The petrol cutter is designed for fast and productive cutting of hard materials. This tool is successfully used where conventional cutting devices - circular, chain or circular saws - cannot cope. The first gas cutters appeared in the 50s of the last century. Currently, they are in service with rescue and fire services and are widely used in construction, incl. on the road, as well as in production and at home.

- 2 Design and principle of operation of a gas cutter

- 3 Choosing a gas cutter: main points

- 4 Intensity of use

- 5 Properties of the working material

- 6 Cutting method

- 7 Ergonomics

- 8 Safety requirements

- 9 Features of choosing a gas cutting tool

- 10 Working with a gas cutter, video

Advantages of gas cutters

The main advantages of this type of cutting tool are mobility and autonomy. Petrol cutters can work indoors and on construction sites where there is no electricity. Being a hand tool, they allow you to cut in hard-to-reach places.

With the purchase of a gas cutter, there is no need to purchase a whole arsenal of cutting machines. After all, this equipment is multifunctional and allows you to solve a wide variety of industrial and household tasks. Thus, gas cutters are used for cutting concrete, asphalt, brick or stone masonry, metal structures, plastics and composite materials. With their help, dismantling work, gating, cutting openings in walls and ceilings, etc. are performed. In addition, these units are successfully used in gardening, as well as in the construction of private houses and auxiliary buildings.

The petrol cutter is a rather massive and heavy tool. Therefore, when choosing a particular model, you should take into account its ergonomics, as well as the ratio of power, weight and vibration level.

Best models

Relying only on tips and tricks when choosing a tool is a bad strategy. But they may well become an additional evaluation criterion. In this review, we have collected five of the most popular models of gas cutters that are worth paying attention to.

HUSQVARNA K 770 14”: 5 HP disc 350 mm depth 125 mm

Classic hand carver. Equipped with a 3.7 kW two-stroke engine. The model is characterized by low fuel consumption and reduced exhaust gas volume. The semi-automatic SmartTension system minimizes the risk of under- or over-tensioning the belt. Together with Active Air Filtration technology, they provide an increase in the interval between maintenance. A large number of design options due to additional systems: safe cutting, protection against incorrect fuel mixture, dust removal systems from both an external and built-in vacuum cleaner.

STIHL GS 461 40 GBE: 5.8 HP chain 400 mm depth 400 mm

A chain cutter allows you to easily cut concrete, brick and other materials during dismantling or construction. It's as easy to use as a chainsaw. Cutting a doorway, sawing Porotherm ceramic bricks to size and many other tasks can be done by a compact tool with a high degree of autonomy.

CEDIMA CKR-1016 HF: 10 kW (380V) 400 mm 165 mm

The model is equipped with an electric motor with high power and torque, which allows you to work with large materials under conditions of special noise and exhaust requirements. The universal design is suitable for cutting any materials: metal, concrete, asphalt, etc.

Advantages: disc diameter 400 mm, cutting depth 165 mm, anti-vibration system, roller guide.

ZITREK Z4000 WET: 2.8 kW (220 V) 350 mm 125 mm

The model has cutting parameters and functions similar to a 5 hp gas cutter, but it operates from a household network and costs just over 100 euros. Such cheapness does not imply similar quality and a high workload of 100 work shifts without a break, but it is capable of completely solving for pennies a problem that unexpectedly confronted a foreman.

Design and principle of operation of a gas cutter

The main component of a gas cutting tool is an engine, mainly a 2-stroke engine, which runs on a fuel mixture of oil and gasoline. The unit is mounted on a housing equipped with special handles and controls. The functional part of the gas cutter is the drive, on which a cutting disc with a diameter of 300-400 mm, protected by a casing, is installed. The transmission of torque from the engine to the drive is carried out via a belt.

The main feature of modern gas cutters is the presence of a multi-stage dust protection system. It prevents contamination of the carburetor, cylinder-piston group and bearings. In addition, dry cutting uses water cooling of the disc. It effectively neutralizes the main flow of dust and prevents a number of negative consequences of overheating, in particular, premature wear of the cutting element and destruction of its structure, and also reduces the load on the engine.

When working with a gas cutter, it is necessary to maintain a right angle between the cutting disc and the surface being processed. This reduces the load on the drive and prevents slippage from the cutting line and damage to the cutting edge. The maximum insertion depth of the disk for various models is in the range of 10-30 cm. When cutting dry materials, you should not use a gas cutter for more than 30-50 seconds - within 15-20 seconds after making the cut, it is necessary to ensure free rotation of the disk.

Powerful models weighing more than 15 kg are equipped with transport trolleys with a remote control system or special legs, which allow the tool to be firmly fixed when cutting.

Preparing the tool for work

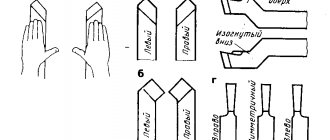

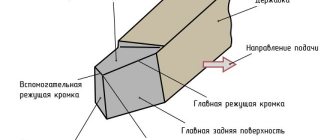

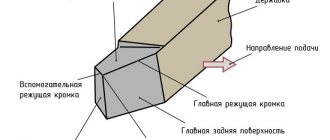

The structure of a typical gas cutter with a disk as a cutting element is shown in the following photograph.

In addition to gas-powered disc cutters, there are chain models, the design of which is almost identical to that of a chainsaw. There are also specialized modifications, such as wall chasers and rail cutters.

Preliminary configuration of gas-powered tools is carried out at the manufacturing plant. In most cases, nothing needs to be adjusted. All types of units are prepared for operation in the same way. The actions are performed in the following sequence:

- visually inspect the technical means and the cutting attachment for external damage;

- install the protective casing in the required position, securing it securely;

- check the existing switches and buttons for free movement, and the throttle lever (when you press its release) for ease of rotation and return to its original position;

- install a disk suitable for the job;

- check the installation of the spark plug - it must be screwed in all the way;

- remove foreign objects and debris from the workplace;

- prepare a fuel mixture consisting of gasoline and oil mixed in a certain proportion;

- check the presence of fuel in the tank of the gas-powered tool, refueling it if necessary.

The ratio between gasoline and oil in the fuel mixture, as well as a detailed description of the safe refueling process, are contained in the user manual for the product model used.

If you plan to use the tool using the wet cutting method, then additionally carry out the following actions:

- connect a tube to the connecting node of the equipment through which water will flow from the water supply or from the tank;

- use a special lever to turn on the water supply (after completing the work, its supply is stopped).

The operating unit must not have any mechanical damage. If they are found, then you need to first repair the device. The discs used should not have chipped cutting edges, cracks or other defects. Do not use wet abrasive wheels or those that have fallen from a height.

Changing a disk is done like this:

- the drive shaft is fixed motionless;

- using a wrench of the required size, unscrew the fastening bolt;

- remove the bolt, washer, as well as the outer flange, leaving only the inner one;

- put the disc on;

- put all the elements in place in the reverse order, tightening the bolt tightly (but not excessively, without unnecessary effort).

When installing a new disk, you must ensure that the rotation speed for which it is designed is greater than that of the tool . The equipment used must not be equipped with working attachments if they are intended for use at lower speeds.

Choosing a gas cutter: main points

To ensure that the gas cutter does not disappoint its owner during operation, before purchasing a particular model, you need to study its individual characteristics:

- design features;

- functionality;

- power;

- weight;

- cutting depth;

- features of the filtration system;

- start time;

- ergonomics;

- ease of maintenance.

You should choose a power cutter based on conditions such as intensity of use, scope and method of application, as well as user requests for ergonomics and safety requirements at work. All this deserves separate consideration, since its effectiveness and ease of use directly depend on the correct choice of tool.

Maintenance

Below are some general routine maintenance instructions. If you have any further questions, please contact your dealer.

Maintenance instructions

Daily

- Check the safe operation of the throttle handle parts (throttle handle and starting throttle lock).

- Check the drive belt tension.

- Check the condition of the blade and drive wheel.

- Check the condition of the blade guard.

- Check the starter and starter cord and clean the outside of the starter air intake.

- Check the tightness of the nuts and bolts and tighten if necessary.

- Check the operation of the stop contact.

Weekly

- Check, clean or replace the plastic filter.

- Check the handles and vibration dampers to ensure they are not damaged.

- Clean the spark plug. Check the gap 0.5 mm.

- Inspect the starter and return spring. Clean the intercostal space on the flywheel.

- Clean the cylinder cooling fins.

- Check that the muffler is firmly attached and not damaged.

- Check the idle speed setting and adjust if necessary.

Intensity of use

Currently, professional and household models are available on the market, the main differences between which are working life, design and functionality. Regarding the first, household gas cutters are designed for approximately 25 hours of operation per month. They have low power and are suitable for small volumes of work. A professional tool has a wider range of applications, and its working life is about 8 hours of continuous operation.

Kerosene burner tank

In typical designs of kerosene cutters (devices produced by the Bobukha Cutter brand are considered especially high-quality), two types of tanks are used: BG-63, with a capacity of 6.5 liters, and BG-68, with a capacity of 8.5 liters. The tank consists of the following elements:

- A cylindrical welded body, the bottom of which has the shape of a concave hemisphere.

- A spherical lid with two sealed holes and a carrying handle.

- Shut-off valve.

- An intake tube with a mesh filter at the end.

- Pressure gauge.

- A manual air pump that creates the necessary pressure to supply kerosene to the hose.

- Thrust ring at the bottom of the housing.

- Two fittings - for connecting a hose, and for filling the tank with kerosene.

When operating the pump, an excess pressure of up to 3 kg/cm2 is created inside the tank body, due to which the kerosene is forced out into the hose. Filling the tank with kerosene should not exceed 70% of its nominal capacity, since part of the energy carrier still evaporates. Despite the careful sealing of the fitting into the tank (welding is used), part of the substance still evaporates during pumping, as a result of which the pressure drops. This circumstance forces the use of a pump to pump kerosene from time to time.

Preparing the tank for use involves thoroughly cleaning it, as well as checking the serviceability of the pump and pressure gauge. Despite the presence of a filter, it is recommended to fill the tank only with pre-filtered kerosene. It is unacceptable to use the tank in an inclined or horizontal state. To comply with fire safety rules and for ease of use, the tank is placed at a distance of no closer than 5 meters from the oxygen cylinder, and no further than 3 meters from the place where the kerosene cutter is used.

Maintenance of the unit consists of periodically cleaning the channels with copper or aluminum needles (steel needles are not recommended).

Properties of working material

Global manufacturers produce three categories of gas cutters: concrete, metal and universal. The concrete cutting tool has a power of 4.2 kW and provides approximately 4700 rpm. Such high characteristics are necessary to ensure that the cutting disc does not get stuck in the material being processed during operation. Petrol cutters for metal have a power of up to 4.2 kW, and their engine provides a lower number of revolutions, sufficient for cutting metal with relatively little resistance. A universal gas-powered tool can work with any material, because... has high power and rpm.

The ideal gas cutter from the best manufacturer

There is no clear answer to the question of which brand of gas cutters is better. The rating above already lists the best manufacturers, such as STIHL, Husqvarna and Makita, which are rightfully popular with both the average user and professional builders. Each of them has its own strengths and weaknesses, but in the end it turns out that the ideal, as always, is unattainable. But this does not mean that you should not strive for it. The main thing is to choose a tool for the needs and types of materials for which a particular device is ideally suited. Only these parameters will tell you which gas cutter is best to buy.

See also:

See also:

Cutting method

You can cut hard materials using the “dry” or “wet” method. The first does not involve the use of water cooling - such gas cutters are suitable for performing small amounts of work in easily accessible areas. The advantage of wet cutting is that it solves the problem of dust during work, but this method is not applicable to solving all production problems.

A water-cooled tool costs significantly more than a “dry” one and is more difficult to repair and maintain.

Petrol cutter Stihl TS 420

In the class of semi-professional equipment ]Stihl[/anchor]”, this model is considered the most convenient to use. It has a compact body, low weight (can be carried and operated with one hand) and reduced emissions (by 70%). The model also features a cutting abrasive disc - wear resistance and reliability. And the impressive power of the device maximizes its scope of application. The equipment is recommended for use in harsh operating conditions: increased loads, long-term continuous operation, cutting hard materials. Has standard equipment.

Advantages of Stihl TS 420 identified by consumers:

- ICE 2-mix. The gasoline unit at maximum loads shows excellent fuel economy - 20%. The peculiarity of the technology allows you to reduce costs.

- Air filter protection. The equipment uses a special cyclonic filter cleaning system, which simplifies the maintenance of the unit, increases the intervals between servicing and increases its service life by 45%.

- Ease of use. The unit can be used either manually or on a trolley. The kit with the gas cutter includes a set of keys for installation.

- Versatility. You can process granite and metal products/structures, concrete and asphalt in extreme conditions - rescue work, construction, dismantling of structures.

- High build quality. German technology has earned a reputation in the market for producing reliable and extremely safe equipment. This fact is confirmed by user reviews of the TS 420 gas cutter model.

- Disk protection. The manufacturer used magnesium disk protection.

- Ergonomic and balanced design. The correct location of adjustment buttons, handles, and gas tank caps ensure maximum comfort and safety in using the equipment.

- Excellent tool handling. Due to the balanced design, the unit is easy to operate, which guarantees precise and neat cuts.

- ElastoStart device. This is a trigger mechanism synchronized with the decompression valve and compensator. Working in tandem of these three components helps prevent oversaturation of the fuel mixture, which inevitably happens when the filter is significantly dirty.

- Anti-vibration mode. Ensures long-term operation of the operator with the device - hands do not get tired, preventing the development of occupational diseases.

- Belt tension system. A unique semi-automatic mechanism - unscrewing the proprietary clamping screws ensures automatic belt tension through a special spring assembly.

User-identified shortcomings of the Stihl TS 420:

- Difficulty replacing the filter. Many users note that the innovative filtration system does not provide for independent replacement of elements.

- Uncomfortable working with the unit on a trolley.

- The body is made of low quality materials.

A fairly large percentage of consumers noted the high build quality of the unit and the external elements of the housing that are unstable to mechanical loads. The equipment requires careful handling. Reviews also indicate the durability of the equipment - the service life without the need for repairs is (based on reviews) 1.5-2 years. There are some complaints regarding difficulties with servicing the machine. A small percentage of consumers indicate that equipment requires regular professional maintenance. According to other criteria, users called the unit powerful and functional equipment.

Video review of the Stihl TS 420 gas cutter:

Ergonomics

When selecting a tool, you should remember that the less it weighs, the easier it is to work with, but the less power and efficiency it will have. It is best to buy a medium-weight petrol cutter with a streamlined body - such a model will provide good maneuverability, and therefore work productivity. Special attention should be paid to the design of the handles. The best option is two handles, the distance between which should be as comfortable as possible for the operator, made of soft, non-slip material. You should also make sure that the design of the tool provides high-quality damping of vibrations that occur during cutting.

Petrol cutter Echo CSG-680

The semi-professional Japanese model CSG-680 gas cutter from ]Echo[/anchor] is a productive and versatile unit. The manufacturer has provided the ability to change disks. It is possible to cut wood, plastic, concrete, and metal products. You can also work with a diamond cutting disc. The design is equipped with a powerful 1-cylinder internal combustion engine (2-stroke type) and is complemented by an air cooling system. The equipment is supplied as standard.

Advantages of Echo CSG-680:

- Convenient belt tension system. The manufacturer has provided additional mechanisms to simplify the belt tensioning procedure.

- Power transmission system. Thanks to the addition, the tool cuts any materials accurately and accurately.

- The presence of a diaphragm carburetor. Allows you to perform cutting operations on materials at the required angle.

- Classic filtration system.

- Innovative starting system. To increase cutting efficiency parameters, the manufacturer used an innovative ignition system - automatic change in ignition timing.

- Convenient location of control units, which facilitates the operation of the tool and makes it safer.

- Availability of additional security systems. The manufacturer has supplemented the unit with a right-hand shield, a special vibration and noise suppression system, a muffler with a spark extinguisher, and a metal screen with a rubberized coating to protect the operator’s hands and face.

Disadvantages of Echo CSG-680:

- Very heavy equipment. My hands get tired after 10-15 minutes of work. Carrying the instrument is also inconvenient due to the bulkiness of the case.

- High price.

- Unbalanced design.

- No smooth start.

In general, consumers called the equipment safe and functional. Many consider this equipment to be the best in its class - reliable, powerful and safe. A small percentage of buyers who tried the equipment in use indicated a high noise level and a weak filtration system. About 20% of buyers were dissatisfied with the quality of the case and its design features.

Video review of the Echo CSG-680 gas cutter:

Security requirements

To avoid injury during operation, gas cutters are equipped with cast protective casings made of hard metal alloys with high impact resistance. In addition, global manufacturers use a system for blocking the disk when it gets stuck in the material being processed, and also supply the manufactured tools with belt and casing tensioning devices.

When working with a gas cutter, it is recommended to use protective gloves, glasses and headphones, and when dry cutting - respiratory protection.

Design

HUSQVARNA K750 cutter diagram

1 – Front handle; 2 – Water supply tap; 3 – Warning sticker; 4 – Air filter cover; 5 – Cylinder cover; 6 – Choke; 7 – Throttle trigger locking lever; 8 – Gas trigger; 9 – Starting gas clamp; 10 – Stop contact; 11 – OilGuard shutdown function (K750 OilGuard); 12 – Starter handle; 13 – Starter; 14 – Muffler; 15 – Fuel tank; 16 – Decompression valve; 17 – Cutting disc shield; 18 – Adjustment knob for protection; 19 – Belt shield; 20 – Water connection with filter; 21 – Cutting lever; 22 – Data plate; 23 – Belt tensioner; 24 – Cutting unit; 25 – Cutting disc; 26 – Universal key;

Petrol cutter Husqvarna k750

Features of choosing a petrol cutting tool

In addition to conventional gas cutters - for metal, concrete and universal - specialized models are also produced. If you need a tool with an increased cutting depth, you should buy a wall chaser. Units for working with metal beams or rails are called rail cutters - they are equipped with devices for fixing the tool. Maximum ease of use is provided by a tool with an adjustable cutting angle. These gas cutters allow you to work in confined spaces – near walls or other obstacles.

Advanced models, which, of course, cost much more than conventional ones, are equipped with a hydraulic drive. The power of such a tool is several times higher than that of standard models, since hydraulics allow it to be increased without increasing the total weight. In addition, the hydraulic drive reduces noise and dust emissions - these gas cutters are perfect for working in enclosed spaces.

When choosing a gas cutting tool and consumables for it, it is necessary to ensure that the parameters of a particular model correspond to the characteristics of the material being processed, as well as the intensity and complexity of the work performed.

In conclusion, we note that you should buy tools from well-known brands with a complete set and reliable quality guarantees. It will be much easier to obtain the spare parts and materials necessary for repair and maintenance for such a gas cutter, and in operation it will be truly reliable and efficient.

Cutter

The design of the cutter, which is equipped with an evaporator, is very similar to a similar unit for gas-oxygen cutting. It includes:

- Main mouthpiece.

- Warming mouthpiece.

- Head.

- Injector.

- Control valves.

- Feed tube.

- Adjusting handwheel.

- Evaporator.

- Fire resistant padding.

The cutter works as follows. Kerosene from the connecting hose enters the fireproof evaporator packing, where it is heated by the flame that is formed at the outlet of the auxiliary heating mouthpiece. At the same time, oxygen is supplied from the cylinder through the injector to the working head of the kerosene cutter. In the head, oxygen is mixed with heated kerosene vapor, after which the mixture is ignited, and in this form it comes out of the gap between the mouthpieces. This is a heating flame, the intensity of which is regulated using handwheels and valves. In this case, the percentage composition of the components changes in favor of oxygen, the temperature of which increases to values corresponding to the local melting of the metal in the cutting zone. The supply tubes are located in the handle of the cutter.

The safety of working with a kerosene cutter is ensured by the functioning of the safety valve, which controls the ignition process. To do this, first open the oxygen valve, and then the kerosene valve. Then the mixture is ignited at the base of the mouthpiece, and the parameters of the resulting flame are controlled by turning the handwheels. If the pressure of the components is outside the permissible limits, the elastic filling mixture located in the gap between the sealing washers overheats/cools, and accordingly releases or presses the seat against the valve neck with a spring. Thus, the supply either increases or stops altogether.

During routine maintenance of cutters, monitor the condition of the seals, clean the heads from formed burrs, and polish the inlet and outlet holes using a clean cotton rag.