Gas melting metal welding involves the use of equipment such as a gas torch. With its help, the metal surfaces to be joined are heated and melted. As a rule, all burners have a simple design, light weight, and are convenient to use. To choose the right tool for the work ahead of you, you should pay attention to the design features, as well as the types of burners.

How does a gas burner work? Operating principle

The design of a gas burner traditionally consists of an insulating sleeve, a nozzle, a diffuser, a mixing chamber, gas regulators, cable connectors, a handle equipped with a button, a cable, a connector and a tip mouthpiece. The gas burner device may include other elements - a piezoelectric element, a cooling system, and a feeding device. The presence or absence of certain components depends on the methods of supplying flammable gas.

- The injection type burner circuit includes an air supply regulator, a nozzle, a mixer, and a distribution manifold. Before final mixing, the gas-air mixture is rarefied, air is sucked in, then the stream is leveled in the diffuser and enters the collector, where it is evenly distributed among the holes.

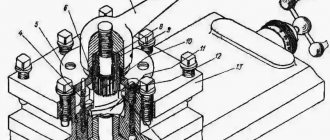

welding torches: injection - a; non-injector - b; 1 - mouthpiece; 2 — tip tube; 3 - mixing chamber; 4 injector; 5, 6 - control valves; 7— trunk; 8 - tube; 9, 10—nipples

In turn, injection burners come in two varieties:

- with full injection or high pressure burners;

- with partial injection, or low pressure burners.

Devices of the first type are used mainly in heating boilers and for heating industrial furnaces. They ensure complete mixing of the components intended for combustion. The second type is common in furnaces for heating soldering irons, autosmokers, and in the furnaces of Strel and Strebel boilers. The combustion zone of such devices is provided with only part of the required air; a sufficient amount of it is drawn from the environment.

- Non-injection burners assume the same pressure for oxygen and fuel gas when they enter the mixer. Their design is complicated by a fan, an electric motor for drive, and air ducts. Due to these parts, non-injection burners can reach 1.9 m in length, which makes the tool not very comfortable to use.

Oxygen and combustion gas are delivered to the mixing nozzle in similar ways. From the cylinder, gases enter the burner through a tube, bypassing the control valve and the receiving nipple. In the mixing chamber, the gas flow rate decreases (as the cross section increases), and oxygen and combustible gas interact until a combustible mixture is formed that is homogeneous throughout the entire volume. Next, the mixture goes out through the nozzle onto the tube, where a welding flame is formed.

Knowing how a gas burner is structured and how it works, as well as how to correctly follow the sequence of parts, you can build such a device at home. However, it should be remembered that in order to ensure a constant rate of exit of the gas mixture from the mouthpiece, you need to carefully select the composition of the gases connected to each other, adjust the diameter of the outlet channel and pay attention to the design of the mouthpiece.

Soldering technology

The area to be soldered must first be cleaned of dirt, rust, dirt and degreased. After preliminary preparation, the products are thoroughly dried and coated with flux. The parts to be soldered must be fixed so that the solderer has both hands free, since he will need to hold the torch and solder while working.

Then the product is heated so that the material is heated evenly along the entire length of the joint. To do this, the torch is continuously moved along the seam.

Pay attention to the burner flame. A properly adjusted flame has a dark core, middle part and edges with clear contours. If excess oxygen is supplied, the flame becomes sharply shorter, and if a lot of combustible gas is supplied, the middle zone disappears, the length of the flame increases, loses clarity, and the fire begins to smoke.

The highest temperature is at the end of the core, so preheating is best done with the outer part of the flame. After the soldering seam is heated to the melting temperature of the solder used, the end of a solder rod coated with flux is applied to the seam, which, when melted, closes the seam.

To avoid burnout, the solder must be heated quickly with a neutral, not very hot, flame. After soldering is completed, it is better not to touch the parts until the solder has completely hardened, so as not to displace the workpieces.

Purpose of the gas burner

A gas burner is used in those areas where stable combustion of fuel is required, the intensity and extent of which can be adjusted. Such a device can carry out:

- lighting. Open flame burners, argan oil burners, regenerative burners, and incandescent burners were popular before the invention of electricity and are rarely used today.

- heating. For example, when heating rooms, for laboratory experiments or for kitchen purposes.

welding torch Welding

torches are used in the industrial and construction fields. Depending on the type of welding, they supply a continuous stream of flammable gases to the weld site (in gas welding) or provide the arc combustion zone with shielding gas (in arc welding).

A portable gas burner for a cylinder will be useful for a tourist holiday. The sealed cylinder is reliably protected from fuel leakage, and the device with piezo ignition allows you to quickly light a fire without using matches or flint. A small can of gas will last more than one season of travel.

Note that a gas burner can be useful at home if:

- there was a need to unscrew a rusty nut;

- you need to decorate a metal or wooden surface in a vintage style;

- it is necessary to trim the ends of the nylon rope or geotextile;

- there is a need to repair the garden path using baked mass;

- you need to warm up the frozen lock;

- I want to cook meat outdoors, but I don’t have a grill. gas burner with piezo ignition

Welding torches operating on propane-oxygen combustible mixture

GZU propane torches are also used for soldering ferrous and non-ferrous metals, and less often for non-critical welding seams of ferrous metal of small thicknesses up to 3 mm. This is due to the lower temperature of the propane-oxygen mixture (up to 2,100°C), which does not allow welding to be performed on equal terms with torches running on acetylene. Nevertheless, such burners are widely used for heating and soldering non-ferrous metals with high-temperature solders.

The compactness of such welding torches, excellent operation of the valve units, allowing for “fine” adjustment of the gas supply, modern, thoughtful design - all this makes the torches convenient and reliable and allows you to work with them both in open space and indoors.

How to use a propane torch

A propane gas torch will be simply necessary when carrying out roofing work, drying casting molds, removing old paint, crimping couplings, soldering copper pipes, etc. Before using the burner, two cylinders are purchased - with oxygen and propane - on which reduction gears are mounted. The latter provide optimal pressure.

When the reducers are connected to the gas burner using hoses, you can unscrew the valves and release the gas. Before igniting, the gases pass through an injector where they are mixed. The temperature of the emerging flame exceeds 2 thousand degrees.

To carry out work, first open the valve with flammable gas, then with oxygen. The mixture coming out of the nozzle must be set on fire. The pressure of the consumables is adjusted based on instrument readings or flame color. Afterwards, using a filler wire, a weld pool is formed, and the molten metal must be moved, forming a seam. When the work is completed, the filler wire is removed and the gas mixture is extinguished.

Popular types

There are many models of gas burners, each with its own design features. Which welding mode to choose depends on the materials being welded and the amount of work . If a pipe leaks at home, it can be repaired with a simple piezotorch with filler wire.

To make plumbing and repair a car, you will need a manual semi-automatic device or a gas device operating in TIG mode.

For semi-automatic

The semi-automatic machine works with filler and welding wire, which is automatically fed into the bath at a constant speed. It can only be used as an additive and melts due to burning gas. In most machines, the wire is also an electrode, at the end of which an arc is created.

All modes are configured before welding begins . After this, with a change in current strength, the amount of supplied gas and the wire feed speed increase.

The length of the hose for supplying consumables is 3 – 5 m.

A simple device allows you to assemble the burner yourself, even without having a drawing yourself. Any house requires welding work during construction and furnishing. The amount of work is small and buying a device is expensive; making a homemade one will cost less.

For argon arc

Argon arc welding is performed in TIG mode. It allows you to cook refractory materials such as aluminum. In the center of the nozzle there is a holder for a tungsten electrode. The arc is constantly in a protective atmosphere.

The gas is adjusted using a valve on the handle. Sleeve length 4 – 8 m.

For spot welding

The devices operate in TIG – WIG mode. They are distinguished from other nozzles by a shaped nozzle, which covers a flint mouthpiece with a tungsten non-consumable electrode. The principle of operation is the spot melting of metal on one or both sides . The connection has neat weld points. No filler wire is used; only the metal of the parts being welded is melted.

At the moment of formation of the connection, the non-consumable electrode is located inside the mouthpiece in a gas environment, which creates additional heating and high pressure. It takes a few seconds to create one weld point. The welder's hand presses the mouthpiece to the metal and presses the button.

To use spot welding, a copper sheet is placed under the parts - an underlayer that removes excess heat and at the same time acts as a current collector.

At the end of welding, the wire afterburner turns on. It completes the formation of the welding site, preventing the wire from cooling sharply.

What gas can be used

Acetylene, hydrogen, and substitute gases (natural gas, propane-butane) can be used as combustible materials for a gas burner. Some designs operate on liquid flammable substances and waste oil.

gas burner cylinder marking

The combustible substance enters the acetylene burner from the generator apparatus, where calcium carbide decomposes into slaked lime and acetylene. The gas for the burner has a pressure of 100-150 mmHg. Nitrogen obtained from atmospheric air is used as a shielding gas, which prevents the formation of scale, and water is used as a catalyst for the decomposition of carbide.

The hydrogen torch is the most popular among similar equipment designed for gas-flame processing. It is important that when using it, only water vapor is released, so it is the safest. When an aqueous alkali solution decomposes, hydrogen burns, followed by the release of energy, which is needed to speed up welding. Hydrogen protects the weld from exposure to oxygen, thereby preventing oxidation of surfaces.

Many owners have an idea of how a liquid fuel gas burner works, since the operation of a kerosene stove is based on this principle. When heated in a special coil, the flammable liquid turns into gas and due to this, significant savings are achieved during subsequent combustion. As a rule, kerosene and Galosha gasoline are used as liquid fuel.

Knowing how to use a gas burner during mining, or a Babington burner, you can significantly save on consumables and reduce the cost of work. Such designs use motor, compressor, and any vegetable oil as fuel. The fuel enters a spherical part, from which it is blown off by a stream of compressed air. The resulting small droplets then ignite.

Video description

Video demonstration of how a stove gas burner works:

- For boiler.

Industrially manufactured heating units are equipped with burners of a given power, and therefore the consumer does not have to make any adjustments. It’s another matter when the boiler has to be assembled from separately purchased components.

In this case, it is necessary to take into account the type of combustion chamber of the unit - closed or open. The type of gas burner suitable for the appropriate operating conditions will depend on this indicator. Power, serviced area, need for automation and other important factors are also taken into account.

- Universal models.

Removable burners designed for installation in any suitable equipment. For example, they can be equipped with boilers and furnaces operating on solid or liquid fuels. At the same time, for maximum efficiency and productivity, such installations are equipped with a powerful air supply system, filters, gearbox and automation.

Indicators related to the flame of the device

gas burner flame

The burner flame power can be low (fuel consumption is 25-400 dm3/h), medium (400-2800 dm3/h) and high (2800-7000 dm3/h). Knowing the maximum and minimum power of a particular burner, you can calculate the fuel consumption and the amount of energy required to meet technological needs.

According to the number of flames, burners are single-flame and multi-flame. If the first type is used primarily for manual oxygen-acetylene welding, the second is widely used for mechanized flame soldering or heating.

Advantages and disadvantages of a gas torch for welding

The gas burner has the following positive qualities:

- a large number of types of devices;

- safety during operation;

- most models are compact and light weight;

- no lengthy preparation for use is required;

- does not leave soot or odor;

- the pressure of the fire can be adjusted;

- You can always find out what the device consists of and, if necessary, assemble a homemade burner.

Disadvantages of using a burner:

- at temperatures below -30°C, operation of the device becomes problematic;

- You cannot refill a flammable container yourself.