The development of technological progress has led to the emergence of various technologies that make it possible to produce products with improved performance characteristics. One of the most popular processes at the moment is extrusion. It represents the technological process of processing plastics, from which various parts are made, and also various profile products are produced.

The technology itself consists of preparing an alloy from polymer materials and then pressing it through special nozzles that give it a certain shape. The main element of the line for the production of plastic products is the extruder.

What is an extruder?

An extruder is a special device (machine) for the production of long products from flexible or granular materials using the extrusion principle. Extrusion is a technological process of continuously extruding molten or paste-like material through a molding tool to continuously produce products of a specific shape and size.

The extruder is combined with other equipment to form an extrusion line for a complete, continuous process.

Important! The main advantage of extruders is the ability to obtain a continuous product along the length and then cut it into pieces of the required size.

The machine has high productivity and provides precise shaping. The width and thickness of the product can be changed using an adjustment system. Maintenance is easy and the operator does not need to exert any physical effort to operate the machine.

Why should you order from us?

Customers purchasing our equipment from our organization will appreciate all the positive aspects of the order:

- Provide full order support.

- Training your staff to ensure maximum efficiency on our lines.

- Warranty and post-warranty service.

- An individual approach to the selection of equipment to solve the problems of each individual client.

- Assistance in developing recipes.

- Work with our staff of technicians and adjusters with over 15 years of experience.

Our organization has extensive experience in independently producing products. This means that cooperation with us, in addition to the favorable cost, gives you the opportunity to select the equipment that best suits your purposes.

Operating principle of extruders

The loader loads raw materials into the machine's hopper. This can also be done manually. The granules are poured into the hopper. They are pushed out of the hopper into the auger area and from there into the laminator. Along the way, the raw materials are mixed to achieve homogeneity of the future melt and are exposed to high temperature and pressure of the extruder components. The outlet is a transparent viscous mass that swells when stretched and melted.

If the extruder is a disk type, two disks are used as the transport device, one fixed and the other with constant rotation. The raw materials entering the hole of the static disk are mixed and homogenized. Equipment equipped with this device is ideal for obtaining homogeneous mixtures.

The piston extruder has low productivity, so its use is mainly limited to pipe production. The principle of operation is the compression of the material by a piston, which gives the finished product the desired shape.

One extruder is not enough for all these tasks. For mass production and high quality, additional machines or equipment are required. Together they form an extrusion line.

This means that not only the extrudate can be directly produced, but also the finished product, such as packaging film, plastic pipes or PVC profiles.

Operating principle and design

It should be said that extrusion is far from a new technology. Its history goes back more than six decades. During this time, a large number of machine designs were created, with the help of which its implementation is ensured. The operating principle of this device is based on the essence of the technological process itself.

The extrusion technological process is a complex physical and chemical process, which is affected by mechanical forces under conditions of high temperature and moisture . Heating of processed products occurs due to the fact that the mechanical energy generated during the fight against internal friction, as well as during plastic deformation, is converted into heat.

There are several variable parameters during the extrusion processing process. The most important ones include:

- composition of raw materials;

- humidity;

- its nature.

During the extrusion technological process, changes may occur:

- material temperature;

- pressure;

- intensity and duration of impact on raw materials.

Extruder device

The operation of this type of equipment is best explained by the simplest type of this machine - a single screw extruder, also known as a single screw or single screw extruder. It has a single propeller and the machine has a single welded frame into which a vertical drive with thrust bearing is integrated.

The electric motor is connected to the gearbox through a special coupling. This ensures that it is below the plasticizing block. Heating is carried out by an electric unit that automatically regulates the temperature. Corrosion resistance is ensured by saturating the extruder elements with nitrogen vapor. Thanks to this, they will not fail and will be quite durable.

In addition to the above-mentioned instruments, instruments are mounted on the frame to monitor the production process. Control is carried out using the operator panel. Due to the compact dimensions of the resulting device, the screw can be placed directly on the output shaft of the gearbox.

Degassing process

Degassing is an important step in the production process. Raw materials for extrusion are not always ideal: they contain impurities, excess moisture and air. In order not to reduce the quality of the material due to imperfect granules, a degassing process is carried out in the machine. This is necessary to remove water, residual solvents and monomers from raw materials using high temperature or artificial vacuum. The process is carried out either using a screw, if the machine uses only one screw, or using a special chamber, if a multi-screw extruder is provided.

Role of the auger

The screw has several functions, depending on which the cylinder can be divided into several important areas:

- In the feed zone, the material is compacted, entering the auger zone, but remains solid;

- In the plasticization zone, the granules are melted, mixed and pressed under pressure as they pass through a screw;

- In the dosing zone, the material, consisting of a mixture of meltable granules and solid granules, is mixed until smooth and fed to the forming tool.

All processes are heated, and the temperature may vary from zone to zone. The quality of the resulting material depends on the conditions and completeness of the passage of raw materials through these processes.

Advantages of single screw and twin screw extruders

The key characteristic of the machine is the number and type of screws. The most common type is the single screw extruder. It is easier to maintain than other types of this machine. It only requires one operator to operate it, as all important controls are located in one place. However, if the machine is part of a larger extrusion line, a support worker may be required. The final number of operators and workers is determined by the technology and production goals.

Another important advantage of a single screw extruder is its ease of transportation. It can be transported from one plant to another or moved to a new location.

Sometimes, however, this extruder does not produce the desired melt quality of the final product, and then a twin-screw machine is used. This allows for better transport of raw materials and is suitable for hygroscopic granules. Often twin-screw machines have a self-cleaning function, which is also convenient to use.

Why is degassing carried out during extrusion?

The quality of the finished product depends on the chemical composition and condition of the raw materials loaded into the extruder. Thermal treatment and evaporation of polymers in vacuum chambers is called degassing. After degassing, the amount of air in the granules is significantly reduced, the percentage of moisture is reduced, and the raw material gets rid of harmful impurities as much as possible.

Extruder machines equipped with screw pairs with degassing systems have special compression and expansion zones. Gaseous components in the expansion zone are removed through holes in the screw or cylinder itself using vacuum pumps. The use of such screws allows you to combine extrusion stages with simultaneous removal of gases without interrupting the entire technological process.

The sequence of operations is as follows:

- loading;

- plasticization (bringing to a homogeneous state);

- melting;

- compression;

- loosening;

- removal of volatile compounds;

- recompression;

- squeezing out the finished mass without containing gases.

If degassing is incomplete, air bubbles will remain in the molten mass. As a result, cavities, voids, and cavities are formed in finished products. Such products are defective.

What does an extruder operator do?

Modern machines are equipped with all the sensors that regulate the optimal conditions for the production of high-quality film. The operator's job, on the other hand, is to set all parameters correctly and maintain them throughout the entire process. The specific conditions depend on the type of material being produced, but there are a few criteria that are most important. They will be described below.

Temperature control

The operator must control the process of converting the granules into the finished molten material. This includes supervision of the operation of thermal automation. The system must ensure that the correct temperature is maintained both in each of the working areas of the extruder and in its components, the most important of which are the extruder head and nozzles. Each zone has its own device to fine-tune the operation of the machine and obtain the best quality in terms of uniformity, shape and other material characteristics. To obtain the best results, an experienced and responsible operator is required who can monitor and correct instrument readings.

Adjusting the auger rotation

The screw is an important part of the functioning of the extruder. It plays a particularly important role when the machine is part of an extrusion line designed to produce pipes or flexible packaging. Barrier screws increase productivity and improve the quality of the final product. Their function is to separate the feedstock from the finished alloy.

This is achieved by dividing the auger into two zones using an additional auger built into the auger. At the beginning of the granule flow line there is more room for granules, towards the end the channel containing the molten polymer increases in volume, and there is less space for unmelted material. Thus, the two factions do not intersect, but smoothly flow into each other.

Depending on the manufacturing process, screws can have different diameters and rotation speeds. The operator controls the latter through the operation of frequency converters. The higher the speed, the higher the performance of the extruder. However, this parameter must be carefully adjusted so as not to degrade the quality of the product. In modern equipment, frequency converters allow you to quickly switch from low to high speeds and vice versa, without intermediate steps.

Changing diameter and shape

Homogeneous molten material, which is the basis of the future product, passes through special holes. They give it the desired shape, such as rings. The operator must set the diameter of the ring, which gives the molten material the shape of a pipe of the desired size. The shape can be changed by applying compressed air. For example, the molten material can be blown further or directed into a gap between lifting rollers, which flatten the material and place it on the bottom of the machine in the form of a sleeve.

The resulting material can be cut on one or both sides using folding devices. Using special knives, the resulting product can be cut into small pieces after drying.

Extruder for feed: drawings and useful recommendations

A simple to use feed extruder makes it possible to independently produce compound feed for animals. This device is considered an indispensable assistant both in large-scale agriculture and in small farms for raising animals and birds. In specialized stores, such equipment costs decent money. To save money, you can assemble the unit yourself; drawings and recommendations from specialists will serve as an auxiliary informant in this matter.

What types of extruders are there?

All extruders, regardless of the scope of application, consist of basic working mechanisms:

- Asynchronous electric motor.

- Loading hopper.

- Auger.

- Heating element.

- Extruder head.

Modern extruders are divided into several categories, depending on the type of transport mechanism used:

- single-screw, twin-screw, multi-screw units;

- piston;

- plunger extruders;

- disk, multi-disk;

- combined.

Screw machines are the simplest and most popular. The auger occupies the central part of the entire machine. Its operation resembles that of a regular meat grinder.

There are different types of screw extruders:

- parallel and conical;

- with normal speed and high speed;

- co-directional and rotating in opposite directions.

Extruder for PVC profile

The production of plastic or composite profiles is mainly carried out by extrusion. For this, depending on the material and complexity of the product shape, single- or twin-screw machines with corresponding forming heads are used.

The range is very wide - from thin strips or tapes to sheets, large panels and complex geometric shapes. Widely used plastic window and door systems are assembled from PVC profiles manufactured in this way.

Adding special components to the polymer makes it possible to obtain complex composites, for example, wood-plastic structures, which are also often used in the manufacture of various building structures.

Extruder for pipe production

It is important that no gas bubbles remain in the homogenized material during pipe production, which is why pipe extruders must be equipped with a degassing system. Typically these are twin-screw machines that, among other things, use so-called barrier screws to reliably separate the not yet solidified semi-finished product from the fully molten product. This ensures complete homogeneity of the composition, which is very important for the performance characteristics of the produced pipe.

Extruders for polyethylene

All plastic films are produced exclusively by extrusion. A blown extruder is used to produce the film. An extruder for stretch film can be made in the form of a narrow slot - the output is a single-layer film of the required thickness and width.

Some models use large-diameter round slot nozzles to produce a film in the form of a sleeve.

Mini-film extruders produce polyethylene up to 300 mm wide and up to 600 microns thick. The small size of the machine allows it to be installed even in a traditional room.

You can buy an extruder for film using the link https://proplast.ru/search/buy/3629/1/extruder%20for%20film/

Fundamental decision

There is a simple, reliable and effective way to solve the problem - buy a plastic extruder

.

This device will not only complete the task of recycling plastic, but will be an effective way to grow your business. Extrusion is a technology for processing containers and other plastic products in order to form the raw materials necessary for the re-production of various parts and products from PVC

. In short, the essence of the technology is the formation of a molten polymer mass with the further formation of small granules having a shape determined by the technical operating conditions.

Thus, using plastic extrusion

You can develop a business, your own business, by offering inexpensive raw materials that are obtained from

production

.

In the foreseeable future, there will be no problem with recyclable materials (and this is the category that most plastic waste falls into). But it is raw materials that make up the majority of manufacturers’ expenses. It is obvious that in modern conditions the possibility of recycling and reusing polymer materials

is a simple and effective solution for business!

It is worth studying the issue in more detail and understanding how a plastic extruder works,

and what prospects are there for running such a business.

Flat slot extrusion

This method is used to crystallize polymers that form melts with reduced viscosity. Compared to tubular films, the structure of flat films is less strong and dense, but they are transparent and flexible. Extrusion of flat sheets occurs at high temperatures, so such films have much fewer defects.

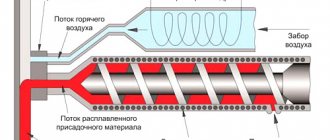

Schematic diagram of the production of polyethylene films using the flat-slot method:

1 – extruder; 2 – slot head, 3 – cooling drums, 4 – edge trimming mechanism, 5 and 6 – pulling rollers, 7 – guide rollers, 8 – winding unit.

The molten polymer is extruded through a slot in the extruder head. The thickness of the groove is adjusted using forming jaws, one of which is fixed, and the other is adjusted to the required distance depending on the given size.

The output is a continuous web, which is fed onto the smooth surface of the cooling drum. The extruder cooling drum is made of chrome-plated steel. Polished surfaces coated with polyethylene film are sprayed with water and cooled to a temperature of 40 to 70 degrees Celsius. The film is then fed through pull rollers, cut and wound into rolls on a winder. The film thickness must be the same along the entire length of the forming slot to achieve the same degree of extrudate viscosity.

Manifold-type extruder heads are very common in modern production. Here the extruded melt flows out from several points simultaneously and is thus distributed more uniformly. The distribution channel is made in the form of an elongated cylinder with a distribution screw inside, which ensures uniform distribution of the melt over the entire width of the slot die and prevents stagnation inside the channel.

The surface temperature of the cooling drum must also be uniform. The temperature difference throughout the entire volume should not exceed two degrees. To produce a super-glossy and transparent polyethylene film, the molten extrudate, forced through the slit, is directed into an ice water bath for more forced cooling.

Advantages of the flat-slot method:

- High process productivity.

- Polyethylene films have excellent optical properties.

- There are practically no areas of different thicknesses.

How does sleeve inflation occur?

To obtain a tubular film, the mass is forced through a ring-shaped hole, resulting in a narrow tube of a certain diameter. The extruder has a pipe expansion function: compressed air is supplied through hoses from the blower into the workpiece at a pressure of 0.13 MPa. The hollow pipe stretches upward, expands in volume, and becomes like a huge vertical bubble of the required size.

Scheme of the process of producing tubular films by blowing in the vertical direction:

1. Sleeve film. 2. Cutting device. 3. Guide shaft. 4. Pulling rollers. 5. Guide cheeks. 7. Extrusion head. 8. Cylindrical tube blank. 10. Control valve. 11. Hose. 12. Receiving coils. 13. Blower. 14. Receiver. 15. Extruder.

In the upper part the sleeve is cooled by air currents. The walls of the sleeve become flat, the opposite sides are connected using guide cheeks, fed to a receiving and winding device, smoothed by rollers and wound onto receiving reels. This technological process continues continuously.

Ring gap is one of the most popular polyethylene extrusion methods. This technology is most often used in the manufacture of sleeve-type polyethylene products, which are widely used in everyday life, construction, manufacturing enterprises, etc.

In order for the resulting film to have uniform thicknesses over the entire surface with a minimum number of folds, the outer and inner cylinders of the extruder ring head must constantly rotate.

Advantages of blown film technology:

- mechanical strength of the canvas;

- minimal losses when cutting films;

- relatively low production cost;

- ease of use (to turn a sleeve into a bag, just weld one edge).

Extrusion lines

In industrial conditions, the extruder is one of the main components of the entire extrusion line, which in addition to it includes a number of other installations and mechanisms:

- Raw material preparation and supply system - sometimes semi-finished products must be pre-dried and calibrated before being fed into the loading hopper.

- Cooling system - installed at the exit of the extruder to accelerate the polymerization of the product. It can be of various types, for example, in the form of an air cooling system or a cooling bath.

- Mechanisms used to pull the finished profile through the machine.

- Marking and lamination systems with different operating principles.

- Winding and cutting mechanisms that give products the required shape for storage and transportation.

Other mechanisms and technological equipment can be used to automate the continuous production process.

Augers

- Auger diameter: 45/97 mm

- Auger length: 1025 mm

- Maximum rotation speed: 35 min-1

- Longitudinal force on the supporting disc bearing of each auger: 145 kN

- Operating torque: 4.2 kNm

- Auger cooling: internal, circulating oil

Screws are the main working body of the extruder. They take unplasticized PVC compound from the feed hole, plasticize it and uniformly feed it in the form of a homogeneous melt to the die. Moving along the screw channel, the material is heated from internal viscous friction and from the heat supplied from electric heaters located on the working cylinder body. As a result of compaction, trapped air is removed from the material and the specific volume of the plug is reduced. To compensate for the decrease in volume, the screw channels are made with decreasing volumes of turns. Therefore, the depth of the screw channel at the outlet is always less than at the inlet. According to the nature of the processes occurring in each section of the screws, they can be divided along the length into 3 main zones:

- feeding (loading) zone - the area where the processed material is in a solid state;

- compression (melting) zone - an area where almost complete melting of the material occurs;

- dosing zone - the area where the material is in a molten viscous flow state.

Coronary polymer treatment

Chemically inert surfaces of polymer products made by extrusion usually do not form strong bonds with printing inks. When ink, glue or dyes are applied to non-porous surfaces, the liquid is not absorbed but beads up and runs off immediately.

For the production of printed packaging or promotional packaging, extrusion lines are equipped with special corona treatment to improve the adhesive properties of the film. The surface energy of films treated with corona discharge increases and is 7-10 dynes/cm above the surface tension of the liquid medium. As a result of microetching, smooth surfaces with an active structure are well wetted and are ready for painting, gluing, flexo printing, patterning and other types of processing.

Benefits of using a grain extruder

A grain extruder is one of the most significant devices for improving the quality of grains. The need to purchase it is justified by many factors. The extruder allows you to increase the quality characteristics of grains several times. Feed processed with an extruder is more economical, easier to digest and completely safe.

This technology is used both in agriculture, helping to significantly reduce feed consumption, and in the food industry to improve the quality of the final product.

Extrusion is by far the most effective way to increase the nutritional value of grains!

Description of the co-extrusion process

The polymers used in coextrusion vary in melting point, viscosity and other properties. Each material must meet certain conditions to achieve consistently high quality plasticization.

A co-extrusion plant consists of 2-3 or more extruders into which a specific type of raw material is loaded. And each melt has its own viscosity and temperature. The materials individually undergo all standard processing steps. Each melt reaches the desired temperature. The molten masses from individual extruders enter under a certain pressure into a common co-extrusion head, where all fractions are combined. After the layers are formed and the finished material is released, subsequent cooling and winding operations are performed according to standard algorithms.

Co-extrusion equipment uses molding tools of the most complex shapes. And when calculating the parameters of the extruder head, polymers with a maximum melting point are taken as a basis.

Features of polymer extrusion

Extrusion technology follows the following algorithm:

- The granules are poured into the machine's hopper.

- The heating turns on.

- The particles melt and form a homogeneous viscous mass, which is the prototype of the future PE film.

For melting, different types of polymers are used, differing in melting temperature. In particular, polyethylene melts at 100-125 °C. Polypropylene - at 80-170°C. Such a wide melting temperature range is due to the presence of various additives in its composition.

In what areas are extruders used?

Extrusion technology has found applications in the areas described below.

- Chemical industry. This is the area where plastics (rubber, plastic, etc.) and ferrites are produced. The chemical composition of the raw materials used remains unchanged, the extruder is primarily designed to obtain the desired shape of the final product. Therefore, installation of such equipment is relatively simple.

- Food industry. Extrusion can also be used in food production. This is usually a more complex process than the previous example. Equipment settings involve subtle changes in temperature, speed, pressure, which lead to changes in the characteristics and properties of the feedstock, for example, denaturation of proteins, decomposition of carbohydrates or gelatinization of starch.

Excellent prospects

The extrusion method is used everywhere; up to 50% of thermoplastics are processed using this method. Extrusion makes it possible to produce the following materials from PVC:

- films;

- sheets;

- pipes;

- hoses;

- capillaries;

- rods;

- siding;

- specialized products regardless of the degree of complexity and configuration;

- applying polymer material to electrical wire elements;

- production of multilayer elements and parts.

At the same time, the amount of processed thermoplastic using extruders is growing every year. Now there is a situation on the market in which the demand for processing exceeds supply. This means that the conditions have been created for starting your own business!

Extrusion Line Manufacturers

Extrusion lines are in great demand and are produced in many countries in Europe and Asia. The traditional leaders in the production of this type of equipment are considered to be Austrian manufacturers, who have been producing such lines since the middle of the last century. European systems have always been of the highest quality, using the latest innovative developments in plastics processing technology.

Recently, the extrusion line market has been flooded with products from Chinese manufacturers. Contrary to popular belief, this does not mean its low quality - both the reliability and properties of the equipment produced generally meet modern requirements. In addition, prices for extruders from China can be significantly lower than in Europe.

Domestic manufacturers are also trying to keep up. For example, extrusion lines produced in the Penza region, or groups from Podolsk and Voskresensk near Moscow, are in demand.

The price of plastic extruders varies depending on the country of origin and the individual characteristics of the machine.

General structure and principle of operation of the equipment

Extruder is a rather complex electromechanical device designed for processing used polyvinyl chloride and producing plastic profile small granules. Such polymer

can be used in the future for the new

production

of various

PVC

products or for organizing the storage of raw materials for their subsequent sale.

production lines

raw materials from recycled

plastic

.

Russian- made

unit fully complies with the requirements of quality, reliability and durability, and the use of domestic components, components and assemblies allows reducing the cost of the equipment.

The single-screw

is the most popular and in demand , as it is the simplest, most reliable and trouble-free in operation, allowing the production of high-quality polymer raw materials using

the extrusion method

.