A significant set of functions and modest dimensions of the Universal 2 lathe make its use attractive not only for a small workshop, but also in an ordinary garage or even at home. This is also facilitated by its moderate power consumption, low noise level and power supply from an AC electrical network of 220 V.

The significant differences between this tabletop machine and similar full-size turning equipment come down to the smaller size of the workpieces and lower cutting speeds. But none of its big brothers can perform milling or drilling operations along with turning machines.

Tabletop lathes of the Universal series: information about the manufacturer

The Universal machine, which became the ancestor of the model range of the same name, was produced at the Moscow machine-tool plant Stankokonstruktsiya from 68 to 75 of the last century. Over the years, the company has produced about 7 thousand copies of this small-sized equipment. The prototype of the tabletop unit was a small-sized lathe “for home” from Austria.

The production of the first Universal was discontinued due to the fact that the Experimental Research Institute of Metal-Cutting Machine Tools, based on this design, developed a more successful model, called Universal 2. In addition to the Stankokonstruktsiya plant, its serial production was undertaken by the Vladimir Precision Equipment Plant, now reorganized into VSZ Tekhnika LLC.

After several modernizations of the base model made at the end of the 80s, other enterprises also began to produce the updated Station Wagon. They were the Votkinsk Machine Plant, Michurinsky, the Orion Design and Technology Bureau in Nizhny Novgorod, and the Penza Instrument-Making Plant.

Accessories

The mechanism in question includes additional accessories that help perform additional functions and make the machine more versatile.

These accessories include two tool holders. Using a movable tool, you can process conical surfaces.

A collet clamp is another additional accessory. It consists of a collet, a ring and a nut.

The famous Universal-3M lathe has been serving faithfully not only amateurs, but also professionals for decades. Its device allows you to process small and medium-sized parts.

The main advantage of such equipment is its versatility and the ability to connect to a regular household network. The standard configuration is sufficient to perform the basic operating functions of the device.

The machine is also distinguished by accuracy, reliability and durability, and therefore is popular to this day.

Types of machine functions and its design

Universal 2 is a machine that can be quite easily transformed into a drilling or milling machine. Therefore , it can be used to cut, trim, cut threads with a cutter, bore holes, and sharpen simple or shaped surfaces. And after moving the main movement unit to a vertically mounted guide, drill, countersink and even mill, as well as grind the planes. Using optional accessories allows you to do the following:

- Sharpen cutting tools.

- Cut sheet material straight (with a circular saw).

- Plane a tree.

- Cut parts of any shape from sheet material (with a jigsaw).

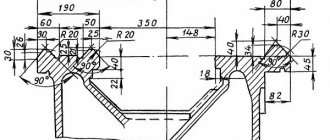

The basis for fastening other parts and components of the machine is a cast iron frame.

The headstock of the product and two guides are attached to it. The main motor is located on the headstock of the product. The thrust head is installed on the guides. The rotation of the spindle by the main and only motor occurs through pulleys and a V-belt. And the feed mechanism, often called a guitar, is connected to the source of movement by a gear transmission.

Device

The layout and design of the Universal-2 are standard. Main parts, components and mechanisms:

- The frame to which all other components are attached. In addition, it ensures reliable installation and minimizes vibration through proper balancing. There are guides for movement on it.

- Headstock with spindle. It is necessary for installing the workpiece and rotating it with specified modes. Unlike most other models, this module is replaceable and can be replaced with other devices if necessary.

- Tailstock. This device is necessary for pressing the part. For this purpose, a quill is used, which is extended using a flywheel. When drilling, a drill is clamped here, which does not rotate itself during processing.

- A support that moves along the guides of the frame. The cutting tool is attached to it for subsequent feeding.

- Guitar. Its gears transmit torque from the spindle to the longitudinal screw, which is responsible for the feed and pitch when cutting threads.

- Main engine. Rotation is transmitted to the spindle pulley via a belt.

- The support in which the tool is mounted and which gives it the job.

- Sharpening device.

- A table mounted on the cross slide of the caliper.

- Elements of fastening to the table: brackets. The clamp guarantees reliable installation of the equipment and compensates for its low weight.

- Replacement equipment. Contents may vary depending on the type of processing. After installing specialized modules, the following types of processing are possible: turning, planing, drilling, grinding, milling, woodworking operations. It is also possible to sharpen the tool.

A detailed description, universal manual and operating instructions for the Universal-2 benchtop lathe are available. Before starting work, it is advisable to study its kinematic and electrical diagram. The documentation also contains a table that allows you to specify the cutting of the desired thread.

Equipment Specifications

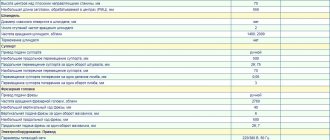

- Accuracy class N.

- Center-to-center distance – 180 mm.

- Maximum turning length is 120 mm.

- The Ø of the through hole of the spindle shaft is 10 mm.

- Spindle rotation speed – from 120 to 3*103 rpm. with 11 switching stages. To adjust it, rearrange the drive belt on the pulleys.

- Maximum blank diameter: above the guides - 125 mm, above the carriage slide - 60 mm.

- The stroke amplitude of the spindle shaft sleeve is 30 mm.

- Feed range – 0.05–0.175 mm/rev. Switching the feed speed is discrete, the number of steps is 6.

- The thread pitch interval is 0.2–2 mm.

- Fastening the chucks to the spindle shaft - M20 thread and Morse taper No. 2.

- The headstock is Morse taper No. 1. The maximum quill stroke is 20 mm.

- The power of the single electric motor is 0.25 kW.

Lathe Universal-3

The design of the third model of the Station Wagon was obtained by modernizing the first. At the same time, a number of significant changes were made to the design of the basic product. The spindle head began to be removed from the bed as easily as before. The pair of cylindrical guides was replaced by one with a slightly larger diameter. The engine power and overall weight parameters of the product have also changed.

At the same time, the machine was able to process larger parts. The cutting speed has also increased. For ease of operation, the new model has the ability to change the direction of movement of the caliper without stopping and changing the direction of rotation of the spindle shaft.

Purpose and scope

The Universal 3 machine is capable of performing the same operations as its predecessor. In addition to turning, it can also drill, countersink, mill and grind flat surfaces after simple adjustments. Just like all the machines in this line, it is not suitable for work in production, because it is not designed for long-term daily use.

aggregation of specialists

Incorrect or prolonged operation of equipment often leads to breakdown of components and if. parts, the operator hears the knocking of the bearings; then they need to be replaced. If work on the equipment is carried out with faulty bearings, the failure can lead to damage to other components and strong.

units noise or rapid heating requires the engine to inspect its windings. In some cases, the unit is completely replaced. If the motor suddenly stops, this indicates an electrical fault.

This situation indicates a breakdown of the trigger mechanism. If the engine is not able to gain speed, experts conclude that it is faulty.

The most common cause of breakdowns is interruptions in the supply of electrical energy. If this problem occurs frequently, it is recommended to purchase a special stabilizer.

Types of stabilizers

Independent disassembly of the structure is strictly prohibited, especially without the presence of certain experience, skills and knowledge.

In such a case, it is recommended to seek help from a specialist; he will not only eliminate the breakdown, but also ensure safe operation of the equipment in the future.

To avoid injury and equipment breakdown, the operator must strictly follow the rules of its operation. Cleaning of the main units of the unit must be carried out constantly.

The benchtop turning unit allows maximum precision processing of metal workpieces. achievements For this purpose it is necessary to adhere to its operating rules. Thanks to the simplicity of the design, the unit ensures precision processing of metal parts.

Standard delivery set

When purchasing a machine, the buyer receives various accessories and tools along with it.

Accessories

Lathe:

- Three-jaw chuck.

- Reverse jaws to chuck.

Additional:

- Circular saw with a platform for it.

- Milling table.

- Jigsaw with support for sheet material.

- Abrasive disc with mandrel for installation.

- Cylindrical plane with table.

- Drill chuck.

- Collet clamp.

Tool

- Key to lathe chuck.

- Drill chuck key.

- Socket and open-end wrenches.

- Jigsaw files.

- Drill Ø 6 mm.

- End mill Ø 6 mm.

- Steel cutters.

- Pobedite-tipped cutters.

- Circular saw.

- Keys s7, s8 (square).

Precautions when working with Consciousness

- equipment, compliance with safety measures during transportation and installation in the premises.

- In the electrical circuit, ensure the serviceability of the emergency device. Working.

- When de-energizing, equip the room for fire protection.

- Place emergency medical supplies and medications in an accessible area.

- Adjust work clothes in such a way as to prevent accidental contact with rotating mechanisms.

The prototype of the new screw-cutting MetalMaster -1830 lathe remains the TSh-3 machine, a pre-perestroika model of the Soviet brand Looks - 3. The station wagon is aesthetically pleasing, equipped with smooth controls and electronic drives. And, most importantly, the machine made a qualitative transition from amateur to professionally advanced for a metalworking machine.