Main nodes

Electrical system includes:

- main motor;

- an engine that causes displacement of the caliper sections;

- cooling engine;

- electric cabinet;

- KP.

To start the unit, alternating current, three hundred and eighty volt voltage, 50 Hz frequency is required. Gearbox adjustments are carried out by the control center.

The functional parameters of the unit are selected by the feed box, which records the indicators of the primary parts of the unit, including the machine support. The bed is reinforced with rigid ribs. Other departments:

- an apron providing longitudinal/transverse feeds;

- spindle head, which changes the balance of nodal revolutions;

- rear grandma.

Gears that facilitate the transfer of spindle rotation speeds.

Information about the manufacturer of the educational screw-cutting lathe TV-11

The TV-11 table-top screw-cutting lathe is produced by the Rostov plant of small-sized machine tools MAGSO, KomTeh-Plus , founded in 1956.

ComTech Financial and Industrial Group , which has existed in the machine tool equipment market for several years and has priority in the production of small-sized metal-cutting machines: lathes, milling, vibrating, sharpening, drilling, which equip schools, vocational schools, colleges, institutes, repair and installation organizations of all regions of Russia.

The machines produced by this company are well known on the Russian market and a number of CIS countries, thanks to the first models of screw-cutting lathes TV-4, TV-6. Model TV-11, deservedly enjoying the reputation of high-quality and reliable equipment. An important feature of the machine is its efficiency and low operating costs.

Machines produced by the Rostov plant of small-sized machine tools MAGSO

- NS-16 - tabletop drilling machine Ø 16

- NGF-110Sh3 - low power milling machine 0.6 kW, table size 100x400 mm

- NGF-110Sh4 - low power milling machine 0.75 kW, table size 100x400 mm

- SNVSH - tabletop drilling machine Ø 16

- SNVSH-2 - tabletop drilling machine Ø 16

- TV-4

- educational screw-cutting lathe Ø 200, RMC 350 mm - TV-6

- educational screw-cutting lathe Ø 200, RMC 350 mm - TV-6M

- educational screw-cutting lathe Ø 200, RMC 350 mm Dubno - TV-7

- educational screw-cutting lathe Ø 220, RMC 330 mm - TV-7M - educational screw-cutting lathe Ø 220 mm, RMC 275 mm

- TV-9 - educational screw-cutting lathe Ø 220 mm, RMC 525 mm

- TV-11 - educational screw-cutting lathe with frequency converter Ø 240, RMC 750 mm

Specifications

The size of the unit is 2.86 x 1.37 x 1.44 m; weight – 3 thousand 445 kilograms. For normal operation, it is necessary to ensure optimal humidity and temperature in the room.

Unit characteristics:

- maximum length of the workpiece – 1m / 1.5m / 2m;

- gearbox: 22 and 9-speed (forward and reverse, respectively) spindle rotation;

- limitation of the upper travel of the caliper – 14 cm;

- feed box – 24-speed longitudinal;

- central electric motor – 11 kilowatts;

- maximum movement of the quill) – 0.2 m;

- maximum processing diameter above the support/bed – 0.25 m/0.5 m;

- spindle hole (through) – 6.6 centimeters;

- spindle rotation (direct) – 10-2 thousand rpm; the opposite – 50-2 thousand.

The unit has 3 separate electric motors. In addition to the main one, two others ensure the functioning of the cooling system.

Design features

Initially, the FT 11 screw-cutting lathe was created on the basis of an older, but successful model 16B25PSp. Basic design solutions have remained unchanged, while more modern mechanisms have been installed.

Screw-cutting lathe FT 11

The main purpose of the unit is to perform finishing and semi-finishing of parts. It can also be used to cut various threads. High-quality and comfortable work is achieved due to the fact that the spindle rotates at high speed.

The unit has the following design features:

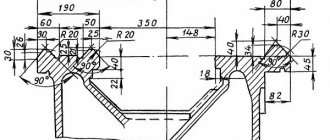

Layout of components of the FT 11 screw-cutting lathe

- turning cones without additional devices - the operation is performed with a natural shift of the caliper located on top;

- selection of the desired spindle speed without the need to stop the machine, which ensured increased productivity;

- the number of revolutions of the spindle head is regulated by special automation;

- Due to the special design of the frame, dust and chips generated during operation do not penetrate into the guide grooves.

The designers also thought through other important details of the FT 11 lathe. Special magnetic starters do not allow spontaneous activation. Equipment performance has been improved by installing relay control circuits and semiconductor components. But these steps made repairing the unit more labor-intensive.

If necessary, during work, without turning off the engine, you can activate the accelerated return stroke of the spindle. This option allows you to speed up the processing of the workpiece.

Design of the FT-11 machine

The basis includes the following components that ensure increased accuracy of work.

Machine bed

It has a solid base, thanks to diagonal ribs, and also includes a pair of guides (flat, prismatic). The first ones are carefully polished and heat-treated, which allows the unit carriage to move perfectly along them. The presence of telescopic shields protects from adverse external factors. The middle guides ensure free movement of the tailstock. Between the pedestals SS there is a container for industrial waste.

Machine speed box

Fixed on the plate of the left cabinet. Equipped with nine direct and three reverse speed stages. Speeds are switched by electromagnetic clutches. From the electric motor to the input shaft of the KS, movement is carried out by a V-belt transmission, and by a flat-toothed belt - from the output to the spindle head.

Headstock

Promotes a change in the balance of the input-output number of revolutions of the unit. The automatic transmission rotates the spindle using the appropriate gear. Mounted on roller and angular contact bearings. A set of gears in the unit contribute to switching speed ranges.

Tailstock

Secures the cam clamp using the handle during light and screw-heavy operations. Adjustment of the degree of pressure is a nut.

Description and purpose

The machine has a classic layout with a stationary spindle for the main movement of the workpiece and a support with a cutter that moves relative to it.

The manufacturer did not modernize the FT11 and the machine was discontinued, so almost all of the remaining units in service lost their ability to provide certified accuracy. Although the owners of this screw-cutting lathe are trying to modernize it, modernization is often limited to installing a digital speed indicator.

Often a major overhaul is not justified and the machine is sold for scrap or left for rough grinding work and training young turners to work with equipment of similar complexity.

Safety precautions

Parts of the unit, rapidly rotating parts, flying production waste, and high voltage pose a potential danger to the person working on the machine. Therefore, strictly follow the safety recommendations for working on metal-cutting equipment.

Before using the machine:

- put on overalls, they should be buttoned up, the sleeves should be tied up so that the rotating parts do not catch them;

- pick up your curls, put on safety glasses;

- make sure the grounding system is reliable;

- use manual shifting to test the handles;

- tighten the loose fasteners.

When sharpening:

- Measuring parts of a running unit is unacceptable;

- the cutting element approach to the workpiece must be careful;

- Do not insert a drill into a rotating chuck;

- do not remove waste without a special device;

- You cannot change gears while the unit is running.

- Do not leave the equipment.

Attention! It is strictly prohibited to operate faulty equipment!

Immediately report any malfunctions of the machine, faulty guards or failure of electrical equipment to the person in charge.

When finished, turn off the electric motor, tidy up the work area, clean and lubricate the machine.

Description

The device has high functionality, especially in terms of producing all classic types of threads. In addition, if the operator sets the necessary settings through the guitar, the machine will be able to produce carvings with non-standard characteristics. To do this, you will also have to reduce the length of the kinematic chain.

Thanks to the special design of the support, the machine can process conical-shaped workpieces without the use of a special ruler. The structure of the bed is designed in such a way that production waste causes minimal damage to the machine components, which has a positive effect on the long-term use of the machine.

The operator can change the spindle speed even while working, which significantly saves time and increases the productivity of the machine. The design features of the bed and other components make it possible to process metals with a special composition. Thanks to the use of an automatic transmission, the machine can:

- Engage the spindle in jog mode.

- When the electric motor is turned off, the operator can brake the spindle regardless of the direction of its movement.

- The spindle speed is adjustable even at idle and under load.

The use of innovative elements of electrical equipment at that time made it possible to improve the adjustment of the spindle and change its rotation speed without deactivating the main wire.

In addition, the spindle of the FT-11 machine has a forced reverse motion, which speeds up the processing of individual parts. For safety reasons, the machine is equipped with magnetic starters, which prevent involuntary activation of the device after the power supply is restored.

Electrical equipment of the machine

Electrical circuit of the TV-11 machine

The electrical equipment of the machine is given in its passport. When reviewing the electrical circuit, you should pay attention to the fact that the life of the machine is provided by three asynchronous electric motors:

- an engine that drives the main mechanisms associated with the intended purpose of the machine;

- cooling system engine;

- acceleration motor.

To receive voltage from an external network, the machine has an input block. The control circuit is located in a separate panel. The machine is powered using several voltage classes, namely:

- electric motors operate at 0.4 kV AC;

- for safety reasons, a voltage class of 24 V is used for local lighting;

- The control circuits operate on two voltage classes: 110 V AC and 12 V DC.

Reduced voltages of 110, 24 and 12 V are obtained from a step-down transformer. To power the control circuits and lighting, another input panel is used. The electrical circuit provides protection of electric motors from technological violations, in particular from overload and short circuit. Electric motors are protected from overloads by thermal relays that respond to an increase in the stator circuit current. Protection devices are installed in the input block. The entire electrical circuit is protected from technological violations by an input circuit breaker.

Lubrication system

The turning process cannot be carried out without the uninterrupted operation of all rotating components and mechanisms. To ensure that all rubbing and rotating parts wear out less, you should monitor the operation of the lubrication system. The following components and mechanisms that are subject to rubbing influences are subject to TV-11 lubrication: headstock and tailstock mechanisms, rotating feedbox components, all guides located on the frame, rubbing and rotating carriage components. The turning mechanism includes the following components that ensure the operation of the lubrication system: an oil reservoir, oil filtration devices (suction, drain and cleaning filters), a gear pump, distribution devices and other parts. The TV-11 lathe has two oil supply streams. The oil is supplied by a gear pump. The first flow lubricates the spindle unit, support pulleys, all gears, spindle assembly supports and other parts. The second flow lubricates the carriage, slides and distributors. An oil indicator is used to control the oil in the system.

Purpose and scope.

The TV-11 desktop lathe is designed to process metals and other materials with high precision in finishing and semi-finishing modes. The machine's passport provides for its operation with any types of metals. The weight of the TV-11 is only 240 kg, which allows it to be used in rooms located on the floors of high-rise buildings and in mobile workshops in which electrical panels with a voltage class of 380 V are installed. The following work can be performed on the TV screw cutting machine:

- grind and bore surfaces shaped like a cylinder or cone;

- drilling holes of various diameters;

- grinding of products from various materials;

- cut blanks of the required sizes;

- cutting various threads using taps and dies;

- trimming the ends of workpieces.