Press shears NG 5222 are designed for cutting long, shaped and strip products, cutting grooves and punching holes in them, creating a force of 40 tons. The machine is equipped with four functional sections, which are designed to perform one of the following operations:

- cutting round bars with a diameter of up to 45 mm, angles at an angle of 90° with maximum dimensions up to 125x125x12 mm, angles at an angle of 45° with maximum dimensions up to 90x90x9 mm, as well as shaped profiles up to No. 18;

- cutting strips up to 150 mm wide and up to 16 mm thick;

- punching holes with a diameter of up to 30 mm in metal up to 16 mm thick;

- cutting open grooves with maximum dimensions of 70x60x10 mm.

The machine can be controlled either by push-button or pedal and is designed for three operating modes:

- single tool stroke;

- continuous running;

- manual rotation.

Equipment.

In addition to the standard equipment, it is possible to supply, for an additional fee, equipment that allows you to cut at right angles a corner of 160x160x12 mm, a channel of profiles 5-18U, an I-beam of 10-18 profiles and increase the length of the workpiece when cutting is carried out along the back stop, from 70 to 100 mm. In this case, the stop is also supplied at an additional cost.

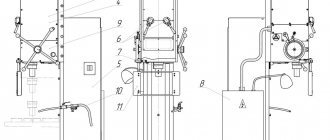

The frame is a welded structure, consisting of front and rear sheets welded to the base.

To install drive shafts and section drives, four borings are made in the frame.

Drive the sheet metal and hole-punching sections from an electric motor through V-belt and gear drives to the eccentric shaft of the sections. The notching device lever is connected by means of a rod to the slider of the sheet section.

The slider of the punching section is balanced by spring balancers.

The centering mechanism is designed to perform the basting operation by moving it using the handle of the punch holder with the punch.

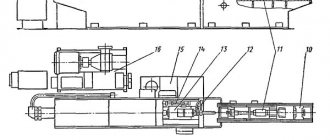

The tool for cutting corners, circles and squares consists of movable and fixed plates. The movable plate is attached to the socket of the slider of the sheet section, the fixed one - in the socket of the frame using L-shaped springs.

The sheet and notching tool consists of two movable and three fixed knives.

Movable knives - guillotine for cutting sheet material and rectangular - for rectangular notching.

The punching section tool consists of a punch and a die. The punch is attached through a punch holder to the slide, and the matrix is attached to the body of the punching device.

The shear press has three workstations served by one operator.

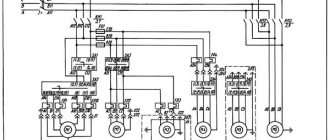

The electrical circuit ensures the operation of the press shears in continuous and single strokes.

Push-button and pedal controls.

Thick, combined lubricant.

Information about the manufacturer of the shear press HB5222

The manufacturer of the NV5222 press shears is the Kuvandyk plant of forging and pressing equipment "Dolina" , founded in 1941.

Machines produced by the Kuvandyk Forging and Pressing Equipment Plant

- GD-162

- straightening machine for cutting reinforcing steel, Ø 16 - Н5222А

– combined shear press, Ø 45 - NB5222

– combined shear press, Ø 50 - NB5224

– combined shear press, Ø 67 - HB5221

– combined shear press, Ø 45 - HB5222

– combined shear press, Ø 50 - NG5222

– combined shear press, Ø 45 - NG5223

– combined shear press, Ø 50 - NG5224

– combined shear press, Ø 67

НВ5222 combined press shears. Purpose, scope

Combined press shears НВ5222 were developed in 1975 and mass-produced since 1977. Developer: SKB KPO and AL, Azov. Manufacturer: Mechanical Press Plant in Kuvandyk.

Combined press shears НВ5222 are used for cutting strip, long and shaped rolled products and punching holes in sheet, strip and shaped rolled products, as well as for performing notching operations.

Combined scissors НВ5222 can be used in machine-building, repair and other factories, when used in climate zones with moderate and cold climates, version UHL, in dry and humid tropical climates - version O, placement category 4 according to GOST 15150-69.

HB5222 shears with four working zones allow you to perform several types of operations on one machine without preliminary reconfiguration of the shears, in any sequence and without changing tools, which provides flexible and economical processing of rolled products, both in large engineering production and in any repair shop.

HB5222 scissors perform the following operations:

- sheet metal cutting, strip cutting;

- rolled section without marking from 70 to 1000 mm along the stop;

- punching triangular and rectangular grooves;

- circle segment;

- a piece of angle, channel, I-beam, shaft profile;

- punching holes of round, rectangular, square and any other shape.

Description of the design of the shear press NV 5222

The frame is a welded structure, consisting of front and rear sheets welded to the base.

To install drive shafts and section drives, four borings are made in the frame. Drive the sheet metal and hole-punching sections from an electric motor through V-belt and gear drives to the eccentric shaft of the sections. The notching device lever is connected by means of a rod to the slider of the sheet section.

The slider of the punching section is balanced by spring balancers.

The centering mechanism is designed to perform the basting operation by moving it using the handle of the punch holder with the punch.

The tool for cutting corners, circles and squares consists of movable and fixed plates. The movable plate is attached to the socket of the slider of the sheet section, the fixed one - in the socket of the frame using L-shaped springs.

The sheet and notching tool consists of two movable and three fixed knives.

Movable knives - guillotine for cutting sheet material and rectangular - for rectangular notching.

The punching section tool consists of a punch and a die. The punch is attached through a punch holder to the slide, and the matrix is attached to the body of the punching device.

Press shears HB 5222 have three workstations, served by one operator.

The electrical circuit ensures the operation of the shear press on continuous and single strokes.

controls .

Thick, combined lubricant

HB5222 press shears and many options for additional equipment allow the use of press shears for processing rolled products of various profiles and different parameters.

To facilitate the movement of strip, long and shaped products when feeding them into the working area of the shears, it is possible to use a roller conveyor module of the MRP drive model.

Additional requirement: the lower air temperature must be at least +5°C

Main parameters of press shears НВ5221:

The parameters are valid for metal with a tensile strength (tensile strength) σ BP = 500 MPa (50 kg/mm2).

- The largest thickness of the sheet to be cut is 16 mm

- The greatest thickness and width of the cut strip is 18 x 190 mm

- The largest diameter of the cut circle is Ø 50 mm

- The largest dimensions of the cut corner are 14 x 125 x 125 mm

- The largest diameter of the hole to be punched is Ø 32 mm

- Frequency of continuous strokes of the slider - 53 min-1

- Drive power - 4.8 kW

- Total vehicle weight - 2.5 tons

Recommendations for optimal use of the machine

Since combined shears are not high-precision separating equipment, when performing adjustment operations it is necessary to ensure that the depth of penetration of the movable and stationary knives into the cut rolled product does not exceed 25% of the original overall dimension of the metal section indicated in the passport. This condition is extremely important for cutting highly plastic metals and alloys (for example, aluminum). As a last resort, it is permissible to use heated cutting, when the original semi-finished product is heated to 150...200 °C. This condition is most often implemented for the separation of high-carbon (containing more than 0.5% C) or alloy steels.

When planning to use a hole-punching press, it is worth initially setting increased (compared to those recommended in the passport) gaps between the side guides of the puller and the workpiece, otherwise it may bend and bulge in the area of action of the hole-punching punch.

The passport for the machine also indicates the conditions for installing the scissors. Since this equipment is not characterized by the shock nature of its work, a special foundation is not required. The absence of an electro-pneumatic activation system allows the shears to be installed outdoors, supplying the moving parts with lubricant suitable for use in the appropriate temperature conditions. The equipment must be covered with a moisture-proof canopy.

General principle of operation of press shears and design of combined press shears НВ5222

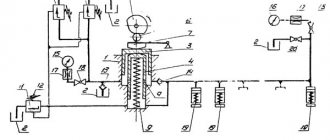

The shear press is driven from an electric motor 3 through a V-belt drive (the belt designation is given in Appendix A), a flywheel 2 and a single-stage gear transmission 1, 4 to an eccentric shaft 6. The gear pair 1, 4 is spur-cut, cylindrical. The support journals of the gear shaft are installed in bearings (bearing designations are given in Appendix B)

The gear shaft Z1=14 has a rim width of 85 mm and is made of steel 40X GOST4543-71 (hardness 240...260 HB), the wheel Z2=126 has a rim width of 80 mm and is made of steel 35L GOST977-88.

The movement is transmitted to the slider 10 of the grade section through the connecting rod 5, and to the slider 8 of the press for punching holes through the balancer 7 and the sinking stone.

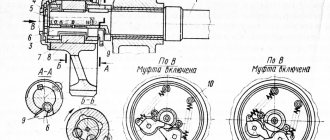

The actuators are turned on and off through a system of levers connected on one side to a connecting rod and a sinking stone, and on the other side to electromagnets 9.

Composition of components and principle of operation

Crank press shears for cutting metal have a fairly uniform structure, which includes the following components:

- AC drive motor;

- the drive shaft on which the switching system is located;

- intermediate gear;

- flywheel;

- crank or eccentric shaft;

- a connecting rod with a slider to which movable knives are attached;

- clamping mechanism for the original workpiece;

- support unit for the cut part of the bar (strip, rolled products);

- adjustable roller conveyor for supplying source material;

- back stop;

- bed.

The process of a single cycle of metal cutting on combined press shears occurs in the following sequence. The operator, including the roller table, introduces the profile to be cut into the working area of the shear press, after which the required length of the workpiece is set using the back stop. After this, the material is fixed in the required position by a clamping device and supported by a compensator, which ensures the constancy of the horizontal axis of the rod/strip during the cutting process. After this, the electric motor of the combined shear press is switched on for the working stroke. The engagement clutch is activated (for large sizes it is pneumoelectric multi-disk; for shears with a force of less than 800 kN, the unit may contain one pressure disk), and the band brake releases the shaft, which transmits the required torque to the crank shaft through a gear transmission. The crank mechanism located there converts rotation into translational movement of the slider with the working knife. The cut product falls along the slide onto the receiving tray, and from there into the box for cut pieces. At this time, the crank mechanism returns to its original - upper - position. The activation system is activated, and the shaft is secured by the synchronous activation of a band-type brake.

Operations performed on press shears NG5224

During the automatic operation of combined press shears, during the reverse stroke of the slide, the next workpiece is pushed and fixed in the cutting zone.

Hydraulically driven shear presses (for example, from the Heck company of the Multicrop series) operate from a hydraulic power cylinder, which controls the reciprocating movement of the slide. Such equipment is characterized by lower productivity, but it provides the ability to hold the slider at the lowest point. In some cases this improves the quality of the cut. Geka shears are distinguished by the presence of an option for angular profile cutting, as well as the possibility of subsequent bending.

Alligator-type metal cutting shears, as well as reinforcing shears designed for mechanized separation of reinforcing steel bars, have slightly different kinematics. There are less torques there, so instead of a friction clutch, the design provides for a structurally simpler rigid coupling with rotary keys. In addition to being unpretentious in maintenance, it does not require a continuous supply of compressed air at a pressure of more than 5...6 at. The slider itself makes not reciprocating, but rocking movements. With a slightly worse cutting quality (this circumstance is not particularly important for scrap), the height of the working space between the movable and stationary knives increases, which makes cutting scrap metal easier.

Fastening the tool (knives) of the combined press shears НВ5222

Attaching knives for cutting sheet metal on nb5222

Fastening the grade section knives on nb5222

Attaching the cutting device knives to the nb5222

Attaching a hole-punching tool to nb5222

Fastening knives for cutting corners, circles, squares on nb5222

Popular CPN models

A large number of varieties of combined industrial type shear presses are produced. In Russia, the following models are most widespread: SMZh625, NV5221, NV5222, NV5224. The most popular model remains the HB5221 installation. Below we will briefly look at the features of these models.

SMF625

It belongs to the category of simple, compact and cheap models, with which you can perform all basic metal work. Areas of application: cutting shaped or long rolled metal, working with metal sheets, punching holes, making triangular notches. The SMZH625 installation can be adapted for use in open areas. An additional application of SMZH625 is working with metal and rolled metal on construction sites with low or medium levels of pollution. The machine is used in temperate climates.

HB5221

This model belongs to the category of large massive machines that are designed to work with large batches of metal. HB5221 is suitable for working with all popular types of rolled metal (shaped, long, strip). This machine can be used for making holes, cutting out various notches and notches. The device has 4 active zones. This allows you to significantly increase labor productivity, which will be very useful in the case of large metallurgical industries (mechanical engineering, production of military equipment, construction of sea vessels, repair work). HB5221 machines have slight design differences due to the climate of primary use. A simple example: the UHL modification of the HB5221 machine is used to work in moderate or cold climates.

HB5222

This model is a modification of the previous HB5221 system. A major difference between this type of installation is that the 4 zones of the HB5222 press system operate in a completely autonomous mode. This allows the operator to efficiently organize work in production. Model HB5222 is designed to work with all types of rolled metal, for cutting sheet metal, for making holes, notches or recesses. This model of scissors is used in construction or engineering industries. Another area of application is small compact workshops, specializing in the dismantling of prefabricated metal structures (machines, equipment).

HB5224

This unit is an improved modification of the HB5221 model. The device is universal - it is suitable for processing sheets, rolled metal, various blanks and solid parts. Like the classic model, the HB5224 system is divided into 4 zones, which perform all basic operations with metal - cutting, making holes, pressing. The basic differences of the HB5224 are improved automation, the use of stronger metal alloys with anti-corrosion additives, the availability of equipment for notching operations, and the ability to cut angle metal.

Knives for shears for cutting long products. Technical requirements

Knives for press shears are manufactured in accordance with GOST 25454-82 Knives for shears for cutting long products. Technical requirements

- Knives should not have cracks, burrs, shells, sharp corners and edges (except for cutting ones);

- The surfaces forming the cutting edge should not have nicks or burns;

- The cutting edge should not be blunted, chipped, or have nicks;

- Knives must be made of steel grades:

- Х12Ф1, ХБФ according to GOST 5990-73 for cold cutting of steel

- R6M5 according to GOST 19256-73, 4Х5В2ФС according to GOST 5990-73 for hot cutting of steel

- Surfaces forming the cutting edge (front, back) and supporting surfaces - 1.25 microns

Types of scissors

Shear presses can differ from each other in a number of parameters - drive type, power, dimensions, list of available operations, number of active zones. The main varieties are the following types of CPN - lever, disk, hydraulic, container, for scrap.

Lever systems

These scissors are small in size, so they are suitable for processing small parts. They are used in small workshops or workshops, as well as in scrap metal collection points. Lever systems are lightweight, so they can be quickly moved from one place to another if necessary. The operating principle of such systems looks like this:

- On the installation, two guillotine knives are fixed above each other. The length of the blades usually does not exceed 10 centimeters. The lower knife is fixed motionless, while the upper knife is driven by muscular force.

- To cut, press or make a hole, a person places the part in the work area. Then he pulls a lever, which creates the required level of pressure, which leads to cutting the part.

- As is clear from the description, lever systems do not have electrical elements. Therefore, with such installations it is possible to cut anywhere without the need to connect the system to a power source.

Disk systems

Such installations are similar in structure and nature of use to lever systems with some important differences:

- Instead of guillotine knives, two sharp disks are used that rotate in the opposite direction relative to each other.

- In most cases, the drives are connected to an electrical power source. The system is controlled using a lever that allows you to bring the disk into the active zone.

Disk systems have many advantages. The advantage is that the worker will not need to waste his energy for work, since cutting is carried out using electric disks connected to a generator. In addition, such cutting is fast and accurate, and deformation and burrs do not form on the part. Disk units are usually small in size, so they are also only suitable for processing small parts in workshops or small workshops.

Hydraulic systems

Hydraulic CPNs usually have medium or large sizes, and they are usually used in medium and large industrial workshops in production. Hydraulics allow you to develop high pressure, which allows you to cut and process even the thickest and most durable metal parts.

The base of hydraulic installations is usually made of concrete, and the frame is made by welding. For cutting, two massive knives are usually used, which are connected to a hydraulic press. The bed is quite large in size, which allows it to dampen vibrations during work, which can significantly improve the quality of cutting. Hydraulic CPN systems can cut metal at an angle. Therefore, they can also be used to make complex frame structures or parts for cars.

CPN for scrap

Such systems are very large in size, and they have a mechanical or mechanical-hydraulic operating principle. Such systems are used for recycling scrap - metal, automobile, steel. Scrap shears are used in large metallurgical plants as part of more complex systems. CPPs for scrap are usually equipped with several autonomous sections, which significantly speeds up and simplifies the operator’s work. Also, many systems are equipped with a compaction chamber, which allows you to package scrap metal.

Container systems

Such systems are similar in design and structure to previous installations, with the only difference being that container installations are more mobile. Whereas systems for working with scrap are usually monolithic systems. If necessary, the container unit can be quickly dismantled and transported to the desired location, which significantly increases the mobility of the CPT. In all other respects, CPTs are similar to previous systems - they consist of several independent departments, the installation is equipped with a special chamber for pressing chopped scrap metal.

Technical characteristics of the combined shear press HB5222

| Parameter name | HB5221 | HB5222 | NG5222 |

| Basic parameters of press shears | |||

| Maximum sheet thickness, mm | 13 | 16 | |

| The largest dimensions of the processed strip with sheet metal shears (thickness x width), mm | 16 x 150 | 18 x 190 | 16 x 150 |

| The largest dimensions of the circle (diameter) processed with grade scissors, mm | 45 | 50 | 45 |

| Largest dimensions of a square processed with grading scissors, mm | 40 | 45 | |

| Largest dimensions of 90° corner, mm | 125 x 125 x 12 | 125 x 125 x 14 | 125 x 125 x 12 |

| The largest dimensions of the corner at 45°, mm | 90 x 90 x 9 | 100 x 100 x 10 | 90 x 90 x 9 |

| The largest dimensions of the corner when cutting with special knives at 90°, mm | 160 x 160 x 12 | 160 x 160 x 12 | |

| Largest channel dimensions, profile number | 18 | 18a | 18 |

| The largest dimensions of the I-beam, profile number | 18 | 18 | 18 |

| The largest diameter of the hole punched by a hole-punching press (diameter x material thickness), mm | Ø 30 x 16 | Ø 32 x 16 | Ø 30 x 16 |

| The largest dimensions of the grooves to be punched (length x width x thickness), mm | 80 x 63 x 10 | 70 x 65 x 10 | |

| Maximum distance from the axis of the punching press to the frame (extension), mm | 500 | 500 | 500 |

| The number of continuous knife strokes per minute is not more than | 58 | 53 | |

| The number of single knife strokes per minute is not more than | 18 | 17 | 18 |

| Maximum length of sheets to be cut along the back stop, mm | 70..1000 | 70..1000 | 70..1000 |

| Nominal cutting force, kN (tf) | 400 (40) | 630 (63) | 400 (40) |

| Electrical equipment of the machine | |||

| Electric motor, kW (rpm) | 4,8 (2790) | 4,8 (2790) | 4,8 (2900) |

| Dimensions and weight of press shears | |||

| Dimensions of press shears (length x width x height), mm | 1900 x 700 x 1950 | 1780 x 1030 x 1865 | 1900 x 1660 x 1950 |

| Weight of press shears, kg | 2070 | 2500 | 1940 |

- Banquetov A.N., Bocharov Yu.A., Dobrinsky N.S. and others. Press-forging equipment, 1970

- Bocharov Yu.A., Prokofiev V, N. Hydraulic drive of forging and pressing machines, 1969

- Belov A.F., Rozanov B.V., Linz V.P. Volumetric stamping on hydraulic presses, 1971

- Zhivov L.I. Forging and stamping equipment, 2006

- Kuzmintsev V.N. Forging with hammers and presses, 1979

- Rozanov B.V. Hydraulic presses, 1959

- Titov Yu.A. Equipment for forging and pressing shops, 2001

- Shcheglov V.F. Forging and pressing machines, 1989

- Berlet Development of forging drawings, 2001

- Rudman L.I. Sheet Forming Equipment Handbook, 1989

- Romanovsky V.P. Handbook of Cold Forging, 1965

- Okhrimenko Ya.M. Technology of forging and stamping production, 1966

- Kuzmintsev V.N. Forging with hammers and presses, 1979

- Meshcherin V.T. Sheet stamping. Atlas of circuits, 1975

Bibliography:

Related Links. Additional Information

- Manufacturers of forging and pressing equipment in Russia

- Classification and designation of hydraulic and crank presses

- Mechanical presses

- Hydraulic presses

- Automatic forging and pressing machines

- Bending and straightening machines

- Guillotine shears, press shears

- Hammers

- Repair of hydraulic systems of metal-cutting machines

- Designations of hydraulic circuits of metal-cutting machines

- Repair of gear hydraulic pumps

Home About the company News Articles Price list Contacts Reference information Interesting video KPO woodworking machines Manufacturers

Main technological parameters of scissors

The passport for this equipment, which is produced by Kuvandyksky, provides the following technical characteristics:

- Maximum dimensions of the strip to be cut, mm: thickness – 16; width – 150.

- The maximum diameter of cut round steel, mm – 45.

- Maximum dimensions of an isosceles angle, mm: for straight cutting - 125×125×12; when cutting at an angle of 45° - 90×90×9.

- The maximum number of channel and I-beam is 18U.

- The maximum diameter of the hole to be punched (for a strip 16 mm thick), mm – 30.

- The maximum dimensions of the cut groove in the workpiece (length × width × thickness), mm - 70 × 65 × 10.

- The maximum length of a sheet or strip cut using a back stop, mm – up to 1000.

- Nominal force, kN – 580.

- Number of strokes, min-1 - 18.

- Electric motor power, kW – 5.5.

Overall dimensions, weight, as well as other design parameters available in the description fully comply with the requirements of GOST 7355. The manufacturer has the right to make minor changes to the design that do not lead to a deterioration in the operational capabilities of the scissors. These changes are reflected in the product passport.

Specifications