What kind of instrument is a grinder?

A grinder or angle grinder is a universal tool and necessary in the household. This tool is used by painters, mechanics, and is in the arsenal of carpenters. Its significance varies depending on the attachments used. Put a circular disk on the machine and you can cut wood. More often, a grinder is used in metalworking for cutting metal: pipes, fittings.

But its main purpose remains grinding work. With the increase in secondary sales of cars, the demand for their repair and painting increases. The most difficult stage in this work is the preparatory stage, that is, cleaning the surfaces of cars from old paint and primer. The cleaner the body is before re-priming, the better the new paint will adhere. In this work, the leading role is played by a grinder with a set of sanding brushes.

What types of brushes are there?

Metal, cup-shaped brushes appeared relatively recently. Before this, sanders worked primarily with different types of sandpaper or sanding stone discs. The paper, no matter how high their rigidity, quickly became clogged with paint particles or erased. It often had to be changed, which reduced productivity. Working with a metal brush for an angle grinder is much more effective in this regard.

Almost every leading tool manufacturer has considered it necessary to throw their brushes onto the market. And each manufacturer has its own approach, its own exclusive approach to the development and manufacture of metal attachments for angle grinders. Some brushes are made from a single thin wire, others from twisted cable, and others from wavy corrugated wire. Wire cord brushes differ in diameter, stiffness, and quality of bristles. Brushes used as attachments for angle grinders are:

- Cup

- Disk

Metal brushes are made from:

- become;

- steel with brass coating;

- brass;

- copper

There are polishing brushes for working on metal surfaces and woodworking. They are made from nylon and other polymers, dried seaweed, and cotton fibers.

The rigidity of processing depends on the structure of the wire, its hardness and thickness. The thinner the wire used in the manufacture of the brush, the softer it acts on the metal. To clean the surface of old paint at the initial stage, it is better to use a nozzle with stiff bristles, and for final cleaning of residual primer and other materials, a nozzle with less rigidity is suitable, which will not “eat” the bare metal.

The wire used to make brushes is:

- Corrugated. Due to its springy properties, this brush softens, on the one hand, the impact on the metal, and on the other, reduces the vibration of the machine.

- Twisted. The bristles twisted together provide rigidity to the surface and are less likely to break and fly out when abraded. The twisted fragments unwind, freeing the bristles for work.

- Smooth.

Brushes differ in the diameter of the cup, which determines the parameters of the surface being processed simultaneously. Angle grinder brushes are consumables, but manufacturers are concerned with making them as efficient as possible and extending their service life.

Material of manufacture

The bristle material is the main evaluation criterion for the nozzle. Other parameters listed above depend on it. Modern manufacturers prefer the following materials:

- Metal. This category includes brushes made of iron, brass, copper, and alloys based on them. Metal bristles have unique properties: with the help of hard bristles you can thoroughly clean the surface of burrs, traces of corrosion and old paint. Soft metal grinder attachments, which include bronze and brass, are designed for processing parts that require delicate handling, such as copper plates.

- Steel. Attachments made of pure and brass-coated steel differ from classic metal brushes on an angle grinder. Stainless steel bristles are excellent for cleaning related metals and aluminum. Steel is used for rough cleaning of products, regardless of the type of surface. The brass layer protects the nozzle from premature corrosion. This circumstance, combined with the high performance characteristics of steel, makes such brushes the optimal choice.

In online store catalogs, steel and other metals are combined into one category. To purchase a tool with steel bristles, you will have to clarify the request form.

- Polymers. The main purpose of nylon brushes is polishing. Polymer materials have less rigidity, so this consumable material works with wood and other surfaces with little strength. In addition, nylon does an excellent job of decorating various surfaces.

An important parameter is the thickness of the pile. Bristles with a diameter of up to 0.3 mm are intended for soft operating conditions, when there is a high risk of unintentional damage to the parts being processed. Using a device with a pile thickness of more than 0.7 mm, you can perform almost any hard work, up to the final cleaning of a welded joint.

What is the correct name for them?

There are discrepancies in the names of the attachments online and on labels. Some call them grinder brushes, others call them cord brushes. What should they really be called? Cord is translated from English as string, cord, rope. And if you look closely, these attachments are made from a variety of steel (or nylon), cut into short bristles, strings or twisted cords. So the essence of this name – cord brush – becomes quite clear. Those who write korshchetka obviously took the name of the nozzle by ear, and since the letter “d” is most often swallowed when pronounced, they began to write it that way. I don’t know about spelling dictionaries, but the Word program in which this article is written recognized the correct spelling as cord-brush - with a hyphen.

Brushing as a process of working with a brush

Brushing is the process of treating metal surfaces with metal brushes in order to remove loose sludge or scale formed during the etching process. This work can be done by hand or with power tools. The brushes themselves for angle grinders are called brushes. With this treatment, the porosity of the galvanic deposit decreases and it becomes denser. The treated surface is more uniform.

Brushing of steel surfaces is carried out with steel brushes with a wire diameter of 0.2–0.4 mm. Non-ferrous metals are processed with wire brushes made of copper or brass. Electroplating is also subjected to brushing in order to increase the density of the coating and give it shine.

Brushing is done according to:

- dry surface;

- surface wetted with water, soap or soda solution.

When brushing with metal brushes, abrasive pastes are not used, since the ends of the wire bristles serve as the abrasive.

Functions

Radial brush for angle grinders with bristles made of twisted steel wire. Photo Practice

Cord brushes are used for processing wooden, metal, concrete, stone, plastic products , as well as surfaces coated with paint and varnish. using brushes :

- cleaning from old paint and varnish, corrosive deposits, slag and scale, tarnish;

- cleaning products before welding;

- grinding and polishing;

- removal of unnecessary part of the deposited metal from welds;

- brushing, texturing and roughening of wood;

- smoothing out roughness;

- deburring;

- grinding off sharp corners;

- roughing and finishing.

Cord brushes are often used as an alternative to abrasive wheels .

How to choose a quality brush?

When choosing a brush for an angle grinder, pay attention to the bristles. It should be distributed evenly over the entire disc, the bristles should be the same length everywhere and distributed evenly around the entire circumference of the cup. It is unacceptable when the bristles are thick on one edge and thin on the other. Such a brush will hit your hand (vibrate), cleaning will be done unevenly, and the brush itself will very soon fail.

Among the parameters for the wire nozzle, manufacturers indicate the recommended speed for the machine. This indicator should not be ignored. If you put a low-speed brush on a machine with a high rotation speed, it will not give the desired result and will quickly fail. Conversely, a metal brush, which the manufacturer designed for use at high speeds, will not work with proper performance at low speeds.

The smaller the diameter of the cup, the less load on the machine engine, the less vibration, and, accordingly, the less tired the hand. But the larger the diameter of the cup, the fewer passes there are. Which brush should you choose? There is no clear answer here. Sometimes craftsmen have time to try several brushes of different diameters and different bristle hardnesses before finding the best option. The choice of brush often depends on the quality of the paintwork. After all, as you know, different enamels and primers have different coating densities.

The need for invention is cunning. Advice from a user

The creative thinking of our people knows no bounds. This recommendation, aimed at improving the performance of brushes, was found on the forums of craftsmen.

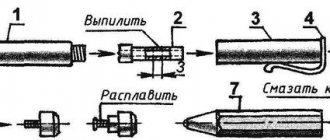

Everyone knows that the bristles of a sanding attachment wear out over time, and this rate of abrasion depends on the stiffness of the bristles and the aggressiveness of the surface being treated. In some brushes, the outer cup is larger than the inner one, which allows you to extend the life of the brush a little, by 15 percent. This can be achieved by cutting off the upper edge of the outer cup of the brush by 5–7 mm.

Types of brushes for angle grinders for metal

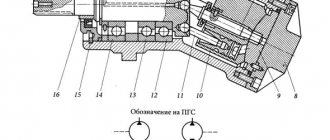

A cord brush for an angle grinder resembles a similar device for a drill in appearance. The main difference is the wide hole in the center. It is designed for installation on an angle grinder. A nut is screwed on top to prevent axial displacement during operation. Some cord brushes are equipped with their own latches.

The main characteristics of the brushes are:

- outer and inner diameter;

- form;

- bristle material;

- type of pile by hardness;

- thickness of bristle elements;

- maximum number of revolutions.

Safety precautions

When processing surfaces, whether metal or wood, safety precautions must be observed. The fact is that the higher the rotation speed of the disc on the grinder, the faster the brush wears out. Metal bristles fly off from it, grains of scale and metal burrs also fly off from the surface being treated. It happens that the cup cannot withstand the load, and the brush itself falls apart.

And all this literally hits the working person. Therefore, when working with such a brush, you need to have glasses, a respirator, mittens and preferably thick overalls. Even if the sun is shining outside and the heat is unbearable.

The loud sound of the grinder tires and makes the worker irritable, so it is also recommended to have headphones. Some workers combine business with pleasure and drown out the sound of their grinder with their favorite music, inserting headphones from a player or phone into their ears.

Forms

The structure of the pile arrangement and the shape of the product depend on the work for which the attachment on the grinder is intended. A wise choice can make life easier for the craftsman performing the work. The tool market offers consumers brushes of the following shapes:

- Cup-shaped. Cup-shaped cord brushes do an excellent job of tough cleaning of large areas. The vertical arrangement of the bristles on the cup brushes ensures the correct force vector.

- Conical. In these devices, the bristles are located at an angle relative to the base plane. This design allows you to process parts with minor recesses on the surface.

- Radial. Such attachments are also called “cart brushes”. They are intended for final cleaning of products from scale formed after the etching procedure. The special arrangement of the pile allows you to work in hard-to-reach places.

- Disk. This form is the most common. The bristles are located on the horizontal plane of the instrument. This design is not suitable for large jobs, but it copes well with narrow recesses.

Various types of wire are used to make brushes:

- Twisted. This type of execution is characterized by wire twisted into bundles in a random order. The force of pressure on the surface is higher, but the service life is much shorter.

- Harnessed. Attachments for grinders with rope pile arranged in a strict order are distinguished by their structural strength, as well as the effect of self-sharpening during operation.

- Corrugated. The wavy structure of the wire gives the brush a springy effect. This softens the impact on the treated surface.

- Smooth. This structure allows you to process almost any surface.

The size of the nozzle depends on the size of the grinder. Their diameter ranges from 75 to 200 mm.

Grinder brushes have proven themselves much better when processing large areas. To clean parts with complex shapes or curved surfaces, we recommend using a similar attachment for a drill, which has exactly the opposite properties.