A set of thread-cutting tools will always come in handy for a craftsman who makes a living by repairing automobiles and household appliances, as well as for an ordinary man whose hands are “not sharpened for an ax.” Correcting a damaged thread or making a suitable screw or nut with your own hands to replace the lost ones, having a suitable tool on hand, will not be difficult and will eliminate the need to rush around the shops in search of the right part. The editors of the YaNashla website present a rating of the best sets of taps and dies for thread cutting for 2022, compiled based on customer reviews and expert recommendations.

A little history

Fasteners, analogues of modern screws, have been known to mankind since the beginning of our era. Jewelers of Ancient Rome used them to make jewelry, and artisans used them to make medical instruments. The manufacture of fasteners was expensive in those days and was not widely used.

The 15th century has arrived. On the battlefields, warriors in armor and armor clashed, the parts of which were fastened with screws and pins. At the same time, watchmakers assembled their products using screws. But the nuts appeared later, about a hundred and fifty years later. There were no generally accepted standards then. Each master made fasteners at his own discretion. In the 17th century, connections close to modern ones appeared, and the thread pitch was inch.

Metric threads first began to be used in France quite recently, in the 19th century.

Nut taps

Nut-type tools are designed for thread cutting in nuts of different diameters. The design of the nut tap is such that the tool does not need to be turned out at the end of the nut hole machining process. Nut accessories can be with different shanks: curved and elongated. With curved ones - used in working with automatic nut-tapping machines. The shank of a nut tap is, in any case, longer than that of other types; this is necessary in order to string nuts onto it as threads are cut into them. This increases speed and productivity.

Thread classification

- Metric. The most common fastening thread. The diameter of the parts is measured in mm.

- Pipe. Used in the installation of pipelines and shut-off and control valves (mixers, taps, valves). Diameter is measured in inches and fractions of an inch, which is why it is also called inch.

- Threads on the outer surface of parts: bolts, studs, pipes are called external, and nuts, blind sockets and couplings are called internal.

- The direction of rotation distinguishes between left and right.

- By the number of passes - single and multi-pass.

- The cross-section can be triangular, rectangular, trapezoidal, etc.

- Can be straight (cylindrical) or conical.

By what parameters are threads distinguished?

Let's look at the characteristics of metric and pipe threads.

- One of the main parameters of a thread is its pitch. It is designated by the letter P. In metric threads this distance is in mm. between the identical sides of two successive turns. In pipe and inch, this is the number of turns per inch.

- There are diameters: outer, middle and inner. Outer is the distance between the tops of the teeth on opposite sides of the part. Denoted D(d). Internal - the same distance between the depressions of the turns. It is designated by the letters D1 (d1). The average is measured at two opposite points in the middle part of the profile.

- A stroke is the distance by which a point on a single-throw screw will move after making a full revolution along the surface of the part. In a single-pass it is equal to the step, in a multi-pass it is the product of the step P and the number of passes.

We will not consider the remaining parameters, since they are needed mainly for calculations. The diameter of a metric thread can be measured with a caliper. To determine the parameters of the pipe, the measurement results with a caliper are compared with the data in a special table. However, an experienced specialist is able to determine the diameter of the pipe thread in inches by eye. Anyway, in the range of 3/8 to 2 inches, it's not difficult.

Metric thread

Widely used in fasteners: screws, bolts and nuts, studs, etc. A large pitch is designated by the letter M and the numerical value of the outer diameter; in the designation of a small pitch, the numerical value of the pitch is added to the letter M and the diameter number.

Metric threads can be conical or cylindrical, depending on the shape (section) of the surface being processed. In both cases, the profile (tooth) angle is 60°. The amount of taper is expressed by the ratio 1:16. Designated MK.

Pipe thread

Performed in accordance with the BSP (British Standard pipe thread) standard. The profile has an angle of 55°. The pitch is measured by the number of turns per inch of length (25.4 mm). The mark P 11 means that eleven turns fit in one inch. P 14 – fourteen turns per 25.4 mm, etc. There are also P 19 and 28 (4 steps in total) Pipe threads are designated by the letter G and a number indicating the size of the flow area of the pipe without taking into account the thickness of its walls. This value is called the nominal diameter of the pipe. Measured in whole and fractional inches. The letter G may not appear on products. Left-hand threads are designated by the letters LH.

Accuracy classes A and B differ. The designation G 1/2-A LH means 3/4 inch, accuracy class A, left. Products are often marked simply, for example, 3/4″ - three quarters of an inch (or 20 mm). It must be remembered that in this case we mean the nominal diameter of the pipe connection. To obtain the outer diameter, you need to add twice the pipe wall thickness to the nominal bore.

How to make a carving

The following methods are used:

- Cutting with a die, tap, cutters on lathes, milling cutters, special cutting heads, restoration of damaged screws with files.

- Rolling with special rollers or a flat die, chipless tap.

- Grinding with a single-thread or multi-thread wheel. This method is used in the manufacture of lead screws.

- Extrusion of plastics and non-ferrous metals using a press.

- Casting. This method is not particularly accurate and is used when processing plastic products and colored flowers.

- Brittle and particularly hard materials: ceramics or carbide parts are subjected to electrical discharge machining.

Die

This is a hardened steel nut with cutting edges. The part is cut with one pass. Chips are removed through the holes between the cutting edges. You can work manually, securing it in a tool/die holder, or on a machine. Usually the dies are made 8 - 10 turns thick. The working part is a cone with two to three turns of the lead-in part. Alloyed or high-speed steels are used as materials for the manufacture of dies: 9ХС, Р6М5, etc. Product marking indicates the degree of accuracy, diameter and steel grade of the product. If you purchased a die that does not indicate the steel grade on the surface, know that it is 9XC steel.

The die can be split, sliding (for die-cuts), round, hexagonal, etc.

The most precise work is done with solid dies. They are also the fastest to wear out.

Interesting! Once upon a time, only split and sliding products were called a die. The lines were uncut and they gave the most accurate results. Now the separation of concepts has been abolished. The name “lerka” has become popular.

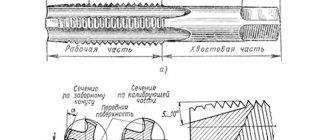

Taps

Special screw with cutting edges. It is screwed into the workpiece, rotated and cuts the surface of the part. Chips are removed through special grooves between the working edges. The tail part is clamped into the holder before the operation begins. The active part is divided into the lead-in cutting and calibrating parts. The highest quality results are obtained by driving the hole alternately with rough, medium and finishing taps. They are easy to distinguish by their profile and marking rings on the shanks.

There are machine-hand and hand tools for nuts and blind sockets. Their lead-in part has a different shape.

Rollers are used for rolling. They do not have chip grooves.

The materials for making taps are carbide alloys and high-speed steels. Before starting work, the workpiece is lubricated with any fatty grease. Working without lubrication is not recommended. You won't get a quality product

Machine and machine-hand taps

To calibrate and create threads in blind and through holes of various shapes, a tool is used - a tap, machine or machine-hand type.

— Machine metal-cutting tools are used to work on lathes, drilling, aggregate and turret machines to cut threads of all types. They process products much faster and can be used for conveyor production and large orders. With this type of equipment you can cut threads in one go if you need threads with pitches of up to three millimeters. Coarse pitch threads are made using several passes using a tap on the metal product.

— Machine-manual equipment can be used to cut threads both manually and using drilling devices (machines). The tool is available in quantities of one or two pieces. In a set of two taps, one metal-cutting tool is used for roughing work, and the other for finishing work. Often a set of machine-manual equipment is used to work with different types of materials: mild steel and cast iron are processed with one tool, and hard steel is processed with two taps. Machine-manual types differ from simply manual thread cutters in the type of shank - there is a square and an annular recess, thanks to which the equipment does not fall out of the chuck during processing of products. A machine-made product for working with metal can make threads in automotive parts, cut fastening threads and small-metric, cylindrical and conical threads. In through armholes and blind ones.

Tool selection criteria

Before purchasing a kit, you should decide on the type and diameter of the tools, which of them are most in demand, and what you should pay attention to:

- If you plan to install a water supply system in a country house, you need to buy a ratchet clamp and pipe dies. The most suitable dies for this type of work will be dies with diameters of 1/2'', 3/4'', 1'', 1 1/4'', 1 1/5'' and 2''. A clamp with a ratchet will make the job easier.

- To repair damaged parts or cut new parts, you will need different sizes of drawers and hand taps. The most popular diameters are considered to be from M3 to M12.

- It is better to select taps of each diameter in sets of two or three numbers, for roughing, medium and finishing. Different numbers are marked by applying ring grooves to the tail section. Rough ones are marked with one ring, medium ones with two and finishing ones with three rings. The rough profile is a truncated cone, the finishing profile has a triangular profile.

- When purchasing kits, you should inspect them carefully. They can slip in two products with the same profile: both rough or two finishing.

- Cutters, as a rule, cut the part in one pass, so they are all finished. Manufactured from high carbon steel. 6. Taps are most often made from carbide materials. Markings indicating the steel grade are applied to the surface of the dies. It can be high-speed or alloy steel.

- It is better to buy tools in convenient cases made of plastic or metal. It is more convenient to carry and store than “loose” ones.

- However, the purchase of “placers” cannot be avoided. There are no 100% universal “cases”.

- Sets vary in the number of items. The more there are, the more expensive the purchase will be.

- They produce professional and household tools. Professional ones are distinguished by high quality, better wear resistance and a higher price.

- To determine the profile and pitch, the case must have a thread gauge.

- When purchasing, you should carefully inspect the tool, especially the condition of the cutting edges. Even a beginner will be able to distinguish high-quality products from cheap fakes.

- It is better to purchase products from well-known brands. Czech and German kits are traditionally of good quality. When choosing manufacturers from the Asia-Pacific region, it is better to focus on products from Taiwan. Buying a Chinese kit is like a lottery. You can get quality, or you can get a one-time fake. The kit from Taiwan is always high quality.

Which company is the best kit to buy?

We invite you to get acquainted with some well-known manufacturers:

- Berger Russian brand with production in Taiwan. High-quality, wear-resistant guides and taps. The sets are supplied with a convenient case and holders. The manufacturer provides a lifetime warranty on its products.

- Biber. The German brand is made in China. It is distinguished by good quality and good equipment. There are three numbers of taps of each diameter, which greatly facilitates the process of cutting the workpiece and guarantees good quality.

- Bovidix. The brand belongs to the USA. Production is launched in Taiwan. Bovidix produces tools from the highest quality materials and constantly uses innovation. Consumers leave the best reviews about this brand.

- JTC. The birthplace of the brand and the country of origin is Taiwan. For 33 years, the company has been producing professional instruments that have gained popularity not only in their homeland, but also in Europe and the USA. Always excellent quality, wear resistance, excellent ergonomics.

- Matrix. German brand with production in China. The company is very young. It produces products of good quality and excellent design and ergonomics.

- Rothenberger. The German company is a world leader in the production of equipment for the installation and maintenance of pipelines. Kits from Rothenberger are well-deservedly popular among professionals. If you are planning to build a country house with heating and plumbing, a tool from Rothenberger will be the best solution to problems when installing pipework.

- Arsenal. A Russian brand with production in Taiwan. On the market since 1998. Arsenal produces inexpensive kits of high quality and wear resistance.

- Master. Brand and country of manufacture: Taiwan. Products under the Mastak brand are developed specifically for delivery to the Russian market. Master is a high-quality professional locksmith kit that features outstanding ergonomics, innovation, ease of use and durability.

- Bucovice. Brand and production in the Czech Republic. Leading manufacturer in the Czech Republic and Europe. Bucovice has always been famous for its high quality, durability and excellent equipment.

Not all the best manufacturers are represented here. However, the listed brands are in demand among professional craftsmen. Before you make a purchase, decide on the diameters of fasteners necessary for your activity, find out how much this or that set costs, its functionality, and the popularity of models from different brands. If you don't do this for a living, it's not worth spending money on a professional kit. For your home, you need to choose budget tools at an affordable price. It is advisable to listen to the advice and recommendations of experts. Professionals, on the contrary, should not waste time on trifles. A good and expensive tool will soon pay for itself.

Taps - broaches

To obtain large-profile threads in metal products, use a broach tap. It is used to process complex through or trapezoidal holes. Broaches can only be used in a lathe. The thread is cut in one pass along the hole. This tap differs from other types in its more precise design and rigidity. It works in tension rather than compression like conventional threading tools. Due to the broaching function, the thickness of the cut is reduced, and the length of the cutting part is increased.

Rating of quality tool sets

Berger BG 21TDS

The tenth line of the rating is occupied by a case with a tool from the Russian brand Berger BG21TDS, manufactured in Taiwan, which in itself indicates the high quality of the products. A convenient plastic suitcase contains 7 single-pass taps and seven dies, with sizes from M3 to M12. In addition, the kit contains the following necessary for the operation of the product:

- two quick-release T-shaped barbs M3 - M6 and M5-M12;

- two holders M3-M12;

- flat screwdriver;

- metal brush.

All components are made of 9ХС steel. The set received the best reviews from customers. Its average price is 1,725 rubles. According to buyers, an excellent combination of price and quality.

Set of dies and taps Berger BG BG21TDS

Advantages:

- durable and comfortable holders;

- availability of quick-release chucks;

- affordable price.

Flaws:

- fixing the lever in the holder with one screw is not always reliable;

- lack of rough and middle taps.

Matrix Master 77337

In ninth place is a product from the German brand Matrix, made in China. The delivery set includes ten dies and twenty taps, two (No. 1 and No. 2) for each diameter, from M3 to M12, for preliminary and finishing holes. The boats are made with a one-way marked entry. This must be kept in mind when using them. The kit includes a plastic case with a comfortable handle and a combination holder with one fixing screw. The entire set, except for the combined holder, is made of 9ХС steel. The average cost of a set is 1879 rubles.

Matrix Master 77337

Advantages:

- high-quality work result;

- small format case;

- affordable price.

Flaws:

- the combination holder is unreliable;

- There is no screwdriver or thread gauge.

Biber 90221

Eighth place is occupied by a Chinese-made set from the German brand Biber. Package Included:

- Ledgers from M3 to M12 – 7 pcs.;

- Taps in the amount of 21 pieces, three of each size - rough, medium and finishing;

- Holder with five fixing screws;

- Holder;

- Screwdriver.

All components are placed in a metal case. Three taps per diameter ensure a perfect final result. Five screws for fixing the leash in the holder ensure that it does not move while performing work. The average cost is 2629 rubles.

Biber 90221

Advantages:

- availability of finishing, medium and roughing taps included;

- reliable fixation in holders;

- high-quality work result.

Flaws:

- not found.

Berger BG 31TDS

The seventh line of the rating is occupied by a set of the Russian brand Berger BG 31TDS, manufactured in Taiwan. The set includes twelve dies with one-way entry, and the same number of single-pass taps, sizes from M3 to M12. In addition, the set contains:

- holder for dies;

- holder M3 to M12;

- two quick-release chucks: M3 – M6 and M5 – M12;

- screwdriver;

- metal brush.

The tool is made of 9ХС steel. A convenient case is provided for storage and transportation. The average cost of a set is 2956 rubles.

Set of dies and taps Berger BG BG31TDS

Advantages:

- wear resistance;

- cuts easily and smoothly;

- reliable and varied holders.

Flaws:

- single pass dies.

JTC 3432

In sixth place is a set of tools from the Taiwanese brand JTC 3432. The material of the components is alloy steel. Set contents:

- 16 dies from M3 to M12 inclusive, plus a 1/8” die;

- 6 taps, two each (roughing and finishing) M3 – M12, plus a 1/8” tap;

- two holders;

- two quick-release chucks with T-shaped handles;

- screwdriver/

The set is stored and transported in a plastic case. Its cost is 5040 rubles.

JTC 3432

Advantages:

- excellent equipment;

- cuts quite easily;

- the quality of work is good;

- The case is convenient for storage and carrying.

Flaws:

- not identified.

Bovidix 288204001

In fifth place is a kit from the American brand Bovidix, made in Taiwan. Designed for cutting internal and external threads M3, M4, M5, M6, M7, M8, M10, M12. For each diameter, two numbers of taps and dies are provided, allowing for rough and finishing cutting with high quality. In addition, the kit includes: holders, quick-release chuck, and screwdriver. Customers especially like the convenient metal case. The internal plastic insert for storing the tool has each socket marked in large letters and numbers. Any detail is easy to find even for people with impaired vision. The average cost of a set is 5292 rubles.

Bovidix 288204001

Advantages:

- excellent quality of the instrument;

- increased wear resistance;

- ease of cutting without defects;

- convenient case.

Flaws:

- single-sided single-start dies.

Rothenberger Super Cut 70781X

In fourth place we placed a set for cutting pipe threads, the German brand Rothenberger Super CUT 70781X, made in Spain. The kit includes:

- conical pipe crowns 1/2'', 3/4'', 1'', 1.1/4'';

- ratchet clamp;

- light and durable, non-removable handle;

- plastic case.

The cutting bits are made of high-quality heat-strengthened steel. Thanks to the improved geometry, the knives easily cut into the material and remove chips perfectly. The quality of work meets the standards. An excellent German instrument, the purchase of which will cost craftsmen 19,239 rubles.

Rothenberger Super Cut 70781X

Advantages:

- excellent equipment, all main sizes of crowns are available;

- all bits are compatible with Rothenberger power tools;

- wear resistance and durability of crowns and ratchets.

Flaws:

- high price.

Arsenal AS-40

In third place is a set from the Russian brand, Taiwanese production Arsenal AS-40. For each diameter there are two dies and two taps, for the primary and finishing passes. The tools are made of chrome vanadium steel. The kit also includes holders, a quick-release chuck, a wrench and a screwdriver. All elements of the set are located in a plastic suitcase. Buyers like the ratio of equipment, quality and cost of the set. Its purchase will cost the buyer 3,089 rubles.

Arsenal AS-40

Advantages:

- wear resistance and durability;

- good equipment;

- convenient case.

Flaws:

- The set does not include a thread gauge;

- The die is secured in the holder with only one screw.

M3 – Hobby CS Bucovice

In second place is a kit from the Czech brand M3 – Hobby CS Bucovice. The set contains three taps of each size, for primary, medium and finishing holes. In addition, the manufacturer added to the set metal drills with diameters from 2.5 to 10.2 mm. This configuration allows craftsmen not to be distracted from work while searching for the right drill. The kit is completed with holders, a screwdriver, a center punch and a thread gauge. The entire tool is stored and transported in a plastic case. Its cost is 8134 rubles.

M3 – Hobby CS Bucovice

Advantages:

- excellent equipment;

- durability and wear resistance;

- convenient case.

Flaws:

- not identified.

How to remove a broken tap from a hole

The tap may break if the thread is cut into a hole with a small diameter, and chips may become trapped when the tool is removed.

Extraction methods

- 1. The double ends of the rigid wire must be inserted into the grooves of the tap and unscrewed;

- 2. You can weld the handle to the broken instrument and use it to remove it;

- 3. There are special mandrels and countersinks that will help cope with this problem;

- 4. If part of the tap remains outside, you can weld a shank with a square tip to it;

- 5. Drilling with screw drills;

- 6. Burning with electrical erosive machines;

- 7. Etching with dilute nitric acid.