Types of turning tools with replaceable inserts

The following types of cutting tools with replaceable inserts are distinguished:

- Boring cutters: have a cone-shaped holder and mechanical fastening for making through and blind holes in parts. They can also be used for cutting internal and external threads in cylindrical products. When making blind holes, the cutting edge should be positioned at an angle of 90°, for through holes - at an angle of 60°.

- Pass-through: used during external processing of metal parts. Their cutting edge is located at an angle of 45°.

- Shaped: necessary for processing shaped surfaces. These cutting tools are capable of ensuring the identical shape and dimensional accuracy of the processed workpieces. Shaped cutters are made from high-quality high-speed steels.

- Parting cutters: used for cutting workpieces into several parts. They are used when processing small and large bar parts. The main cutting edge of the tool is at an angle of 90°.

- Multi-faceted carbide cutters: equipped with polyhedron-shaped inserts.

- Grooving: intended for cutting grooves in cylindrical and conical products. They are characterized by high structural rigidity and high productivity. These tools are able to withstand high loads during turning operations.

The choice of the type of thread cutters with replaceable inserts depends on the type of technical operations performed during the processing of metal parts. The quality of the instrument depends on the precision of manufacturing and the professional skills of the craftsman.

What are the benefits of using carbide inserts for cutters?

- Versatility of use of one turning tool. By changing carbide inserts, it is possible to process metals and alloys characterized by different composition, structure and hardness. If you have the necessary set of attachments on hand, then problems with metalworking associated with finding and reinstalling the necessary tool will not arise. This is especially true for automated production facilities with a large range of products.

- Savings. The plate costs much less than the cutter. If the cutting part breaks, you do not have to replace the entire tool. In addition, the service life of its housing increases by more than 20 times compared to a soldered analogue.

- Changing (rotating) the insert takes less time than reinstalling the cutter. And this is one of the components of increasing productivity.

- The attachments allow you to change the cutting mode over a wide range, which creates convenience in work, increases its speed and quality.

- Large assortment of nozzles. Selecting the right insert for each technological operation is much easier than the tool itself. For small industries (especially household lathes), it is more profitable to have a certain set of attachments than to purchase a large number of cutters of various types.

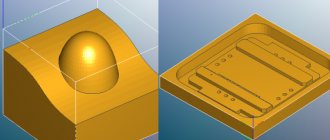

What can you do with carbide inserts?

- Surface treatment of workpieces.

- Thread cutting.

- Internal boring.

- Scan.

- Sampling of grooves, grooves and the like.

- Cut out the materials. For example, sheet glass, getinax, non-ferrous metals.

Nuances of choosing a cutter

When purchasing cutting tools, you need to pay attention to the following criteria:

- A type of cutting tool. Different types of cutters differ in profile shape, determined by the technical features of carbide inserts.

- Dimensional characteristics. The different dimensions of products processed on a lathe determine the dimensions of the cutting tool. For modern types of cutters, you can select workpieces with distinctive dimensional characteristics.

- Back angle value. This indicator affects the accuracy of finishing of the material. The surface cutting cleanliness is directly proportional to the clearance angle. This parameter is taken into account when turning metal workpieces with soft surfaces.

- Accuracy class. This parameter is used to calculate the accuracy of the cutting performed. According to GOST 9253-59, 3 main accuracy classes are established for plates. When measuring this parameter, it is possible to cut workpieces with tools with different tolerance values.

If these criteria are not taken into account, then the thread cutters will not be able to be firmly fixed on the lathe and produce precise processing of metal parts.

When purchasing cutting tools, it is important to choose the right inserts. These parts are made of hard metal alloys. The ratio of metals determines the operating characteristics of the cutting tool. There are 2 main types of plates:

- With increased strength. They are resistant to vibration, shock and other physical stress that occurs during cutting. It is recommended to purchase this category of plates if you need to cut a large amount of metal from the workpiece.

- With increased heat resistance. They can withstand high temperatures that arise during long-term processing of workpieces and exposure to frictional forces. Heat-resistant plates are fixed mechanically. They are used when working at high speeds.

Materials of manufacture are indicated on the markings of carbide inserts. Each alloy has a unique image. In the manufacture of cutting parts, tungsten is used, which has high strength and resistance to large temperature changes. Additionally, titanium carbide or cobalt can be used. Plates made of ceramic materials are used during finishing or semi-finishing of metal products. They can be used for cutting workpieces made of heat-resistant alloys. The percentage of these components determines the category of replacement plates. On the marking, titanium is designated by the letter “T”, cobalt by the symbol “K”. Example of marking: T14K7 (percentage of titanium carbide - 14%, cobalt - 7%).

For large volumes of turning work, it is recommended to purchase a set of turning tools with replaceable inserts, which will allow you to quickly adjust the tool during various technological operations. When choosing sets, it is important to consider the manufacturer's brand. The most popular replacement plates on the market are from the following companies:

- LLC “Instrument-Service”: a Ukrainian company that produces parts for cutting tools.

- Interpipe: is the largest organization for the production of pipe and threaded connections in Eastern Europe. The products are manufactured at the Novomoskovsk pipe plant, located in the Ukrainian city of Dnepr.

- BDS-Machinen: German company producing devices and parts for magnetic drilling machines.

- Proxxon: an organization that develops parts for cutting small workpieces. Production takes place in Germany.

- Ceratizit: a company producing metal-cutting tools and their main components. The headquarters is located in Luxembourg.

The cost of a set of turning tools depends on the manufacturer's costs and the financial policies of suppliers. Imported parts have the highest price. The average price of a set is 15,000 rubles. Additionally, you can purchase certain types of plates. Their average price is 164 rubles.

Features of using carbide inserts

Dimensions – in mm.

- Primary sharpening of the cutting edge is carried out at the manufacturer. Since it gradually wears out, the product simply turns over, that is, its other face, previously unused, becomes working. Therefore, there is no need to systematically sharpen the edge, which is typical for brazed turning tools.

- For rough processing of workpieces, thicker plates (up to 6) with long edges (up to 25) are used. Technological operations called finishing (for example, grinding) are performed with small products. Their minimum dimensions are: length – 7, thickness – 3.

Manufacturers of quality carbide inserts

Judging by the reviews of amateurs and professionals on thematic websites, there are no significant complaints about the products of the following manufacturers.

- Ceratizit (Luxembourg).

- Proxxon, BDS-Machinen (Germany).

- Ukrainian "Instrument-Service".

What to consider when choosing replacement nozzles

It is understood that they are purchased as a set, but without a cutter.

- Correspondence of linear parameters of tool and inserts.

- Specifics of product use. If metalworking involves removing significant layers from the workpiece, then you should select attachments whose material is inert to high temperatures. Working at high speeds is accompanied by increased vibrations. In this case, you need to pay attention to such characteristics of the samples as resistance to loads (mechanical).

- Type of parts processing. This already comes to the question of the required shape of the nozzles.

Cutting modes

Cutting modes are a set of parameters that determine the conditions for processing parts using a turning tool. The cutting process is influenced by the following factors:

- Cutting speed is the path of movement of the machined surface of the workpiece relative to the cutting edge per unit time. Measured in m/min or m/s. In the drawings it is designated by the Latin letter V.

- Feed is the path traveled by the cutting edge in 1 stroke or revolution of the workpiece being processed. Measured in mm/rev. In the drawings it is marked with the Latin symbol S.

- Depth of cut is the distance between the machined and machined surfaces. It shows the amount of metal layer being removed. In the diagrams it is denoted by the Latin letter t.

- The cross-sectional area of the cut layer is the product of the cutting depth and the feed. It is a nominal value and affects the presence of roughness. In the diagrams it is indicated by the Latin symbol f.

These parameters are tabular values and are specified in GOST 25762-83.

Download GOST 25762-83

Each type of cutting tools with mechanically fastened inserts has additional cutting modes. Cutting cutters carry out transverse movements, boring tools move longitudinally relative to the surface of the workpiece. During operation, the average speed of the cutting edges is tenths of mm. The feed is 0.1 mm/rev.

Cost of carbide inserts

They are sold in sets, so the price depends on the configuration, shape, size and a number of other indicators. In addition, they may also include cutter bodies, which increases the cost. If we talk about its average value, then a kit without tools will cost 5,310 rubles, and with it – about 7,980.

In principle, it’s not that expensive, considering that, according to experts, the use of replaceable attachments gives a monthly saving of about 450 rubles on one lathe (with average equipment load).

Advantages and disadvantages of incisors

Thread cutters with replaceable inserts have the following advantages:

- low cost: cost less than solid type incisors;

- allow you to save a large amount of time resources during the preparation of cutting tools for various technological operations;

- the plates are able to withstand high loads because they are made of carbide materials;

- cutting cutters can be used to process parts with small dimensions and uneven terrain;

- the cutting tool can be readjusted if necessary;

- high service life of the holders, which allows the tool to be firmly secured to the lathe;

- do not require additional sharpening or soldering;

- during processing, reduce cutting force and temperature by 35 - 40%;

- provide the ability to change cutting modes on the fly;

- unification of all cutter models: allows you to select the right insert for processing workpieces made of certain types of metals.

Experts highlight the following disadvantages of cutters with replaceable inserts:

- due to the presence of many fasteners for carbide inserts, the total weight of the cutting tool increases;

- cutters are not able to provide optimal geometric parameters of the cutting edge due to the different shapes of the plates and the peculiarities of their fastening;

- high complexity of manufacturing cutting tools.

The quality of a thread cutter depends on the type of processing and cutting mode. The cutter retains its benefits longer at low cutting speeds and during internal cross turning. The cutting tool wears out faster during external longitudinal turning. To increase its durability, lubricating and cooling media are used. You can also increase the rigidity of the tool by increasing the area of the holder.

general information

For the manufacture of all models of attachments for cutters, only alloys characterized by an improved formula are used - AL 20 (40) and AP 25 (40) . The geometry of any sample is thought out to the smallest detail. This allows the corresponding technological operations to be carried out with maximum accuracy and in a short time, with a significant reduction in the percentage of defects.

Existing standards

Carbide inserts come in several types. A detailed description of each of them can be found in the relevant GOST.

- 19042 from 1980. This standard defines the designation system, categorization and requirements for the shape of carbide inserts (replaces GOST under the same number from 1973).

- 19086 from 1980. This document outlines all the characteristics of chipbreakers, as well as replaceable attachments of the supporting and cutting type.

- 25395 from 1990. GOST applies to the type of carbide inserts that are fastened to the holders of through-cutting, boring and revolving cutters by soldering (01, 61, 02 and 62).