Also on topic:

MINERAL RESOURCES

The main industrial uses of tin are in tinplate (tinned iron) for making containers, in solders for electronics, in household piping, in bearing alloys, and in coatings of tin and its alloys. Tin forms various compounds, many of which have industrial applications. The most economically important tin mineral is cassiterite (tin oxide). The world's cassiterite deposits are developed in Southeast Asia, mainly in Indonesia, Malaysia and Thailand. Other important deposits of cassiterite are found in South America (Brazil and Bolivia), China and Australia. See also TIN PRODUCTION.

Story

Tin has been known to people for six thousand years. But as a component of bronze. Pure metal was isolated by the 12th century. Eight centuries later, the history of the discovery was supplemented by the solution to the phenomenon of the “tin plague.”

Tin as a metal is mentioned in the books of the Bible and the early Middle Ages encyclopedist Roger Bacon.

The etymology of the name is interesting. The name stannum comes from Sanskrit and means “strong, steadfast.” This was the name given to alloys, and only since the 4th century has the term been applied to tin.

The term “tin” is found in the Baltic and all Slavic languages. However, among the Slavs it means lead. In the Baltic group, the basis is the name of the metal by color: white or yellow.

What is

Tin is an element of the periodic table.

It is a light silvery-white shiny metal. Consists of ten isotopes.

Tin cube

Tin belongs to the group of light non-ferrous metals.

The international designation is Sn (Stannum).

The world price of a ton of raw materials on the London Metal Exchange is $21,000.

Being in nature

In terms of prevalence on the planet, tin is in 47th position; in the earth’s crust its mass content is calculated in thousandths of a percent.

The main metal carrier mineral in nature is cassiterite (another name for tin stone) - almost 80% of the composition.

Forms of occurrence in rocks and minerals – dispersed and mineral (oxides, hydroxides, silicates, sulfides, spinels).

There are deposits on all continents, reserves amount to millions of tons.

In Russia, the regions of deposits are Khabarovsk, Primorsky Territories, Yakutia, Chukotka.

Application

O. is a component of alloys: with copper (bronze), copper and zinc (brass), antimony (babbitt), lead (solder), zirconium, titanium, niobium (nuclear reactors, turbines, superconductors), etc. O. is used for application coatings on metals, including tinning of tinplate, production of foil, measuring parts. devices, heat exchangers, art. products, etc. SnO2 oxide is used for the manufacture of heat-resistant enamels and glazes. Tin(II) salts are used in mordant dyeing of fabrics. Crystallic. SnS2 (“gold leaf”) is included in paints that imitate gilding; tin fluoride is an additive in fluoride-containing toothpastes.

Physico-chemical characteristics

Metal is endowed with many advantages: ductile, lightweight, malleable, non-toxic.

Chemical properties do not appear at ordinary temperatures.

| Properties of the atom | |

| Name, symbol, number | Tin / Stannum (Sn), 50 |

| Atomic mass (molar mass) | 118.710(7) a. e.m. (g/mol) |

| Electronic configuration | [Kr] 4d10 5s2 5p2 |

| Atomic radius | 162 pm |

| Chemical properties | |

| Covalent radius | 141 pm |

| Ion radius | (+4e) 71 (+2) 93 pm |

| Electronegativity | 1.96 (Pauling scale) |

| Electrode potential | −0,136 |

| Oxidation states | +4, +2 |

| Ionization energy (first electron) | 708.2 (7.34) kJ/mol (eV) |

| Thermodynamic properties of a simple substance | |

| Density (at normal conditions) | 7.31 g/cm³ |

| Melting temperature | 231.91 °C |

| Boiling temperature | 2893 K, 2620 °C |

| Ud. heat of fusion | 7.19; kJ/mol |

| Ud. heat of vaporization | 296 kJ/mol |

| Molar heat capacity | 27.11 J/(K mol) |

| Molar volume | 16.3 cm³/mol |

| Crystal lattice of a simple substance | |

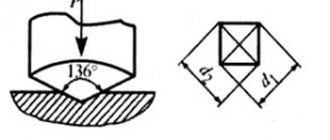

| Lattice structure | tetragonal |

| Lattice parameters | a=5.831; c=3.181 Å |

| c/a ratio | 0,546 |

| Debye temperature | 170.00 K |

Disadvantages: low melting point, vulnerability to the “tin plague”.

"Tin Plague"

Under normal pressure, the metal takes one of two modifications:

- α-Sn. Temperature less than +13.2°C. Dull gray powder (tin gray).

- β-Sn. Temperature above +13.2°C. Metal, white tin.

Gray and white tin

At air temperatures below +13.2°C, β-tin is reformatted into the α-modification. The structure of the lattice changes, the silver metal becomes a gray powder.

The process proceeds fastest at -33°C. Because of its speed, it was dubbed the “tin plague.” It destroyed Napoleon's army during his campaign in Russia and many museum exhibits when the premises froze.

Advantages and disadvantages

The advantages of tin lie in the following characteristics of the metal:

- high corrosion resistance, as well as immunity to salts and a number of organic acids;

- in the inability to react with sulfur, which may be contained in other materials (this allows you to combine tin and, for example, plastic in the same products);

- in the absence of toxicity - a quality that allows the use of Sn in the food industry.

Tin is characterized by the following disadvantages:

- low temperature of transition to the liquid state;

- susceptibility to the “tin plague”.

Receiving technology

The source for obtaining the metal is cassiterite.

Cassiterite crystals - tin ore

The process is simple:

- The ore is crushed to particles no larger than a centimeter.

- The flotation method is used to separate waste rock. The metal content increases to 42-68%.

- Sulfur and arsenic are removed by oxygen roasting of the concentrate.

- The resulting product is loaded into the melting furnace, alternating layers of concentrate with charcoal. The result is reduced tin.

- The second restoration option is aluminum or zinc.

Tin ore

If necessary, the metal is additionally purified by zone smelting or electrochemical refining.

Historical reference.

Tin was probably used back in the days of Homer and Moses. Its discovery was most likely associated with the accidental recovery of alluvial cassiterite (tin stone); alluvial deposits occur at or near the surface, and tin ores are much more easily reduced than ores of other metals. The ancient Britons were well acquainted with tin: ancient forges containing slag were discovered in Cornwall in southwest England. Metal was obviously inaccessible and expensive, because... Tin objects are rare among Roman and Greek antiquities, although tin is mentioned in the Bible in the Fourth Book of Moses (Numbers), and the word cassiterite, which is still used today to designate the oxide tin ore, is of Greek origin. Malacca and East India are mentioned as sources of tin in Arabic literature of the 8th–9th centuries. and various authors in the 16th century. in connection with the Great Geographical Discoveries. The history of tin mining in Saxony and Bohemia dates back to the 12th century, but in the 17th century. The 30 Years' War (1618–1648) destroyed this industry. Production was subsequently resumed, but soon declined due to the discovery of rich deposits in America.

Tin brands

Metallurgists smelt several grades of metal:

| Brand | Amount of impurities (%) |

| OVCh-000 | 0,001 |

| O1pch | 0,085 |

| O1 | 0,010 |

| O2 | 0,435 |

| O3 | 1,51 |

| O4 | 3,51 |

The first four grades of tin are produced in the form of ingots, wire, and rods. Pigs are smelted from O3 and O4. This is the source code for tin products.

Where is it used?

Metal is in demand as an independent material, in alloys and compounds.

Its chemical and physical properties make it possible to produce safe, rust-resistant products and coatings.

Tin soldier in mold after casting

Metal

Pure metal is in demand as:

- Containers of food products.

- Packaging foil.

- Anode in chemical current sources.

It is also a coating for copper wires. The metal protects the copper “filling” from the harmful effects of sulfur contained in the insulating material.

Tin cup from Gdansk (Poland)

Tin is the most environmentally friendly of light non-ferrous metals.

Connections

Metal compounds have found application in various segments of the economic complex:

- Aviation and mechanical engineering . Additive in titanium alloys.

- Electrical engineering. Superconducting wire (niobium compound).

- Optics. Abrasive for finishing glass surfaces.

- Light industry . Yellow dye for wool.

- Agriculture . Pesticides.

- Decor. Component of “golden” paints.

Isomers of artificial origin are used in medicine as a source of gamma radiation.

A third of the mined tin is used to make tableware. Another 60% is taken by bearings, packaging foil, and solders. Less than 7% remains for other purposes.

Prospects

The potential of two-dimensional tin layers created using graphene technology is being explored. The name of the material is consonant with its “parent” – stanen.

Appendix B (for reference). Method of sampling ingots, sheets and billets for analysis

Appendix B (for reference)

B.1 Selection of ingots

B.1.1

Rule

A number of bars are randomly selected from a stack. Sawing is carried out systematically in selected ingots, and the resulting sawdust is combined. Analysis samples are obtained by sawing a sample of fused sawdust.

B.1.2

Materials and tools

B.1.2.1 Brush with steel wire.

B.1.2.2 Brush with soft bristles.

B.1.2.3 Electric hacksaw equipped with a steel blade for rough cutting.

B.1.2.4 Large magnet.

B.1.2.5 Degreasing solvent.

B.1.2.6 Diffuser or equipment for coning and quartering.

B.1.3

Process

B.1.3.1 Sampling of ingots from a batch

Based on the number of ingots in the package, randomly select the number of ingot samples in accordance with the sampling frequency from the batch given in Table B.1

Table B.1 - Selection frequency rate for a batch of ingots

| Number of ingots per batch | Number of ingot samples |

| 1-4 | 1 |

| 5-20 | 2 |

| 21-40 | 4 |

| 41-60 | 6 |

| Over 60 | 10% of bars in the lot |

B.1.3.2 Obtaining ingot samples

Ensure that the ingot sample (B.1.3.1) is free of oil and grease. Clean the ingot samples to a complete surface using a steel wire brush (B.1.2.1). Then use a soft brush (B.1.2.2) to remove any substances contaminating the free surfaces.

B.1.3.3 Sawing ingot samples

Cut by sawing, using a hacksaw (B.1.2.3), a quarter of the length of each sample ingot (B.1.3.2).

Note - The cut should not be made at the end of the ingot boss. If any ingot sample has end stops that are more than one quarter of the ingot's length, the cut should be closer to the center of the ingot's length so that the sample is taken from the full cross-section of the ingot.

Collect a file from each ingot sample. Mix the total sawdust particles and remove free iron using a magnet (B.1.2.4).

B.1.3.4 Obtaining sample for analysis

Reduce the particle size distribution of the sample obtained in B.1.3.3 by sample scattering or by coning and quartering (B.1.2.6) to obtain one or more average samples of suitable size for analysis.

B.2 Selection of sheets and blanks

B.2.1 Rule

Small pieces are cut from a number of sheets or blanks in a batch.

The pieces are scattered, melted and cast into a chill mold. Drilling is preferred over sawing, with chips taken from the casting to obtain a sample for analysis.

B.2.2 Materials and tools

In addition to small installations for melting and casting tin alloys, the following is required:

B.2.2.1 Hydraulic shears or cutter to cut small pieces from sheets or blanks.

B.2.2.2 Balances capable of weighing up to 200 g in 1 g divisions.

B.2.2.3 Saw, drill or milling machine.

B.2.2.4 Hand magnet.

B.2.3 Process

B.2.3.1 For both sheets and blanks weighing up to 50 g

Randomly select four sheets or blanks from the batch. For each of the selected sheets or blanks, use scissors or a cutter (B.2.2.1) to cut approximately 50 g small pieces at random locations. Scatter small pieces according to size.

B.2.3.2 For workpieces weighing up to 50 g

Randomly select a number of whole pieces to obtain a combined mass of approximately 200 g.

B.2.3.3 Obtaining sample for analysis

Melt scattered small pieces (B.2.3.1) or selected blanks (B.2.3.2) in a clean iron die or fireclay crucible. Mix well and pour the injection molding into a clean iron or steel mold.

Take the shavings obtained by sawing, drilling or milling from the resulting casting. Remove free iron from the chips that was introduced during the process of producing the chips using a magnet (B.2.2.4) and thoroughly mix to obtain a sample for analysis.

Alloys

Metallurgy uses tin as a component of alloys. According to the scope of application, they distinguish between bearings, low-melting compounds and solders.

Molten Tin

A classification of alloys by type has been developed:

Babbitts

An alloy based on tin or lead. It is used as a layer created by spraying or filling.

Disadvantages: low strength, quick fatigue. Due to these properties, the alloy is used only in bearings protected by a housing.

Bronze

Copper-tin alloy with a dominance of copper. Pros: hardness, fusibility, resistance to processing, rust, mechanical damage, atmospheric disasters.

Used as a foundry metal in the chemical industry, automotive industry, and exterior decoration of buildings.

Solders

They are easy- and hard-melting. The main component of the alloy is tin.

There are several brands, depending on the ratio of elements. The alloys are used for soldering everything: from cookware, medical equipment, radio components, heating radiators to electronic equipment.

Pewters

Alloy with copper, antimony, bismuth. Decorative, aesthetic option. It is used to make dishes and small objects that decorate life. But application limits toxicity.

In some countries the use of the alloy is prohibited. Such products can only be found in antique dealers.

Connections.

Tin forms a variety of chemical compounds, many of which have important industrial applications. In addition to numerous inorganic compounds, the tin atom is capable of forming a chemical bond with carbon, which allows the production of organometallic compounds known as organotin compounds (see also ORGANOMETALLIC COMPOUNDS). Aqueous solutions of tin chlorides, sulfates and fluoroborates serve as electrolytes for the precipitation of tin and its alloys. Tin oxide is used in ceramic glazes; it gives the glaze opacity and serves as a coloring pigment. Tin oxide can also be deposited from solutions as a thin film on various products, which adds strength to glass products (or reduces the weight of vessels while maintaining their strength). The introduction of zinc stannate and other tin derivatives into plastic and synthetic materials reduces their flammability and prevents the formation of toxic smoke, and this area of application becomes the most important for tin compounds. A huge amount of organotin compounds are used as stabilizers for polyvinyl chloride, a substance used to make containers, pipelines, transparent roofing material, window frames, gutters, etc. Other organotin compounds are used as agricultural chemicals, for making paints and preserving wood.

Meaning for humans

The microelement is a participant in metabolism and promotes the growth of skeletal tissues.

Diet

Products from several groups are rich in tin:

- Meat – chicken, turkey, beef, pork.

- Dairy products, including hard cheeses.

- Legumes.

- Vegetables – potatoes, beets.

- Sunflower seeds.

Every day a person needs 3-11 mg of the substance. He gets them from food. The excess is disposed of naturally, so poisoning is excluded.

Symptoms of deficiency

A lack of microelement disrupts the mineral balance of the body.

The result is the following symptoms:

- Unmotivated exhaustion.

- Growth inhibition.

- Hearing impairment.

- Dullness, brittleness, hair loss.

Element deficiency is a rare occurrence. Just like oversupply.

Oversupply

Occurs in people who come into contact with the substance (mining in mines, working in a metallurgical plant) or fans of canned foods.

Tin Coated Tin Can

The integrity of the shell of cans is compromised during long-term storage. Some of the tin passes into the contents.

The oversaturation of the body with metal is signaled by:

- Metallic taste in the mouth.

- Lack of appetite, gastrointestinal upset (vomiting, diarrhea).

- Anemia, migraines, dizziness.

- The skin becomes inflamed, pale, becoming grayish. Blueness appears on the gums.

On the emotional level, this is increased aggressiveness and excitability.