Home / Accessories and parts

Back

Reading time: 2 min

0

1786

Various tools are used to connect plastic parts - welding modules, soldering irons, hair dryers and guns.

All of them are united by a common operating principle - high temperature affects polypropylene or polyvinyl chloride, as a result of which the edging softens and facilitates the joining of elements.

However, different types of welding operations require different thermal tools. The operations performed by a hot-melt gun for plastic cannot replace a soldering iron or welding module. How, for example, to distinguish the first from the last.

- General information

- Operating principle of a heat gun

- Preparing for work

- Welding

general information

First, let's understand the terms that many beginners constantly confuse. So, you can buy a welding gun (also known as a heat gun) or a hair dryer. What are the differences between them?

A soldering iron is a device designed only for soldering pipes. Its design includes a metal heating element, which heats up and melts the pipe joints. Then the pipes are connected to each other.

A welding gun (or heat gun) and a hair dryer are one and the same device. It would be more correct to call such a device simply a welding gun. Since the principle of its operation is identical to a household hair dryer, for example.

Why is a hair dryer sometimes called a gun? It's simple. Previously, hair dryers had an elongated, non-ergonomic shape. Manufacturers took this point into account and began producing hair dryers with a comfortable handle. Why did the device look like a “pistol?” For this reason, many craftsmen say “hair dryer” and “gun”, meaning the same device.

For your convenience, in this article we will use the term “pistol”, although it is erroneous.

General information

The soldering iron is intended only for welding tubular parts made of plastic. Its design features an electric heater that heats the pipe joints until they melt. In this form, the ends of the two parts are well connected.

A welding gun, also known as a hair dryer, works like a regular household hair dryer, used to dry painted elements and remove moisture from the item.

However, such an electrical device is called so because its shape is very similar in appearance to a pistol.

Features of heat guns

A plastic gun is a simple device. It consists of an electric heater and a fan, all built into a compact housing. Manufacturers produce pistols of varying power, but 1500 W and above is considered optimal. The heating temperature also depends on the model. Heat guns for home repairs can heat polymers up to 700 degrees. This temperature is sufficient for soldering most types of plastics.

The heat gun you choose must have manual temperature control. First of all, it's convenient. Secondly, it will teach you how to independently select the optimal temperature. Don't rely on automatic mode. This plastic soldering machine will become your full-fledged tool and increase your capabilities.

Tools and materials for plastic repair.

To repair plastic parts of a car, special materials and tools are used , without which it is not possible to carry out high-quality bumper repairs. You also need to know the type of plastic, which is practically impossible to visually determine, so most manufacturers leave markings to determine the type of plastic.

Now about each of them.

Soldering iron. The most important tool in this matter. Used for joining plastic fragments, mesh reinforcement, and for welding seams. The criteria for choosing a soldering iron are quite simple. It is desirable that the handle be wooden, since the plastic one begins to melt after the 3rd bumper. The power is at least 100 W, otherwise the process of soldering the bumper will turn into a “long-playing song”.

Hair dryer. It is also called a professional, construction, industrial, thermo-gun. When choosing it, you should pay attention to the power; it should be at least 1600W. The temperature of the directional air flow is also important; depending on the hair dryer, it ranges from 80-700 degrees. Air temperature adjustment has 2 options:

1. Smooth temperature control - allows you to use this tool most widely

2. adjustable in several positions

It is better to purchase a hair dryer complete with various attachments for directing the air flow. When purchasing such a kit, be sure to inquire about the overheat protection function. Otherwise, a hair dryer that does not have overheating protection may fail.

There are also hair dryers with electronic temperature control. Due to precise regulation of flow and temperature, they are used for various types of work: plastic repair, metal soldering, hot pressing, welding of various materials.

Which one to use is up to you to choose. It all depends on the area of application of this tool.

Personally, I use this heat gun for welding plastic.

Plastic welding occurs by reinforcing the bumper with a plastic welding rod. This is perhaps the simplest and most reliable method of bumper repair. Welding rods are universal and suitable for all types of plastics.

Especially for you, dear visitor to my blog, I recorded a detailed video on how to repair a plastic bumper with a hairdryer using welding rods.

Materials for repairing bumpers. Bumper repair equipment. Welding the bumper. Hairdryer for repairing bumpers. Repair of plastic bumpers. All this in one video.

This is what we got!

Fast and reliable. I give a 2-year warranty on such bumpers, subject to adequate use.

You can place an ORDER I guarantee reliability and quality.

Preparatory work

For welding plastic, there are the same preparatory work as for welding metal. So don’t take working with polymers as something simple and frivolous. The quality of the connection, and therefore the durability, largely depends on preparation. And this is very important in water supply systems, for example.

Clean the surface of the parts from dirt. Degrease. Then sand the area of the future seam, if necessary. After sanding, clean the surface from any dust that has formed. This can be done using a blower device.

Types of soldering irons

Most specialists to repair a plastic bumper use both standard soldering irons, which are used for soldering radios and electrical circuits, and special tools that are suitable for reconstructing bumpers.

Let's consider the characteristics of a traditional soldering iron, which is used to work with electrical appliances. This tool is available with a straight or curved tip; it can also have a variety of shapes, for example, a straight design or a pistol shape. A standard soldering iron is usually used when working with plastic, when you need to connect bumper parts by thermal action. It is also used when you need to seal seams.

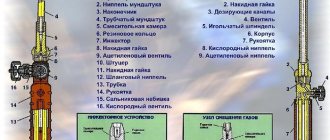

Consider a soldering iron-gun hot air gun. It works by supplying air, which is heated to a temperature of 80 to 600°C. The instrument is supplemented with a special smooth thermoregulation system. In addition, a soldering iron gun usually comes with various attachments. These additional accessories provide precise direction of the flow of hot air to the place where parts are sealed. The best model of a hot air gun is a tool with a power of more than 1600 W.

Let's consider the third version of the soldering iron - a hot-air soldering station. It is a kind of complex that combines a modern model of a traditional soldering iron and a hair dryer.

The main advantage of this model of soldering iron is the fact that when working with it, the operator has the ability to adjust the operating temperature exactly in accordance with the technological task assigned to a particular operation. The model is usually supplemented with various attachments.

Welding process

After all the parts are prepared, they need to be precisely aligned and fastened together. This can be done using clamps. Next, turn on the heat gun for welding and set the temperature. It must correspond to the melting temperature of the material from which the parts are made.

After the gun heats up, make so-called tacks in several places of the future seam. Tack welds are small weld points located around the perimeter of the joint. Using tacks you will ensure reliable fastening of parts at the initial stage. You can remove the clamps and proceed to forming the seam.

Use plastic rods to fill the joint. The rods must be made of the same material as the parts. Apply the rod to the joint and heat it with a gun. The rod will melt along with the part. As soon as the rod and the part become plastic, begin to move along the entire joint. The seam must be made from both sides of the parts, it is better to start from the back.

Avoid excessive melting of the plastic. It should be plastic, not fluid. To make the seam more aesthetically pleasing, use special rollers that smooth the joint. The seam must be smoothed before it completely cools down. If the seam has cooled down, you can additionally warm it up with a gun and smooth it out.

If special staples are used for soldering instead of rods, then select the optimal size in advance.

Content

Tool types

The principle of working with the tool

Features of work

The car bumper is the most prominent part of the body, so it is also the first to encounter obstacles.

Very often such meetings end in minor and major damage. Motorists decide to replace the bumper as a last resort, when it is almost impossible to assemble and restore it. If there is any hope, they try to restore the bumper using soldering; the repair procedure will cost less than a new part. By the way, if you really want to choose the cheapest option, buy a soldering iron at the nearest radio parts store. It will be inexpensive, and the procedure will be carried out just as well as professional equipment. Here we will tell you more about it.

Soldering iron for bumpers

Previously, almost all car bumpers were made of metal, now more and more body parts are becoming plastic. Restoration and repair require new technologies and tools.

Tool types

Before choosing equipment for bumper repair, you need to understand what requirements are required for it:

- tool power;

- heating rate;

- temperature retention time;

- safety and ease of use.

To repair plastic body parts use:

- electric soldering iron for working with wires and microcircuits (has a straight or curved nozzle, plastic or wooden handle, new models can be in the form of a gun, recommended power from 50 W);

- manual hot air device (heat gun) (supplies and heats a stream of air from 80 to 600 °C, the temperature of the air supply is adjusted manually, the hot air gun is equipped with various nozzles for more accurate supply of a stream of air, recommended power from 1600 W);

- Soldering station (hot air) (combining an electric soldering iron and a hot air gun into one device with the ability to adjust temperature, the kit includes a variety of attachments for precision soldering).

Manual hot air device

The principle of working with the tool

To repair a plastic bumper, you need to know that you can solder only one type of plastic. The type of plastic can be found out from the car's instructions or the markings on the back of the bumper:

- PP (PP) – polypropylene, the most durable and pliable material, melts at a temperature of 175 ° C, has the lowest density among plastics, is resistant to abrasion and acids, alkalis and organic solvents. The sensitivity of the composition to oxygen and UV rays is compensated by stabilizers;

- ABS (ABS) is an impact-resistant thermoplastic resin, destroyed by exposure to sunlight and UV rays, toxic when heated above 90 ° C;

- PBT (PBT) - polybutylene terephthalate, resistant to alcohol, hydrocarbons, gasoline, brake fluid, diesel and hydraulic oil, kerosene, solvent. Does not change color when heated. Does not lose properties during prolonged use at 120 °C, and tolerates short-term exposure to temperatures of 210 °C.

- PA (PA) - polyamide, durable and rigid material, resistant to high temperatures, does not break at low temperatures, has a high degree of protection from oxygen, fats, fire and chemical compounds;

- PS (PS) – polystyrene, a hard and brittle material with low density. Good dielectric, frost-resistant. Deformed by acetone, toluene, gasoline. Easily takes the desired shape and is painted. When heated above 300 °C, it begins to smoke and emit harmful fumes;

- PVC (PVC) – polyvinyl chloride, a plastic synthetic polymer, resistant to acids, alkalis, alcohols, mineral oils, gasoline. Durable, lightweight, wear-resistant material resistant to weather and temperature. Second most popular after polypropylene;

- TPO thermoplastic polyolefin is an impact-resistant copolymer containing up to 50% ethylene propylene rubber.

Soldering of polypropylene material

Fiberglass is not marked, the letters GF indicate the presence of glass fiber in the composition, and the numbers after them indicate the proportion in the composition. The PUR marking indicates a polyurethane composition.

The work of the selected tool is to change the state of the plastic:

- heating to plasticity (the part is easily deformed and takes the desired shape);

- melting (the process of direct welding of parts of a part, 350–400 °C);

- destruction (the connecting seam becomes brittle due to overheating of the material).

Soldering a crack on a bumper

All work on repairing a car bumper must be done while wearing a respirator with a high degree of chemical protection in rooms with good ventilation due to the toxic fumes that occur when the plastic is heated.

Preparing the surface for use with a soldering iron:

- remove the bumper if necessary;

- clean the surface of the bumper from dirt and grease;

- sand the surface and apply a primer;

- place the fiberglass on the glue;

- after the surface has hardened, apply another layer of glue with a spatula;

- after complete drying, sand the surface, coat with varnish and enamel;

- solder the missing pieces.