Clock lathes are placed in a separate group for a reason. The fact is that, unlike their competitors, they are much more accurate, which allows you to get rid of defects or, at least, reduce them to a minimum.

This is not even prevented by the rather small size and the absence of a chuck and tool holder in classic models. Therefore, they will be discussed in this article.

Design features of the machines

As already mentioned in the introduction, classic models of watch lathes do not have a chuck and a tool holder. Their design simply does not imply their use.

Although, in our time this has ceased to be a problem, since they are installed in modern models. However, despite modernization, watch lathes still have rather small dimensions, which are about thirty-five centimeters in length.

Important!

Design features vary depending on which model was chosen.

Location of controls for the T-28 lathe

Location of controls for the T-28 lathe

List of controls for the T-28 lathe

- Engine start handle

- Headstock spindle braking handle

- Divider handle

- Collet holder handwheel

- Spindle lock handle

- Caliper cross feed handle

- Tool slide longitudinal feed handle

- Tailstock quill clamp handle

- Tailstock quill feed handwheel

- Tailstock clamp handle

- Caliper clamp nut

Lubrication points of the T-28 lathe

- Headstock spindle bearings

- Supports for caliper lead screws and tool slides

- Tailstock quill feed screw support

Device

And now it’s worth talking about the design of these machines. In total, there are six main elements of the device:

- bed;

- caliper;

- facial pastern;

- backstock;

- headstock;

- open motor.

So, now I’ll tell you about each of them in more detail.

bed

This element is designed to secure all nodes on it - both movable and fixed. It is the basis not only for watchmaking, but also for all other types of machines, so it is the most important element.

The frame also allows the mechanism to rest against the foundation and accept any load that arises during the work. But, even despite this, it is still considered the most durable part in the machine.

The frame is made mainly of cast iron, but sometimes it is also made of low-carbon steel.

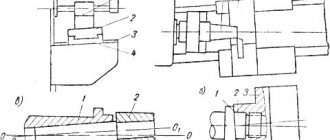

Caliper

This detail is also one of the most important. Thanks to the support, the fixed workpiece can be moved along and across the spindle axis, as well as at an angle to this very axis. Thanks to this, you can easily prepare parts.

The support has a cross design and also has three moving units: lower and longitudinal slides, as well as a longitudinal carriage. If you read the technical literature, you will find that these nodes are almost always called differently, but this is not so important.

Facial pastern

The front headstock (or face) performs two functions at the same time: it gives rotation to the future part, and also supports it during operation.

On the facestock there is a control panel with which you can adjust the speed of rotation of the workpiece. To simplify the work, many workers attach a detailed diagram near this panel with a description of where to turn to speed up or slow down the rotation. This can also be useful for those who have just started working.

Tailstock

The tail (or back) headstock is needed for fixing parts with a large length. In addition, various tools such as drills or reamers can be installed on it.

During operation, axle loads occur. All this load goes to the thrust ball bearing. Also, the center equipment is installed and fixed on the tailstock due to the conical hole of the bushing. You can install any tool in such a center and then fix it. This will prevent the tool from rotating along with the part.

Headstock

It is located next to the rear headstock and is part of it. As the name implies, the clamping head clamps the workpiece. Has valves for clamping, as well as special moving parts.

Open motor

The motor (or open motor) is what allows the headstock to rotate the workpiece using the spindle. Connected to the mains, it begins to turn the spindle using straps, and with it the workpiece, allowing it to be processed from all sides.

Nowadays, mainly for lathes, including clockwork ones, they mainly use motors with a squirrel-cage rotor, but this also depends on the manufacturer and purpose of the machine.

LiveInternetLiveInternet

Quote from message Ryazanochka77

Read in full In your quotation book or community!

Weaving loom: in ancient times and today.

Loom

- a mechanism for producing various textile fabrics from threads, an auxiliary or main tool for the weaver. There are a huge number of types and models of machines: manual, mechanical and automatic, shuttle and shuttleless, multi-shank and single-shank, flat and round. Weaving looms are also distinguished by the types of fabric produced - wool and silk, cotton, iron, glass and others.

My friend looked around in our Moscow room. -Where is the loom? You wrote to me about him... “Here he is,” I pointed to a wooden structure in the corner between the window and the closet.

- So you wove these rugs on it??

In the 60s of the twentieth century, many villages wove rugs on looms, crosses, which were inherited from grandmothers and great-grandmothers. Someone’s husband/uncle/grandfather is a jack of all trades and has a bright mind, he made a machine. Or they ordered from the masters. Where did the craftsmen themselves learn to make weaving machines?

In 1911, the book “Improved Handloom” was published. Author I.V. Levinsky. And in 1924 - “How to build a loom and weave simple fabrics.” The author is engineer V.A. Dobrovolsky.

and a page from it

The style is “clerical”, which K. Chukovskoy angrily wrote about, but the drawings and drawings are clear. Weaving machine (krosna). 1930

Weaving is an ancient traditional craft of the inhabitants of the village of Vodly and the surrounding bygone villages. Author - N.V. Ulyanova. School ethnographic museum of the village. Vodla Pudozh district of Karelia. From the memories of old-timers.

When this is woven with little cells. They dyed, and they dyed with alder from the tree, they tore up the bark, they dyed flaxseeds. They'll paint this one, and then... oh, and then when they got the paint, there were rollers like this. And so they coated the rollers with paint and rolled them, making this, motley makers. They make skirts like this, but you can’t buy them like that in a store. They kept linen skirts for the holidays. Sundresses, and linen ones, there were ropes before this place, here there were ropes. The lace was tied. I remember there was a blue moth, made into a cage, but ours didn’t have moths. It was woven from my grandmother and mother, and the gypsies stole it. And our grandmother and mother had towels, but now we don’t have them, well, these are sewn and embroidered. And this kind of material was all woven by hand, the Rednians of the School, they made it on thicker bags, and with me during the war they wove these skirts. Schools and blankets were made, sewn and wrapped with these blankets. They already regretted the rug. When I went to work as a young man in 1945, there was no pay. You will put some kind of blunder on your head. They made the rug. And there, for example, in my youth, you’ll wear it out, you’ll tear it out, and throw it in a ball: the shirt is torn, or the pants are torn, they’ll cut it out, and this one. Back then, they kept very little, fewer dresses, so they would make them for the villages. They buried the blood like this, and those who were richer were thrown on the floor.

Egozinka

cited her aunt’s memories of her great-grandmother Maria.

“My grandmother Masha wove these rugs for me (for Aunt Egozinka) as a dowry. I lived with her when I was 16-17 years old. And having observed, apparently, that the gentlemen were already knocking on the threshold, she got down to business. I remember how the loom stood by the window (my grandmother called it KROSNA), how pleasant it was to touch its smooth, polished wooden surfaces. I remember the word - nitchenka. And at the bottom there were pedals... I wove the shanks on some kind of hand-held machine - these are beautiful sticks with patterns. My grandmother selected colors, calling them pistachio, azure, fawn... I remember the silence in the room, my grandmother’s quiet singing. She deftly throws the shuttle and slams it with the frame (BERDO). The walkers are knocking on the wall, the old cat Muska is purring..."

: — My grandmother in Sokolovskoye had two of them in good condition. Previously, linen was woven on them, and coarser and rather thin linen was woven into shirts, sweaters, skirts, towels, and tablecloths. It will be enough for us to collect seven sweats, you will spend half a day fiddling around. My grandmother kept the mills in the barn, and she weaved at home, so when assembled they took up most of the hut.

: - And I remembered how my grandmother forced us to help “warp” - this was when they made a new thing - the basis for starting to weave rugs. We scurried about on the wall for about 8 meters, then we filmed it in a braid, and then wound it on a shaft. Before this, they threaded it (feed it with a needle) into the strings, and when it was all aligned through the strings, they wound it onto the shaft. Well, then they threaded it through the reed and let’s weave. They didn’t trust me to weave, but I know how to warp and feed into nets and reeds; my grandmother couldn’t see well anymore.

How the main threads moved , shows olsha5

, who is engaged in weaving, weaves fabrics with a bran pattern.

and braid it so it doesn’t get tangled

- Do you know why these rugs were woven? In those days you couldn’t wash the floors - they were unpainted. It took my grandmother and I half a day to wash the floors. First they rubbed it with broken bricks, then washed it off several times. The pine floor turned white, as if after shavings. So they covered it with rugs so it wouldn’t get dirty.

- Once upon a time it was like that. But my grandmother lived in an apartment with a painted floor. And the rugs were there because that’s how it’s supposed to be. The bare floor is not comme il faut, like

But my grandmother lived in an apartment with a painted floor. And the rugs were there because that’s how it’s supposed to be. The bare floor is not comme il faut, like

Tatyana Lesnaya - I filmed this in Suzdal. The weaver said that now almost no one knows how to thread such a loom. They were helped by their 96-year-old grandmother. Refueled for 2 days. Nowadays this is only in museums or in villages in attics or sheds (Fasting nature.

Skvortsova A.F. Agafya's grandmother's doormats. I remember my post-war childhood. Throughout the fall and part of the winter, mother and grandmother spun flax. Closer to spring, a loom was installed in the hut. In her free time from working on the collective farm, her mother wove canvas. Severe necessity forced me to do this. There was no factory production, and there was no money to purchase it either. Towels, tablecloths, underwear and bed linen were made from homespun fabric. And its quality depended on the peasant woman’s ability to weave finely and tightly. In the spring, the canvases were bleached on a snow crust.

Life in the village gradually improved, and the need to weave canvas disappeared. But rugs - bright, colorful, elegant - were still required. Moreover, the townspeople, fed up with carpets and rugs, began to look for old craftswomen and buy rugs from them. But the trouble is, there are fewer and fewer such craftswomen left in our villages and provincial towns. This is a labor-intensive and troublesome task.

How Krosna was founded , dinaza

13 meters of warp, that is, the main threads, white in the photo. It’s not an easy task, it’s boring, it’s the least favorite thing, you need an assistant. We spent the entire day, or even two days, threading the machine with the main threads.

seredina77

(in the first photo)

“So far we have found this machine - we have visited quite a lot of villages, seen people, talked to them, got some interesting ideas about their life and morals... For this, it was even worth going on a trip and dragging the machine 600 miles. So Dinka found an 80-year-old granny - a weaver. I haven’t seen her work myself, but Dinka said that it was very interesting and of high quality. This granny weaves in the winter, and puts the loom away in the summer (after Easter). This is how it was traditionally - in the summer you have to farm the land and grow crops. Dinka kept dreaming of coming to this granny in winter to learn her skills. And the granny walked all the way to the neighboring village, persuading the girls there to learn from her and adopt their skills. Grandmothers die, and with them their crafts are forgotten.

Voldemar T. in the video told how he learned to weave rugs. Filmed in the mid-90s.

Weaver Lidiya Nikolaevna shows the operation of a weaving mill that is more than a hundred years old. Museum of the History of the City of Myshkin, Yaroslavl Region. M. V. Vasilyevich is an artist. A reed used to punch the weft into the fabric for compaction. I. V. Belkovsky is an artist. “Winter Sun” 1994. Crocheted round rugs. (I tried washing a crocheted rug in an automatic washing machine - it washed well. Note: Ryazanochka77)

Magazine "Around the World". August 1979. Weaving rugs in Paloma.

... And in winter, when there is a lot of free time, women in Paloma weave rugs. Everyone knows how to weave; they learned it from their mothers when they were girls. Previously, fine linen yarn was woven into sundresses, shirts, towels, tablecloths and sheets, in rows for bags. They also wove paths. “We worked all winter, “sloughed,” the women recall. And in the summer, a lot of work was devoted to flax; it was necessary to sow it, grease it, soak it, knead it, comb it, and only then spin it. All this, of course, was done by hand. Now, of course, no one sows their own flax and they no longer weave linen; the need for this hard work disappeared, but the ability to weave and the habit of this activity remained. Winter days seem empty without him. So they weave rugs. Thus, the former craft, which was part of women’s duties, acquired the character of a creative activity “for the soul” and became the joy of a free hour.

They are no longer woven from linen yarn, but from rags, dyed in different colors, cut into thin strips and twisted. Simple spool threads are used as the base. Not only the material from which the rugs are woven has changed, their sizes and patterns have changed. Rugs are now woven wide, up to 80 centimeters wide, and old rugs are remade especially for this purpose. Most likely, they do this because rugs are no longer just tracks that cover the floor; their purpose has become more diverse - they cover sofas, hang them as carpets over beds. But the traditional pattern in the form of multi-colored transverse stripes is not entirely suitable for this. Some craftswomen make a new design - checkerboard, from squares (not without the influence, of course, of factory-made blankets and bedspreads). In one day, an experienced craftswoman, working without stopping, can weave up to three meters.

Magazine “Around the World. February 1989. Belarusian SSR

Towels, made by Neglub weavers on wooden frames, began to circulate throughout the world. What kind of international exhibitions have they been to? They were in New York and Montreal, Tokyo, Paris and Brussels and returned from everywhere with gold medals. Even the American Metropolitan Museum could not resist this beauty: it acquired several Neglyub towels for its collection.

Neglyubka (Belarus. Neglyubka) is a village, the center of the Neglyubsky village council of the Vetkovsky district of the Gomel region of Belarus.

The book “Beautiful - with your own hands.” Author-compiler S. Ghazaryan. The book has a section on homemade table loom and weaving.

When I was at school, in the girls' labor room there was a loom like this.

It was fragile, something was broken, so the teacher showed it in class as a visual aid. They didn’t try to weave on it.

There was also such a machine made of wood. Here I will tell you about the “device” of the machine.

The loom consists of a hem, a shuttle and a hip, a beam and a roller. Two types of threads are used in weaving - warp thread and weft thread. The warp thread is wound on a beam, from which it unwinds during the work process, going around the roller that performs the guiding function, and passing through the lamellas (holes) and through the eyes of the heddles, moving upward for the shed. The weft thread passes into the shed. This is how the fabric appears on the loom. This is the operating principle of a loom.

There are manual, automatic and power looms. Handmade ones were invented early in history; they required the hard work of a weaver. With the development of science and technology, weaving machines also changed. Now one person can operate a dozen automatic looms.

Resourceful needlewomen wove this way.

It is hardly possible to weave rugs on it. They wove scarves and bags.

There were such machines for weaving.

On one forum, a visitor wanted to buy old and “scary” rugs, which surprised good people.

- So I was going to lay them in the boundary. My beds are narrow, but the boundaries are wide, and grass and ants grow on them - I’m tired of it! I’m already struggling with her in every way. But it won’t grow under rugs. She's not that interested. Incl. let them be at least as old as they are. Technology of “narrow ridges” according to Mitlider.

Nowadays a variety of table looms and weaving frames are produced; it is impossible to write about them all - the post will be longer.

Modern loom Glimakra Julia (Julia). Made in Sweden. In Russia, some needlewomen have this machine. The width of the fabric is up to 68 cm. It can be used to weave rugs.

Japanese loom

Modern table loom Emilia (Emilia) Made in Sweden. Available in two versions: with a filling width of 50 cm and with a filling width of 35 cm. Fixed on the table.

I bought this machine in a Moscow store. The width of the finished canvas is up to 35 cm.

Weaved from strips from old clothes. The width of one canvas is at most 30 cm. I crocheted the canvases together. They are not very dense and are not suitable as rugs, because on this machine it is difficult to punch the weft to the canvas. It can be folded and placed on a bench as a seat, or it can be spread out on the grass, on a hammock. Gave it to a friend for her dacha. (Algerian carpet, hand-woven, made of woolen threads on a cotton base - they brought it when my husband was in school, I can’t stand it).

The weaving of rugs is not dying. This is a rare handicraft because the loom is not easy to acquire. Takes up a lot of space. Instead of weaving, thick crocheted rugs are made from strips of old clothes. Or they braid a braid and sew it into a circle.

Price range

Prices for different models vary depending on functionality, convenience and age. For example, on online trading platforms you can buy a fairly simple watch lathe for three hundred and fifty dollars. However, this is not suitable for industrial production, and such machines will be mostly outdated.

At the same time, you can buy a sort of “King from the world of watchmaking machines” - Schaublin 70. It is produced by a Swiss factory, and its quality is simply at the highest level. However, for such a treasure you need to pay about 662,400 rubles, which is quite a substantial amount.

At the moment, this is the most expensive machine currently produced, so all other models are priced between those sold on trading platforms on the Internet and with Schaublin 70. Basically, the price of new models will range from 200,000 to 500,000 thousand.

Information about the manufacturer of the tabletop drilling machine model SUS-1

The manufacturer of the tabletop drilling machine model SUS-1 is the Vilnius state enterprise Praktika .

Machine tools produced by Vilnius Machine Tool Plant

- 6E80sh

- universal cantilever milling machine 200 x 800 - 6M80

- horizontal cantilever milling machine with rotary table (universal) 200 x 800 - 6N10

- vertical cantilever milling machine 200 x 800 - 6N80

- horizontal cantilever milling machine with rotary table (universal) 200 x 800 - 6N80G

- horizontal cantilever milling machine 200 x 800 - 6N80SH

- universal universal cantilever milling machine 200 x 800 - 6P80G

- horizontal cantilever milling machine 200 x 800 - 6Р10

- vertical cantilever milling machine 200 x 800 - 6Р80

- horizontal cantilever milling machine with rotary table (universal) 200 x 800 - 6R80G

- horizontal cantilever milling machine 200 x 800 - 6Р80Ш

- universal universal cantilever milling machine 200 x 800 - 6T10

- vertical cantilever milling machine 200 x 800 - 6T80

- horizontal cantilever milling machine with rotary table (universal) 200 x 800 - 6T80SH

- universal cantilever milling machine 200 x 800 - NS-12A

- tabletop drilling machine Ø 12 - SUS-1

desktop drilling machine Ø 12

Criterias of choice

When choosing a watch lathe, you need to look at the companies that sell them. Of course, you need to buy only from good and trusted manufacturers who have been supplying high-quality machines to the market for a long time.

The second thing you should pay attention to is the price. To be honest, such machines are quite expensive, so you need to calculate in advance how much money will be left after the purchase?

Third, what types of work will be performed and what size the workpieces will be. Depending on this, it will be possible to select the appropriate size of machine for the job.

And lastly, fourthly, the age of the machine. It is clear that old watch lathes have a higher chance of breaking than new ones that have just rolled off the assembly line. This means that after the purchase you will have to spend money on repairs. Although, old machines will cost less than new ones.

Technical characteristics of the T-28 machine

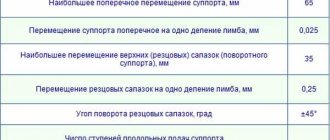

| Parameter name | T-65 | S-95 | T-28 |

| Basic machine parameters | |||

| Accuracy class | N | N | N |

| The largest diameter of the workpiece above the bed, mm | 120 | 50 | 130 |

| The largest diameter of the workpiece above the support, mm | 30 | 12 | 14 |

| Height of centers above flat bed guides, mm | 65 | 32 | 65 |

| Maximum length of the workpiece at centers (RMC), mm | 200 | 125 | 220 |

| Maximum turning length, mm | 70 | 38 | 55 |

| Maximum height of the cutter holder, mm | 7 x 7 | 6 x 9 | 8 x 8 |

| Height from the cutting surface to the center line, mm | 6 | 6 | 6 |

| The greatest distance from the axis of the centers to the edge of the tool holder, mm | 50 | ||

| Spindle | |||

| Diameter of through hole in spindle, mm | 10 | 8 | 10 |

| Morse taper spindle | № 1 | 39°30` | № 0 |

| Number of speed steps for direct spindle rotation | 3 | 3 | 3 |

| Spindle direct rotation frequency, rpm | 77, 66, 55 | 1300..3000 | 1440, 2500, 4300 |

| Caliper. Submissions | |||

| Maximum lateral movement of the caliper, mm | 70 | 44 | 55 |

| Transverse movement of the caliper by one division of the dial, mm | 0,05 | 0,01 | 0,01 |

| Maximum movement of the cutting slide, mm | 70 | 38 | 55 |

| Movement of the cutting slide by one division of the dial, mm | 0,05 | 0,01 | 0,01 |

| Angle of rotation of the cutting slide, degrees | ±90° | ±90° | ±60° |

| Tailstock | |||

| Tailstock cone | Morse No. 1 | 39°30` | Morse No. 0 |

| Maximum movement of the quill, mm | 45 | 30 | 45 |

| Electrical equipment | |||

| Main drive electric motor, kW | 0.25 1400 rpm | 0.15 2700 rpm | 0.27 2800 rpm |

| Dimensions and weight of the machine | |||

| Machine dimensions (length width height), mm | 675 x 300 x 250 | 420 x 200 x 250 | 650 x 255 x 222 |

| Machine weight, kg | 19 | 19,2 | 25 |

Popular models

Of course, among the models of watch lathes, there are those that stand out and become popular. And so, among them three samples can be distinguished: T28, T65 and C95. All of them are produced in Russia. Now about each in more detail.

T-28

So, let's start with an analogue of the Swiss Schaublin 70. T28 is designed for fine processing of metal parts.

This lathe excels at drilling, facing, boring cylinders and cones.

His field is the production of tools and devices, which he does very well. The T28 also has a local electric motor, which provides a drive for torsion of the fixed part. Workpieces can be fastened in three different ways, depending on the purpose of the work:

- on the faceplate;

- in the centers;

- in a collet.

There is nothing special in the design, everything is as usual: a bed, a support, two headstocks, a rear one and a front one.

T65

This watch lathe, like the previous model, is designed for turning small-sized parts. In design it is very similar to the T28.

Its main advantages are its fairly simple design and fairly easy operation. Thanks to this, even a beginner can handle it. The T65 also has a fairly powerful motor that produces up to twelve thousand revolutions per minute.

S95

This machine is a copy of the German Boley No.1b. Mainly used in large-scale watch production, where it has received great recognition.

The bed is a point beam, which is located on two parallel posts. On top of it there are guides, thanks to which you can fix the headstock and caliper.

Equipment for the T-28 lathe

Equipment for the T-28 lathe

Standard equipment of the T-28 lathe

- Т28-09-21 — Center of the headstock

- Т28-09-22 — Faceplate

- Т28-09-23 — Leash

- Т28-09-24 — Base

- Т28-09-25 — Clamp

- Т28-09-27 — Podruchnik

- Т28-09-28 — Special key

- T28-09-31 — Table

- Т28-09-32 — Prismatic table

- Т28-09-33 — Open-end wrench 16

- Т28-09-34 — Tailstock center

- Set of collets - Set of collets 1..4mm through 0.5mm and 5mm

Accessories available at extra cost

- Т28-04 — Rack with rollers

- Т28-05 — Device for internal grinding

- Т28-06а — Device for external grinding

- Т28-07 — Grinding device support

- T28-08 - Headstock for grinding - quill

What else do you need to know?

All three models given above are designed for hand carrying, and therefore weigh accordingly: the T28 weighs about twenty-five kilograms, and all the others - about nineteen. The accuracy of all of them is quite high - it is class “H”.

Of course, you can’t do your work without a watch lathe. It is very important when working with complex parts due to its precision and quality. At the same time, you also need to be careful with your choice, because not all lathes will work perfectly. Therefore, you first need to take a good look at which machine to choose, and only then buy it, and then you will be happy.

General view of the tabletop drilling machine SUS-1

Photo of drilling machine sus-1

Photo of drilling machine sus-1

Photo of the drilling machine sus-1. Spindle feed dial

Photo of drilling machine sus-1

Spindle assembly of tabletop drilling machine SUS-1

Drawing of the spindle assembly of the Sus-1 drilling machine

Spindle of tabletop drilling machine SUS-1

The spindle assembly is mounted in the housing, and spindle 1 is mounted in sleeve 4 on ball bearings 3 and 5.

The spindle receives rotation from sleeve 7 and pulley 6 through a spline connection.

The spindle feed is manual, carried out by rotating the steering wheel using a gear shaft 8 and a sleeve with a rack 4.

Nut 2 is designed to remove the drill chuck from the spindle cone.

The belt tensioner knob adjusts the distance between the feed and take-up pulleys of the machine

FPSh-5M combined school jointing and sawing machine. Purpose, scope

The FPSh-5M machine is designed to facilitate the work of school workshop teachers when preparing the source material necessary for independent work by high school students.

The woodworking jointing and sawing machine FPSh-5M is a device for processing lumber of softwood and hardwood.

The woodworking machine FPSh-5M is designed to perform the following work:

- cutting lumber with a thickness of no more than 40 mm

- jointing of lumber, width no more than 135 mm

The machine must be operated in closed, dry domestic premises.

The design according to the degree of moisture protection is unprotected.

The FPSh-5M machine can operate under the following conditions.

- altitude above sea level - up to 1000 m;

- ambient temperature - from plus 5 to plus 40 °C;

- relative humidity of the surrounding air - no more than 80% at a temperature of plus 20 ° C.

The machine's electric motor is powered and controlled from a three-phase alternating current network with a rated voltage of 230 V and a frequency of 50 Hz. The machines do not require permanent grounding.

Location of components of the SUS-1 drilling machine

Location of components of the drilling machine sus-1

Specification of components of the drilling machine SUS-1

- Column (Bracket)

- Headstock clamping device

- Electric drive (Electric motor)

- Headstock lifting mechanism

- bracket

- Plate

- Spindle

- Headstock

- Belt tension mechanism

- Lamp

Spindle head of tabletop drilling machine SUS-1

The spindle head is based on a cast iron body. The housing contains a spindle unit, a belt tensioning mechanism, and local lighting of the machine.

An electric motor is attached to the back of the headstock.

The spindle head can be rotated on the column and locked in the desired position.

To move the spindle head along column 1 (Fig. 2), clamping device 2 must be released.

By turning nut 4 to the left or right, you can raise or lower the spindle head 8.

Setting the spindle movement scale of the SUS-1 drilling machine

Setting the spindle movement scale of the sus-1 machine

Setting the drilling depth of the SUS-1 machine

When drilling holes to a given depth, you should use the dial mechanism, which makes it possible to drill until it stops. The cover pos. is released. 1 turn counterclockwise. Using the spindle manual feed handle pos. 1 pic. 6.1 the drill is brought into contact with the part. Holding the handle in this position, dial pos. 2, turning it counterclockwise, adjusts to the desired drilling depth. The dial division value is 1 mm. The drilling depth is measured in relation to the arrow pos. 3, and is fixed by turning the cover. Drilling is done until it stops.

Drilling through holes can be done with the limb released, pos. 2, which is released by turning the cover pos. 1.

Spindle speed control

The spindle speed is changed using a V-belt drive. There are five spindle speeds (Fig. 6.2). To change the spindle rotation speed, the casing covering the V-belt drive is raised until it is automatically locked (lock pos. 16 Fig. 6.1). Handle pos. o The slide is released from the clamp. When replacing the belt, it is necessary to move the slide, reducing the distance between the pulleys. To do this, the belt tension handle is turned all the way. If the handle stroke is insufficient, it is released by screws pos. 17. At the same time, the screw pos. 18, which is screwed all the way into the nut pos. 19. The handle is fixed with a screw pos. 17. The belt is put on and its tension is adjusted in the reverse order.

If the belt is partially worn, tensioning is carried out in the same way as replacing it.

With the belt tense, the recommended position of the handle pos. 2 is shown in Fig. 6.1 View B. In case of significant deviation of the handle from the recommended position, adjustment should be made by releasing the bolt pos. 17 and turning the handle.

Electrical equipment and electrical circuit of the SUS-1 drilling machine

Power supply of the SUS-1 drilling machine is ~380 or ~220 Volts. Machines manufactured for industrial enterprises and educational institutions have a supply voltage of ~380 V, for mobile workshops - ~220 V. Local lighting has a safe voltage of ~24 V.

All electrical equipment of the machine: switches, transformer, fuses are placed under the work table plate.

Electrical diagram of the drilling machine SUS-1 at 380V