Engine selection and installation

The gasoline engine makes it possible to perform work regardless of the presence of a nearby energy source. This vibrating plate is in demand among small construction teams performing contract work on private development sites.

To carry out work within the personal territory, it is better to use a tamping machine with a 220V electric motor. It operates much quieter, does not require refueling, and the power supply can be easily provided through an extension cord that can be extended to any location on the site.

The electric motor is fixed to a welded channel using bolts and connected to the vibration mechanism using a belt drive. If the vibrator eccentric is connected to the motor with a rigid connection or mounted on a shaft, then the motor bearings will constantly fail due to vibration effects.

The center of gravity of the engine must be on the central axis of the vibration platform. If this is not done, then during operation the vibrating plate made by yourself will constantly move to the side and you will have to make additional efforts to keep it in the desired direction. Vibration-damping pads made of thick rubber must be placed under the motor feet.

Torque transmission

It is recommended to use a soft V-belt drive as a transmission to transmit torque from the engine to the vibration mechanism. It will ensure reliable rotation of the eccentric and protect the motor bearings from the effects of vibration.

It is recommended to use double-belt pulleys. This will give greater grip to the belts and ensure trouble-free operation in the event of a break in one of the belts.

To protect against possible injuries, the belt drive must be covered with a protective cover, and if this cannot be done, then a bumper guard must be installed.

Peculiarities

Compaction of soil, backfill layer or concrete casting during construction work requires the participation of special equipment. In private construction, problems often arise related to deformation or subsidence of the foundation.

- The cause of these events is poor compaction of the sand backfill layer. According to the technology, the density should correspond to the condition of a long-used country road. Checking the quality of the compaction is usually done by walking along the compacted area - if there are no traces of shoes left, the job has been done to the proper standard.

- Soil compaction is required not only in critical areas. Conventional tiling of garden paths requires the creation of a layer of sand cushion, which also requires the maximum degree of compaction, otherwise the coating will begin to fail and move apart. It is impossible to achieve high quality work manually, and a vibrating plate comes to the rescue.

- For home use, not everyone can purchase a ready-made device, since the cheapest sample will cost 20 thousand rubles. People who are able to operate metalworking tools and a welding inverter prefer to make their own vibrating plates, which saves money and brings the desired result.

The role of the control knob in the vibrator plate device

In a device such as a vibrating plate, when the market is replete with various models, often differing only in design, it is important to think about the safety of workers. Honestly, it would be better if the model had no handle at all. But such devices will have a significant impact on your wallet and will weigh from 700 kg, but they are controlled remotely. If the handle is present, then it is necessary to ensure that it is equipped with a vibration-proof pad.

Look

All advertisements for the sale of vibrating plates

The device of the vibrating plate does not involve complex schemes and mechanisms of action. But since this equipment is often actively used in difficult conditions, it is necessary to pay attention to proper care of it. Replacement of vibrating plate filters, spark plugs, oil, timely maintenance - and your vibrating plate will serve faithfully for many years.

Bomag vibrating plate device

Operating principle

The operation of a vibrating plate is based on the use of a rotating shaft with an eccentric, which generates strong vibration. The shaft is mounted on a massive metal base, which with its weight acts on the soil, compacting it due to its weight.

On the same base, a motor is installed, which is necessary to drive the eccentric shaft into rotation. To control the structure and give the installation the desired direction, a long handle is installed.

There are several types of vibrating plates:

- electrical;

- diesel;

- gasoline.

By weight they are divided into:

- light (up to 75 kg);

- universal (from 75 to 90 kg);

- medium-heavy (from 90 to 140 kg);

- heavy (140-200 kg or more).

There are also different ways to move the vibrating plate:

- upright, capable of moving only forward and requiring a platform of sufficient size to turn around;

- reversible, capable of moving both forward and backward, which makes them more convenient in conditions of limited space.

Lightweight and versatile vibrating plates are used for compacting paths, paving slabs, and landscaping work. During construction and foundation work, medium-heavy and heavy-duty installations are required that provide maximum compaction combined with high productivity.

Important! The weight of a vibrating plate created at home should not be too large, otherwise it will be difficult to move it and there will be a danger for the worker servicing the installation.

Video review of what a vibrating plate is

Vibrating plate configuration options

Nutrition classification

- electrical,

- diesel and

- gasoline vibrating plate.

Electric. Electric is considered the most economical. This is exactly what they recommend collecting with your own hands for your own household.

Moreover, in terms of technical characteristics, vibrating plates with an electric motor are in no way inferior to their competitors. The only downside is the condition of having an accessible electrical network.

Gasoline. It will cost more than electric ones, but cheaper than diesel ones.

However, it will be more profitable to buy fuel for diesel engines, although the engine itself will be the most expensive of the three described.

Also, its disadvantage will be high noise, which reduces comfort at work.

The power of the installed motor must be sufficient to operate a heavy slab. Otherwise, the latter will load in bulk material.

Classification of vibrating plates by weight

The mass of the vibrating plate will be the primary determinant for the selection of component parts if you make the mechanism yourself.

Highlight:

- Lightweight slabs . Weighing 75 kg. For processing layers up to 15 cm thick. Such slabs are used for landscaping work, laying paving slabs, and damping polyurethane mats.

- Universal plates . Their weight ranges from 75 to 90 kg. The maximum layer to be treated is 25 cm. They are used for landscape work, repair of road surfaces, including patching on asphalt.

- Medium-heavy . Weight 90-140 kg. The thickness of the treated layer is up to 60 cm. Application - laying road surfaces in layers, backfilling trenches along the perimeter of the foundation.

Classification by direction of movement

According to the direction of movement during the compaction process, vibrating plates can be straight or reverse.

Straight lines can only move forward, and if a second pass over the compacted layer is necessary, such a machine will have to be turned around. And this, albeit small, is still a waste of time.

Reversible vibrating plates can move both forward and backward. They give higher performance. Typically, devices with slabs weighing more than 100 kg are equipped with reverse.

Additions to the package

An additional advantage would be if the vibrating plate is equipped with an irrigation system.

It protects the unit from sticking to the compacted surface. They should carefully protect the engine from water.

Belts and couplings must be protected with special covers.

This way, small particles of bulk materials will not clog into the mechanism, and the machine itself will last much longer.

Mechanism design

The main element of the vibrating plate, from which the creation of the installation begins, is the metal base.

- There are steel and cast iron samples, however, the use of cast iron at home is not advisable.

- It is capable of cracking, cannot be welded, and is fragile.

- Typically, steel sheets with a thickness of 8 mm or more are used. Additional elements are installed on the surface of the base to increase the mass.

- They also serve as the basis for installing the engine and vibration mechanism. In most cases, this is a regular shaft mounted on two bearings, on which a load is attached in the longitudinal direction. The rotation of the shaft creates a driving force, which, due to its own weight and inertial force, forms frequent short-term loads on the ground.

The operating efficiency of a vibrating plate depends on the weight, base area and rotation mode of the eccentric shaft. A slab that is too spacious is not capable of generating high pressure, since the weight of the installation is distributed over the area and reduces the specific pressure.

A small base gives greater efficiency, but it acts too selectively, pointwise.

This mode does not allow uniform compaction of the soil over the entire area of the site. The rotation of the eccentric shaft creates a significant load on all structural elements. Too intense vibration can destroy the vibrating plate, have a negative impact on the operation of the engine, and negatively affect the well-being of the worker.

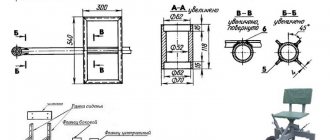

An example of a drawing of a gasoline vibrating plate:

Making a tamping plate

The plate for the vibrating tamper can be manufactured at the factory or made by hand from a metal sheet with a thickness of at least 8 mm. A homemade vibrating plate should provide such a weight to the device that it will give a tight fit to the surface being treated.

Its dimensions should not exceed 800 x 500 mm, excluding the curved edge, which will ensure convenient operation and the ability to use the device without additional assistants.

A flat steel plate, when moving over soil or concrete mixture, will constantly cling to an uneven surface. To avoid this, the front and rear edges of the slab are slightly bent upward, resulting in a structure reminiscent of a sled. To do this, stepping back a little from the edge, you need to make a cut in the metal to a depth of 5-6 mm using a grinder and bend the strip. Repeat this operation on the other edge of the sheet. The contact line after the bend must be welded using electric welding.

Making a tamping plate.

To install the motor and vibration mechanism on the platform, you need to secure the support frame. It can be made from two installed pieces of metal channel. They must be installed parallel to each other transverse to the axis of the tamping platform. Drill mounting holes for the motor and vibrator in them and weld them with electric welding.

Purpose of vibrating plates

A similar mechanism is used for compacting crumbly areas of earth and building materials, as well as uncured surfaces of asphalt and concrete. It is especially effective in small areas and sidewalks, as well as where heavy equipment cannot enter.

The use of this device will greatly facilitate manual labor in homestead or country landscape construction. The easiest way to compact the soil on a garden path or a small parking lot near a house is by mechanized method.

The tamping vibrodynamics will also help out during excavation work on laying underground communications, when you need to compact the soil at the bottom of the trench.

This device operates due to vibrations that occur during the rotation of a flywheel mounted on eccentrics:

- By displacing the ballast through the drive, the vibration created is transmitted to the iron base - the sole.

- The heavier it is, the stronger the oscillatory process and the denser the compaction.

- A similar device is used in vibrating platforms at factories for the production of reinforced concrete products and vibrating tumblers for cleaning various objects from burrs, scale and other defects.

Vibrating plate: scope of application and technical characteristics

A vibrating plate is a unit whose main function is compaction. It is used in various fields: for soil compaction during construction, landscape planning, for compacting bulk materials (sand, pebbles, gravel), when laying asphalt, paving slabs, paving stones.

Vibrating plates are suitable for performing work volumes not exceeding 1000 sq. m.

The machine is small in size and therefore maneuverable. It can be used both in open areas (when compacting land, parking, road surfaces, floors in large industrial premises, etc.) and in confined spaces (in ditches, trenches, near buildings, near curbs, wells, hatches etc.).

A vibrating plate for compacting soil and other bulk materials is recommended for use in areas not exceeding 1000 m². In large areas, large-sized and more powerful equipment is used for these purposes.

Each vibrating plate model has its own performance indicators, which determine the features of its use and scope of application. So, when choosing a vibrating plate, you should pay attention to the following technical characteristics:

- dimensions of the base plate, mm;

- vibration frequency, Hz;

The process of compacting the required mass with a vibrating plate is carried out as a result of the occurrence of shock vibrations in the unbalance.

- compaction depth, mm;

- vibration amplitude, mm;

- power, kWt;

- unit weight, kg;

- electricity or fuel consumption, kW/h or l/h;

- maximum productivity, m2/h;

- Overall dimensions of the device, mm.

How to assemble a vibrating plate yourself

Materials

- Sheet of steel measuring 50x80cm and thickness 8 mm;

- An area vibrator and an electric motor for it, for example IV-98E. Some craftsmen build vibrating plates with a washing machine motor

- Two pieces of channel up to 45cm long;

- M10 and M12 bolts with nuts and washers;

- Metal pipes 1.5 m long and 20-25 mm in diameter;

- Shock absorbers.

Tool

- Welding machine,

- hammer,

- grinder with cutting wheels,

- drill and a set of metal drills for it,

- set of wrenches,

- tape measure and marker.

Step-by-step instructions for assembling a vibrating plate

- On the steel sheet, cuts are made on both sides approximately 5 mm deep, this is enough to bend the sheet. Moreover, the incision should be 10 cm from the front, and 5 cm from the back.

- Bend the edges of the sheet at an angle of 20-30 degrees, and weld the bend points.

- The prepared channels are welded parallel to the bent edges. The distance from the center line of the sheet to the channels is about 5-10 cm.

- A vibrator is mounted in the center of the channels, securing its legs using an electric drill and bolts with nuts and washers;

- Shock-absorbing cushions are attached to the slab;

- A U-shaped handle is formed from the pipe, at the edges of which holes for bolts are drilled;

- Using metal corners, the handle is secured to the sole through shock absorbers;

- Connect the power cable and provide start-up protection.

- A vibrating plate made in this way will have a mass of about 60 kg. For ease of transportation, you can add an axle with wheels to it.

Advice! If you want to increase the weight of the vibrating plate, you can weld several metal sheets or reinforcing rods to it.

Before starting the structure for the first time, check all its components for secure fastening or absence. damage and chips. Keep it clean and your homemade vibrating plate will last a very long time.

If you have chosen a gasoline engine for the mechanism, you will have to clean the spark plugs more often, check the oil level, and change filters.

The first time the oil should be changed after 25 hours of operation, after which it can be done after 80-100 hours. It is better to fill the oil with the engine warm but turned off.

By making a vibrating plate with your own hands, you can save up to 10,000 rubles.

Plate and frame

The plate is a sheet of metal, the thickness of which can provide sufficient rigidity.

- Typically, steel sheets of 8 mm and thicker are used.

- The average size of the working surface of the stove is 60*40 cm, although there are other options.

- The front and rear edges of the slab are raised for unhindered movement along the surface of the site.

The frame consists of a stand for the engine and eccentric shaft. It also serves as an additional load, which gives the vibrating plate greater efficiency and increases the amount of forcing force.

Another task that the frame solves along the way is strengthening the rigidity and strength of the base, compensating for mechanical loads from the rotating rotor.

The design of the homemade frame can be anything. The main task is to strengthen and weigh the slab, so they use pieces of channel bars, rails and other massive and durable elements. The only thing to remember is that the vibrating plate must sooner or later be placed in storage, which may require carrying it manually. Excessive weight will create difficulties.

Vibration mechanism

The vibration mechanism of a vibrating plate, or vibration exciter, can have two design options:

- unbalanced, which is a rotor unbalanced relative to the axis of rotation;

- planetary, using the energy of moving elements that move along special closed paths.

Making a planetary mechanism at home is impractical, since it is difficult both to create and to maintain. It is difficult to make an unbalanced vibrator, and the magnitude of the driving force is the same in both cases, so the choice is obvious.

The eccentric rotor is mechanically connected to the engine via a drive belt. To do this, pulleys located in the same vertical plane are installed on both elements. With their help, you can adjust the gear ratio and change the vibration frequency of the installation.

Additional items

Additional elements are:

- handle (carrier) used to guide the vibrating plate during operation;

- a trolley on which the device is installed when moving from one place to another;

- tension mechanism, which ensures tight contact of the drive belt with the pulleys of the engine and vibration mechanism.

The handle is a long U-shaped bracket made of a tube. It is attached to the plate through a swivel joint, which partially compensates for vibration and protects the worker from its effects.

The trolley is a separate element, although rigid mounting options are available. It is brought under the stove, the unit tilted towards itself by the handle, supported on a trolley and transported to the desired location. When rigidly mounted, the legs with wheels are installed on the base in an inverted position.

If it is necessary to move the vibrating plate, the installation is turned over and transported to another location.

The tensioning mechanism ensures tight contact between the drive belt and pulleys. It is important that the roller has a groove that matches the groove of the pulleys. This will help extend the life of the belt. If the vibrating plate roller is installed on the outside, the groove size must match the back of the belt. For tensioning, an adjusting screw is used, which allows you to loosen the belt for replacement or tighten it to working condition.

What is a vibrating plate?

Why do you need a vibrating plate?

The processes of compacting various loose bases are integral to construction work. For example, crushed stone, sand, soil and other similar materials.

Basically, these are the stages of preparation for pouring concrete, asphalt, laying tiles or building a foundation.

In order to mechanize the compaction process, so-called vibrating plates are used. The mechanism of their action is quite simple.

The device creates vibrations under the action of which small particles of the compacting layer are knocked as close to each other as possible, excess air is displaced and at the finish a flat base of the required density is obtained.

Buying such a car for yourself is quite unprofitable. A homemade vibrating plate will cost much more profitably.

Structural design of the vibrating plate mechanism

A vibrator is mounted on a weighty platform, and a motor is installed above it. The last two nodes are connected by a coupling and a V-belt drive.

The rotational movements of the engine are converted into oscillatory movements using a vibrator and transmitted to a heavy platform, which in turn acts on the compacted surface.

The device's reverse function makes it possible to perform work in narrow trenches and pits.

The stove itself is made of steel or cast iron, preferably of good quality. Otherwise, the service life of the device is significantly reduced, and cracks appear on the surface of the base.

The size of the working surface of the slab affects the pressure exerted by the mechanism on the compacted layer. A slab with a smaller area compacts the soil better.

Important! For sufficient compaction of asphalt, the device must have at least 10 kN. It is better to lay tiles using a slab weighing 75-90 kg and a force of 18-20 kN.

The density of the finishing layer depends on the vibration force. The higher it is, the better the material is compacted.

Frequency and cycle of vibration motor use

First of all, you need to determine the vibration frequency of the engine. It can vary from 750 to 3000 rpm. A high frequency with a small amplitude, or a low frequency vibration with a large amplitude may also be needed. In construction, as a rule, vibration motors with a high vibration frequency of 2 to 3 thousand revolutions per minute are used. However, a lot depends on the size and weight of the installation.

The higher the frequency, the more the installation structure is exposed to fatigue stresses, therefore, the steel of the load-bearing frame must be stronger and thicker. If the permissible frequency limit is exceeded, the structure will quickly deform. In this case, it is also necessary to take into account the operating cycle of the installation.

Under heavy loads and frequent use of the vibration unit, it is not recommended to use a motor with a speed of more than 1500 rpm.

Vibrating plate motor: what to choose?

As mentioned above, the engine can consume gasoline, diesel, or electricity. The operating principle of a vibrating plate does not change depending on the type of engine, but the range of work directly depends on it.

The most popular gasoline engines are Honda, Robin, Wacker. These engines are 4-speed, so they must be “fed” with pure AI-92 gasoline. Oil marking is SAE 10 W 30 or SAE 10 W 40. Popular diesel engines are Hatz, Lombardini, and Kipor.

Not so often, but still some manufacturers offer electric vibrating plates. They are well suited for work in buildings where access to fresh air is limited; this particular type does not emit exhaust gases. A significant disadvantage is, of course, that the machine is connected to an outlet.

The heaviest are diesel vibrating plates. Their mass can reach a ton. For example, the Wacker DPU 130 diesel vibrating plate, according to the manufacturer, is capable of replacing a roller weighing 7 tons. This specimen has a two-section base plate and develops a centrifugal force of 130 kN. Comments about performance are probably superfluous, but such vibrating plates are also the most expensive. A gasoline vibrating plate, in turn, weighs a maximum of half a ton, the lowest limit is 50 kg.

Photo source: atlascopco.com More often, vibrating plates are equipped with gasoline and diesel engines

Homemade vibration motor for concrete

To compact the concrete mass in foundations and other reinforced concrete structures, surface-type or submersible vibration motors are used. For a surface vibrator, a vibration motor with a power of 1 to 1.5 kW, operating on a 220 V network, is suitable.

Its diagram is shown below, and it consists of:

- Handles for holding, guiding and carrying the device.

- Electric motor of sufficient power.

- Power cable.

- Eccentric unbalance.

- Bases of the required size.

Professional models of vibration motors have an adjustable eccentric, which allows you to adjust the amplitude of vibrations and the force with which compaction is performed. The eccentric is fixed on the output shaft of the electric motor. To do this, a bracket is rigidly fixed to the shaft, and the unbalance in turn is attached to it with a threaded connection. By loosening the thread, you can adjust the position of the eccentric in relation to the motor shaft, thus changing the amplitude of the device.

Description, drawings and dimensions of vibrating plates with gasoline and electric motors

You can assemble a vibrating plate with an electric or gasoline engine with your own hands. Installation is quite simple in design and requires readily available consumables.

The dimensions of the unit are selected individually, depending on the purpose. Typically, installations are made with a base no more than 1 x 1 m. Such a do-it-yourself concrete vibrating plate is quite wide, but not too bulky and interacts well with a medium-power engine. The thickness of the steel sheet should be about 8 mm.

The compact dimensions of the vibrating plate make it easier for the operator to interact with the device

Do-it-yourself drawings and photos of a vibrating plate show how the main elements of the unit should be located. The base is always located in the lower part, and the motor part is installed on top of it. The frame and handle make it easier for the operator to control the device.

For convenient movement, the vibrating plate can be equipped with wheels; it will be easier to unfold. Important! Drawings of a 220 V electric vibrating plate with your own hands and gasoline units are almost no different from each other. Devices of any type are assembled using a single algorithm.

Useful features

All vibration installations have additional devices that make work easier or provide additional protection. In order to move the device to a new place of work, the presence of wheels and a folding handle will make this task performed without unnecessary effort.

Various covers will protect the machine from particles from the compacted surface. The slab wetting system is effective when rolling hot asphalt. Without it, it will stick to the top layer.

Work to strengthen the bottom of trenches or compact soil in narrow places is practically impossible without ensuring reverse movement.

Final work

After assembling the slab, all metal parts must be primed and painted to protect against corrosion. Securely fasten the supply cable to the control handle to prevent the possibility of running over it. The engine switch must be located on the structure itself to provide an emergency stop during operation.

After this, the vibrating plate made by yourself must be tested. Freshly dug soil is best suited for this. Testing on bulk material will not allow you to test operation at full load.

As you can see, it is quite possible to make a vibration machine yourself. But for this you need to have basic knowledge and experience in plumbing and welding.

Advantages of homemade products

The cost of a device made independently is much lower than that of ready-made equipment. In appearance, it resembles a walk-behind tractor with a vibration motor. Quality and durability are ensured by the simplicity of the design. The efficiency of such a vibrator is no lower than that of a purchased one, and sometimes even higher.

Advantages of a homemade vibrating plate:

- Full compliance with the operating conditions for which it is manufactured allows you to perform the assigned functions with high quality.

- The owner chooses which vibrating plate to make: with an electric motor or an internal combustion engine.

- Everyone also worries about their own safety. Therefore, all the necessary protection systems will be provided and installed.

- Having your own device will allow you to choose the time and place of work according to your circumstances.

Advantages of a homemade tamping machine

The main advantage of a home-made vibrating plate is its low cost and the ability to perform high-quality and efficient work. The simple design ensures the reliability and durability of the mechanism. In addition, a homemade vibrating plate allows you to:

- Safely tamp any surfaces;

- reduce the amount of manual labor when performing work;

- improve the quality of footpaths and platforms;

- It is good to compact dry cement and semi-dry concrete mixtures when laying them.

Having a mechanism for compacting loose soils and bulk materials will allow you to carry out any amount of landscaping and exterior design work.

Review of purchasing options.

Operating rules

Any person wants his equipment to work as long as possible and not break down. In the case of a vibration device, for this you need to follow the rules that apply to both a homemade device and a branded one:

- Each time before starting work, it is necessary to meticulously inspect the device. If you find cracks or loose connections, do not start using the equipment until the defects are eliminated.

- The gasoline engine requires maintenance more than other components. Inspection and cleaning of spark plugs and checking the oil level must be carried out regularly.

- The vibration unit also requires attention. If there is no oil, eccentrics and bearings fail.

- The device itself must be cleaned of dirt.

- Do not transport the vibrator while it is running.

- It is prohibited to use the equipment on hardened asphalt or concrete.

Possibility of reverse movement

Movements of a homemade vibrating plate made as described above are only possible in one direction. Therefore, after walking a certain distance, you have to turn it around and only then move in the opposite direction. This reduces the speed of work and requires additional physical effort on the part of the operator.

Another drawing of a variant with a gasoline engine.

In order to provide the vibration machine with the ability to reverse movement, it is necessary to install a device that changes the direction of rotation of the motor. After its installation and connection, the vibrating plate will be able to move in two directions.

When the edge of the treated area is reached, the operator turns off the engine and starts rotating it in the opposite direction. The vibrator eccentric will also become reversible and provide the machine with a return movement.

Purchasing a unit

If you still decide to purchase a unit, you need to take into account both the main criteria and minor nuances that will make the work easier or increase its service life. However, we cannot fail to mention the manufacturers of vibratory ramming devices.

- Equipment from European manufacturers is especially important. German technology is distinguished by its reliability and long service life. Even rental samples show good quality and speed of work. All equipment has a double safety margin. Wacker, Weber, Ammann, Bomag produce professional equipment.

- Israeli Shatal and Czech NTC have fewer resources than the Germans, but they also turn out to be good workers at construction sites and on private property.

- South Korean equipment from Jeonil Minery is not inferior to products from the Czech Republic or Israel. In the Asian market, this is the best offer among all vibration units.

- Russian products from, Motoprom and SZPO are inferior to average European models in terms of convenience and functionality. However, modernization continues, and new, more advanced models appear on sale.

- The Chinese, as usual, charge a price. Their products are only suitable for occasional, light-duty work. Among the mass of unknown manufacturers, the companies TEKPACK, MASALTA, DYNAMIC, CIMAR stand out.

Description of the technique

A vibrating plate is a construction tool that is used for compacting crushed stone, soil, sand, asphalt and various other bulk materials.

Without the use of such units, it will be impossible to pour a high-quality foundation, make a garden path, or level the surface for arranging a lawn. Today you can find various models of equipment on sale with different parameters, operating principles and costs. The operating principle of such equipment is extremely simple. A vibrator is installed on a heavy working platform, on which the motor is mounted. The drive is connected to the vibrator by a belt drive or clutch. During operation, the engine creates numerous rotational movements, which are transmitted to the vibrator and converted into low-frequency vibrations. Such impulses are transmitted to a heavy plate, which compacts the materials.

Some modifications are equipped with front and rear reverse gears, which allows you to conveniently work in narrow pits and trenches. The working plate can be made of cast iron or steel, and the characteristics will depend on the quality of the material and its dimensions. Preference should be given to units in which the working plate is made of thick steel. But when using cast iron blanks, such slabs can become cracked and quickly fail, resulting in expensive repairs.

Vibrating plates, depending on the engine used, are usually divided into several categories:

- Gasoline.

- Diesel.

- Electrical.

For a small amount of work, an electric vibrating plate, which combines affordable cost, power and versatility of use, would be an excellent option. But modifications equipped with diesel and gasoline engines are intended primarily for professional use and are distinguished by mobility, increased power and functionality.

Depending on their weight, such equipment is usually divided into the following categories:

- Lightweight - up to 75 kilograms.

- Universal - 75-90 kilograms.

- Medium-heavy - 90-140 kilograms.

- Heavy - 140 kilograms or more.

Each equipment is designed to perform certain jobs. For example, lightweight vibrating plates are used for compacting paving slabs and landscaping. Universal models do an excellent job of vibrating sand and gravel; using this technique you can compact sand, perform asphalt patching and various types of landscaping work. Heavy equipment can be used for layer-by-layer compaction and laying of the roadway, vibrating trenches and preparing the site for laying the foundation.

The equipment presented in specialized stores is distinguished by its reliability and versatility in use. The disadvantage of such equipment is its high cost. Even the simplest universal and lightweight electric vibrating columns can cost 50,000 rubles or more, let alone professional equipment, which is estimated at 100-200 thousand rubles. Therefore, many homeowners who need to carry out various types of construction work, lay walkways and level the base for the lawn, independently construct vibrating plates with a gasoline engine.

Despite the apparent complexity of such equipment, it is quite possible to make it yourself.

How to make a homemade vibrating plate with a washing machine motor

A simple option for making a vibrating plate with your own hands is to use a motor from a washing machine. The method is convenient because such a motor is easy to obtain by simply removing it from old equipment. In addition, the device can be connected to a 220 V household outlet, which will significantly simplify its use.

Instructions on how to make a vibrating plate with your own hands show the standard assembly diagram:

- the metal sheet is cut along the edges with a grinder and bent upward, and then the seams are welded using a welding machine;

- Using channels located at a distance of about 10 cm from each other, a vibrator with a motor installed on it is connected to the plate, while you need to ensure the strength of the fasteners and their even position;

- the motor from the washing machine is fixed with bolts, usually M10 or M12 are used;

- After installing the engine, they begin to make the handle; it can be made from any piece of steel pipe of a suitable diameter and secured to the base with silent blocks or elastic pads.

Attention! When installing the handle, it is necessary to use not only rigid bolts, but also shock absorption, otherwise the device will simply be pulled out of your hands.

A do-it-yourself vibrating plate with a washing machine motor is already ready at this stage. However, it is recommended to modify it and equip it with wheels for more convenient movement. To do this, a piece of pipe is welded to the base of the structure. Along its edges, using a welding machine, rings are mounted, the diameter corresponding to the selected wheels. The latter are fixed inside with the possibility of subsequent dismantling.

The motor power of about 1.5 kW ensures quick and easy leveling of a layer of concrete or sand up to 200 mm thick. A do-it-yourself electric vibrating plate with a washing machine motor is suitable for most repair and country work.

The concrete vibrator consists of an electric motor, a vibrating device and a flexible shaft. A replacement for the first element is constructed from a jackhammer, hammer drill, drill and other devices that transmit vibrations. There is no need to neglect the design of a flexible shaft for the vibrator, because thanks to it the tip is safely lowered into the solution and transmits the desired vibration. This product can operate from a 220 V home electrical network.

The vibratory ramming machine, constructed from a hammer drill, operates on the basis of impact force. A metal peak is created for the nozzle. This design helps to penetrate the thickness of the concrete, which is extremely necessary after pouring the pile base.

It is important to determine the required length of the nozzle. To process a large area, choose a large sheet to which the puncher itself is attached

It is necessary to firmly strengthen the structure, because the vibration force can be destructive for the product. In cases where the equipment elements are horizontal, the nozzle should be positioned at a slight angle. And this can be achieved by attaching the washer as a support. Then a vibration unit of the hammer drill is installed in it.

Control handle and vibration damping system

During operation, thanks to the front location of the eccentric and the resulting vibrations, the platform with the engine installed on it begins to move along the surface independently. But to set the correct direction of movement, a control handle is needed.

According to its design, it can have one or two inclined posts with a transverse handle-crossbar. It is recommended to install a vibration damping device in the upper part of the handle so that vibrations are not transmitted to the hands during operation. You can use springs as protection; the stand itself can be made of two pipes, one of which will go inside the other. The springs are fixed by steel rings installed on the pipes.

If you have the financial opportunity, then instead of a homemade spring structure, you can install silent blocks from a passenger car. This will provide sufficient vibration damping, and the structure itself will be less noisy.

Concrete pouring technology

A day later, after the curb has hardened, you can start pouring concrete. If you plan to create a platform on which cars will drive, the concrete base should be reinforced. For this purpose, reinforcement about a dozen thick, which is knitted in cells of 15-20 centimeters, is suitable. If the paths are designed exclusively for pedestrians, then they do not need to be reinforced.

So that the moisture seeping onto the concrete through the paving slabs can penetrate further and not stagnate inside, you need to make special drainage holes. An asbestos pipe is used for this, cut into pieces 15-20 centimeters high. Pieces of asbestos pipe are laid out at a rate of 1 per 1 square meter. m. throughout the territory.

Once the concrete has been poured, they cannot be removed. The height of the asbestos pipe must match the height of the concrete layer. You can make holes in the shape of squares from boards, but after the concrete hardens, all the wood must be removed.

When preparing concrete, grade 150 cement is used. It is poured with a 15-centimeter layer if there is no reinforcement and a 20-centimeter layer if reinforcement is laid. When filling a large area, you need to make a “temperature joint” every 3 meters. It is necessary to prevent cracking of the base in winter.

The seam can be made by pressing the edge side of the board into the concrete. After getting cold, they need to be taken out and the void filled with elastic material. The top of the seam is coated with concrete to align it with the rest of the surface.

After a day, the wooden formwork is removed from the drainage holes. The holes are filled to the top with small crushed stone.

The main malfunctions of a gas generator and their causes.

Gasoline generator engine malfunctions

The gas generator does not start, or starts but stalls. This is a fairly common problem. Several factors influence this: spark, fuel supply, gas distribution mechanism, major mechanical damage (such as a hole in the crankcase or a broken connecting rod). There may be no spark due to a burnt coil, cap or spark plug. It is also possible that the sensor relay or oil sensor may fail (cuts off the spark when the oil level is low), and faulty wiring components are also possible. The fuel supply is disrupted, the fuel system (carburetor, tap, filter, gas tank) is clogged, system elements (carburetor, tap, fuel pump) are faulty. Long downtime of equipment is detrimental to the fuel system. The timing belt is responsible for gas distribution; large gaps and carbon deposits on the valves prevent the engine from working efficiently and sometimes even starting.

The engine is smoking. The main reason is the exhaustion of the piston group; oil from the crankcase enters the combustion chamber (the piston and cylinder are worn out). Too much oil also produces smoke.

The engine is knocking. Production of crankshaft, connecting rod, bearings.

Engine wedge. Also due to oil starvation there is strong production and carbon deposits in the combustion chamber.

Gasoline in the crankcase. Gasoline and oil are leaking from the crankcase. The carburetor is faulty, most likely the needle does not hold. Causes include wear or dirt in the carburetor.

Malfunctions of the electrical part of the gas generator

The gas generator does not produce current. The engine starts normally, but there is no current. The reasons are trivial: the AVR burned out (the generator does not excite), faulty diodes, problems with electrical wiring, problems in the stator or rotor, and also individual modules fail (on some generators). On inverter generators, the main fault is the inverter board.

The gas generator produces current, but the current is too strong or too weak, or the connected devices burn. There are two reasons: the engine does not operate at 3000 rpm (3000 rpm).

220 volts), faulty electronic components (automatic transfer switch, inverter board, capacitors, diodes)

When connecting devices, the engine stalls or does not turn on - again there is a problem with the engine. Something is clogged or not adjusted.

How to fix problems with a vibrator

The main cause of vibrator breakdowns is leakage of the oil seal located on the shaft, causing oil to leak out. If the vibration mechanism is operated without lubrication, the gears wear out, which leads to failure of the entire assembly. Often in such cases, repair is not limited to just replacing them, because associated parts are also destroyed. The vibration unit is disassembled and overhauled.

Other possible reasons that the oscillating unit does not work, and ways to eliminate them, are given in the table below.

| Cause of problems | Remedy |

| The engine runs at low speed | It is necessary to increase the engine speed |

| The drive belt is loose (sagging) | If the degree of wear allows, then give it a stretch, otherwise simply replace the part |

| Belt broke | Installing a new belt for the vibrating plate |

| Engine malfunction | Repairing the drive unit |

In order to identify a problem with the vibrator in time, you should monitor for oil leaks: if it occurs, then you need to immediately replace the seals.