Design and principle of operation

The functioning of a forging hammer is based on the dynamic impacts of the working body - the rod, connected to the head (the striking part of the machine) and devices that control the force of impact. Other required structural elements are:

- a piston connected to a woman;

- base (fixed on a solid surface);

- bed (guides for moving units are fixed on it);

- drive equipment;

- shield fence (for operator safety);

- electrical equipment;

- compressor cylinder (for pneumatic hammers).

Early machines were either foot or hand driven. A modern forging hammer is equipped with a convenient control system that minimizes the effort of the forge worker.

Rice. 1. Pneumatic hammer device.

(1 - working cylinder, 2 - compressor cylinder, 3 - piston, 4 - crank mechanism, 5 - woman, 6 and 7 - upper and lower strikers, 8 - cushion, 9 - air distribution mechanism, 10 - deformable workpiece)

Briefly, the device works like this:

- the workpiece is placed in the lower part of the hammer (usually the hammer);

- set the device to a certain impact frequency and set it in motion;

- after activating the hammer, the driven upper part hits the workpiece;

- the dynamic effect continues until the workpiece acquires the desired shape.

When a forging hammer operates, the reciprocating movement of the crank mechanism is converted into the same movement of the piston. This allows you to perform many operations on it.

Homemade hammer: super hammer

It will be easier to make a homemade blacksmith hammer for forging metal products if you divide all operations into several stages in the following sequence:

- preparing the base for installation of a forging hammer;

- designing a machine frame with springs;

- assembly of the working mechanism;

- installation of a homemade device.

Important! The design of a forging hammer largely depends on its type. It is possible to make a mechanical version at home, but constructing an electric or hydraulic hammer yourself is extremely problematic.

But before detailed instructions indicating how to make a blacksmith hammer, it should be noted the importance of creating a drawing of the future design.

Blueprints

You can make a forging hammer with your own hands in a workshop or garage. But before work, it is important to determine the current dimensions of the unit, describe all its component parts, which will subsequently make it possible to determine the weight of the product and its functionality.

To do this, you will need to draw up yourself or find on the Internet drawings and an assembly diagram of such a structure with a detailed description of all its parts.

On a note! It is easier to make mechanical-type forging hammers with your own hands, based on the classification of such units according to the nature of the force used.

Foundation

After creating the drawing, the forging devices proceed to forming the foundation. A homemade forging hammer must be installed on a flat area prepared in advance. This is necessary for the normal operation of the device and eliminating the risk of it tipping over during operation.

Electrical diagram of a forging hammer.

At the site where the structure will be installed, you need to dig a hole of the current size. Its bottom is carefully sprinkled with sand and crushed stone, watered and compacted. A reinforcing frame is mounted on top of the completed layer of sand cushion, for which reinforcement with a diameter of 12-14 mm is used.

It is extremely important not to forget about dressing, which is carried out every 250-300 mm.

The concrete solution is prepared in a ratio of 1:2:3, which will require the following materials:

- cement grade M400;

- crushed stone fraction 10-20;

- sand.

Filling should be done at a time, constantly compacting the mass. This will avoid the formation of voids inside the foundation.

At the final stage of manufacturing the base for a homemade hammer for forging into uncured concrete, it is worth installing anchor bolts, onto which the unit will subsequently be additionally fixed.

Frame

When assembling a homemade forging hammer, it requires a welding machine, with which the structure frame is assembled. It is made from profile pipes or other types of rolled metal that have high strength.

For additional stability of the product, you need to install spacers, as well as cross beams.

Hammer assembly

To begin work, you will need to assemble the frame of the unit and install it on the prepared base. The lower slides are fixed with anchor bolts and nuts, and the remaining guides and jumpers are welded to them using a welding machine.

The shaft is inserted into the racks, and then a lever with a hammer is attached to it. Drives with a pedal or lever are assembled in the same way.

A homemade forging hammer is equipped with an anvil. It performs an extremely important function, so its installation must be carried out with all responsibility. The anvil is fixed exactly under the lower position of the side, and a block of wood is placed under it.

It will act as a shock absorber when the hammer hits the anvil. The anvil is made from a piece of rail or channel, but preferably with a hardened front part. After the structure is assembled, it is painted.

Forging machine capabilities

The dimensional hammer is designed to perform the following blacksmith operations:

- bending parts (sometimes the workpiece is preheated);

- drawing (extension of the template by reducing the cross section);

- making holes (a punch/piercing is placed on the rod);

- sediment (reverse action to drawing);

- chopping (using axes).

Some of them are clear.

Rice. 2. Operations performed using a forging hammer.

Most well-known products perform all of the above operations. However, there is an important criterion for their classification.

Electrical equipment of hammer MA4129A

Electrical diagram of forging hammer MA4129A

Electrical diagram of the forging hammer ma4129a

The electrical equipment of the hammer consists of an electric motor, a push-button station with “Start” and “Stop” buttons, an electrical control cabinet and a power supply cable.

Instructions for installation and operation of electrical equipment of the hammer MA4129A

The electric motor is attached to the sub-motor plate and installed in the niche of the frame. The electrical control cabinet and push-button station are located near the hammer, on the side of the control handle, on a wall or stand in a vertical position with a deviation from the vertical of no more than +5.

The control cabinet contains electrical equipment, the elements of which are connected to each other by installation wires in accordance with the circuit and wiring diagrams. The switch handles are located on the cabinet lid. The input batch switch can be replaced with an automatic one.

The electrical control cabinets supplied with the hammer are rated at 360V with a 36V AC 50Hz control circuit. By special order they can be manufactured for other voltages of the power circuit and control circuit with a current frequency of 60 Hz.

Before installation, you must open the cabinet with a special key and perform the following work:

- remove protective grease

- check the tightness of bolted connections

- release the magnetic systems of relays and starters from the locking devices installed before transportation

Types of devices

This criterion is the type of substance used in the compressor cylinder. Hammers are distinguished:

Rice. 3. Mechanical forging hammer with foot drive.

- steam-air (steam or atmospheric air);

- hydraulic and hydrostatic (fluid under pressure);

- gasoline (work on the principle of internal combustion engines);

- gas (liquefied gas);

- electromagnetic (the energy of electric and magnetic fields is used);

- mechanical (powered by human physical effort);

- spring-spring (the spring accelerates the fall of the piston down);

- pneumatic (gas under pressure).

Among the listed devices, the forging pneumatic hammer stands apart. It has its own pneumatic cylinder, which eliminates the need to use additional energy sources and make the structure heavier. More details about the devices below.

MA4129A Location of the components of the forging hammer

Location of the components of the hammer ma4129a

List of components of the MA4129A forging hammer:

- Bed - MA4129A-11-001SB

- Drive - MA4129-21-001SB

- Control - MA4129-41-001SB

- Fencing - MA4129-71-001SB

- Oil line - MA4129-81-001SB

- Electrical equipment - MA4129-91-001SB

Features of pneumatic hammers

The equipment refers to forging devices that perform all the previously listed operations, as well as twisting, cutting and shaping of workpieces.

They are controlled by hand lever or pedal. Structurally, the forging pneumatic hammer is complemented by an oil pump that lubricates the working cylinders (of which, by the way, there can be two). Conventionally, pneumatic hammers are divided into 2 groups:

- for artistic forging (models with a mass of falling parts up to 75 kg);

- for production (MPF - from 150 to 2000 kg).

The advantages of the equipment are energy intensity, sensitivity of adjustment of operating modes, ease of control, and durability. The disadvantage is the large size and weight, but the need for transportation rarely arises.

General view of the MA4129A forging hammer

Photo of forging hammer ma4129a

Photo of forging hammer ma4129a

Photo of forging hammer ma4129a. Back view

3-D model of a forging hammer ma4129a from the site asmcg-studio.ru

3-D model of a forging hammer ma4129a from the site asmcg-studio.ru

3-D model of a forging hammer ma4129a from the site asmcg-studio.ru

Technical characteristics of the MA4129A forging hammer

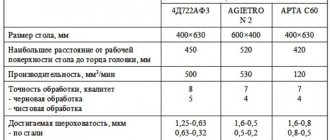

| Parameter name | MA4132 | MA4129 | MA4129A |

| Basic parameters of the hammer | |||

| Nominal mass of falling parts, kg | 160 | 75 | 60 |

| Impact energy, not less, kJ (kGf*m) | 3,3 (330) | 1,55 (155) | 1,55 (155) |

| Maximum stroke of the woman, mm | 460 | 385 | 365 |

| Impact frequency, 1/min | 210 | 210 | 220 |

| Distance from the axis of the wheel to the frame (offset), mm | 340 | 300 | 280 |

| Distance from the mirror of the lower striker to the lower edge of the woman's box (clear height of the working area), mm | 360 | 370 | 260 |

| Dimensions of the upper striker mirror, mm | 75 x 190 | 63 x 130 | 63 x 130 |

| Distance from the bottom striker mirror to the floor level, mm | 800 | 800 | 800 |

| Optimal cross-section of a square workpiece, mm | 80 x 80 | 60 x 60 | 60 x 60 |

| Optimal diameter of round workpiece, mm | 90 | 80 | 80 |

| Electric motor, kW | 15 | 7,5 | 7,5 |

| Hammer dimensions and weight | |||

| Hammer dimensions (length x width x height), mm | 930 x 1860 x 2160 | 1566 x 790 x 1900 | 830 x 1860 x 1900 |

| Hammer weight, kg | 3540 | 3100 | 3190 |

- Pneumatic forging hammer MA4129A. Operating manual, 1967

- Banquetov A.N., Bocharov Yu.A., Dobrinsky N.S. and others. Press-forging equipment, 1970

- Bocharov Yu.A., Prokofiev V, N. Hydraulic drive of forging and pressing machines, 1969

- Belov A.F., Rozanov B.V., Linz V.P. Volumetric stamping on hydraulic presses, 1971

- Zhivov L.I. Forging and stamping equipment, 2006

- Kuzmintsev V.N. Forging with hammers and presses, 1979

- Rozanov B.V. Hydraulic presses, 1959

- Titov Yu.A. Equipment for forging and pressing shops, 2001

- Shcheglov V.F. Forging and pressing machines, 1989

- Berlet Development of forging drawings, 2001

- Rudman L.I. Sheet Forming Equipment Handbook, 1989

- Romanovsky V.P. Handbook of Cold Forging, 1965

- Okhrimenko Ya.M. Technology of forging and stamping production, 1966

- Kuzmintsev V.N. Forging with hammers and presses, 1979

- Meshcherin V.T. Sheet stamping. Atlas of circuits, 1975

Bibliography:

Related Links. Additional Information

- Manufacturers of forging and pressing equipment in Russia

- Classification and designation of hydraulic and crank presses

- Mechanical presses

- Hydraulic presses

- Automatic forging and pressing machines

- Bending and straightening machines

- Guillotine shears, press shears

- Hammers

- Repair of hydraulic systems of metal-cutting machines

- Designations of hydraulic circuits of metal-cutting machines

- Repair of gear hydraulic pumps

Home About the company News Articles Price list Contacts Reference information Interesting video KPO woodworking machines Manufacturers

Construction of a frame structure for a forging hammer

A channel is used to make the frame. Typically, its parameters are selected based on which products will be processed. As a rule, a 12x8 cm channel is suitable for household equipment.

IMPORTANT TO KNOW: Types of magnetic drilling machines

The distance at which the channel sections will be located from each other is selected taking into account the size of the anvil - it can be 80-100 cm.

Either the same channel or an iron pipe are used as metal spacers.

In this case, the spacer in the front part of the frame - the future location of the anvil - must be mounted under the channel.

Since it is the front part of the forging installation that will be subject to heavy loads during the working process.

The rear spacer of the installation should be welded near the top level of the channels.