Cast iron is an alloy of iron containing carbon. Its composition may also include manganese, phosphorus, silicon, sulfur and other components. Initially, the materials for the production of cast iron are iron ores, fuel materials, and fluxes. As a rule, iron ores containing from 30 to 70% iron and other chemicals in waste rock, as well as harmful sulfur- and phosphorus-containing compounds, are used as raw materials for the production of cast iron. The fuel material for the production of cast iron is coke, which is the result of dry, that is, without the participation of air, processing of stone coke. The fluxes used, most often quartz, dolomite, sandstones and limestones, make it possible to reduce the melting temperature of waste rock, and also bring it, along with ash, from fuel to slag.

Blast furnace production of cast iron

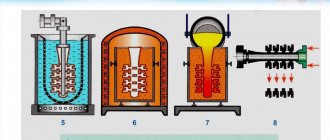

The blast furnace process is most widely used in the production of cast iron. It includes a number of physical, physicochemical, as well as mechanical manifestations observed in an operating blast furnace. The initial components placed in this furnace (coke, iron-containing materials with fluxes) during all operations are converted into an alloy of cast iron, releasing blast furnace gases with slag. The task of blast furnace production of pig iron is to create this alloy from iron-containing components by melting them in blast furnaces at very high temperatures.

Therefore, the blast furnace shop is one of the most important in the structure of an iron production plant. In addition, the production of cast iron in a blast furnace is the basis for the production of steel and rolled products - the final products of the metallurgical cycle of other enterprises. Some cast iron is a commercial product, supplied in solid form in the form of small ingots (ingots). They are produced on casting machines installed away from the blast furnace shop in a special casting department. The other part of the cast iron is used for steel production. The gas obtained during the iron production process is used in open-hearth and coke production in metallurgy. It serves as the main fuel for heating devices in rolling shops and blast furnace heaters.

Cast iron is smelted in furnaces, where iron-containing components with fluxes and fuel are placed, alternating in layers. From the influence of their mass, they descend to the bottom of the furnace, where heated air is supplied through special openings under a certain pressure. It maintains the required combustion conditions for the loaded coke. The technological process of cast iron production involves the recovery of iron, as well as other elements from their oxides. During the reduction process, oxygen is removed from the oxides and components or oxides with less oxygen content are obtained from them.

One of the leading methods for producing cast iron is the reduction of iron from the action of carbon monoxide. It is formed from the combustion of natural gas in a furnace. It is also worth noting that the reduction of iron, provided for by the technology of cast iron production for these furnaces, is carried out gradually, in the process of step-by-step extraction of oxygen from the oxides. The blast furnace process assumes that both carbon oxides and solid carbon itself are involved in the process of iron reduction.

A certain amount of iron is also reduced with hydrogen. In the iron production scheme, the reduction of iron from the action of hydrogen or carbon monoxide is considered indirect (that is, indirect), and the reduction with solid carbon is called direct. In fact, the reduction of iron in this case is carried out in two stages. By the time the iron ore composition reaches the decomposition zone of the blast furnace, where the temperature is about 1000°C or more, the iron oxides have time to partially be reduced indirectly in the zone where lower temperatures operate. As a result of their direct decomposition by carbon, complete reduction of iron is obtained.

Evaporation of charge moisture

The charge loaded into a blast furnace contains hygroscopic and sometimes hydrate moisture. Hygroscopic moisture easily evaporates and is removed at the top, since the temperature of the top gases is higher than the temperature of moisture evaporation.

H2Ozh → H2Sap.

Hydrate moisture is removed at temperatures above 400 °C, and the released water vapor interacts with carbon monoxide or carbon, enriching the gas stream with hydrogen.

H2Opar + CO = CO2 + H2,

H2Opar + C = CO + H2.

Production of high-strength cast iron

In the production of high-strength cast iron, a large place is given to the carburization of iron. Cast iron with these characteristics is formed when iron reduced in a blast furnace from ore material takes in a lot of carbon and other elements. The beginning of the process of carburization of iron is characterized by its formation in a spongy state in the furnace section where temperatures reach 500°C. The newly reduced iron acts as a catalyst to help break down carbon monoxide into two components: carbon dioxide and black carbon. As a result of the decomposition of carbon monoxide at a temperature of 550-650°C, carbides of iron and other metals are obtained. Endowed with special activity, black carbon actively enters into chemical interaction with iron particles.

At temperatures of 1000°C or more, iron carbide decomposes into iron and carbon. As the amount of carbon increases, the temperature during the melting process becomes significantly lower. Thus, pure iron melts at a temperature of 1539°C, and its alloy with carbon can melt from 1147°C. Melting of the alloy occurs in areas of blast furnaces where high temperatures operate, that is, at the bottom of the mine. The resulting liquid alloy is cast iron. As it flows down, washing the hot parts of the coke, it becomes even more carbonized.

Carburization of the metal is completed below the level of the slag tap hole - in the metal receptacle. Here the ratio of carbon to metal is influenced by the content of other components. The final carbon content in the production of gray cast iron, for example, may depend on the resistance of the carbides, which is largely determined by the impurities contained in the cast iron. For example, an admixture of manganese promotes carburization of the metal, since it is part of the carbide that dissolves in cast iron. Vanadium, chromium, and titanium have a similar effect. Silicon with phosphorus or sulfur prevents the formation of carbides. Because of this, ferromanganese and mirror cast irons always contain more carbon than pig irons, ferrosilicon or foundry cast irons.

During melting, not only the iron itself is restored, but also a number of different elements that were in the ore mass. As part of the charge materials in the furnace, in addition to iron oxides, oxides and individual chemical elements such as manganese, chromium, vanadium, titanium, lead, copper, zinc, arsenic, etc. are also supplied. They are in fully or partially reduced form along with sulfur particles get into cast iron and affect its properties for the worse or for the better. In the basics of cast iron production, it is believed that most often silicon and manganese serve as valuable impurities, and sulfur and phosphorus serve as harmful impurities.

The presence of sulfur components in cast iron can be reduced to the optimum limit by off-furnace desulfurization. If you keep cast iron with 2% manganese in a cast iron ladle or mixer, then a certain amount of sulfur in its various compounds with manganese will pass from the metal composition into slag. This is possible due to a decrease in the solubility of this compound in metals due to a decrease in temperature. Such desulfurization in a cast iron ladle can reach 60%. In addition, there are also methods for out-of-furnace desulfurization of cast iron. In cast iron production around the world, desulfurizing additives such as lime, soda ash or magnesium metal are often used for these purposes.

Registration of a license

The domestic policy of the Russian Federation provides a favorable climate for the development of metallurgical enterprises. All that remains is to competently approach the issue of production and business organization.

The first step is to determine in what form the enterprise will be registered. An individual entrepreneur is absolutely not suitable, since he will have to work with large suppliers of raw materials and wholesale buyers of products. The choice of the form of a legal entity depends on the number of founders and attracted investments. It is allowed to open an LLC, partnership, or JSC. In each case, the management strategy, the size of the management company and the documents for registration are different.

To work in the metallurgical industry you will need a license. Permission is issued for ferrous and non-ferrous metals. There are licensing authorities in the regions, where you should apply with a package of documents. To obtain a license, the business plan includes from 60 thousand rubles. The document is issued after 45 days. The license is valid for an unlimited period. Thanks to such a document, you can legally collect, accept, transport, process and sell metal.

The license is issued on the basis of the following documents:

- statements;

- confirmation of the right to use the territory, premises, office;

- equipment passports;

- decisions on the appointment of the general director;

- diplomas of employees and management;

- Unified State Register of Legal Entities, INN, OGRN certificates;

- constituent agreement and articles of association;

- receipt for paid duty.

The document is issued if the production meets licensing requirements. These requirements include the qualifications of personnel, compliance of the premises with established standards, and the availability of specific equipment. The cost of a license is about 1300 rubles.

Features of the cast iron production process

During the melting process, molten slag flows into the furnace with the general mixture. Due to its density, which is less than that of cast iron, it floats on top of it. This phenomenon is observed in the area of the furnace steam. The original slag is obtained from the fusion of ores found in waste rocks, as well as oxide fluxes. When flowing down, during the process of accumulation, the slag changes significantly in composition. Thanks to reactions with the components of incompletely burnt coke and molten cast iron, manganese and iron are reduced from their oxides, and in addition, sulfur compounds, ash and coke are dissolved.

The uniform operation of blast furnaces and the high-quality production of cast iron castings with its type depend on such slag properties as fusibility, viscosity, fluidity, melting point, and sulfur absorption capacity. These qualities of the slag are dictated by its chemical content and the mineralogical properties of the initial charge components. The chemical content of the slag determines the final composition of the cast iron, which explains the fact that for the production of various cast irons (foundry, pig iron, etc.), slag with certain properties is usually selected. The molten slag and the resulting cast iron are alternately released into special holes - slag and cast iron tapholes, first the slag, then the cast iron.

Personnel issues and search for premises

Structurally, production at a factory or plant consists of several main premises and workshops. You will need a factory laboratory, a quality control department, a rolling and foundry shop, mine preparation and slag removal services, steel production itself, a blast furnace shop and a blower.

Additionally, service units are needed - gas service, repair department, transport and communications department, power plant, compressor room, etc.

In addition to the above, production requires a medical service, design and planning departments responsible for sales, reporting, labor protection and fire safety.

The staff is staffed taking into account the activities and scale of production. According to the laws, if a manufacturing enterprise employs up to 100 workers, it is classified as small. The staff is recruited with the utmost responsibility. The requirements for the quality and volume of products will be high, so the employees must be qualified. Good specialists need not only to be found, but also to be motivated for long-term mutually beneficial cooperation. The average salary of an employee in this area is about 25 thousand rubles per month.

Working conditions must comply with standards. Workers are exposed to elevated temperatures, which is harmful to the respiratory and cardiovascular systems. Production is hazardous, so everything possible must be done to ensure appropriate working conditions in the premises (hoods, hygiene, safety precautions, etc.).

Hydrous iron oxide

Hydrous iron oxide is usually represented in ores by the minerals limonite or goethite. Ores containing these minerals are called brown iron ores (general formula Fe2 O3 ⋅ nH2 O). Brown iron ore is formed by the oxidation of other types of iron ores. It is most abundant in the earth's crust, but is used in relatively small quantities because it is difficult to enrich. Mined ores usually contain 25 - 50% Fe and an increased amount of phosphorus (0.5 - 1.5% P). The composition of ore can be varied not only in different deposits, but also within the same deposit.

Brown iron ores are the most easily reduced ores due to their low density and high porosity. In most cases, ores are contaminated with harmful impurities - phosphorus, sulfur, arsenic. The waste rock is clayey, sometimes siliceous-clayey.

Iron ores

Iron ores are rocks from which, at a given level of technological development, it is economically feasible to extract iron.

The upper zone of the earth's crust, about 16 km thick, contains on average 4.9% Fe, which is part of more than 350 rock minerals. Such widespread rocks as granite and basalt contain 3–9% Fe. However, currently such iron-poor rocks are not yet used. Iron is not found in the earth's crust in its pure form, but is usually found in compounds with oxygen, since it has a relatively high affinity for oxygen. In nature, in most cases, iron occurs in the form of:

- magnetic iron oxide Fe3 O4 (magnetic iron ore or magnetite);

- anhydrous iron oxide Fe2 O3 (red iron ore or hematite);

- hydrous iron oxide Fe2 O3 ⋅ nH2 O (brown iron ore or goethite);

- compounds of iron with carbon dioxide FeСO3.

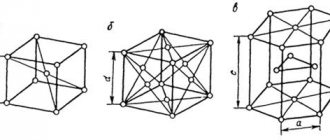

Magnetic iron oxide

Magnetic iron oxide in ores is represented by the mineral magnetite. Ore containing mainly magnetite is called magnetic iron ore. Magnetite can be considered as iron oxide FeO ⋅ Fe2 O3. Under the influence of atmospheric moisture and oxygen, ferric oxide in the FeO ⋅ Fe2 O3 molecule reacts with atmospheric oxygen, turning into anhydrous iron oxide Fe2 O3.

The resulting mineral is hematite in composition, but has a different crystal lattice and is called martite. Therefore, magnetite under natural conditions is always oxidized. To characterize the oxidation of magnetite, it is customary to use the ratio Fetotal / FeFeO. In pure magnetite this ratio is 3.0. Usually, ores in which this ratio is less than 3.5 are classified as magnetic iron ores. With a ratio of 3.5 - 7.0, the ores are classified as semi-martites, and with a ratio greater than 7 - as martites.

Magnetic iron ore is usually found in the form of strong lump ores. It contains: 55 – 60% Fe, 0.02 – 2.5% S, 0.02 – 0.7% P and usually acidic gangue (SiO2, Al2 O3). Magnetite is characterized by high magnetic susceptibility, and therefore magnetic iron ores can be enriched using the electromagnetic method.