t have one, then you can try to make a special form in which we will make our blocks. This method is not as effective as with a machine, but it also has a right to life.

Pros and cons of making your own

There are several advantages to making your own cinder block machine:

- reducing the cost of the construction process from homemade blocks;

- the ability to make a machine to suit your needs;

- the ability to equip the equipment with the necessary containers at your request;

- the ability to make a new matrix if it becomes unusable.

There are also disadvantages, including the length of time it takes to manufacture the machine and possible mistakes made due to inexperience.

Mixture composition

The production of slag blocks at home obliges the craftsman to adhere to a specific composition, as well as certain proportions of all components. Thus, the binding ingredient in this material is usually cement of a grade not lower than M400. As for the filling component, it can consist entirely of slag or be mixed. The last option is obtained by adding a small amount of crushed stone, sand (simple or expanded clay), crushed brick and fine expanded clay.

When making cinder blocks, the following proportions must be observed:

- 8-9 parts of the filling component;

- 1.5-2 parts of astringent ingredient.

For example, out of 9 parts, at least 6 are accounted for by this component, and the rest is made up of crushed stone and sand. In theory, when making it yourself, it is permissible to use concrete or brick scraps, screenings.

The standard proportions of cinder block are:

- 2 parts sand;

- 2 parts crushed stone;

- 7 parts slag;

- 2 parts of Portland cement marked M400.

As for water, it is customary to add it in an approximate ratio of 0.5 parts. The result is a semi-dry solution. To ensure its high quality, you need to take a small handful and throw it on a hard surface. If the thrown lump crumbled, but under compression conditions regained its previous shape, then the composition can be considered suitable for further use.

If you plan to obtain colored cinder blocks, then the recipe is supplemented with colored chalk or brick chips. To increase the strength characteristics of this material, special plasticizers are used. In some cases, they resort to adding gypsum, ash or sawdust.

Specifics of production of building blocks by vibrocompression

A brick press is a device that uses the principle of forming products using a vibrator by creating excess pressure (“load”).

Vibrocompression involves the use of a rigid concrete mixture, which contributes to the production of the most strong, durable and reliable products. Since this technology uses a “weight”, it becomes possible to use coarse aggregates, including materials that are waste from various industries. The use of expanded clay, slag, sawdust, broken bricks, and screenings reduces the cost of manufacturing building blocks. A brick making press involves the use of a rigid matrix, due to which the geometric dimensions of the blocks are more repeatable, which has a positive effect on the speed and quality of construction of load-bearing structures.

Sequence of operations when using vibration compacting equipment:

- the prepared working mixture is poured into a special measured form;

- a measured portion of the mixture enters the molding matrix, where it is compacted under the influence of the punch, while the proportion of air in the semi-dry mixture is reduced by more than half (up to 25%);

- during compaction of the mixture, a vibration mechanism is activated, and the combination of pressure and vibration forms the most dense cement paste, in which the filler particles are placed at a minimum distance from each other, while the air concentration in the mixture is reduced to 3-5%;

Since the working process is accompanied by high pressure on the mixture, various materials, including coarse-grained ones, can be used as fillers

- the impact of the punch lasts no more than a minute, after which the formed product is squeezed out of the matrix using an extruder (as an option, the matrix rises up, and the product remains on a special pallet;

- the resulting blocks are dried (naturally or by steaming).

Price for machines

On the construction market and in advertisements on the Internet you can find many options for professional equipment for producing cinder blocks.

The standard kit includes a vibrating machine with molds for 4 blocks, a concrete mixer (300 l) and wheelbarrows (2 pcs.) for feeding and transporting the mixture. Such an installation will cost an average of about 170,000 rubles in Russia. There are options for 900,000 rubles, and there are also options for 70,000 rubles. and even for 35,000 rubles.

In general, it all depends on the performance of the equipment, its release date, mobility, functionality and configuration. It’s worth adding to the price delivery across Russia to your destination.