A portable barbecue is the most desirable attribute for complete outdoor recreation. There are multiple industrial designs of this product that can satisfy many outdoor enthusiasts. But it is much preferable to make a collapsible grill with your own hands.

A homemade version of such a portable roaster always compares favorably with industrial products, since it is cheaper and it becomes possible to incorporate all the necessary nuances into your own design.

There are numerous drawings and detailed descriptions of the process of making such crafts, but only a few have proven themselves to be preferable samples that are worthy of repetition. As a rule, they are time-tested, scrupulously tested by practice and fully perform their assigned tasks.

Let's consider several of the most popular versions of making homemade barbecues of a collapsible design.

To replicate all the metal structures proposed below, you will need a number of tools and materials:

- Directly the material. Steel ~ 3-5 mm thick.

- Grinder with a set of cutting and grinding wheels.

- Metal ruler and square.

- Measuring and marking tools.

- Fasteners Bolts with M5 nuts or homemade threaded studs.

If you have all of the above, you can begin to directly create a collapsible barbecue.

Design Features

They belong to the group of portable devices.

They can be disassembled at any time and stored in a house or barn, or taken with you if you are afraid to leave the grill on the site. Let's consider the main advantages of such designs:

Light weight

Parts for mobile prefabricated barbecues are made from thin sheets of metal. Their thickness rarely exceeds 2-4 millimeters. In the lightest and cheapest models, the thickness of the firebox walls ranges from 0.5 to 1.5 mm.

Thanks to this, it is possible to reduce the weight of the product to 5 kg, and in some cases achieve even less weight.

Compactness

After use, the structure is disassembled into several parts, after which all parts can be put into a box or a special bag-cover. As a result, the grill takes up little space.

It fits easily into the trunk of a car or a backpack. This makes it easier to get out into nature. And if such a device is used in the country, it can easily be put away for storage when the barbecue season is over.

Easy assembly

Most manufacturers make barbecues consisting of 5 parts - 2 short walls with legs, 2 long firebox walls and a durable bottom, which is usually a simple sheet of metal.

Most often, parts are fixed in specially cut grooves. Less commonly, the package includes special bolts that increase the reliability of the assembly.

Lower prices compared to stationary barbecues. This is also due to the reduced amount of material and simplified design, which is less reliable in prefabricated models.

Easy cleaning . Over time, fumes, soot, and ash residues accumulate on any grill. In folding grills-diplomates, as well as stationary models, it is not so easy to remove dirt.

Optimization of collapsible roasters for convenient transportation and reducing their cost also had a negative effect.

Therefore, when purchasing, you need to consider the following disadvantages of such devices:

Fragility

Thin sheets of metal quickly burn out when exposed to high temperatures. It’s rare that a collapsible grill can last more than 5 years if the thickness of its parts is less than 1.5 mm.

Low heat capacity

Thin metal walls cannot accumulate heat well. As a result, more coal is wasted than in structures made of metal larger than 4 mm.

Wall deformation

One of the common problems with prefabricated barbecues. Due to the low thickness of the metal, the parts begin to wear out, after which the assembly of the fryer becomes more complicated or becomes impossible.

Low corrosion resistance

Many budget models are made from structural steel, which rusts easily. Less commonly, special heat-resistant steel is used as the main material.

The best option - a stainless steel grill - will cost more.

Advantages and disadvantages of a portable barbecue

The main advantages of making a folding barbecue with your own hands include:

- compactness and ease of transportation (especially if we are talking about the diplomat model);

- small weight of the product (on average weighs from 6 to 8 kg);

- the ability to install on any surface due to the stability of the structure (only if the product is manufactured correctly);

- ease of operation and further maintenance;

- strength and durability;

- the ability to make a product of original design;

- affordable price.

When making a camp grill yourself, you can think through everything down to the smallest detail, creating a truly exclusive model that is more reminiscent of a real grill complex. And if the product is additionally equipped with a stainless steel grill, it can also be used as a barbecue. In other words, a self-made grill will delight owners with its versatility and functionality.

As for the disadvantages, it is worth adding to them:

- small wall thickness so that the product has low weight. This leads to the fact that the grill does not hold heat well;

- rapid wear of parts due to constant assembly and disassembly of the structure;

- poor stability. This only appears if the grill weighs very little, or if it was originally designed incorrectly;

- unaesthetic, which can be easily corrected by painting the product.

How to choose?

Before buying a collapsible barbecue, it is important to decide for yourself in what situations you are going to use it. The characteristics of the product will depend on this.

When going on a picnic without a car, there is nothing left to do but choose the thinnest-walled models, and dispose of the grill after use. If you have a car, then it’s easier - you can choose a grill with walls up to 1 mm or larger. When used in a summer cottage and rarely carried (or seasonal use), you can look at large and heavy models.

When choosing, pay attention to the following criteria:

Metal thickness

Up to 1 mm - the structure is short-lived, will quickly burn out and become deformed. From 1 to 2 mm - the grill will last 2-3 seasons if handled carefully.

With a wall thickness of 2 to 4 mm, you can count on long-term use and high strength of the device. But we must take into account that it will have the appropriate weight. Models with parts over 5 mm thick are rare.

Firebox wall height

The optimal depth of the roasting pan is 15 cm, when the meat is evenly fried over the coals. If the skewers are placed higher, the kebabs will turn out too dry.

If you fix them too low, the meat will burn on top before it has time to fry inside.

Grill width

For most models, this figure ranges from 30 cm to 40 cm. For the width of the firebox, skewers or grill grates of suitable length are selected.

Grill length

Determines how much meat can be cooked at once. The standard for 6 skewers is 45-50 cm. For a large family or large company, manufacturers offer models about 80 cm long.

They can easily accommodate 10-12 skewers.

Material

The best choice is a stainless steel grill. It is lightweight, not subject to corrosion, and is highly durable and reliable. In second place is heat-resistant steel.

The risk of its deformation during barbecue frying is minimal. Structural steel is cheaper, but burns out faster.

We do it ourselves (no welding!)

Purchased versions of barbecues often last quite a short time, quickly “burn out”, and deteriorate.

There is an exit. It is much more reliable to use a self-made product made of thick and durable metal. To make a small collapsible grill, you will need:

Metal sheets (thickness - 3 mm, other dimensions are arbitrarily proportional)

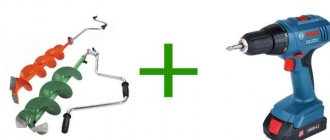

Bulgarian

Screwdriver

Metal wheels, including grinding wheels

First, one pattern is made, and then all the other parts are drawn out from it.

Dimensions:

- the width of the leg at the bottom is 5 cm, at the top - 3 cm (sawed at an angle, rounded at the top, because a sharp corner will be dangerous);

- slot along the leg - 15 cm;

- total length of the barbecue including legs is 30 cm;

- the working area (where coal is laid) will be 41 cm wide, 17 cm high;

- the distance from the groove to the cut (where the side wall insert will be) is 1.5 cm;

- a piece 2 cm wide is sawn off from below for the bottom.

We cut out the marked template, placing it on a convenient surface and using a grinder.

We'll sand the edges, but there's no need to make any slits yet, because the product will be used under the grille. If needed, it will not be difficult to add them at any time. Another option is to simply make notches for the skewers.

Next, we’ll make a second similar part (marking it according to the first template), and then the side walls. The main long parts differ from the remaining two in the location of the slots: they will be on top so that the grill can be raised.

When all the parts are ready, we begin assembly. Insert the side walls into the slots on the main ones and close the lid on top.

A handle is attached to the top side.

It is very important to make the slot so that it is not close to the middle of the side, otherwise it will be inconvenient to carry and disassemble the grill.

Holes are made according to personal choice. If desired, you can raise the bottom with firewood or something else. In any case, an additional outlet for steam will not hurt.

The cuts for the skewers are made, as usual, not very deep, exactly opposite each other on opposite side walls. It’s better to make them in advance just in case, even if you plan to use a wire rack rather than them.

It is recommended to sand and round the edges for safety and a beautiful appearance.

The width of the side wall will be approximately 31.5 cm, and the height will be equal to the same side of the main part.

The folded bottom part, which needed to be left 2cm if the bottom was removed, looks like this:

As you can see, you can make such a grill yourself quite easily and quickly. However, the maximum sheet metal thickness for it is 3-4 mm. It will be much more difficult to work with material of 5 or more millimeters, because it bends much worse even in a vice, and, moreover, by hand.

Even to bend the bottom of the main parts, you will have to weld them to the rail with the edge that needs to be deformed. Using a hammer, carefully form the bend itself.

There is a minor drawback: after these steps, the metal will look a little beaten. However, this is compensated by the fact that it is located in the inner part of the grill and will not be visible from the outside.

The diameter of the lower holes is 13 mm.

The finished grill looks like this:

Manufacturing scheme

To make a “suitcase” you will need minimal welding skills.

- The bottom is cut out of a sheet of iron, and holes about 10 cm in diameter are made on the sides using a drill.

- The sidewalls are cut out and bent inward (in the drawing this is a broken line). In order for them to bend without problems, loops should be placed using fasteners or welding between the bottom and the walls.

- Next, removable walls are cut out from the end, which are inserted into the sides and bottom when assembling the barbecue. To do this, thin slits are made on the side, as shown in the diagram.

- 4 nuts are welded to the bottom for future legs of the structure. To do this you will need 4 reinforcement rods 60 cm long.

- For ease of carrying, you should weld a handle to the suitcase.

- It can be closed with a special latch or a regular hook screwed to the wall. This detail is also necessary to ensure that the suitcase does not fall apart and does not open during transportation.

- To make the result look aesthetically attractive, you can cover the “suitcase” with heat-resistant paint in cans, which can withstand temperatures up to +600ºС and does not deform.

Drawings with dimensions

Below are a variety of drawings of collapsible barbecues that you can make yourself:

Care and operation

In order for a do-it-yourself grill suitcase to last as long as possible, it is necessary to consider its protective treatment and strictly observe the operating and storage conditions of the product:

- the structure is treated with anti-corrosion agents, and the metal is blued, increasing its resistance not only to fire, but also to various mechanical damage;

- when painting the product, silicone enamel is selected, which can be purchased at any car service center;

- With the onset of the cold season, the product is disassembled, inspected for defects, and carefully packaged before the onset of warm weather. At the same time, all its moving elements are lubricated with machine oil.

In conclusion, it is worth noting that according to the drawing, you can easily and simply make a collapsible barbecue on your own, having little welding skills. By spending a little free time and energy, you will have a great opportunity to delight yourself and your loved ones with aromatic and deliciously prepared barbecue in nature.

Rating of the best models

Sokol 62-0033 ★5.0

The best collapsible grill, according to buyers, has a medium-sized brazier, is distinguished by its reliable design and thick walls that are resistant to heat.

The brand name is used as a laconic and at the same time stylish decor. The lack of leg locks is not everyone's cup of tea, but for most users this drawback is not that significant.

Average user rating: 5

Specifications

- Material: steel.

- The thickness of the firebox walls is 1.5 mm.

- Width - 29.5 cm.

- Length - 44.5 cm.

- Height - 50.5 cm.

- The height of the roasting pan is 15.5 cm.

- Weight - 8.7 kg.

pros

- Thick walls.

- Does not deform at high temperatures.

- Attractive appearance.

- Durable metal.

Minuses

- There are no leg locks. The grill falls apart when carried when assembled; it must be assembled immediately before use.

You can order with delivery from the Yandex warehouse on the product page in Yandex.Market.

Useful tips for beginners

Experienced professionals give practical advice to beginners:

- When choosing consumables for making a collapsible barbecue, you should give preference to heat-resistant sheets rather than heat-resistant ones. They are more resistant to corrosion and can withstand high temperatures;

- for ease of transportation of the product in the trunk of a car, its legs should be made not 60 cm long, but 50 cm. Moreover, it is not recommended to use aluminum in their manufacture;

- For those who do not know how to use welding, it is worth choosing to make a barbecue using the groove assembly system.

You can independently make not only a collapsible grill diplomat, but also original products with which you can surprise your family and friends. To do this, experts recommend using empty gas cylinders or small metal barrels. With some imagination and a little effort, you can make a barbecue that is distinguished not only by its aesthetic appearance, but also by:

- functionality;

- sufficient wall thickness;

- mobility;

- affordable cost;

- ease of use.