Why does a chainsaw need attachments?

There are special attachments for chainsaws on sale, with the help of which the functionality of the tool is significantly increased.

Using additional equipment from a chainsaw, you can make a wood splitter; it will help you cope with logs that are difficult to split with an ax, or a boat motor, for trips on a rubber boat.

Essentially, attachments are necessary to get the most out of your chainsaw so that it doesn't sit on the shelf gathering dust, but is used every day to solve a wide variety of tasks.

No special education or skills are required to install the attachments; everything is simple and easy.

What attachments are there for chainsaws?

Today, a large selection of chainsaw attachments have been developed by manufacturers and are commercially available. More specifically, for your saw you can buy:

- Boat motor attachment.

- Winch.

- Pump.

- Motor drill.

- Wood splitter

- Device for cutting boards.

If you like to make things with your own hands, then the saw will be an excellent assistant, because it can be used as a power unit for your inventions. For example, the video below shows how you can make a go-kart for your child from a simple chainsaw. It's very interesting and not as difficult as it seems.

And the next video shows a homemade snow blower, the engine of which is a Shtil chainsaw. The idea is very good, but the snow blower is a little unfinished, but it is still able to make cleaning the territory of a private house easier.

Now let’s look at each of the attachments in more detail, look at the pros and cons of use, and draw a conclusion about how the use of the attachment affects the life of the chainsaw and its performance.

boat motor

The attachment is designed for installation on small rubber boats with a transom. Characteristics:

- Gear ratio 1:2.

- Maximum speed in still water is 20 km/h.

- Three-blade propeller with a diameter of 150 mm.

- Fuel consumption is 1 liter per hour.

- Weight when assembled is 8 kg.

Such characteristics allow the nozzle to be used by those who do not need high speed movement through the water, but simply need to get from point “A” to point “B”. It is popular among fishermen because it is light and compact and fits into the trunk of a passenger car.

All necessary fasteners are supplied with the nozzle. There are instructions for installing the nozzle and its proper use.

The main advantage of using such an attachment for a chainsaw is saving on the purchase of a boat motor.

You can learn how to install a chainsaw on a boat motor attachment by watching the video.

Winch

Another useful attachment for a chainsaw is a winch. It can be used to lift loads weighing up to one and a half tons. A conventional electric winch requires an electric current to operate, which significantly reduces its capabilities. A chainsaw with a winch can be used anywhere.

Having such an attachment on a firewood harvesting site, you can load tree trunks, cross-cut into several logs. Also, if necessary, such an attachment will allow you to pull out a stuck passenger car; it is not suitable for trucks.

The cost of a winch for a chainsaw is a little more expensive than an electric one, but its mobility and ease of use make up for the difference.

There are several models of chainsaw winches on sale, which may differ in cable length, size and weight. On average, the length of the cable is about 30 meters, weight no more than 12 kg.

This is interesting: using a plow together with a chainsaw winch, you can cultivate a plot of land with a minimum of effort.

How to plow the ground with a chainsaw and winch is shown in the video. The advantages of this method are that in this way it is possible to cultivate land in suburban areas where there is no possibility of connecting to electricity.

water pump

A special attachment called a chainsaw pump will help pump out water from a flooded cellar, pump up a water tank for irrigation from a well, or simply pump water from one place to another.

The device is quite simple and does not require special skills to install on the saw. Its advantage is mobility and connection speed. In addition to the nozzle, you will need to purchase hoses. Pumps, like other saw attachments, are produced by several manufacturers, so they can have different performance and other characteristics.

This attachment is universal and can be installed on chainsaws of various models and brands. For those who are not used to paying for additional equipment for a chainsaw, you can make a pump yourself.

Motor drill

Another useful attachment in everyday life is a motorized auger (ice auger). There are a lot of options for this console, including homemade ones. It can be useful not only for fans of winter fishing, because it can be used to drill holes for installing fence posts.

The advantage over electric options is mobility, since the drill can be used regardless of the availability of electricity.

Important! To install the drill attachment, you will need to remove the standard clutch and drive sprocket from the chainsaw, for which you need to lock the crankshaft. You can find information on how to properly remove the clutch from a chainsaw on our website.

An adapter coupling is supplied with the saw drill, which is installed instead of the drive sprocket.

Wood splitter

Thick lumps are difficult to split with an ax; to make the process easier, you can install a wood splitter attachment on a chainsaw. It is screwed into the block and, due to its cone-shaped shape, splits it.

The attachment is universal and can work on various models of chainsaws. User reviews about this device are positive, because it really facilitates the process of splitting large lumps.

The cost of the wood splitter attachment is reasonable, currently it does not exceed 1000 rubles. You can buy it on specialized websites or in petrol stores. Installation of this gadget does not require any specific skills; the manufacturers provide instructions.

Jointer

If you need to plane a small number of boards, but you do not have a specialized machine, then the jointer attachment will help you do this.

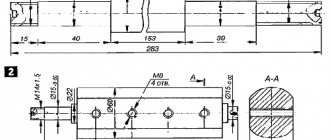

The attachment is mounted on standard bolts for fastening the tire; instead of the clutch, a drive pulley is installed on which the belt is put. Through the belt, a force is transmitted from the drive pulley to the driven pulley, which causes the planing shaft with two knives to rotate.

The system is very simple and reliable; the quality of processing depends on the maximum number of revolutions of the chainsaw on which it is installed.

Important! Manufacturers do not recommend using a jointer attachment, since with it the chainsaw operates for a long time at maximum speed with virtually no load, which can cause the engine to overheat.

In order to compensate for the lack of load on the engine when using the jointer attachment, you can slightly reduce the maximum number of revolutions. You can find instructions for adjusting the carburetor of a chainsaw on our website.

The attachment is not universal; for it to work, you need to replace the drive sprocket with a pulley; the mounts are different for all chainsaws. Therefore, when purchasing, you need to consult and choose a model of attachment suitable for your chainsaw.

Bark beetle

Another attachment for a chainsaw, which is designed for cleaning tree trunks from bark.

It is very similar to a jointer, is attached in a similar way and has two pulleys and a belt. The main difference is that the bark beetle does not have a stop bar that prevents the knives from going deep, as a result of which they only remove a certain amount of chips.

Bulgarian

One of the most popular attachments, about which users leave only positive reviews, is an angle grinder, or it is also called an angle grinder, but it is not one, because it is intended only for cutting.

Attaches to the standard place of the tire. Not universal, it is selected for the model of chainsaw for which it is intended. Not expensive and easy to use. Consists of the following elements:

- drive pulley;

- frames;

- driven pulley with shaft and disk mount;

- force transmitting belt;

- protection.

The simplicity of the design and standard grinder consumables (discs) made this attachment very popular. Its advantage is mobility, the ability to be used in places where there is no electricity.

By the way, you can read in one of the articles on our website about how to make an angle grinder from a chainsaw.

In place of the cutting disc for metal, which is shown in the photo, you can install carbide ones for cutting concrete and use a saw with an attachment as a wall chaser.

Advice. When working with an angle grinder attachment, the engine experiences significant load, so it is not recommended for chainsaws with a power of less than 2 kW.

The following video shows how to assemble, install, configure and operate the attachment. The video shows that the Shtil MS 180 chainsaw with a power of 1.5 kW cannot cope with the load, and a drop in speed is noticeable. To prevent this from happening again, use more powerful saws.

Homemade goats

When planning to make a sawhorse for sawing firewood, you can choose any of the designs described. But if standard X-shaped stands can be made from both wood and metal, then clamping stands can only be made from metal. Metal ones of any kind are lighter and more durable, but also more expensive, especially if you consider that wooden trestles can be assembled from waste material - bars and boards left after construction, pickets, thick branches.

The simplest goats consist of two intersecting supports, the connection of which is shifted upward from the center. They connect at an angle of about 45 degrees. But if you make the mount movable, you can change both this angle and the working height of the equipment. But to prevent the legs from moving apart, you will need to come up with a stopper. This can be strong twine or chain.

Advice! Double-horned sawhorses for firewood are not reliable and convenient; it is advisable to strengthen them with one or two additional supports.

Homemade four-horned goats from bars and picket fences Source proraboff.rf

Attachments for Shtil and Husqvarna chainsaws

There is no special attachment that would be suitable only for the Shtil chainsaw and would have any unique functionality that others do not have. Everything that can be installed on Shtil saws has analogues for other chainsaws, the same with Husqvarna chainsaws. For this reason, when choosing a chainsaw, you should not pay attention to the advice of sellers regarding the purchase of a specific model, due to the possibility of installing additional equipment on it that expands the functionality.

The only thing you should pay attention to when choosing is power, because to work with attachments it is recommended to have a more powerful chainsaw.

What devices can you make with your own hands?

Many “garage” craftsmen do not spend money on buying chainsaw attachments, but make them themselves. In fact, there is nothing complicated about them and almost everything can be made with your own hands. All you need for this is a welding machine, sandpaper and the necessary knowledge and experience; spare parts from old tools and mechanisms, for example: chains, belts, pulleys, shafts, etc., can also be useful.

On the Internet you can find information on how to make an angle grinder attachment, a pump, a winch or a drill. In order to dispel doubts, we suggest watching a video that shows a homemade attachment for a Shtil chainsaw made from an old fishing drill.

Do-it-yourself sawhorses for sawing wood - how to make a device for sawing with a chainsaw

Preparation of firewood for the winter is familiar to almost every rural resident and land owner. And of course, for convenient sawing of firewood you need a special tool called a sawhorse. Surely many have seen photos of sawhorses for firewood in magazines or on the Internet. This is not a complicated device that you can build with your own hands, and besides, it should certainly be in the household. With their help, it is convenient to process wood, wooden blocks or metal profiles.

Solving the question of what to make a goat out of at the dacha is quite easy. Indeed, to make this simple traditional design, it is enough to use the following materials:

- a wooden beam of a regular shape. Assembling a device from this material is simple, but it is susceptible to high humidity.

- wooden posts of medium diameter, which are used to build fences. This method is financially economical, but do not count on its reliability.

- metal strips that will ensure the reliability of the structure and will serve for many years.

- various items sent for scrap.

Although the sawmill for sawing wood has a simple design, it is essentially a machine. Therefore, in the process of its manufacture it is necessary to take into account some nuances:

- it is necessary to have a plan (drawing) of the future structure with step-by-step instructions and calculation of the dimensions of all parts.

- It is important to correctly calculate the inclination of the supporting elements for ease of use.

By observing these nuances, you will get a reliable, stable and comfortable-to-use trestle design. In addition, due to its mobility, it can be installed anywhere.

When assembling, the main thing to consider is the size of the equipment, which depends on:

- human height,

- parameters of the future device,

- strength and size of the wood requiring processing.

Depending on this, the length of working time spent will be determined.

A device with a height of 90-110 cm is considered a win-win option. As a result, the person working behind it will not have to lean forward too much, and the hands will not get too tired due to the horizontal position.

There will be minimal stress on the spine, and the work process will become much easier.

When cutting wood using a two-handed saw, a stable support for the second hand is required. This should be taken care of in advance when assembling the device.

It is possible to make a stop from wood that can be installed in any desired place.

Chainsaw sawhorses must have a strong surface and room for free positioning of the wood for cutting, in order to avoid the chainsaw itself becoming jammed while cutting the blade.

An ordinary hand saw is most often used for preparing medium-sized firewood, so the goat will fit standard dimensions and is not difficult to build with your own hands, having in stock:

- wooden beam with a cross-section of 10x10 cm and a length of 1 to 1.2 m.

- beam with a cross-section of 5x5 cm and a length of 1.0 m for installing the legs of the device in the amount of 4 pieces.

- the same timber, but 36 cm long for making “horns” in the amount of 2 pieces.

- 1 inch beams in the amount of 2 or 4 pieces for strengthening the legs.

- self-tapping screws in the amount of 30-40 pcs. for fastening parts.

- stain, paint or varnish to protect the sawhorses from rotting timbers.

You can also use any available material suitable for constructing goats.

For assembly you need to prepare the following tool:

- hacksaw - for cutting and leveling the surface of the timber,

- corner - to control the evenness of elements important for the stability of the structure,

- graphite pencil for making the necessary marks,

- screwdriver or screwdriver for tightening the fastener,

- hammer,

- chisel,

- roulette,

- paint brush (4-5 cm).

Once the necessary material and tools are prepared, you can proceed directly to assembling the device. First, it is worth processing the main beams. Apply markings for future cuts in the amount of 6 pieces on each side. In total there should be 12 grooves for the arrangement of legs and horns.

To securely fasten each of the grooves, a depth of 2.5 cm is sufficient. For tight fastening of the beams, the grooves need to be sawed 2-3 mm less than for the legs. After processing and installing the structure on the legs, you should proceed to the fastening device using self-tapping screws.

Be sure to install reinforcement parts to ensure reliable stability and strength of the device, as well as to ensure the safety of the operator.

Saw off the lower parts of the legs so as to install fastener reinforcement elements. The assembled structure must be coated with a protective agent in the form of stain.

Dry the product and successfully use it on the farm.

To make sawhorses for a two-handed saw and similar tools, care should be taken to ensure increased stability of the structure. A more powerful beam at least 100 mm thick and a metal tie will help ensure this.

The width of the racks at the bottom is wider than at the top. In addition, you can provide a wooden screed from an ordinary short board.

You can make the device mobile by building folding trestles. But this is a labor-intensive and financially expensive process. For this you will need: 4 strong small beams, a metal pipe 1-3 m long, a limiter, drills for wooden parts.

The assembly process is quite simple. You need to make beams from a board 50 mm thick. Make cut marks for the legs. Make holes for the pipe on each strip.

Place the base in them and install the legs. Install a limiter so that they do not move apart. Metal sawhorses

The most durable, stable and long-lasting option for sawing wood. To create it yourself you will need:

- pipe (angle) with a diameter of 5.0 cm - 5 pieces, for the base,

- wooden beam no more than 10 cm and section 50x59 mm,

- grinder or hacksaw,

- yardstick,

- piece of chalk,

- welding machine, bolts.

Before starting work, it is necessary to prepare a sketch of the future device. After this, you can begin preparing the main beam, with marks for the installation of legs and horns.

Then the other necessary structural elements are prepared. To ensure mobility of the structure, the connecting units must be bolted so that they can be disassembled if necessary.

The connections of the stationary device can be welded using a welding machine. Finally, a beam is fixed to the base for the entire length of the structure to avoid contact between the saw and the metal.

Using our recommendations on how to make a sawhorse, you will create a stable structure, and cutting firewood on it will be a pleasure. You can also view ready-made sketches, photo and video materials on the Internet.

The finished product should be able to withstand significant weight, but it is important to store it in a dry area, avoiding humid climates or moisture.

Equally important is the correct use of sawhorses. You should not load too massive and heavy logs on it.

The folding design of the sawhorses is suitable for cutting firewood using a hand saw or chainsaw. This device is simply indispensable in the homestead for collecting firewood and stove logs to light the stove, barbecue or fireplace in the house.