A reciprocating saw is a versatile tool for cutting a huge variety of materials. The device has a convenient design and allows you to cope with any housework during the renovation process. Each model of electric hacksaw has its own characteristics and technical parameters, according to which the choice is made.

The main function of a reciprocating saw is to cut various materials. Externally, a reciprocating saw resembles a small hammer drill, which has a narrow cutting blade at the location where the drill is installed. The moment you press the “Start” button, a small motor comes into action, which sets the hacksaw blade in motion. This design makes the reciprocating saw easy to hold in your hand, and the thin cutting blade can be used to cut hard-to-reach parts or pieces.

What is a reciprocating saw

In appearance, this device is a long tool with a pistol grip, at the end of which there is a working blade. There is a trigger and several switches on the body. In fact, the design of the device is simple, and anyone can understand its operation.

In fact, this is an ordinary electric hacksaw, and its operating principle is exactly the same as that of a jigsaw. Although the latter is a descendant of the electric saw, because it began to be produced 20-25 years later. It turns out that the blade performs a reciprocating movement, thereby selecting the material to be cut with its teeth. When the tool was improved, that is, they began to use a pendulum stroke, it became a revolutionary invention, because the cutting efficiency of the reciprocating saw greatly increased. This characteristic will be discussed separately.

This is how you cut window frames - quickly and easily

What is a reciprocating saw used for?

Skeptics claim that the reciprocating saw can be replaced with other tools, at least the same grinder. There is no point in arguing with them, you just need to point out that the convenient oblong shape of the tool, plus its continuation - the canvas, make it possible to use this device in the most inaccessible places. For example, if you need to trim a pipe protruding from a wall or foundation exactly along the plane of the building structure. No cutting power tool can handle this except a reciprocating saw.

A reciprocating saw can be used to cut the pipe flush with the wall surface.

This is an excellent tool for pruning trees. There are practically no restrictions on the thickness of the trunk; the main thing is to know how to cut correctly. Today, many landscape designers choose reciprocating saws to create landscape architecture, as they are the most convenient in their segment.

With this tool you can saw slab and sheet building materials, creating the required structures from them. The high maneuverability of the device allows you to bend the blade, cut bends, chamfers, curved parts, etc. Let us add that today builders are increasingly choosing this tool when solving dismantling problems. It can be used to cut almost any structure. Particularly significant is the fact that they use a saber to saw logs in which steel nails are hammered. It cuts through both wood and steel easily.

Cutting a metal ventilation system duct with a reciprocating saw is not a problem.

If we talk about additional positive characteristics, we note:

- saw operation without dust;

- sparks do not jump out when cutting metals, and scale and smudges do not form on cut edges;

- cut workpieces do not overheat;

- high safety factor;

- unpretentiousness at work;

- long term service life.

A reciprocating saw is something between a chain saw and a jigsaw

Classification

Any electrical tools have their own classification. So, reciprocating saws are:

- Household. They are distinguished by a small set of characteristics, compactness, low energy consumption and low price.

- Amateur. This is a transitional segment between professional and household saw models. The power indicators and other characteristics of such tools are in a wide range, which opens up opportunities for choosing a device for a specific range of tasks.

- Professional. The most expensive tools that are designed to last a long time. They are distinguished by high reliability indicators and an increased number of options that simplify the work process.

The durable cutting part allows you to cut thick materials that a jigsaw cannot handle.

Technical characteristics of reciprocating saws: corded and battery-powered

Like all power tools, the reciprocating saw is divided into two main groups: household and professional. The first ones cannot be called low quality, they are simply equipped for low-intensity work. That is, these models must be operated taking into account the time during which they heat up, so these devices require rest.

The little “household worker” can easily deal with even a thick log

Household sabers are well equipped, their functionality is almost exactly the same as that of professional tools, they just do not have such a long service life. And it is not required at home. But “household workers” are several times cheaper than “professionals”.

Expert's point of view

Victor Isakin

Tool selection specialist for the 220 Volt retail chain

Ask a Question

“When choosing a reciprocating saw, be guided by the characteristics according to the passport, where the manufacturer must indicate the time of continuous operation of the device. Never pay attention to such terms that sellers use to appeal to: semi-professional, universal, household, etc.”

Battery model

Tool power

This is the most important technical characteristic. The ratio here is this: the more powerful the saw, the higher its productivity. But there is also a downside: the weight of the unit, its size and price increase. Power characteristics vary from 0.5 to 1.5 kW. But experts offer, so to speak, a golden mean that has stood the test of time - from 0.9 to 1.2 kW. Such saws are convenient in terms of light weight and size, but with fairly high performance.

The more powerful the device, the larger it is in size and weight.

Other parameters of the saw also depend on the power characteristics: cutting speed and stroke length of the equipment. That is, we can say with confidence that a more powerful model will cut a large structure faster and provide the best cutting depth in the hardest material. This is exactly what manufacturers indicate in the product data sheet. These are the ones you need to pay attention to when choosing a reciprocating saw. Here are the technical specifications recommended by experts:

- saw stroke amplitude: 19−32 mm;

- frequency of movement or stroke length of equipment: 2500−3000 strokes/min;

- cutting depth: 220−255 mm.

Model Bison 750 W

The last parameter is very important. The designated range ensures that the saw can be used for many types of work. And here the task is to cut wood, metal, and concrete. And when they talk about a tool - this is a reciprocating saw for metal, the interpretation of the purpose is incorrect. Any saw can cut any material. The main thing is to choose the right file. Returning to the depth of cut, let's add cutting trees in the garden as an example. To do this, there is no need to purchase a saw with a large depth; here a parameter in the range of 19-25 mm will be sufficient.

An electric hacksaw makes it easy to cut trees in the garden.

Speed controller

Everyone knows that materials with different structures need to be sawed at different speeds. Therefore, reciprocating saw manufacturers supply the tool with different cutting speeds. But in different models it is implemented differently:

- The first option is the trigger itself, which is pressed with your finger to make the saw work. The harder you press it, the more the instrument “accelerates”. This design is called stepless.

- The second option is a wheel or slider. By installing them in a certain position, the speed of movement of the working body is set. In this case, the trigger does not depend on speed. This design makes it possible to more accurately set the speed of the saber.

Speed regulator in the form of a wheel on a trigger

Pendulum stroke

The essence of this option is that during the reverse stroke the hacksaw deviates from the cutting line. That is why the file does not heat up so much; its movement cleans the cutting area from sawdust. This increases the cutting speed.

Attention! Not all reciprocating saws are equipped with a pendulum stroke, and it is not always necessary. For example, to cut along a curve, this option must be disabled.

Branded manufacturers make the pendulum stroke adjustable in their tools. This increases the efficiency of the saw when cutting materials of different structures. The denser the material that is being cut, the larger the width of the blade should be.

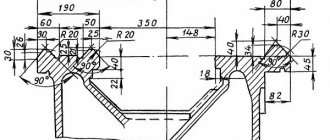

Availability of support shoe

This structural element of a reciprocating saw is a regular stop that rests the tool on the cutting plane. This creates a tight connection between the saw and the material being cut, which increases the quality of the cut. Not all models have swivel shoes. And this is an improved design that allows you to cut along a curved line with a stop. At the same time, fixing the rotary shoe allows cutting in any inclined plane, plus from bottom to top. It should be added that this structural addition helps to rationally use the resource of the hacksaw, especially if it has a multifunctional purpose. That is, the blade has several different shaped teeth used for cutting different materials.

Support shoe between body and blade

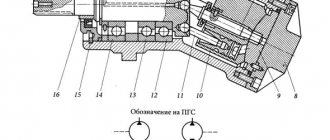

Mechanism for replacing a hacksaw (blade)

Many manufacturers have not produced reciprocating saws for a long time, in which the blade is changed (inserted or pulled out) using a special tool. Now the file is changed either using a latch in the form of a lever, or using a locking ring. But these models have one drawback - the file can only be pulled out if the chuck is in the extended position. If work is stopped and the chuck remains inside the protective casing, the saw will have to be turned on again to push the chuck out. It is impossible to remove the cartridge by hand by pulling it by the file.

This is how a file is removed or installed in a reciprocating saw chuck using a latch

When changing a hacksaw, it is recommended to check it for play. If this defect is present, then you should know that this is a decrease in the quality of the cut and the durability of the tool. Let us add that today many manufacturers offer cartridges in which the blade can be installed with the teeth facing up. And if you choose a reciprocating saw based on this indicator, then you should choose exactly this model.

Safety clutch

This element of the reciprocating saw design has one important purpose - to preserve the integrity of the tool and protect a person from injury. The thing is that if the saw blade gets jammed in the process of cutting any material, then the tool will kick back. So the clutch will prevent this from happening. Unfortunately, it should be noted that not all models offered on the market have this element.

Overloads and protection against them

Our compatriots are accustomed to the fact that any tool should be used to the maximum. In this regard, power tools are more delicate devices than mechanical ones, because their design is based on an electric motor. If you overload it, it will quickly burn out. And repairs are expensive. Therefore, many manufacturers install overload protection, which simply turns off the power to the saw if the latter exceeds the level set by the manufacturer. A very useful option.

Other useful devices

Let's look at what else you need to pay attention to when choosing a reciprocating saw:

- Soft start is usually installed on powerful saws. Its main purpose is a jerk-free start of operation and protection of the supply network from overload.

- Brake. Essentially, this is a quick stop of the saw as soon as you stop pressing the trigger. The convenience lies in the fact that you do not have to wait for the blade to stop moving if, for example, the blade needs to be replaced.

There is a red button on the side of the handle - this is a trigger lock

- Trigger blocking. There are two functional components here: the first is the trigger mechanism, after pressing which electricity is supplied to the saw motor, the second is the fixation of the trigger in a certain position. The second position makes it easier to use the power tool.

- Double insulation. This is a requirement of European standards, but it should be noted that this is not only the safety of operation of the device, it also increases its service life. Plus, this tool can be used outdoors in wet weather.

Saws from European manufacturers can be used in any weather conditions

- Vibration dampening. In household appliances, elastic linings are installed on the handle and gearbox to protect against tool vibration. The design of professional models includes a counterweight that dampens not only vibration, but also noise. That is, only professional reciprocating saws have a vibration damping system.

- Housing insulation. Here you need to understand that rubber gaskets are installed everywhere between the parts of the device body, which protect the insides of the instrument from dirt, dust and water. But if the housing is broken, they will not save the operator from electric shock. Therefore, a rubber “shirt” is installed on top of the plastic case. It is this that protects a person from electric shock.

A reciprocating saw with a rubber “jacket” on the body that protects a person from electric current

- Brushes. These elements have one drawback - they wear down to the metal fasteners, which disables the conductive element. A new approach to eliminating this problem is brushes that stop working if they wear out to a certain level, leaving the conductive plane of the rotating shaft completely intact.

- Power cable. For many, this is not the most important selection criterion, but it is the one that gives freedom of action. Therefore, many manufacturers make the cable length 4 m. There is another approach, for example, the Bosch reciprocating saw - its design uses a wire with a hinged input, which prevents the cable from bending at the point of contact with the tool body.

Long power cable and swivel connection for freedom of action

Cordless reciprocating saws

A little more needs to be said about battery types. Note that such saws have always had lower technical characteristics than their networked counterparts. But today manufacturers focus specifically on the production of cordless tools. They are simply more convenient to use and do not depend on the location of the outlet. Therefore, modern cordless saws are not inferior in performance to corded saws, the battery life has increased significantly, the latter are quickly charged (usually no more than 1 hour). Such saws have become much lighter, their price has decreased, so more and more often in the hands of builders you can see reciprocating saws without wires.

Cordless tools are easy to use – give you freedom of action

Scope of application of the tool

Reciprocating saws are capable of processing the following types of materials of varying thicknesses:

Scope of application of reciprocating saw

- wood;

- plywood;

- boards with metal elements - nails, staples, screws;

- metal profile;

- brick;

- stone;

- foam concrete;

- plastic.

Thanks to the ability of the blade to bend up to 30°, it is possible to cut pipes close to the wall surface.

Types of reciprocating saw blades

Reciprocating saw blades are a hacksaw with teeth on one side sharpened at a certain angle. They are made from high-strength steel alloys and various types of durable metals. All reciprocating saw files are marked, and by the mark you can always determine for what needs the blade can be used. Let's list the main brands of files:

- HCS. This variety is used for cutting not the most durable materials: wood, plastic, rubber and others. Made from high carbon steel. Their length does not exceed 40 cm. It is very important to choose the right hacksaw according to the location of the teeth. Most often they are located along the canvas at the same distance. But if there is a need, for example, to cut boards that may contain nails, then a blade with a variable pitch is used.

- H.S.S. These files are used if it is necessary to cut sheet steel or profiles, as well as aluminum workpieces of any shape and size. Manufacturing material – tool steel. The length of such canvases varies within 30 cm.

- BIM. These paintings have the combined properties of the previous two. Therefore, they can be used for cutting both hard and soft materials. For example, if we are talking about a saw for aerated concrete, then we should use just such blades.

- HM/CT. These files are made of hard steel alloys. They are the most durable and expensive. They can be used to cut metal, concrete, fiberglass and other durable materials. Their length varies between 75−150 mm. The photo below shows a metal reciprocating saw blade from Bosch.

Metal cutting blade for reciprocating saw

How to choose the right blade based on teeth

Before buying a reciprocating saw blade, you need to pay attention to the following parameters regarding the size, shape and method of sharpening the teeth. Let’s immediately make a reservation that, along with the power of the electric motor, it is the teeth that influence the performance and cutting quality of the power tool:

- The larger the teeth, the faster they cut the material. But at the same time, the quality of the cut leaves much to be desired. And vice versa - the smaller the teeth, the longer it will take to cut.

- Manufacturers produce blades with ground and milled teeth. The former are used when cutting soft materials, the latter for hard materials.

Blade with large teeth

It is also necessary to indicate the method of fastening the saw blade itself in the saw chuck. Usually the parameters and shape are unified, so the files fit the cartridges of almost all models. Let us only add that the shank of the blade can have a different shape: T-shaped, U-shaped, F - standard. All this must be indicated in the labeling. For example, T144DF – BIM. Here “T” is the type of shank, 144 is the length of the blade in mm, “D” is the largest tooth size, where the gradation occurs in ascending order from A to D, and “F” is the designation that the working edge of the tool is made from bimetal.

Ergonomics issues

When choosing, try to find the very model that will be convenient for you to work with. That is, the device must meet your expectations and solve the tasks that you outline for it. The choice determines not only the level of safety during operation, but also the level of productivity and efficiency.

Each tool has its own characteristics, so pay attention not only to the power and weight, but also to the handle, which should be comfortable for you. Pay attention not only to the thickness and slope of the handle, but also to the presence of anti-slip folds that will allow you to hold the tool in one hand.

Pay attention to the possibility of a comfortable grip with the second hand. The casing, which is located on the base of the gearbox, is responsible for this. It should fit comfortably in your hand and have large sides. You may find it more convenient to use a device that comes with an additional rotary handle.

Which is the best electric reciprocating saw to buy?

It is clear that all of the above selection criteria determine the need to purchase one or another type of electric hacksaw. But you need to understand that any reciprocating saw’s intended purpose is determined by the blade installed on it. For example, they inserted “HCS” - saw only wood or plastic.

Reciprocating saw with wood blade

Electric hacksaw for wood

So, let’s immediately make a reservation that there are no electric saws for metal separately, but for wood separately. Therefore, we will base our choice on the canvas. As for wood blades, there are three standard sizes of hacksaws, depending on the size and shape of the teeth:

- With large teeth , which are used for sawing logs, thick beams and trees. They have a tooth pitch of 4-8 mm. The number of teeth per inch is in the range of 3-6 pieces.

- With averages. They are used for cutting medium-sized parts. They have a distance between teeth of 3−3.5 mm.

- With small ones , whose pitch is only 2.5 mm. It is clear what these canvases can be used for.

HCS blade for cutting wood and other soft materials

There is one more point regarding the angle of the teeth. There is a blade with straight teeth, and there is one with inclined teeth. The former are used for transverse cutting, the latter only for longitudinal cutting. Prices for electric wood saws vary depending on the power of the electric motor and the number of optional functions. The more of the latter, the more expensive the device.

Electric hacksaw for metal

Here we will not describe the differences between the blades, because they still have the same positions as wood saws. Just different distances between the teeth. So there is a strict rule that states that the distance between the teeth of the cutting blades should not be greater than the thickness of the metal. This should be taken as the basis for the choice. Let us add that manufacturers must indicate on the packaging how thick the metal can be cut with the saw you have chosen.

Metal cutting saw

Choice of power of electric saws for wood, metal, concrete and other materials

As mentioned above, all reciprocating saws can be divided into two main categories: household and professional. The former are used in dachas or suburban areas for pruning trees, dismantling wooden building structures, laying steel, cast iron and plastic pipes, if they need to be trimmed to the required size. They are rarely used to cut large concrete structures, although this is not a problem. This process will just take a long time. Therefore, the power of household sabers does not exceed 800 W.

1.3 kW reciprocating saw from Bosch

As for professional tools, the power here is higher - up to 1.2 kW, and the service life is quite long. In any case, these tools can cut thick workpieces without stopping to rest to cool the electric motor.

Using Guides

During the work process, it is not always possible to maintain perfect accuracy when making a cut. There are cases when the edges of the cut turn out to be split due to the sharp approach of the cutting blade to the workpiece. Going beyond the marking line and not observing the angle also happen quite often.

To avoid this kind of defects, you can use guides. These devices, as a rule, are not included in the equipment supply, as they are professional.

What is bush hammer in construction?

Review and comparison of reciprocating saws

We will consider well-known manufacturers who offer high-quality products. Everyone knows their names, the quality of the power tools offered is excellent, but the price is not the lowest, judging by the options offered.

Choosing a reciprocating saw is not so easy with a huge variety of models

Reciprocating saws from Bosch

The well-known German manufacturer offers a fairly huge range of models of corded and cordless reciprocating saws. There is no point in talking about the high quality of products from Bosch; this is a well-known fact. Let us add that on all forums they talk about sabers from Bosch only in an amazing way. Of course, these are not the cheapest tools, but you can overpay for such quality.

Reciprocating saw from Bosch

Makita reciprocating saws

A tool from a Japanese manufacturer is, first of all, of high quality. According to experts, Makita are universal reciprocating saws that are suitable for blades for various purposes. At the same time, some models boast the ability to rotate the file 180°, providing a cut from bottom to top. The blade itself is secured in the cartridge using a latch. The power tool is equipped with electronics that automatically monitor the depth of cut, control the load and speed of movement of the working tool.

Makita reciprocating saw

Reciprocating saws Interskol

These are products of a domestic manufacturer, which in terms of their characteristics are not inferior to the best foreign ones, and in terms of price - significantly lower. At the same time, all models of Interskol saws are provided with full optional functionality, which indicates that these electric hacksaws are modern power tools of their class. The company offers both household and professional appliances. Therefore, there is a choice in this direction.

Reciprocating saw from the domestic manufacturer Interskol

Device and purpose

A reciprocating saw is indispensable both in everyday life and when professionals perform larger volumes of work. This device got its name because of the unique shape of the hacksaw blade.

The base of the reciprocating saw resembles the body of a hammer drill. The only difference is the handle, which is integrated with the rear part of the casing. The blade of the tool is located in the front part. There is also a support shoe, which allows you to fix the tool in a comfortable position during the cutting process.

The reciprocating saw blade performs translational rather than rotational movements. This is the main difference between the device.

A reciprocating saw is a universal, simple and safe tool that is a good assistant during various repair work.

With the help of such a device, various materials such as wood or metal are cut.

Rating of the best reciprocating saws

Let's start the rating of reciprocating saws by dividing them into two groups: corded and cordless. First of all, let’s look at the battery ones, or rather, which of the models offered by the market are most in demand today. In this case, the opinion of not only specialists, but also consumers is taken into account.

Rating of the best cordless reciprocating saws

| Place | Model | Characteristics | Advantages and disadvantages | price, rub. |

| 1 | BOSCH GSA 10.8 V-LI 0 | Stroke size – 15 mm. The number of strokes is 3000 per minute. Battery – Li-Ion. Battery voltage – 10.8 V. Weight – 1.2 kg. Dimensions: 286×132 mm. | Powerful saw, easily cuts any material. There is a backlight. The ride is smooth, without strain. The battery capacity is not enough. The price is high. | 6000-8000 |

| 2 | Makita JR102DZ | Cutting height – 50 mm. Stroke size – 13 mm. Number of strokes – 3300. Weight – 1.1 kg. The battery is lithium-ion. Voltage - 10.8 V. | There is a backlight. There is a rotation speed adjustment. There is no pendulum motion. No soft start. Replacement of equipment with a special key. In a good sense, a workhorse at a low price. | 3500-4200 |

| 3 | Reciprocating saw AEG BUS 18-0 | Stroke size – 19 mm. Number of strokes per minute – 3300. Weight – 3.5 kg. The battery is lithium-ion. Capacity - 3 Ah. Voltage - 18 V. | All options are present, with the exception of maintaining constant speed under heavy loads. There is also no soft start. Vibration occurs when cutting. | 8000-8500 |

Rating of the best corded low-power reciprocating saws

| Place | Model | Characteristics | Advantages and disadvantages | price, rub. |

| 1 | AEG US 400 XE | Power – 400 W. Stroke size – 13 mm. Number of strokes – 3500. Weight – 1.8 kg. The length of the power cable is 4 m. | Compact and highly reliable. Adjustable cutting depth - yes. Replacement of equipment - without a key. There is no soft start or pendulum motion. The fastening of the files is universal. | 6500-7500 |

| 2 | Bosch PSA 700 E | Power – 710 W. Cutting height – 150 mm. Stroke size – 20 mm. Speed – 2700. Weight – 3 kg. Cable length – 2.5 m. | One of the most powerful models in its category with good performance. The package includes one wood saw. A simple tool, reliable, with good characteristics. Weak functionality: no backlight, no brake, no speed control, no electronic engine protection. But with such characteristics, the price is quite reasonable. | 5300-5800 |

| 3 | Elitech PS 500 | Power – 500 W. The cutting depth for wood is 60 mm, for metal – 6 mm. Stroke size – 15 mm. Number of strokes – 2350. Number of speeds – 1. Weight – 1.7 kg. Dimensions: 306×198×72 mm. Cable length – 2 m. | Fastening of canvases is universal. Replacement of equipment - without a key. Speed control - no. Brake - no. The saw blade is adjustable in 8 positions. The set includes two canvases. | 2200-2500 |

Rating of the best networked powerful reciprocating saws

| Place | Model | Characteristics | Advantages and disadvantages | price, rub. |

| 1 | Makita JR3070CT | Power – 1.51 kW. Cutting depth – 225 mm for wood. The stroke is 32 mm. Number of strokes – 2800. Weight – 4.6 kg. Dimensions: 550×130×300 mm. The length of the power cable is 2.5 m. | Adjustment of cutting depth - without a key. Pendulum stroke – yes. The fastening of the files is universal. Soft start - yes. Speed support under load – yes. | 12000-13000 |

| 2 | Stomer SSS-1000 | Power – 1.1 kW. The cutting depth for metal is 6 mm, for wood – 150 mm. The stroke is 20 mm. Number of strokes – 2500. Weight – 3.84 kg. Dimensions: 570×110×245 mm. | Speed adjustable - yes. Pendulum stroke - no. Universal fastening of canvases. Replacement of equipment is keyless. Contents: two files and a set of brushes. | 5000 |

| 3 | Reciprocating saw Hilti WSR 900-PE | Power – 900 W. Stroke length – 32 mm. Number of strokes per minute – 2700. Number of smooth running modes – 6. Weight – 3.5 kg. Dimensions: 442×88×211 mm. | Pendulum stroke – yes. Stroke length regulator – yes. There is a speed regulator. Vibration absorption – yes. Changing equipment - without a key. | 50000 |

We must pay tribute to other models, which in many respects are not inferior to those described in the table. Of course, well-known brands will always be in demand by both professionals and home craftsmen. Everyone wants to have a good quality tool at hand. But, for example, reciprocating saws from (PIT) are no worse than Makita or Bosch.

Features of choice

The first criterion to pay attention to is the power of the tool. Only when you have decided on this parameter can you proceed to the next criteria.

- Pay attention to the keyless blade change. If you plan to work with various materials, then this feature will be useful to you.

- A useful option is to adjust the cutting depth. It is needed when working with materials of various thicknesses. In addition to precision processing, it also saves the life of the blades, ensuring equal wear along the entire length. There are two options for changing the depth of cut - without a key and with it. It is much more convenient to use the option without a key.

A reciprocating saw blade can only be designed to work with one type of tool, or it can have a universal shank. A more convenient option for household needs is when you can insert different types of blades without wasting time searching for a branded one.

Smooth start is ensured by electronic speed control. It also guarantees high precision in operation and maintains stable speed. It is worth paying attention to ergonomics. Good equipment has the following characteristics:

- Possibility to rotate the blade 180 degrees;

- Counterweight;

- Adjusting the guide shoe;

- The presence of vibration-absorbing rubber pads.

In cheap models, the pendulum movement of the blades is constantly on. But there is also equipment for which this mode can be disabled. Thanks to this feature, the saw makes a smoother and cleaner cut and vibrates less.

After just a few hours of training, confident operation of the device is possible. This device will be especially easy to master for those who have previously dealt with a chain saw. To start the process, just press the start button smoothly and bring the device to the cutting zone. The equipment is immersed in the material independently, and the master only needs to direct it in the right direction. Caring for an electric reciprocating saw is simple: regular cleaning and lubrication.

Reciprocating Saw Repair

What can you say specifically about reciprocating saw repair? If you are not a specialist in this matter, then you should not open and disassemble the tool. Take it to a service center where professionals will take care of it. The only thing you can do with your own hands is to change the blade if it breaks under the load.

Graphite brushes

The main reasons why the saw stops working:

- the electric motor burned out;

- The graphite brushes are worn out.

The first one cannot be repaired. It is replaced with a new one. The latter also change, but this is a simpler operation, which includes disassembling the saw body, removing old brushes and installing new ones. The brushes are inserted into special grooves, inside which they are pressed against the conductive plane of the spring. Each brush has a shank in the form of a stranded copper wire; it is connected to the electrical part of the device with a regular screw. Therefore, replacing brushes does not cause difficulties.

The main thing is not to overload the saw

Related article:

Chainsaw: which brand to choose. It is difficult to imagine life on a summer cottage without working with wood. An important tool for this is a chainsaw. So which model is right for you according to your goals and budget?