How to cut logs into boards using a circular saw

Because how can you cut a log into boards? And is it possible to cut logs into boards using an ordinary circular saw? Below we will try to answer these questions and carefully outline the process of sawing logs into boards using an ordinary circular saw.

For longitudinal sawing of logs, a machine called a saw frame is usually used, in which the cutting equipment is strip saws stretched in a frame that makes reciprocating movements. On such a machine, the log is cut into boards in one pass. With all this, the log is attached to carts moving on rails. The log moves strictly progressively, without turning around its own axis. The rails along which the cart moves act as guides, so they are positioned quite accurately.

Similar longitudinal sawing of logs into boards can be done using a circular saw, if the longitudinal movement of the log is ensured. It is clear that it is difficult to hold a round log in a suitable position on a horizontal circular table. When sawing into boards, it will certainly roll and “scour” left and right. This situation must be excluded. Let’s say right away that you can’t count on a circular saw as a guide. On the contrary, the saw should be one hundred percent freed from performing such a role. Therefore, to fix the log in a suitable position, we came up with a fairly common additional device - a fin. This is how we christened this device when we adapted a circular saw for sawing small aspen logs during the construction of a Russian bathhouse. Together with a ruler (side guide) installed on the table, the driftwood really helped us.

Rice. 1. How to cut a log into boards using a circular saw: 1 - clamp; 2 - spacer; 3 - fin; 4 - circular saw; 5 - log; 6 — circular table; 7 — guide ruler; 8 — clamp stop; 9 - gasket; δ is the thickness of the sawn board. |

The thickness of the fin corresponds to the width of the cut, and the fin is installed with the ability to adjust its position. The two of them spread the log onto the boards. They begin to saw the log , simply pressing it against the ruler, in other words, because they are sawing ordinary boards. After the fin is one hundred percent in the cut, a spacer slightly wider than the width of the cut is inserted into the last one (from the end of the log). A piece of flat ratfil came up as a spacer. Next, a special clamp-handle was installed at the end of the log, which, firstly, held the board against the log until the end of the cut, and secondly, by which it was comfortable to pull the log. The spacer file, which had a notch on both sides, perfectly kept the board “in place,” in other words, the board being cut did not move relative to the log due to vibration. The peculiarity of the design of the clamp was that it had an additional jumper, which, when installing the clamp in the center plane of the log, does not allow the clamp to rotate upward around the axis of the clamping screw when acting on it with a hand. To ensure that the cuts when sawing a log are parallel, a flat is formed on the bottom of the log (first with an ax and then with a plane), which will determine the correct orientation of the cut first when sawing. The position of the ruler—its distance from the saw—determines the thickness of the board. So, the presence of a ruler on the table, a flat on the log, as well as a “fin” and a clamp will ensure successful sawing. When working, one of the “sawmills” pulls the logs using a clamp, the other presses the log against the ruler.

If you have to work alone, you will have to design something else. Firstly, in front of the machine (from where you are going to push the log ) you should install a stand under the log (goats) with a height equal to the height of the machine table. Secondly, in front of the saw on the machine table, you will need a clamping device that can ensure contact of the log with the ruler from the beginning of sawing to the end. The clamping device must securely hold the log against the ruler, without creating much resistance to pulling the log during sawing. Such a device, assembled from a small wheel with a pneumatic tire, for example, from a children's bicycle, and a rotary lever is shown in Fig. 2.

| Rice. 2. Clamping device: 1 — nut (rotary), 2 — clamping screw; 3 — front fork; 4 - wheel; 5 — “chain” fork; 6 — carriage unit; 7 - traverse; 8 — tip of the “chain” fork. |

The easiest way to make a lever is from parts of an old bicycle frame. The seat and down tubes are sawed off from the bottom bracket assembly, leaving only the “chain” fork, from which, in turn, the rear fork is separated. The front fork, having previously removed the tips from the feathers, is welded to the “chain” fork. A handle from a bicycle handlebar is placed on the rod of the front fork. In the middle of the “chain” fork (opposite the front fork), plates with slots for installing the wheel axle are attached (welded) to its stays (see Fig. 2). In addition to this part, you will need to make a rotary nut - a support for the pressure screw, the screw itself, a traverse and the lever axis. You will also need some fasteners (nuts, washers, pins), shown in Fig. 2.

Before sawing the log into boards, flats are formed on it (bottom and sides). The side flats of the log ensure the strict direction of its forward movement when sawing and the constancy of the force of the pressure wheel, which makes the work calm and confident. Before starting sawing, the wheel is pressed against the log manually, while simultaneously turning the screw using the handwheel. The screw in this device serves only to fix the position of the lever with the wheel, therefore it is equipped with a small handwheel, for example, from a water tap. This makes it possible to dose the force of the wheel on the log “by touch”.

Now the market offers a wide range of woodworking equipment. Many varieties of motor and electric saws have appeared. If you are going to cut logs into boards for a long time and seriously, and you don’t have a machine yet, consider using a saw from a chainsaw as a saw unit. Its drive will have to be located under the machine table, like a circular saw, and the saw itself will have to be installed vertically above the table. Using such a machine, you can cut much larger logs into boards and prepare lumber for doors, windows and other large products.

Chainsaw

Before picking up a chainsaw, you need to properly cut the log. In this way, it will be possible to obtain the maximum amount of high-quality boards with a small amount of waste.

To begin with, a mark is applied to the tree that corresponds to the type of lumber planned. Then the log is fixed on the work surface so that it does not move or dangle.

Using the rip saw attachment, attach it tightly to the body of the chainsaw and prepare the base surface against which the cut will be made. Under no circumstances should you put pressure on the saw; it should move smoothly along the working surface. Well, for the convenience of work, it is best to invite a partner. Extra hands will help secure workpieces to insert wedges into the cut.

With flexible saw

For working with wood, only band sawing machines are used. There are also rope and chain (bar) ones, but they are used for granite, marble and other rocks. The main options for sawing on band saws are: transverse, longitudinal and curved.

Similar woodworking tools are divided into floor and tabletop. Floor-standing ones consist of a one-piece construction; due to their high performance and power, they are used in industry. Tabletop designs are convenient for manual household use. Can be installed on a table or workbench; some models come with a special stand.

Note! The main difference and advantage of a band sawing machine is quiet operation. Therefore, they are well suited for home or garden.

Depending on the model, the machine can be equipped with two or three pulleys for tensioning the cutting belt. One is connected to the engine and is the drive. To preserve the saw in contact with a metal pulley, use a special bandage made of rubber, PVC or cork. Wood sawing machines equipped with a brush and sealed bearings on the pulleys are more reliable.

| pros | Minuses |

| low energy consumption, high output volume, quiet operation, safety, small amount of waste, large cutting height - up to 360 millimeters | maximum wood feed speed is slightly more than a meter per minute, difficult to use with conifers, resin interferes with the tape, cutting accuracy deteriorates, low productivity |

Sawing technology

It may seem to some that sawing a log into boards at home is as easy as shelling pears. But this is a wrong judgment, especially when it comes to the production of building material for the construction of any structure.

Before dissolving the log , you need to decide what size the lumber should be and what quality the final boards should have. The choice of a suitable tool depends on these factors.

The main phase of dissolution must be started only after inspecting the logs. You may need to remove bark and knots from them. If the logs do not have any flaws or defects, the processing process will go much faster, and the final lumber will exceed all the expectations of the master.

Circular. Nano board cutting machine

Today, there are several types of cutting logs, depending on the orientation of the growth rings of the felled tree.

DISC MACHINE. HOW TO SAW A LOG AT HOME???

- Radial. In this case, the cut must be made along the radius of the growth rings. The finished lumber will meet high quality requirements and will not deform even after long-term use.

- Tangential. This variety involves sawing the log tangentially relative to the growth rings. However, the resulting lumber will not have the desired strength.

- Parallel. The most understandable cutting option occurs parallel to the grain of the wood.

When unraveling logs in the direction of the grain, it is best to use the roundwood option. Initially, the round timber slab is cut off from the 1st side part. Then the log is turned over 180 degrees, and the 2nd croaker is removed.

In order for the boards to be even, the processed log must be constantly turned over.

Regardless of the chosen method of cutting different logs, it is necessary to adhere to several general rules that correspond to the sawing technology.

- The log should not move during processing. It should be securely fastened to the work surface.

- When using a chainsaw, you will need a chain for longitudinal processing so that the cut is smooth and the saw does not go sideways. It is very important that the chain is sharpened and does not sag.

- When cutting with your own hands, you should choose small-sized logs.

- Before you start cutting, you should make markings that correspond to the selected type of cut.

- It is important to pay special attention to safety precautions at any stage of log processing.

Knowing how to split logs correctly is only part of the wood sawing technology. It is much more difficult to work from a drawing when you need to turn a paper drawing into reality. If there is a clear diagram, each cutting detail undergoes careful measurements. The cuts of the mowing line must be even, which is extremely important in the manufacture of decorative products.

Setting up a sawmill

In order for work on the sawmill to be effective, it is necessary to regularly check and adjust all the important mechanisms of the equipment.

During operation, the following points must be monitored:

- Fabric tension. It is recommended to use the band saw for no more than 2 hours continuously. If it overheats, remove the fabric and leave to rest for 24 hours.

- Saw layout. To obtain a quality cut, you must constantly check this parameter. The optimal layout is considered to be when the ratio of sawdust and air between the log and the saw is 3:1.

- Speed of sawmill operation. If you cut logs at high speed, you will get a better cut, but at the same time the service life of the band saw will be reduced. It is best not to exceed 1/2 of the allowable value.

- To increase the service life of the band saw machine mechanisms, it is necessary to use band saw lubricant. The optimal composition includes lubricating oil for chainsaws and diesel fuel in a 1:1 ratio. The solution is applied in small quantities to both sides of the canvas.

After checking and adjusting the band saw mechanisms, they begin to prepare the wood.

What will you need?

Many simple and complex devices have been developed for cutting logs. The choice of a particular tool depends on the required number of logs and their sizes.

When the question of sawing huge quantities of wooden boards comes up, a sawmill comes to mind. This device is a woodworking machine equipped with several saws, thanks to which the log is cut longitudinally.

The uniqueness of the sawmill is that it allows you to process logs with a diameter of up to 80 cm and a length of 7 m.

To cut a tree trunk, you can use a circular saw equipped with circular saws. Their design may contain one cutting disk or several at once. Single-disc circular saws work with low-quality material. Multi-disc ones are designed for cutting round timber of large diameters.

Today, band sawmills are in great demand. They are divided into horizontal and vertical types. The main cutting element in the design is a ribbon web stretched over pulleys. Band sawmills carry out longitudinal and mixed cutting of wood. The entire work process is accompanied by minimal waste.

The presented types of cutting tools are most often used in the industrial sector. However, their analogues in miniature sizes can be found at the dacha of carpenters and people whose hobby involves making decorative wood products.

In addition to stationary equipment, there are many hand tools that allow you to process tree trunks. We are talking about a chainsaw and a hacksaw with teeth for longitudinal cutting.

Woodworking experts recommend chainsaws for home use. They are distinguished by high power and are able to operate continuously for a long time, since they do not require connection to the mains. With a chainsaw, you can go to a plot where you can process a huge number of trunks. Moreover, this hand tool has several types of attachments designed for specific cutting options.

- Attachment for longitudinal sawing. Designed for horizontal cutting of logs.

- Lightweight nozzle. It cannot be called a high-quality element of a chainsaw, since the resulting cut has unevenness.

- Okarevatel. This attachment can split a log into boards of the required size in a short period of time.

At the sawmill

When working with a sawmill, it is important to take into account the thickness of the boards, the taper and rotation of the raw material. A master can make cuts on a band-type sawmill according to several schemes.

- Simple sawing. In this case, the log is cut from start to finish to produce unprocessed boards, since the log is not rotated. This method is considered the simplest, but has several disadvantages. The resulting boards have to be cut from the sides, and the lumber itself loses quality. Even during operation, the center boards can crack.

- Circular sawing. The cut is made, after which the sawyer turns the log over to the other side. In this way, the tree is processed to its center. This method is considered the best for processing medium and high grade raw materials.

- Sawing timber. Initially, the cut is made in a circle, and the center of the log takes the form of a beam of a specific size, which is subsequently cut without any waste residue. This pattern is suitable for cutting low and medium grade wood.

To apply beam sawing and circular cutting patterns, specialists use 2 methods.

The first involves not taking the taper into account, and the second requires paying attention to it. In the first method, the worst face for the initial cut is selected. However, without taking into account the taper, many slabs will remain. Sawing on the good side of the log moves parallel to the bark, thanks to which the master will receive a large number of elongated boards of excellent quality.

To start cutting a good edge of the raw material, taking into account the taper, it is necessary to fix the log so that the saw is directed parallel to the bark.

In both cases, the final boards have the same characteristics. However, using the second method, it is much easier for the sawyer to select the best edge.

As for the issue of turning the log over. When turning the raw material 180 degrees, uncut boards are obtained, the sides of which require additional processing. At 90 degrees, semi-edged and unedged boards come out, which need to be finished only on one side.

A 180-degree rotation allows you to obtain high-quality samples of the final material with wide dimensions. If the sawmill has only one saw, it is much more convenient to turn the raw materials over in the same way as a right angle.

After the opposite edges have been cut, the worst part of the log is processed without taking into account the taper. But a good edge requires a cut parallel to the bark, which increases the quality of the final lumber.

Types of working attachments

Sawing logs with a chainsaw is carried out in different ways; craftsmen work with wood along the grain, as well as across it. It all depends on what attachments are used in the chainsaw.

Attachment for longitudinal sawing

It is used for sawing logs lengthwise, the process takes place in a horizontal position. After work, the master receives the same thickness of the product. The finished materials undergo a drying process, after which the boards are used in construction.

In appearance, the device is a small frame; it is attached to the tire on each side.

Device for longitudinal cutting of logs

Sawing with a lightweight attachment

The method is not very productive, but is used quite often. The element is fastened on one side, but the workpieces are slightly uneven. Such materials are necessary for the construction of sheds or fences.

Drum debarker – debarker

Attachment for a chainsaw for removing bark

With the help of such an attachment it is easy to dissolve a log; it works due to a V-belt drive. Attached to belts on both sides, special pulleys are used for this. The speed of rotation of the shaft depends on the size of the pulleys, so the performance of the attachment is easy to change.

This technology forces the master to carefully monitor each stage of the process; some specialists use an assistant during this cutting. But this option requires increased security measures.

Safety regulations

When working with cutting equipment, it is important to follow safety rules that will help you avoid even minimal injuries:

- No strangers, especially children, should be present near the workplace or on the work site;

- When working with a circular saw, it is important to put a protective cover on it;

- for your own protection when cutting logs, you should wear special equipment - goggles and a mask;

- There should be a first aid kit at hand;

- Do not pour gasoline into a hot chainsaw tank;

- under no circumstances should you turn on the chainsaw outside the workplace;

- The logs to be processed should only be installed on the right side of the master;

- When working with cutting equipment, it is strictly forbidden to apply force to it.

Additionally, you can watch detailed instructions in the video on sawing logs into boards.

The advantage of sawing logs with a chainsaw

The method of cutting logs using a chainsaw has several advantages.

The ability to work under any conditions - the chainsaw is not afraid of humidity, so specialists can cut logs during the rain; in this case, the equipment will not deteriorate.

High productivity - it is allowed to carry out woodworking throughout the day, but it must be taken into account that the power of the device must be at least 7 horsepower.

Autonomous device - the equipment runs on gasoline and does not depend on electricity; the workplace can be mounted in any area where it will be more convenient to carry out the process.

Chainsaw components

Ease of use - the chainsaw is equipped with a soft start and adjustable chain rotation speed; these conditions ensure that beginners in this business obtain high-quality results.

The undoubted advantage is that the equipment costs much less than a small sawmill. During a breakdown, repairs are inexpensive and do not take much time.

Sawing logs into boards at home

Many people make their own sawmill for sawing logs. Let's consider two main options for their manufacture.

- Weld a frame from metal plates and angles and attach the engine to its lower part. Place a shaft with pulleys at the top. Then attach one or more circular saw blades to the shaft. Attach a guide made of a metal square or timber to the table. While pressing against the guides, feed the log and move it forward. If you use one saw, then you need to attach a ruler or apply markings to the surface of the table.

- Weld a frame from a profile pipe and channels. Attach a saw with a gasoline or electric drive to a carriage with vertical feed. To ensure that the cutting of logs into boards is as accurate as possible, attach a ruler to the vertical stand. Use a rod or sanded pipe to guide the carriage. They are necessary for the carriage to move vertically. Install a screw in the bearing that will move the carriage as it moves. Also, don't forget to prepare the log clamps.

Dissolving logs on a circular saw

When using the second option for work, it is the saw that is driven, on a specially attached frame. The log itself remains in place. If you use a reciprocating saw rather than a chain saw, the process will be a little longer because it only works in one direction.

How to cut a log into boards

options for how to properly cut a log into boards. It all depends on your needs. The sawing technology itself is as follows:

- The bark is removed (but this can be done at home later);

- A log is fixed on the frame or guides ;

- One slab is sawed off to obtain a smooth surface;

- Next, place a flat surface on the frame (table), fix and saw off the second slab;

- They spread the entire log onto boards.

Longitudinal sawing of logs

The difficulty of such a cut is that the entire length of the log must be maintained at the same thickness. It is best to use special equipment for these purposes, which is attached to a log.

Longitudinal cut

This type of dissolving of logs into boards, slats, beams is used. Sawmills, furniture factories, and procurement plants use many different devices. We will look at how to cut logs into boards at home.

For cutting at home, you can use a saw, an angle grinder with special attachments, or a circular saw.

Cross cut

It is carried out to obtain parts in the form of cylinders and disks.

Types of log cutting

Sawing logs into boards is carried out in two main ways:

- radial

- tangential.

In addition, additional methods are possible:

- mixed

- semi-radial (rustic)

- central.

Radial sawing is a type of sawing during which the axis of the cut runs through the core of the log and, as a result, the annual rings in the section of the board form an angle of 76 - 900. The lumber obtained by such a cut has a uniform color and texture. Timber almost does not undergo deformation during drying and does not swell when moistened, because the dimensions of the wood change mainly along the line of the rings (across the grain). In radial sawn timber, the annual rings are arranged according to thickness. Such materials are distinguished by the highest performance indicators in comparison with other types of lumber.

Tangential cutting is carried out along tangents to the lines of annual rings at a short distance from its core. The surfaces of the resulting boards are distinguished by a pronounced texture and a bright wavy pattern of annual rings. Such lumber is characterized by higher coefficients of shrinkage and swelling from moisture compared to radial cut boards. As a result, they are greatly deformed when exposed to moisture. Such boards are in demand for use in dry conditions.

Rustic (semi-radial) and mixed types of cutting have characteristics of two main types of cutting simultaneously: radial and tangential. Therefore, they exhibit average shrinkage and swelling coefficients. Rustic cut boards are distinguished by straight lines of annual rings, which are located at angles of 46 - 75 degrees. to the layers. Mixed sawn timber is distinguished by the fact that the lines change from straight at the edges (along the width) of the board to arched towards the middle.

The center cut is made right in the center of the trunk and contains its core. Taking into account the fact that the core of the trunk is wood with the lowest strength indicators, center-cut lumber is characterized by a structure that is heterogeneous in strength.

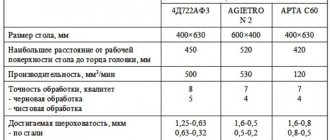

Wood balance when sawing

| Log diameter | Volume yield,% | ||||

| sleepers | boards | general | sawdust | piece otx. | |

| 28 | 55,3 | 20,4 | 75,7 | 5,2 | 13,1 |

| 38 | 61,3 | 13,7 | 74,8 | 6,3 | 12,9 |

Preparing for cutting

Before sawing a log into boards, you need to remove the skin from it. This can be done with a sharpened shovel, scraper, or electric plane.

When using a shovel, the movements are done on your own.

It is believed that the best results are obtained when the bark is removed with a scraper - it does not affect the tree.

Cross cutting of logs

This is not difficult even for working at home. Place the log on the sawhorses or secure it to the guides. And you can saw off pieces of the desired size.

HOW TO MAKE A PERFECT STRAIGHT CUT WHEN ASSEMBLYING A FRAME

If you are not a tough frame construction professional, then you most likely have problems with straight cutting with a manual circular saw.

A good, even cut is very desirable when assembling a frame. Even if you have a laser-guided saw, it still takes skill and a steady hand.

Usually, for a straight long cut, they use a cord rubbed with chalk: they beat off a straight line with it and saw along it. But if you don’t have the skill, this doesn’t really help. It is good to have a rigid guide against which the edge of the saw rests - then the cut should be straight. To do this, I had to come up with equipment from what was at hand.

SAW CROSSLY

For cutting at an angle, an aluminum corner 50 x 50 x 2 mm was useful. I press it with clamps to the board that needs to be sawed. In this case, it is necessary to take into account the distance from the edge of the saw base to the saw blade.

Instead of a corner, I sometimes used a rectangular aluminum profile 40 x 20 x 2 mm, 1 m long.

One day I found an old locksmith’s corner with a steel shelf in the barn. With its help, it turned out to be convenient to make cuts at right angles, since the shelf is well fixed at the edge of the board.

SAW Lengthwise

If you need to straighten the edge of the board, you need a long guide. I use a rectangular profile 50 x 20 mm, 2 m long. If the board is shorter than 2 m, then it’s quite simple: we fasten the profile with two clamps and saw along it. But if the board is longer, then the profile needs its own guides and fastening. Can be fastened with two self-tapping screws. And I make a straight line using a strong thread, stretched like a string.

To fasten the thread, use a sharp knife to make a slit along the fibers at the required distance from the edge of the board at the beginning, and tuck the end of the thread there with a knot that prevents it from slipping out. At the other end there are two slits: in the upper one the thread is tensioned, and the lower one fixes it. If the tensioned thread oscillates when released and stops in the same position each time, then it is well tensioned.

We install the profile lengthwise at the same minimum distance without touching the thread and fasten it with self-tapping screws. To prevent the profile from moving during fastening, it must be pressed firmly. Having made the first pass with the saw, we rearrange the profile further. Ideally, another board of the same thickness should be placed under the other edge of the saw for support. If there is no such support, you will have to monitor the horizontal position of the saw, but this is easier than sawing in a straight line without a guide.

This way I was able to do an extreme leveling of a ceiling beam that had too much of a downward hump.

Sources:

https://stroy-podskazka.ru/brevno/kak-raspilit-na-doski-v-domashnih-usloviyah/ https://atmwood.com.ua/2018/01/30/kak-raspilit-brevno-na- doski/ https://kak-svoimi-rukami.com/2018/08/idealno-pryamoj-raspil-ruchnoj-cirkulyarkoj-moj-sovet/