Cold forging capabilities

product created by cold forging

The cold forging method involves torsion and bending of rods of a certain cross-section. The result is a set of parts from which the finished product is assembled.

Specialized Azhur machines allow you to perform the following operations:

- bending elements according to a template using the rotation method. This procedure is performed using special templates compatible with the spindle. The role of the machine is to control the accuracy of the corners;

- the rod is twisted on a machine of the same type with additional attachments included in the package;

- winding of rings is carried out on a special nozzle;

- cutting of forged parts is carried out on a special type of machine - scissor. The parts of the part are shifted relative to each other, creating an even, neat cut.

Now let’s learn more about the “Azhur” machine of each model.

Advantages of cold forging using the Azhur machine

In this way, you can easily twist and bend rods of the required cross-section. This makes it possible to make parts of a certain type and, based on them, assemble a finished product.

Capabilities of openwork universal machines today:

- Bend elements by rotation strictly according to specified parameters. Most often combined with a spindle. A modern forging and universal openwork machine is capable of controlling angular inclination with high precision.

- To twist the rod, use the same machine with additional attachment equipment.

- To screw the rings, add an additional nozzle.

- All forged parts are cut on a scissor unit. All side faces of the mechanism are made offset with respect to the rubbing surfaces. Thus, the cut is smooth and thoughtful.

Currently, “Azhur” forging machines are produced with a different model range.

Bending machine "Azhur-1M"

machine "Azhur-1M"

It can produce almost any popular elements used in artistic forging products:

- baskets;

- volutes;

- rings;

- peaks;

- reverse folds;

- endings;

- torsion bars;

- snails

The power of the machine is 3000 W, it operates from 220 or 380 V networks. “Azhur-1M” works with workpieces with a diameter of 8 to 16 mm, profile pipes No. 15 and No. 20. Torsion bars are made from 10 - 20 mm rod. The working shafts rotate at a speed of 7.5 revolutions per minute.

Additionally, the Azhur machine is equipped with:

- a power unit that drives the forging module;

- forge for heating the ends of the rod;

- forging module with a set of eccentric rollers. With its help, the ends of the rods “crow’s foot”, “faceted peak”, “dome peak” and others are formed;

- a drum for making a “ring” part with a diameter of 114 mm from a rod of round or square cross-section from 6 to 12 mm;

- snail - used to make curled elements from a profile pipe, round or square rod. Completely eliminates the appearance of creases;

- torsion bar - used to perform the element of the same name, comes in a set with washers and adapters.

The machine includes an electrical part, a mechanical part and a forge. Mechanical elements:

- electric motor;

- bed;

- forging module;

- gearbox;

- equipment

An electric motor drives the lower roller of the forging module through a gearbox. From here the movement goes to the upper and middle rollers. Eccentrics are placed on these shafts; during torsion, they bend the workpiece into the required shape. The workpiece is preheated.

Some elements are created using a drum or “snail” installed on the middle shaft. To create a “torsion bar” and “basket”, devices are installed on the upper roller. The heating forge is powered by a gas burner.

Equipment improvement

Successful business development in any case will require improvement of equipment and the acquisition of additional machines, components and parts. Experienced forging equipment manufacturers have the greatest advantage in this matter. One of them is, which has its own machining workshop. However, the quality of the resulting products is not the best.

Azhurstal provides more opportunities to expand production and produce new decorative elements. This manufacturer uses its own equipment, and any innovation is almost immediately implemented by the design department. Each customer should be confident that their machine will be improved and equipped with the necessary equipment. Not everyone is ready to establish contact with a new partner. All products are tested before they are put into production, which eliminates mistakes in the design of machines.

Rolling machine "Azhur-2"

machine "Azhur-2

The purpose of “Azhura-2” is to apply a convex ornament to a profile pipe, strip, square and round rod. The power of the electric motor is 3000 W, it operates from a three-phase network of 380 V, modification for 220 V is possible. The equipment rolls up to 4.5 linear meters per minute.

Maximum cross-sectional size of the workpiece, in mm:

- profile pipe 40 x 40;

- stripes 20 x 20;

- round bar diameter 20;

- side of the square is 20.

The shafts rotate at speeds of up to 7.5 revolutions per minute. There are two configurations of the machine: basic and complete.

The basic package includes:

- forging module;

- power unit;

- upper and lower shafts;

- gear cage with adjustment - necessary for simultaneous rotation of both shafts at any position of the upper one;

- strip guide;

- guide mechanism for square;

- rollers for rolling cuts in the shape of a square;

- rolling textured rollers;

- "Greek" ornament for stripe.

The complete package additionally includes:

- 37 types of rolling reliefs;

- 7 sets of shafts for rolling different reliefs onto a profile pipe, square;

- horizontal straightening mechanism;

- smooth adjustment of rolling speed.

The rolling machine "Azhur" consists of the following elements:

- electric motor;

- welded steel frame;

- gearbox with gears;

- forging module with a straightening mechanism;

- electrical part

The motor, through a gearbox with gears, supplies rotational motion to the shafts of the forging module. Forming rollers are located here. The rod passes between the upper and lower rollers and takes on the shape of the rollers. After which the part is fed to a straightening mechanism: two balancers, which give the part a flat or curved shape.

Reliability and durability of machines

Fulfilling a large number of orders requires reliability of both the equipment being operated and the components used. This is due to the continuous production of products, in which all elements experience increased load. A significant requirement is the ability to quickly repair in the event of a machine breakdown. Therefore, when choosing a specific manufacturer, you should pay attention to several factors at once: the durability of the equipment, the safety margin of the design and the ability to quickly purchase spare parts and components:

- The estimated service life of equipment before major repairs for Profi machines is from 3 (“Profi-2 EM”, “Profi-4M”) to 5 years (“Profi-5”).

- In terms of availability and delivery time of spare parts, including slow-moving ones, the clear leader is. This manufacturer has a representative office in Russia, Kazakhstan, Ukraine and many other countries, but this does not prevent it from using its equipment. Therefore, all necessary components are always available in warehouses and can be promptly delivered to the client from the nearest point.

- Difficulties with the supply of spare parts arise from the Chinese company, whose production is located abroad. Even with an immediate response from the company to your request, delivery will take a lot of time.

Rolling and bending machine "Azhur-Universal"

machine "Azhur-Universal"

This model is a combination of two previous machines “Azhur-1M” and “Azhur-2”, which allows you to create almost all known forging elements, process edges, and roll ornaments onto parts of different profiles.

The machine is offered in two configurations: basic and complete. It works with workpieces from 8 to 20 mm in diameter, strips up to 60 mm wide. The working shafts rotate at a speed of 8.5 revolutions per minute. The equipment is equipped with a 3000 W motor operating from a three-phase 380 V network. The machine is designed to work in small- and medium-scale production.

Mechanical elements of the rolling-bending device "Azhur-Universal":

- electric motor;

- bed;

- two forging modules;

- gearbox;

- electrical part

By means of a belt drive, the electric motor transmits movement to the gearbox and rollers of both forging modules. Eccentrics are located on the middle and lower rollers of the first forging module; they make parts in the shape of a “spade”, “peak”, “crow’s foot”. A “snail” is attached to the outer part of the middle roller. Using a combination of the console and the top roller, “torsion bars” are performed.

Horizontal press "Azhur-3M"

hydraulic press "Azhur-3M"

The hydraulic horizontal press "Azhur-3M" is designed for the production of metal fences, bars made of rods with a diameter of up to 20 mm, and strips with a width of up to 20 mm. Designed for use in large-scale production.

Electric motor power is 5500 W, rotation speed is 1450 rpm. Operates from a three-phase 380 V network. The press creates a force of 30 tons. It comes with equipment for making patterns: “wave”, “cartouche”, “angle”, “semicircle”, “French profile”, “eshka”, “chervonka” and others.

The press consists of the main elements:

- base;

- gear hydraulic pump in tandem;

- electromechanical hydraulic valve equipped with a safety valve;

- hydraulic tank;

- hydraulic cylinder;

- stamp with column guides;

- oil filter;

- electrical panel

Machine oil 403 and Shell Tellus 46 are used as the working fluid. The pump unit is protected from overloads by a safety valve. The press is installed on a hard surface of asphalt or concrete and adjusted horizontally according to the level.

Machine for twisted pipe "Azhur-4"

machine "Azhur-4"

This machine can produce twisted pipes with a diameter of 10 - 160 mm, with a given coil angle. This element greatly decorates the finished product and is used as a stand for a lantern, furniture, or fences.

The machine produces up to 4 linear meters of twisted pipe per minute. It is equipped with a 3300 W electric motor powered by a three-phase power supply. The rotation speed of the shafts is 18 revolutions per minute.

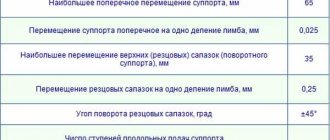

On the base there is a support plate with grooves (3 pieces) located at an angle. Sliders (3 pieces) equipped with movable brackets are attached to the base plate. On the back surface of the plate there are rulers to control movement. Each bracket is equipped with rotating plates, which rotate along their axes relative to the bracket. You can set the position of the plate using the lock.

The rotary plates are equipped with rollers on bearings and an electric motor with a gearbox. The transmission of motion is carried out through a cam-type clutch. The steady rest allows you to change cartridges for pipes of different sizes.

Pipe bending machine "Azhur-6"

machine "Azhur-6"

The three-roll machine is designed for bending profiles and rolling along a radius; it works with pipes with a diameter of up to 80 mm, strips up to 100 mm, channels no larger than No. 12, angles up to No. 63. Bending in horizontal and vertical planes is possible. The power of the electric motor is 1100 W, it operates from a three-phase power supply of 380 V. The rollers rotate at a speed of up to 11 meters per minute.

Rollers are located on three supports; a chain drive runs on them from the electric motor shaft. The pressure roller moves along the groove on the plate. The location of the slider is determined by the travel screw. The chain tension is adjusted with a screw and nut. To prevent the mechanism from becoming clogged with debris and dust, it is covered with a protective shield. During bending, the part may move and damage the plate or shield, which is why bumpers are provided.

Video with the presentation of machines for artistic forging “Azhur-1M” and “Azhur-2”:

Equipment price

Due to the difference in equipment, it turned out to be quite difficult to estimate the cost of equipping the forge. Therefore, we selected equipment for comparison based on the following task - the machine must produce a minimum set of forged elements necessary for the manufacture of the most popular products: fences, gratings, fencing, gates and gazebos. Information that we were able to find: - A machine with standard functionality from Blacksmith dealers is “UNV3-02”. It costs 360,000 rubles. It can perform operations such as: bending round and square pipes, rolling pipes, twisting rods and producing “basket”, “curl”, “ring” and “foot” elements. — The cost of the basic configuration of the Decor-1 machine is 149,050 rubles. The basic package includes: a small forging block, drive-d1, ex, stamp “Snail” - universal U” and drums for winding rings “B-114”. The machine at this price can produce the following functions: rolling out “foots”, rings with a diameter of 60-180mm, “curl”, “arc” and “ring” products. Additional items must be purchased separately. — A machine of the “Master” series with standard functionality is “Master-2U”. It will cost from 189,000 rubles, depending on the configuration. At this price, the machine produces curls, donuts and volutes with a length of 210 mm with loose and unfastened ends. — “Azhur” offers an artistic forging machine “Azhur-1M” for 187,740 rubles in the basic configuration, which can be supplemented with any of the devices to choose from: “snails” for currencies, drums for rings, rollers for a clamp strip and preparation of a profile pipe. The cost of additional components starts from 2000 rubles. — On the website we found a very attractive price for the equipment - less than 200,000 rubles for the basic package. Machines with a similar cost include: “Profi-4M” (from 185,000 rubles), “Profi-3M” (from 170,000 rubles), “Profi-2EM” (from 130,000 rubles), “Profi-2R” (from 93,000 rubles). Machines with similar prices can produce crow's foot jamming and spiral twisting (volute, monogram, curl). True, upon closer inspection, it turned out that some of the devices will still have to be purchased separately, but there are few options for further equipment for the machines.

From the point of view of the ratio of price and number of components that are truly suitable for achieving our goal, the best option is machines from.