Any activity on a plot of land takes a lot of time and effort. For this reason, gardeners are increasingly using special equipment, such as walk-behind tractors. However, it is impossible to do everything with this unit. Without a special adapter, you will not be able to weed or hill up the ground, or clear the area of snow and construction debris. A cart with a seat for a walk-behind tractor nowadays costs quite a lot of money. However, there is a way out. Today we will talk about how you can make a homemade adapter for a home walk-behind tractor without any special effort.

Purpose and types of adapters

An adapter is a trailer that increases the functionality of small-scale mechanization equipment.

It has a frame and a wheel axle. With its help, a walk-behind tractor is converted into a full-fledged mini tractor that is capable of plowing and planting. In this case, the tillage speed increases from 5 to 8−10 km/h. In addition, the adapter gives the walk-behind tractor stability and the ability to fully use agricultural implements. Almost all adapters have a driver's seat and levers that lift agricultural implements. This mechanism has footrests and a brake pedal that locks the wheels when stopping. All parts are mounted on a durable frame.

A hitch is located in front or behind the adapter, allowing you to connect the entire structure to the walk-behind tractor. In addition, many devices are equipped with an additional coupling mechanism. It is convenient to hang equipment for cultivating the soil on it.

There are two main types of design:

- With movable joint. It is also called a fracture adapter. This is the simplest device and the easiest to make. In it the hitch is located in the front part. But in this case, controlling the walk-behind tractor will be more difficult, since you will have to turn the entire power unit completely.

- With steering gear. Here the joint between the adapter and the walk-behind tractor is rigid, and control is achieved through the built-in steering unit. This design is the most convenient to use, but difficult to manufacture.

In addition, adapters are available with body and without body. The design of the bodywork includes a metal box measuring 130 x 110 x 80 cm, intended for transporting tools and crops. Bodyless ones are the simplest ones; they are needed only for hanging land-cultivating equipment.

Therefore, when making a homemade adapter for a walk-behind tractor, you need to have a good understanding of the goals and objectives of this device, as well as know what materials and spare parts are available. If necessary, you need to collect all the missing parts.

Design and principle of operation

Essentially, the adapter is presented in the form of a trolley that is attached to the walk-behind tractor. After which the structure turns into a mini-tractor. The main details of such a unit:

- a frame to which other constituent elements are attached;

- driver's seat with lift lever;

- 2 wheels;

- clutch device;

- wheel axle.

In this video we will analyze the front adapter:

It is one of the most important elements of the device, since other elements are connected to it. Therefore, it must be made of high-quality and durable materials.

Driver's seat

One of the main advantages of the adapter is a comfortable seat for the operator.

Wheels

There are 2 types of wheels available - metal and rubber. The former are used for heavy types of work in the field. The latter are designed for driving on dirt roads.

Clutch device

The hitch is responsible for connecting the attachments and the mechanical unit itself. This fastening is defined as one of the most important, therefore it is made of high-strength metals - steel or cast iron.

The length of such a device is about 2 meters, width – 80 centimeters.

Depending on the clutch, the following design options can be considered:

- with movable clutch. This device is the lightest. The clutch here is located in the front, but control in this case is more difficult, since it is necessary to deploy the entire power unit;

- with steering. The clutch here is rigid, and control is achieved through a mechanical steering unit. This control is easier to use, but more difficult to produce.

There are different adapters for walk-behind tractors of different performance. For mechanisms with low power - with a short mount, for powerful ones - with a long one.

Preparing for work and reviewing elements

The adapter is, without a doubt, a very important component of the walk-behind tractor, so it must be reliable and convenient. There are several points to pay attention to:

- Coupling mechanism. It must be durable and have the necessary rigidity. Therefore, it is always made of cast iron or steel. The gaps in the connection nodes should be minimal, since this affects the strength of the fixation of the connecting element.

- Material for production. Based on operating experience, it is clear that adapters made from sheet steel are the most reliable. They are assembled using a welding machine. At the same time, the quality of the welds must be ideal. Otherwise, during operation it will be because of them that a breakdown will occur.

- Driver's seat. The seat is made to be comfortable and adjustable in height, because you will have to spend several hours in a row in it while working.

If these conditions are met, production begins. First, make your own drawings of the hitch for the walk-behind tractor or choose suitable ones on the Internet. After all, the more diagrams and drawings you study, the better the result.

Manufacturing a device with a movable joint

This is the simplest device. The adapter itself will be located behind the walk-behind tractor. It is not difficult to make, but the process requires attention and concentration. The service life of the mechanism depends on the quality of work. This adapter is suitable for heavy walk-behind tractors, for example, “Neva”. It has an engine power of over 7 hp. With. and weight from 105 kg. This allows you to pull not only the adapter, but also agricultural implements without slipping.

For manufacturing you will need the following materials and tools:

- electric drill with the necessary set of drills;

- DC welding machine and electrodes;

- grinder with a set of cutting and grinding discs;

- hammer, file, square, various hardware;

- sheet metal with a thickness of at least 5 mm;

- several profile pipes measuring 40 x 50 and 50 x 50 mm;

- round water pipe with thick walls with a diameter of 30−45 mm;

- steel rods with a diameter suitable for a round pipe;

- channel 40 x 50 mm;

- two wheels from a Zhiguli or Oka with bearings and hubs;

- driver's seat.

You can choose any adapter size, but based on the needs of the mini-equipment. The frame itself can be made slightly higher or lower than the axis of the walk-behind tractor. For wheels, the optimal suspension is portal, providing decent ground clearance. It is not necessary to install shock absorbers on the adapter - this complicates the design. The easiest way is to take a seat with built-in elastic elements.

Next, they proceed directly to the manufacture of individual units .

- Hitch. This is a welded mechanism, which is a hinge that operates in two planes. It is then installed into the base of the adapter frame and bolted to it. It consists of two pieces of 40 x 50 pipes welded to each other and a piece of round water pipe. A welded tee is inserted into it. The tee itself consists of a rod and part of the same pipe. This is the most critical unit, so the welds must be perfect.

- Adapter frame. Here you will need a profile pipe and channel. They are welded together, strengthened, and then made into racks for the wheels. Next, the racks are fixed with braces welded to the frame and wheel hubs. Install and secure the wheels.

- Several pieces of pipe are welded to the main frame to install the seat.

- Fix and adjust the seat. It is placed so that when the steering wheel is turned, the operator’s back does not leave the backrest. There is no need to remove the walk-behind tractor controls - this is done when the power plant is located behind the driver.

- Install the finished coupling device.

- Attached to the walk-behind tractor.

A bracket for attachments is made. It is located on the rear cross member of the frame. To do this, add several levers and rods that will change the lifting height of agricultural implements.

Next, the wheel locking mechanism is made. To do this, use a ready-made brake system from any passenger car and fit it to the installed wheel hubs.

Do-it-yourself walk-behind tractor adapter, drawings and dimensions

Below are the drawings and dimensions, as well as the materials required for the manufacture of an adapter for a walk-behind tractor of complex design.

What you will need to make the adapter

— Metal sheets for footrests

- Square metal. Profile

Below is a kinetic diagram that will help ensure the balance of the structure and avoid additional load. The drawing below shows the diagram of a mini tractor made from a Neva walk-behind tractor.

The engine of the power unit (2), driving the front wheels (1), transmits torque through the chain (3) to the reverse gearbox (4), and from it, through the cardan transmission (5) to the rear axle (6), driving rotation of the rear drive wheels (7).

— When making the frame, you must not forget about the arrangement of the bushing and fork to ensure free rotation of the trailer.

— The body of the adapter to the walk-behind tractor is made of steel sheet, and the sides of the body must be at least 30–35 cm high.

— The seat is installed on a beam welded to the main frame using bolts. The distance from the beginning of the frame to the seat should be 80-90 cm.

— Checking the robotic capability of the entire mechanism.

Additional simple adapter drawings

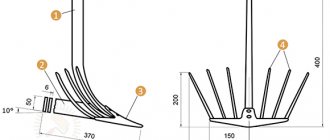

Below is a drawing of one of the simplest adapters in terms of design.

The following are welded to a frame made of square profiled pipe measuring 50*50 mm and thickness 2 mm:

— Footrest in the form of a perpendicularly installed pipe;

— A stand with a seat installed on it;

— Square pipe of the same cross-section for installing wheels;

Drawings of key adapter components

Hitch mechanism

. It looks like a welded structure inserted into the main frame and secured with bolts. It consists of two sections of a square pipe welded onto each other and a section of a regular “water” pipe with a caliber of 1-1.5 inches.

A rod with a welded homemade tee is inserted into the pipe, not fully inserted, clamped with a bolt. The rod is lubricated with grease and ensures that the tee rotates along the axis to ensure a rolling effect when moving on uneven ground.

Wheel mount

. The design consists of two pipe sections welded perpendicularly. The horizontal section is inserted into the mounting pipe and fastened with a bolt. An axle with a wheel is mounted on the vertical part (on bearings).

Other adapter components are not so important, and we will not consider them.

Adapter for walk-behind tractor Neva

Drawings and dimensions for different walk-behind tractors may vary depending on the design. So for popular models of walk-behind tractors Neva, MTZ, OKA, homemade adapters can differ significantly.

By making a homemade adapter for a walk-behind tractor and using various types of attachments with it, you can not only make your work easier, but also significantly increase productivity.

Walk-behind tractor with steering control

With this method, the power unit will be located behind the driver and rigidly attached to the front adapter.

Consequently, the coefficient of adhesion of the driving wheels to the soil will increase. This, in turn, will increase traction force, which will make it possible to work with any attachments. For such experiments, the light Salyut walk-behind tractor, which weighs about 75 kg and has a power of 6.5 liters, is best suited. With. In this case, you will need a steering column with a gearbox. But this is for this case, if you dare to make a walk-behind tractor with front steering. This procedure is much more complex and painstaking than a simple joint, but the result will please you - you will get a walk-behind tractor with a steering wheel and a seat, and all the necessary levers will be at your fingertips.

During manufacturing, you will need not only a steering wheel and gearbox, but also steering rods with coulters . You will definitely need gas, clutch and brake pedals located under your feet. They are connected to standard controls with homemade rods or steel cables.

Design features of front and rear adapters for walk-behind tractors

Many farmers use walk-behind tractors to work in their fields. The adapter for the walk-behind tractor makes it possible to speed up its execution. This unit is used as a trailer that moves on wheels and is attached to a motor cultivator. You can add attachments to the device and mount a chair. Often gardeners make such a unit themselves.

Front adapter for walk-behind tractor with steering control

Auto mechanic, specializes in agricultural equipment.

It is impossible to imagine modern agricultural, household, and garden farming without such units as a walk-behind tractor and a cultivator. Thanks to their mechanical strength, they simplify a person’s life by performing some of his physical functions.

The use of attachments and additional tools increases the number of possible works performed by the walk-behind tractor. One such device is an adapter.

Purpose

An adapter for a walk-behind tractor was created for the convenience of gardening. If you attach a hinge to it, you can expand the scope of application of the device:

- remove hay;

- level the soil surface;

- transport goods;

- harrow the ground;

- clear the area of snow.

An adapter is a device that is designed for movement on a motor cultivator. With it, you can control the unit while sitting in a chair, and at the same time cultivate the soil. The trailer for the Neva motor-cultivator is equipped with a steering control. It makes it easier to use the walk-behind tractor.

You can install different attachments for harvesting, a plow, a mower, etc.

This trailer speeds up work in the field. Using this design, you can increase the speed of the cultivator from 5 to 10 km/h. Let's look at the adapter device. The adapter for the motor cultivator consists of:

- frames;

- operator seats;

- two wheels;

- axles;

- coupling mechanism.

After attaching the adapter, the cultivator looks and is used like a mini-tractor. To create an adapter for a cultivator with front steering, you need a frame. The operator's seat is installed on it. The frame is fixed to the chassis.

The seat is fixed to the frame. This will make it easier for the operator to control the cultivator. The wheel system will help move the unit around the site. There are 2 types of wheels: metal (used in the field) and rubber (used for driving on the road).

The hitch for a walk-behind tractor is made of steel or cast iron by welding. She attaches the cart to the cultivator. The U-shaped fastening system is considered the best. With this design the device will be stable.

- The highest travel speed on a walk-behind tractor with a trailer is 12 km/h.

- Maximum load capacity - 100 kg.

- The track diameter is 67 cm.

- Dimensions are 130x70x71 cm.

- The weight of the device is 22 kg.

- The warranty period is 5 years.

Advantages and disadvantages

After the walk-behind tractor has undergone modernization, the designers note the positive qualities of the front adapter:

- ease of operation;

- disclosure of traction resource - existing abilities increase;

- the possibilities of work are expanded - soil cultivation will speed up;

- if necessary, the unit is disassembled and assembled;

- good balance in weight and axles;

- You can move around on the device.

The disadvantages include the fact that in the presence of a movable coupling, stability deteriorates.

The adapter for the walk-behind tractor consists of the following structural elements:

- The frame is built central or staircase. Suitable materials are metal pipes and corners. The design model must include a fork and bushing that will ensure free rotation of the trailer. There are converted vehicles in which the aggregate device and the trailer are combined. In this option, you should make a new stand for the transmission and engine.

- Suspension systems can be axial, bridge, rotary, portal. It is constructed without the use of elastic fragments.

- A steel sheet is used for the body.

- The hitch is an important element of the converter; it makes the walk-behind tractor stable and securely connected. The coupling unit is made of a 15 cm pin.

- The seat is the driver's workplace.

- The steering is used with a rigid connection. You can build it with your own hands or purchase it in a special store. Craftsmen install steering rods and racks from a VAZ or Volga car.

Types of adapters for walk-behind tractors

The adapter for the walk-behind tractor comes in several types. The design is distinguished by the coupling method:

- Strong connection to the motor cultivator. The device has a separate steering wheel. Steering wheels are located at the front or rear (both options are possible).

- Movable connection. At the same time, the angle between the cultivator and the cart changes all the time. Turning requires a lot of effort due to the fact that the connection point is movable.

The devices are also divided according to the presence of drive wheels into:

- Front. The hitch assembly is located at the rear.

- Rear. The hitch assembly is located at the front.

Trailers are divided into:

In addition to garden work, universal ones are useful for transporting crops.

Trailers are divided according to the size of the drawbar:

Structures with a short drawbar are attached to low-power walk-behind tractors. Trailers with a long drawbar are attached to powerful cultivators.

There are 2 types of trailers: on 1 axle or on 2 axles. These couplings are created by the manufacturer. The factory calculated such a design and mounted a tow bar on it. A spring was installed under the seat, designed to allow the vehicle to move smoothly on rocky surfaces.

The APM has special footrests and a brake that is pressed with the foot to stop the cultivator. Pneumatic tires were mounted on the adapter, which ensure smooth running at high speed.

You can buy the device in a specialty store unassembled in packaging. It's easy to assemble. There are instructions for this. To assemble the device, no additional knowledge or skills are required. Afterwards you need to check how the design works.

If all components work well, you can start operating the device. When purchasing a design, you also need to choose a soft lining for the seat. Then the driver's work will become more convenient. The HorseAM IS 1 adapter for the Magnum walk-behind tractor, and adapters for the PNO-1, AM-3 K, BUM-3, KTZ-03 cultivators are very popular among farmers.

With steering

A high-quality adapter with a steering wheel for a walk-behind tractor makes it easier to control the cultivator. In terms of its functions, such a walk-behind tractor is comparable to a mini-tractor, only it is more economical in fuel consumption. The standard APM unit does not have a steering wheel.

Control is carried out using the cultivator steering wheel. But other manufacturers produce units with steering. The trolley is designed for more convenient work on the cultivator, so the presence of a steering wheel will make control easier.

With movable joint

When a trailer is movably coupled to a motor-cultivator, the angle of the vertical axis between the cart and the cultivator changes. It is easier to make such a device, but when turning it will be necessary to apply more force. This type of trailer is inferior in geometric characteristics: the turning radius becomes larger.

Front and rear adapters

There are several types of trailers depending on which wheels are driving:

- Front-wheel drive. The unit is fixed at the back of the walk-behind tractor. This is the simplest and most popular modification. It makes it possible to easily control the cultivator and perform a large amount of work.

- Rear drive. The unit is located in front of the cultivator. This design makes it possible to perform work when using a hitch located at the rear of the cultivator.

- Four-wheel drive. The trailer can be located either in front or behind the cultivator. This design differs from the previous ones in that not 2 wheels rotate, but all 4 at once. This device performs the functions of a mini-tractor. At the same time, the maneuverability of the structure, its maneuverability increases, and additional traction with the soil is provided. The 4x4 drive is considered the most efficient.

Choosing an adapter for a walk-behind tractor

03.12.2019

Part I

First, the man took a digging stick and began cultivating the land. The stick eventually evolved into a hand shovel and life became easier. The process moved forward and internal combustion engines appeared, followed by self-propelled tractors - walk-behind tractors. With the advent of the walk-behind tractor, life generally became wonderful, but sooner or later, there comes a time when walking behind the walk-behind tractor becomes completely uncomfortable. And today we are seeing a trend in which the consumer wants to work even more comfortably, so to speak, sitting on a chair and operating equipment. The era of walking behind a walk-behind tractor is ending, and a new era is coming - walk-behind tractors with an adapter.

Today we will look at adapter options for various walk-behind tractors; we will consider not only arable adapters, but also riding modules. But first, let's look at the design features of the adapter. Essentially, the adapter consists of a frame, an operator’s seat, a device for connecting to a walk-behind tractor, a lifting mechanism for the coupling device, wheels and a braking system. Each of these elements, when choosing, is fundamentally important. Therefore, manufacturers of these devices, as a rule, indicate the models of walk-behind tractors with which one or another adapter can be mounted. Of course, any self-respecting manufacturer strives to unify the product for the widest possible model range, which is why more and more productive and high-tech units are constantly appearing. In Belarus, for some reason unknown to me, the majority of both walk-behind tractor users and new buyers have no idea that there are adapters that can make their work easier, so we, the promtoblok.by company, will inform you in this article what types there are adapters and which one is most suitable for a particular walk-behind tractor.

Adapter Tselina PM-05

Let's start with, perhaps, the simplest, classic version of the adapter, the main purpose of which is driving performance and the ability to work with passive attachments. We present to your attention the adapter Tselina-PM-05. This adapter has a fairly simple layout: frame, band brakes, operator's seat and lifting mechanism. This adapter is produced on . Can be equipped with wheels 4.00x10 or 19x7.00*8. The design is quite simple, but at the same time reliable and unpretentious in maintenance. The main complaints from buyers are related to weak brakes and a fairly simple floating hitch system. The adapter has a seat adjustment, which will allow the consumer to use heavy attachments, and when lifting, it will not rest against the chair. With the Tselina-PM-05 adapter, you can use both passive and active attachments. However, an active hitch can only be installed in cases where the active hitch is mounted on a drawbar, and it is located in front of the walk-behind tractor. As a rule, these are walk-behind tractors of the MB, Neva, Agat, Oka, Tselina, Avangard and Mobile K series. But walk-behind tractors with a PTO cannot work in tandem with an adapter and an active attachment, since the PTO is located at the rear of the walk-behind tractor, and the coupling device is also there , respectively.

— Tselina-PM-05 is aggregated with walk-behind tractors: OKA, Agat, Avangard, Neva, Mobile K, Tselina

— Attachments for working with the Tselina-PM-05 adapter: plow, perch, double hiller, rippers, weeders, harrow, passive potato planters and potato diggers, potato digger. Active attachments: Zarya rotary mower, snow blower, blade shovel, utility brush.

— For the PM-05 adapter the following are available: axle extensions, wheel weights, lugs.

AM adapters

The adapter for the AM walk-behind tractor is not much different from the previous one, it is made by analogy with Tselina, it has the same properties and characteristics. Can be equipped with wheels 4.00x8, 4.00x10, 5.00x10, 5.00x12. It is aggregated with MB series walk-behind tractors; you can also connect heavy walk-behind tractors: MotorSich, MTZ, Grasshopper. The AM adapter is a little more expensive. But within 400-500 rubles.

Adapter APM 350 PRO

The next adapter is produced at the Gagarin plant in Russia and is called APM-350 PRO. The purpose of this unit is actually the same as that of AM and Tselina. But there is one small feature. This adapter is adjustable in length and height. This was specially designed to be universal when connecting any class of walk-behind tractor. So, all types of walk-behind tractors, from light class to heavy class, can work with the APM-350 PRO. In terms of functionality, this unit is no different from the adapters above; the cost of a complete set exceeds 500 rubles. However, the lack of price is compensated by the ability to work with various walk-behind tractors; we often hear that the consumer has 2 walk-behind tractors, medium and heavy, and with an adapter he wants to work on both.

So the 350 PRO fully provides this opportunity. In addition, since the adapter is produced by the company that produces Mobil K walk-behind tractors, a special attachment was developed for them to work with a rotary mower, unlike classic adapters, when cutting grass, on turns, it is not possible to lift the mower above the field, in this adapter, With the help of this rod, you can move on a walk-behind tractor with an adapter to the mowing area without removing the mower, and lift the mower when turning. But, this option is only possible for Mobile K walk-behind tractors and most likely for AGAT (Salyut 5) walk-behind tractors; we have not yet tested this theory.

Adapter with APM 350 body

The next unique development that the Gagarin plant can boast of is the adapter-riding module-trailer APM-350 with a body. I would like to pay special attention to this adapter. The situation is this: today, when turning to our online store PROmotoblok.by to purchase a walk-behind tractor, most consumers buy a walk-behind tractor immediately with a trailer. The cost of a trailer is about 500-700 rubles, depending on the weight of the cargo being transported. In the classic version it is 260 kg, 500 kg. The fact is that over time, the consumer begins to get tired, moving on foot behind the walk-behind tractor, and he thinks about an adapter. I suggest that every buyer of a walk-behind tractor with a trailer think carefully when purchasing and immediately purchase an adapter with an APM-350 body. The cost of such an adapter will be slightly higher than just a trailer, but significantly lower than buying a trailer and a separate adapter separately. The load capacity of the body is 350 kg, the dimensions of the body are 80 x 100 cm. Additionally, the sides can be increased. APM-350 consists of a frame, a floating attachment, a seat, a body, and is equipped with band brakes. Compatible with MB walk-behind tractors: AGAT, OKA, NEVA, AVANTGARD, Tselina. On the APM-350, in tandem with MB-type belt walk-behind tractors, you can use any passive equipment, as well as active ones. It can also be used with walk-behind tractors that have a PTO: UGRA, MTZ, but with these walk-behind tractors it will be impossible to use an active hitch, only passive tools: a plow, hillers, rippers, potato diggers, etc. The design of this adapter is truly unique; today it is universal for most walk-behind tractors, and also the most favorable in terms of price-functionality-quality.

All-wheel drive adapter AMPK-1 for UGRA walk-behind tractors

All-wheel drive adapter AMPK-1. This is a unique development for the market by PJSC Kadvi, which is aggregated only with UGRA walk-behind tractors. UGRA is a walk-behind tractor with a PTO (power take-off shaft), unlike other walk-behind tractors with a PTO, there are 2 of them on UGRA. Upper and lower (master and slave). The upper one is designed for connecting attachments, and the lower one was designed specifically for connecting to the AMPK-1 adapter. The lower PTO transmits torque to the adapter gearbox and thus we get a unique design of the UGRA all-wheel drive motor tractor. The adapter itself is relatively inexpensive, but the characteristics we get in the end are worth every penny spent on it. Firstly, this is a very high cross-country ability, regardless of the soil; this adapter can be used not only for arable purposes, but also for off-road driving. Consumers of outdoor activities, hunters, foresters, mushroom pickers and fishermen gave particularly high marks.

Having a UGRA walk-behind tractor and an AMPK-1 adapter, you can climb into the most inaccessible corners of nature; traction and all-wheel drive allow you to feel confident off-road. As for use on the site. Any passive attachment can be connected to a floating hitch. Plows, hillers, rippers, weeders, potato digger, potato planter, potato digger, blade shovel, trailer up to 500 kg. The only thing that saddens me is the inability to use a rotary mower, snow blower, brush, or potato digger. In this case, you will have to disconnect the walk-behind tractor from the adapter and work on foot. Many begin to compare the UGRA motor tractor (motoblock + adapter) with a mini tractor, because structurally, it has almost the same functionality. But, on the adapter you can use walk-behind implements, which are several times cheaper than tractor ones; secondly, even the cheapest mini tractor will cost 3 times more. AMPK-1 consists of: frame, operator seat, drive cardan, gearbox, floating coupling system, brake system, wheels.

There are 2 options to choose from: wheels 4.00 x 10 and 19 x 7.00*8. At the moment, Kadvi PJSC ships AMPK-1 adapters only by pre-order, since the demand is so high that we have to wait several months. Our store has a limited batch of AMPK-1 in stock, if possible, we try to get into this queue as quickly as possible so that they are always available in Belarus.

Part II - Rides and Adapters

KV-2 layout module for AGAT (Salyut) walk-behind tractors

We all know such a wonderful brand as AGAT, also known as Salyut 5. At one time, the company produced walk-behind tractors under the Salyut 5 brand, which to this day do not need advertising at all. The walk-behind tractor, originally from the USSR, turned out to be so ideal that legends are beginning to be made about it, and this is understandable: the gear reducer, ideally selected gear ratios in the gearbox, and the low and slightly forward center of gravity allow you to operate the walk-behind tractor with one hand. The highest reliability and product quality have done their job. Later, the AGAT plant began producing Salyut 5 under another brand name - “AGAT”. They did not change anything in the already ideal design, they only diversified the number of imported engines. Therefore, now, Salute 5 is produced under the AGAT brand.

A little later, the company decided to create its own riding adapter. We decided to add a steering gear to the design for user convenience. The name for the unit was chosen KV-2. We present to your attention the KV-2 riding adapter for the Agat walk-behind tractor (Salyut 5). Now, having taken a closer look at this adapter, we drew attention to one of the most important miscalculations of the enterprise. They did not install a floating hitch on their ride unit, which severely limited its functionality. Or rather, it not only limited, but actually destroyed such a wonderful project. We negotiated with the manufacturer for a long time, but in response they threw up their hands, in turn telling us that they were going to design a completely different module, which would take everything into account. We waited until mid-2022, they presented us with a new model of a walk-behind tractor called “Gver”.

There is no point in trying now to find in a search what GVER is, it is virtually impossible. But at my discretion, the company made an even more unsuccessful project. Now I'll tell you why. Instead of modifying the KV-2 and correcting this significant drawback, it was necessary to simply modify the KV-2 and equip it with a floating coupling device (by the way, our company promotoblok.by will be engaged in this development, I hope in the near future we will succeed, in this In this case, we will be able to offer the consumer the most functional and well-thought-out unit at a very affordable price), they didn’t even produce a walk-behind tractor with a module, they released a frame structure into which they simply installed a gearbox and an engine from a walk-behind tractor. They tied all this to the frame, made a front linkage system and a rear linkage system, but did not give a choice of engines, installing only a 6.5 hp Lifan. The plant, of course, has found its buyers and produces Gwer only by pre-order, for a specific consumer, but the whole design raises a lot of questions for me. After all, when we have a walk-behind tractor, we can aggregate active attachments to it; if we connect it with an adapter, we get the opportunity to work while sitting with passive attachments and with some active attachments. If you combine the AGAT walk-behind tractor with the KV-2 module, you simply get the opportunity to move while sitting and drag a cart behind you; unfortunately, that’s all it can do. But with the introduction of a floating attachment system, the situation will change dramatically, then we will get an amazing product that is also suitable for passive attachments, for transporting cargo, and for moving over rough terrain. The guys from Russia came up with a particularly great idea, attaching wheels from VAZ to this tandem, which fit both the walk-behind tractor and the adapter without any modifications. Today, in its factory version, the KV-2 module is suitable for those who do a lot of cargo transportation and also prefer cross-country trips, i.e. in fact, it can be used as a vehicle.

Front adapter "TANDEM" PM-06 "Virgin"

The front adapter “TANDEM” PM-06 “Celina” is a plowing and riding module with a floating hitch at the rear and a body at the front. The steering is organized through a gearbox, i.e. turning is done through the steering wheel. This module is aggregated with MB series walk-behind tractors: OKA, AVANTGARDE, Neva, Tselina and AGAT. The main difference from standard adapters is that this module is front-facing. This means that you get drive to the rear axle, the axle of the walk-behind tractor. When driving on muddy and slippery roads, this of course gives a serious advantage over classic adapters that are connected to the rear of the walk-behind tractor, so we get drive to the front axle.

On the other hand, any advantage brings with it certain disadvantages. The most significant drawback of the PM-06 is connecting the walk-behind tractor using a drawbar, i.e. that part on which active equipment is hung. And if in the case of APM-350, APM-350 PRO, AM and Tselina PM-05 you can connect a mower, snow blower, brush, then in the case of PM-06 “Tselina” it is completely impossible to do this. As a result, we get, conditionally, a motorized tractor and can use it with passive attachments: plows, hillers, rippers, potato diggers, potato planter, potato digger, etc. The front body is quite modest in size, tipper, with a maximum load capacity of 300 kg. Who is this adapter suitable for? Yes, in principle, for everyone, it turned out to be very maneuverable, has sufficient maneuverability, but is slightly inferior in functionality to the classic adapter. Its cost is quite steep, but life with such an adapter will become easier and more fun.

Part III - our plans

Adapters KTZ-02 and KTZ-03

In the near future, we plan to offer you such adapters as KTZ-02 and KTZ-03, which are produced in Russia. These are quite well-thought-out adapters for most walk-behind tractors that have won the hearts of Russian consumers. We hope that our negotiations with the KTZ company will be successful and they will arrive in our store in the spring of 2022. Therefore, buying a KTZ adapter in Belarus will become a reality, not a dream.

Adapter BUM-4

If everything is clear with the light and medium class of walk-behind tractors, a decent number of different adapters and modules are produced for them, but for heavy equipment there is practically nothing on the Belarusian market. Therefore, we drew attention to a very interesting and relevant development from Ukrainian. They are developing a very interesting adapter for heavy walk-behind tractors from MTZ, MotorSich, Grasshopper.

At the same time, they decided not to limit themselves only to a floating coupling device; they are trying, through the driveshaft, to transmit torque from the PTO to the adapter itself. This means that the entire active hitch for heavy walk-behind tractors will be able to work through the PTO of the adapter; in addition, the passive hitch is also available on this adapter. The steering control is organized through a gearbox, and the uniqueness of this design is that the adapter is mounted to the walk-behind tractor at the rear, and the rear wheels rotate from the steering, which gives the highest maneuverability to this large adapter. In fact, if the guys manage to fully implement their project, we will get an adapter that will change the walk-behind tractor in a cardinal sense and in its understanding. Let's take the MTZ walk-behind tractor as an example, prices for them start at 2000 and a kopeck, while there are options for choosing a 9 and 13 hp motor. around 7000+. But, again, if the guys implement this project in full, we will get an adapter from walk-behind tractors within 3,500 rubles, which will be in no way, absolutely in no way inferior in functionality to a mini tractor, and at the same time, the attachments will be mounted on walk-behind tractors, and they are an order of magnitude lower in cost than a tractor. I sincerely and look forward to our partners from Ukraine providing a ready-made version of this adapter in order to bring them to Belarus and provide them to you, our dear customers. I hope by spring 2022 you will be able to buy the BUM-4 adapter in our online store.

How to make an adapter for a walk-behind tractor with your own hands

A gardener or farmer who wants to increase the volume of work can make an adapter for a walk-behind tractor with his own hands. Let's look at how to make a front adapter with a steering wheel yourself. To do this, a frame is made, a lever is welded to it, then a coupling unit is created, after that the trailer rotation mechanism is made, then the braces need to be welded.

In this way, you can make a homemade all-wheel drive trailer for both small and heavy walk-behind tractors. Let's look at step-by-step instructions for making a trailer yourself below.

Scheme and design elements

To make an adapter with your own hands, you must first complete the drawings and diagrams of this device. And using a ready-made diagram indicating all the parts, assemblies, structural elements and their dimensions, it will be easier to start making the unit yourself.

Required materials and tools

Let's consider what is needed to create the device.

Materials and tools:

- Two wheels with an axle. The radius of the wheels should be 15-18 inches. You can take wheels from a car.

- Bearings for wheel and steering systems. Metal profile corner or channel, metal pipe.

- Nuts, screws, washers.

- Lubricant: grease.

- Welding machine, drill with drill bit, wires, disks.

- Bulgarian.

- Screwdriver, wrench, screwdriver.

- Frame for turning the cultivator using the steering wheel.

Drawings and dimensions

First you need to complete the drawing. First of all, the kinetic scheme is calculated. Then they carry out the basic diagram, which shows the dimensions of all parts. All parts, components and fasteners of the structure will be manufactured according to this scheme. Before you start creating the unit, you need to clarify all the data available on the diagram and check their compliance with the indicators of all workpieces.

DIY front adapter for walk-behind tractor

Homemade front adapter with steering for a walk-behind tractor: photo report on making a homemade product.

Dear site visitors, You are Your Own Builder! We present to your attention another homemade product from the craftsman Mikhail, who is engaged in the construction of various homemade mini tractors and other agricultural equipment. technology.

This time we will look at a rather useful homemade product that will undoubtedly be useful to owners of walk-behind tractors - a homemade front adapter with steering control for a walk-behind tractor.

This device greatly facilitates the work of cultivating a vegetable garden, because essentially by installing the adapter on a walk-behind tractor, it will already be a mini tractor with steering control, and working on a mini tractor is much easier than with a walk-behind tractor.

The process of building an adapter for a walk-behind tractor is presented in these detailed photos:

Front axle with homemade steering knuckles.

The homemade frame is welded from a profile pipe.

The base for the seat is welded to the frame.

Steering rack from a VAZ car.

Steering rods are also from a VAZ car.

As a result, the author made a mini tractor from a walk-behind tractor with his own hands.

Owner reviews

On forums, adapter owners express their opinions on the use of this design, its characteristics and how you can make the device yourself. Here are reviews from some owners of this equipment.

Sergey Petrovich, 53 years old, farmer

For several years, when using a walk-behind tractor, I had to constantly walk behind it and hold it by the handle. Our site is located at a great distance from the house. Therefore, on the advice of friends, we purchased an adapter that comes with a steering wheel and a seat. Now it has become convenient to work. Labor productivity has increased. In addition, with the help of the new device it is possible to transport crops over long distances.

Victor, 42 years old, summer resident

Great difficulties were experienced when clearing snow in winter. For this purpose, we used a walk-behind tractor and a snow blower that is mounted on it. My neighbor helped me make drawings and assemble the design of the adapter for the walk-behind tractor. After the device was manufactured, snow removal work became much easier. The trailer turned out to be durable and reliable.

Making an adapter for a walk-behind tractor with your own hands

Any activity on a plot of land takes a lot of time and effort. For this reason, gardeners are increasingly using special equipment, such as walk-behind tractors. However, it is impossible to do everything with this unit. Without a special adapter, you will not be able to weed or hill up the ground, or clear the area of snow and construction debris. A cart with a seat for a walk-behind tractor nowadays costs quite a lot of money. However, there is a way out. Today we will talk about how you can make a homemade adapter for a home walk-behind tractor without any special effort.

Description of the adapter for the walk-behind tractor

The adapter is a special module for moving on a walk-behind tractor. With its help, you will be able to operate the unit in a sitting position and at the same time cultivate the land. For example, the adapter for the MTZ walk-behind tractor has steering control. It is quite possible to do it yourself. One of the sections of the article below is devoted to how this can be done. In the meantime, let's talk about the purpose of this attachment.

Using an adapter can greatly simplify the use of this home appliance. You will have the opportunity to change attachments for hilling or planting potatoes, a flat cutter, a plow and other devices. The adapter also speeds up absolutely any garden work . In other words, if such a device is used in practice, the speed of the workforce will increase from 5 to 10-11 km/h.

Adapter design features

This attachment includes:

- frame;

- driver's seat;

- a pair of wheels;

- wheel axle;

- coupling device.

That is, the adapter gives the impression of a cart that is attached to the main equipment. As a result, it looks like a mini tractor.

Now let's talk about each component in detail.

- To make a front adapter for a walk-behind walk-behind tractor with your own hands, a frame is required. The body or driver's seat is attached to it. The frame is mounted on the chassis.

- For ease of use, a driver's seat is attached to the frame. This is designed to make it pleasant and easy to operate the equipment during gardening work.

- The wheels and axle make it easier for the operator to garden with this small tractor.

- There are two types of wheels for a home tractor - rubber and metal. Metal wheels can be used for reliable work in the fields. Rubber wheels are equipped with a deep tread pattern. This way they can allow the operator to move the unit on unpaved roads and, if necessary, off-road. In any case, the wheels for the adapter are supplied with the purchase as part of the equipment itself. But if the user wants to change them, you need to pay attention to their type and size.

- Device for coupling (fastening) with a walk-behind tractor. The mount for the MTZ unit is made of steel or cast iron, using welding. The hitch is one of the essential components of the units. It provides a reliable connection to the part with the motor of the trailed equipment. The U-shaped attachment point is considered the most commonly used, because thanks to this device the vehicle is more stable.

Algorithm of actions

To begin assembling additional equipment for a motor cultivator, you will need a drawing, in accordance with which the fastening elements and the construction of fragments will be made. If you have special skills and experience, you can make a homemade adapter for a walk-behind tractor and a drawing yourself. If you are afraid of making a mistake, you should take ready-made drawings. Before designing, it is recommended to check and verify the compliance of dimensions and numbers.

Tools and consumables:

- metal corners, square profile;

- bearings for the steering wheel and column;

- metal sheets;

- a pair of wheels, preferably on an axle;

- drills, electrodes, discs for grinders;

- fasteners;

- wrenches of various sizes;

- electric welding machine;

- lubricants – grease;

- Bulgarian;

- screwdriver;

- drill.

At the preparatory stage, it is necessary to select a kinematic diagram that provides indicators of the equilibrium of the entire structure. Overload warning must also be provided. It is recommended to use ready-made drawings of an adapter with a steering wheel to a walk-behind tractor.

Work progress:

- The beginning of work is the manufacture of the frame. The structure is made from cut parts of the selected steel building material. The metal is cut to the required length using a grinder. The fragments are fastened with bolts or welding.

- A 1.8 m piece of square metal profiled product is welded to a metal profile 60 cm long. The elements are placed perpendicularly. This fragment will serve as a mount for tires. The wheel stand must be at least thirty centimeters high.

- The spacers are welded to the main frame and wheel bushings. The size of the frame is 40x40 cm, it can vary depending on the individual project.

- A profile is welded to the edge of the frame. The axial pipes are bolted together.

- The control lever is welded to the frame. To increase power performance during control, the lever is constructed with one or more elbows with a length of 70-80 centimeters. The knee fragments are fastened with bolts. It is recommended to check the dimensions of the adapter for the walk-behind tractor with the drawings and diagrams, because they will help you create an error-free design with your own hands.

- A pipe 30-40 cm long serves as a stand under the seat; it is welded to the main frame. With a driver's seat, the equipment is easier to control during gardening.

- The coupling part of the mechanism is welded to the walk-behind tractor at the rear. The fastening is made of steel or cast iron material. An electric welding machine is used to connect spare parts. The fastener is an important component that ensures reliable coupling. The most suitable is a U-shaped connecting node. Thanks to this spare part, transport becomes sustainable.

- There are two types of wheels suitable for the walk-behind tractor adapter - rubber or metal. The latter option is used for work in the field. The rubber wheel has a deep tread, which will allow you to move on unpaved roads and, if necessary, drive off-road. Wheel radius fits 15 to 18 inches. Suitable wheels are from the domestic automobile industry - VAZ, Moskvich.

- I treat the resulting device with a primer and paint it. This technique will prevent metal corrosion.

Video review of the front adapter

Making the front adapter - video

Instructions for making the adapter

Now we’ll tell you how to make a front adapter with steering for your small tractor yourself.

To produce an adapter for a walk-behind walk-behind tractor, you will need the following materials:

- Two identical wheels on an axle. The radius of the wheels ranges from 15 to 18 inches. Even wheels from an old Soviet Volga might work.

- Bearings for steering wheels and columns.

- Steel for the frame (channel, pipe or angle).

- Fastening elements (washers, bolts, nuts).

- Lubricants (litol or grease).

- Consumables (drills, electrodes, discs for grinders).

- Set of wrenches.

- Bulgarian.

- Welding machine.

- Drill.

Working on a walk-behind tractor with steering control

Let's say a few words about the control features of a walk-behind tractor with a steering wheel, and why it is recommended to use this option during assembly. It’s not for nothing that this type of conventional and home-made machines is so popular, because it has a lot of advantages:

- the operator will not have to waste his energy walking behind the mini tractor;

- the traction potential of the equipment is realized one hundred percent;

- such a mini tractor is more maneuverable and functional;

- Now, in order to cultivate a plot far from home, you will not have to additionally transport a walk-behind tractor - you can simply drive it, like a regular car or tractor;

- control is more lightweight and convenient than other types;

- Now you don’t need to hold the entire mass of this heavy and bulky device in your hands,

- it becomes possible to quickly assemble and disassemble the unit;

- control parts are not significantly modified during rework;

- good balance in weight along the axes.

We will not mention here the noise of operation and other characteristic features of, in principle, all tractors . Let's just talk about one characteristic drawback - not very reliable stability, which is associated with a movable coupling. However, the advantages are, of course, more impressive.

Drawings of an adapter for a walk-behind tractor with steering control

Adapters for walk-behind tractors are divided depending on the method of their attachment.

The following types of devices are distinguished:

- Rear adapter for walk-behind tractor. The hitch is located at the front of the device, so after connection the adapter will be located at the rear of the unit;

- Front adapter for walk-behind tractor. Accordingly, traction occurs from the rear. The adapter is located in front of the motorcycle and will definitely have a steering wheel for control. Devices with steering control have a more complex design type, and therefore their price on the market is much higher.

Depending on the area of use, the following adapters are available:

- Shortened . Small in size, which can be used with a light walk-behind tractor. The low weight allows the adapter to be attached directly to the wheel of the unit;

- Elongated. Copes with heavy-duty agricultural machinery. They are distinguished by their significant dimensions and relatively large mass.

Depending on the presence of the body, the following designs are distinguished:

- Bodywork. The existing body allows you to transport various cargo over long distances. They are actively used for everyday tasks and harvesting;

- Bodyless. They are used only for connecting to a walk-behind tractor.

When choosing an adapter, you need to pay attention to the design features of the device. It must fully meet the needs of the owner.

Types of adapters for walk-behind tractors

There are several types of adapters for mini tractors, including homemade ones.

- With lifting lever. The presented type of suspended equipment will simplify control and movement around the site.

- For transporting goods. They are equipped with special bodies that can withstand maximum loads.

- With long or short drawbar. The short type is for a lightweight type, the long type is for a heavy mechanism.

- With telescopic drawbar. This design allows for width adjustment.

This technique is also divided by type of design:

Adapter with steering

The presented type assumes rigid fixation on the walk-behind tractor. The steering gear is carried out in the format of a separate independent unit. In addition, a pair of wheels, which acts as a steering gear, is installed both at the front and at the rear. Each of them is tailored to personal preferences. The position of the steering gear is also related to spare parts, daily use. Operating a “home” mini-tractor with a homemade adapter is no more difficult than, for example, an ATV.

Adapter with movable hitch

Involves a movable connection of the trailer to the walk-behind tractor.

This system is more difficult to control, but making such a module with your own hands is much easier. Requires more effort when turning. The module can be mounted either rear or front. Even the primitive structure of a walk-behind tractor involves load distribution. Therefore, it is recommended to place the seat in the module near the drive axle. Under the weight of the operator, the wheels of the walk-behind tractor will be pressed to the ground, which prevents slipping during movement. There is nothing complicated in designing an adapter and working with a mini tractor. This is available to anyone who has set out to get a home tractor on their plot, which will make a person’s work easier every day. So try to design, build and create - and cultivate the land with pleasure.

vote

Article rating

Types of adapters

Depending on the attachment to the device, walk-behind tractors can be:

- rear - the hitch is located in the front part, and therefore the adapter itself is in the rear part;

- in the front - the hitch - in the rear, respectively, it is located in front of the unit, but with a steering wheel.

By area of use:

- shortened – small in size. Used with units designed to perform light work;

- elongated – large and heavy, used with heavy-duty walk-behind tractors.

Depending on the selected walk-behind tractor, you can choose an adapter that suits it.

Depending on the body:

- bodywork – there is a body available for transporting cargo of different sizes;

- bodyless - used exclusively for coupling with a walk-behind tractor.

In addition to the above classification, they can also be divided into simple and universal. The latter are used, in addition to their direct purpose, for transporting goods.

With steering

The steering adapter makes it possible to turn an ordinary walk-behind tractor into a real mini-tractor. The engine power will remain unchanged, but the number of functions performed will increase significantly.

Fastening occurs thanks to the hitch, which is placed in front of the adapter.

The design includes the following elements:

- a pair of wheels;

- clutch mechanism;

- brake and gas;

- operator seat;

- frame.

At the back there is a mechanism to which, if necessary, attachments can be attached.

With movable joint

Such units are also called adapter-fracture. This is the easiest and most economical device to manufacture. The movable clutch is located in the front part. The disadvantage is that you have to turn the entire mechanism without using additional controls. Because of this, the radius and rotation angle will be larger.

Front and rear adapters

The front adapter is similar in design to the steering adapter. However, the clutch mechanism is located at the rear. This type of design is very convenient, as it can be disassembled and easily transported.

In the rear, the arrangement is the opposite of the front - the hitch is in front of the unit, respectively, the adapter itself is at the rear.

The front one is most often used in those jobs where the power of the unit plays a key role, namely digging and loosening.

Attention! The rear one is perfect for hilling, since the operator must closely monitor the process.