0

Sheets and plates of thermoplastics are most often produced by calendering - rolling on multi-roll rolling machines. Corrugated sheets for honeycomb plastics are also produced by rolling on profile rolls. Shaped products from sheets are produced by pressing in dies using a rigid or elastic punch (an air-filled rubber bag).

The method of pneumatic and vacuum molding is widely used. In pneumatic forming, a sheet blank, heated to a plastic state, is clamped around the perimeter of the matrix, after which the blank is deposited onto the matrix using compressed air pressure. During vacuum forming, a vacuum is created inside the matrix, as a result of which the workpiece is drawn into the matrix, fitting its surface. This method is used to produce shaped lids, open tanks, fairings and other thin-walled products.

Pressing

Pressing is used for the manufacture of shaped products from thermosets and curable thermoplastics. The starting material is tablets, granules, crumbs; for products with powder fillers - press powders. The process is carried out in molds consisting of a matrix and a punch. Molding is carried out at elevated temperatures (the molds are heated), which ensures the hardening of the material.

A measured amount of preheated press material is poured into the matrix, after which a mechanical or hydraulic force is applied to the punch and the product is subjected to short-term holding in the mold under constant pressure, resulting in the material hardening. Then the punch is retracted; and the hardened product is removed from the matrix by ejectors.

Molding modes (preheating temperature, pressing temperature and pressure, holding time) depend on the formulation of the pressing material, the size and configuration of the product and are selected experimentally. Typically, the preheating temperature is 130–180°C, the pressing temperature is 200–220°C, the pressing pressure is 10–30 MPa, and the holding time is 15–30 s.

Currently, fully automated multi-position rotary pressing units with automatic high-frequency heating are used, the productivity of which is 100 pressings per minute and above.

The accuracy of the dimensions of the part depends on the accuracy of the manufacture of the matrix and punch, the accuracy of dosing the press material and on compliance with the pressing conditions.

The surface quality of the parts is high. With proper finishing of the forming surfaces of the matrix and punch (chrome plating, polishing), it is possible to obtain a surface with a roughness of Ra = 0.080–0.160 μm.

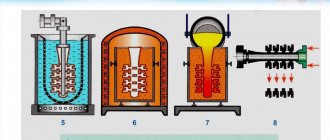

Injection molding

Injection molding is used to mold thermoplastics. The starting material (granules, tablets) is heated until completely softened. The casting mass of a fluid consistency is fed into a heated cylinder, from where it is extruded by a piston through the gating channels into cooled metal molds. Once cooled and solidified, the mold is opened and the castings are removed using ejectors. The sprues and burrs formed in the mold parting cavity are cut off and cleaned. The softening temperature of the casting mass depends on its composition. Pressure 100-150 MPa. Mold temperature 20-40°C.

Injection molding is more productive and produces higher, more consistent product quality than pressing. It is possible to obtain a surface with a roughness of Ra = 0.02–0.04 µm.

Modern injection molding machines with multi-position molds and a fully automated workflow have a capacity of up to 200 castings per minute.

To eliminate internal stresses and increase the homogeneity of the structure, the castings are subjected to normalization: heating without access of air (usually in mineral oil) at 140-160°C for 1.5-2 hours, followed by slow cooling.

How to start production: step-by-step instructions

To implement a project, draw up a competent guide to action.

Include the following sections in your business plan:

- analysis and summary of ideas;

- registration and paperwork;

- production plan; financial plan; sales channels; marketing and advertising.

Let's look at the basic points of the plan in more detail.

Analytics

Conduct an analysis before starting a project. Explore the domestic market in the region. Find out how in demand plastic goods are in your city, and if there are analogue enterprises. If there are competing factories, evaluate the real business prospects and develop your own concept. Think over your competitive advantages - this will help you take your place in the market. Study the cost of equipment and assess your financial capabilities. At this stage, it is easy to abandon the project if data analysis shows high business risks.

Registration

If the business concept does not involve large-scale production, register as an individual entrepreneur. The period during which the certificate will be issued is only three working days. The fee is 800 rubles, you can register an individual entrepreneur online for free. Accounting reporting - to a minimum.

Required documents:

- statement;

- TIN code;

- passport;

- duty payment receipt.

After registration, you need to open a bank account.

If the business is aimed at further expansion, modernization of production and entering the market outside the region, it is better to immediately register an LLC.

Advantages:

- you can have co-founders;

- work with legal entities;

- receive a tax refund.

The package of documents stated above will require the charter of the organization. The state duty is 4,000 rubles.

The next step is tax registration. Contact the branch at your place of registration and submit the appropriate application. Specify the tax form. Choose the simplified tax system at a rate of 6% of income or 15% of the difference between investments and profit.

The following are available as OKVED activity codes:

22.29 - production of plastic products; 32.40 - production of children's products made of plastic.

Please note! When working with polymers, the material releases toxic substances.

To avoid harm to the environment, comply with sanitary, environmental and fire requirements. Violation of them is subject to large fines, including the closure of production.

All goods must have certificates of compliance with GOST requirements, especially when it comes to toys and plastic utensils.

Extrusion

Extrusion molding is used for the production of rods, pipes, hoses, plates, films, and shaped profiles (handrails, baseboards, etc.) from thermoplastics. The process is carried out on continuous screw presses (extruders). The casting mass is fed through the loading hopper into a heated screw cylinder, picked up by the turns of the screw (which in turn is heated) and moves along the cylinder, undergoing mixing and compaction. Compaction of the mass is achieved by reducing the pitch or height of the auger turns. A die with a hole corresponding to the cross-sectional shape of the product is installed at the outlet end of the cylinder. The molded product, emerging as a continuous strand from the die, is cooled. After hardening, it is cut into pieces of the required length.

Recently, heat resulting from friction of the mass against the cylinder walls and screw turns (“adiabatic extrusion”) has been used to heat the casting mass. This method simplifies the design of the press and increases the efficiency of the process.

The extrusion method is widely used for applying insulating sheaths to conductors, cables, etc. The conductors to be coated are fed from the coil through the central hole in the screw and are enveloped in the molding mass in the die.

To produce films, an angular head is installed at the output end of the press. The workpiece leaves the die in the form of a thin-walled pipe, is rotated at an angle of 90°, inflated with compressed air until the walls of the required thickness are obtained, and enters a wedge-shaped gap between two endless belts, where it is flattened. The resulting double tape is fed by exhaust rollers for cutting.

From pipes obtained by extrusion, hollow products (flasks, bottles, flasks, etc.) are made (by blowing in molds). The bottom of the products is welded.

Molding of fiberglass plastics

Small-sized fiberglass products are produced by hot pressing in metal molds. This method is not applicable for the manufacture of large-sized products, since it requires powerful pressing equipment and the production of expensive and bulky molds.

Large-sized shell structures are most often made by spraying plastic into a viscous-flowing state along with glass fiber onto the model. Plastic and chopped fiber are fed in the required proportion into the sprayer. The stream emerging from the sprayer is applied to the model until a layer of the required thickness is formed.

Positive models, which reproduce the internal contour of the product, are used in cases where it is necessary to obtain a smooth and precise internal surface. Negative models, which reproduce the outer contour of the product, are used to obtain a clean and accurate outer surface.

When making products from cold-curing plastics, models are made from wood, gypsum, cement, and also from thermosetting plastics. During hot curing, metal heated models are used. The surface of the layer applied to the model is compacted by rolling with rollers or crimping with compressed air through an elastic cover made of heat-resistant rubber or elastic silicone plastic. After curing, the surface of the product is cleaned, primed and coated with finishing synthetic varnish.

The dimensional accuracy of products produced by the spraying method is low. For large parts, the difference in size can reach several millimeters. The strength of such products is inferior to the strength of products pressed under high pressure.

To manufacture hollow parts in the shape of bodies of rotation (pipes, cones, etc.), the method of winding continuous strands of glass fiber impregnated with synthetic on a rotating mandrel is used. The spinner feeder is mounted on a support that performs a reciprocating movement relative to the mandrel. Winding is usually done crosswise in several layers. The wound layers are compacted with rollers.

When producing high-strength boards with oriented fiber, winding is done on a large-diameter drum, the still unhardened winding is cut along the generatrix, straightened and pressed in flat or shaped dies.

Equipment for the production of plastic products

Standard set of equipment for opening a workshop for the production of plastic goods:

- melting unit;

- device for loading and feeding polymer sheets;

- pressing molds;

- refrigeration equipment;

- bending apparatus;

- stripping unit;

- gluing machine;

- line for painting and drawing;

- line for packaging finished products.

Additionally, you can purchase a 3D printer. The device has a high printing speed and allows you to realize almost any idea. It's easy to work with. The only drawback of the printer is low performance. For large-scale production the thing is useless, but for individual orders it’s just right.

You can choose between domestic or foreign equipment. Start from your financial capabilities. Machines from Europe will last much longer, but will also cost 2-3 times more. By the way, among Russian manufacturers you can also find high-quality lines for processing plastic. But it is better to refuse Chinese automatic lines - they often break down and are expensive to repair.

Welding of plastics

Thermoplastics of all types lend themselves well to welding. Highly elastic plastics (polyolefins, polyamides, polymethyl methacrylates) are welded by resistance welding without the use of filler material. Thin sheets and films are overlap welded by passing the films between rollers heated by electric current. Plates, bars and other similar products are butt welded. The surfaces to be welded are compressed under a pressure of 0.1-0.3 MPa; the joint is heated with high frequency currents or ultrasound. The strength of the welded joint is close to the strength of the material itself.

Plastics with less plasticity (vinyl plastics, fluoroplastic) are welded using a filler rod made from the same material as the parts being welded, but with the addition of a plasticizer. The edges to be joined are cut to form a weld pool. Welding is performed with a jet of hot air. The strength of the weld is 70-80% of the strength of the material itself.

Methods for welding thermosetting and hardening plastics, as well as fiberglass, have also been developed.

Plastics are well bonded using adhesives, which are a solution of a given polymer in an appropriate solvent. Some adhesives (polyvinyl acetate, phenol-neoprene, based on modified epoxides, etc.) have wide versatility in relation to the materials being glued. These adhesives can be used to bond plastics to metal, glass, ceramics, etc.

Manufacturing of plastic products - types of products

The scope of use of plastic as a material has virtually no restrictions. This is an additional argument in favor of business.

Potential clients of the production plant:

- plastic goods are:

- agricultural industry;

- medical institutions;

- construction companies;

- automobile enterprises.

The most popular types of products:

- packages;

- disposable tableware;

- bottles and other containers for drinks, household chemicals, hygiene products;

- buckets, basins, water tanks;

- containers for food and household items;

- children's assortment - toys, dishes;

- spare parts for cars;

- linoleum;

- construction fasteners;

- equipment for playgrounds, leisure and entertainment centers, schools and kindergartens.