Content

- Is it possible to cook stainless steel with a semi-automatic machine and what is it?

- Advantages and disadvantages of semi-automatic welding

- Video about semi-automatic welding of stainless steel

- Features of welding stainless steel semi-automatically

- Use of Gas in Stainless Steel Welding

- Materials and equipment required for welding

- Welding wire selection

- Preliminary work before welding begins

- Semi-automatic welding of stainless steel with other types of metals

- Tables with semi-automatic welding settings

- Final work after welding

What alloy steels can be welded semi-automatically

Stainless steel means a metal that can resist corrosion. For this purpose, it contains alloying additives in the form of chromium, nickel, manganese, and molybdenum. There are low-alloy, medium-alloy and high-alloy metals. A semi-automatic machine can weld all types, but only under certain conditions.

Low-alloy steels (alloying element content 3-5%) and medium-alloy steels (5-10%) are welded “cold”, i.e. You can attach the blanks and immediately cook with a semi-automatic device. High-alloy metals (additive content more than 10%) can be welded in the same way, but it is better to use preheating to 300-400º C. This category of stainless steels is called austenitic (high content of chromium and nickel), it welds perfectly at any thickness and resists corrosion for a long time if choose the right welding wire.

Is it possible to cook stainless steel with a semi-automatic machine and what is it?

Semi-automatic welding of stainless steel involves joining workpieces together in a protective gas environment. There are two technologies: MIG (metal inert gas welding) and MAG (active gas welding). To carry out this type of welding, shielding gas and welding wire are required, which is automatically continuously fed into the welding zone. Thus, the filler material melts together with the workpiece steel, forming a weld. The shielding gas coming from the cylinder is needed to prevent oxygen from penetrating into the welding zone and oxidizing the metal.

How to choose a good semi-automatic machine

When welding stainless steel parts at home, the parts themselves are rarely very thick, usually no more than 2-3 mm.

For this reason, there is no need to buy an expensive semi-automatic machine for welding stainless steel. Its cost is measured in tens and hundreds of thousands of rubles, which is affordable only for medium and small enterprises. However, welding equipment manufacturers have developed good options for those who resort to welding from time to time. For work at home, a power of 10 kW is enough to weld chrome steel. Such devices cost no more than 25 thousand rubles, and a large range of them is offered by domestic manufacturers.

An example of such a semi-automatic device is the Resanta SAIPA-165. Its characteristics:

- power - 5 kW;

- arc voltage - from 17 to 26 V;

- maximum current consumption - 22 A;

- compatible with wire with a diameter of 0.6 to 0.9 mm;

- dimensions - 300x140x270 mm;

- weight - 11.5 kg.

The optimal choice for a dacha, house or garage worth 16 to 20 thousand rubles. If you are favorable towards domestic goods, it is also worth considering the products of the Svarog and FEB brands.

Semi-automatic welding of stainless steel is a method that takes into account the specifics of the material being processed. The result will be a high-quality weld, a minimum of defects on the surface, and its uniformity. If you know the intricacies of welding stainless steel using MIG/MAG, write about it in the comments. You can also express your opinion regarding this or that semi-automatic welding machine if you have used it.

Advantages and disadvantages of semi-automatic welding

Advantages:

- high productivity without loss of weld quality;

- absence of strong smoke, which makes welding indoors easier;

- a small amount of metal spatter (due to the gradual feeding of the welding wire);

- the ability to weld thin and thick workpieces;

- reduced amount of welding material consumption.

Flaws:

- the need to use a gas cylinder

This disadvantage lies in the difficulty of transporting the cylinder to the welding site. But if you take into account all the listed advantages, then you can easily turn a blind eye to this drawback.

Features of welding stainless steel semi-automatically

Like any other method, semi-automatic welding has its own characteristics. Let's look at the most important

of them:

- The gas mixture for welding should include 70% carbon dioxide and 30% argon

- The welding angle should be from 5 to 10 degrees relative to the part for better weld penetration. This is especially true for welding thick parts

- reverse polarity

- The visible length of the filler material should be between 6 and 12 mm. When forming a seam, the distance from the nozzle to the metal should be minimal

There are usually 3 methods of joining workpieces using semi-automatic welding:

1. Jet transfer

It is used when it is necessary to weld thick-walled parts together. For this purpose, flux-cored wire and special heads are used.

2. Short arc

weld thin stainless steel to prevent metal burning

3. In a protective gas environment

The most traditional welding method, where argon, carbon dioxide or a mixture of both is used as a shielding gas. We'll talk about this in more detail below.

Material that does not rust

Various alloying additives are added to low-carbon steel: chromium - at least 12%, nickel, etc. Chromium, when interacting with oxygen from the air, forms a very thin oxide film on the surface, which prevents the rusting process and the action of a chemically aggressive environment. The surface anti-corrosion layer is restored if damaged. Stainless steel has its own characteristics:

- Low thermal conductivity prevents heat removal from the welding site. As a result, overheating and burning of the metal occurs, and alloying elements burn out.

- Low melting point reduces energy costs.

- Low electrical conductivity leads to a decrease in voltage on the metal of the workpiece, which causes overheating and the formation of burns, especially on thin parts

- Large thermal expansion deforms parts when heated.

A material with such properties is difficult to weld. There are several methods, one of which is welding using a semi-automatic machine. A beginner can learn how to cook stainless steel semi-automatically on the website mrll.ru.

Use of Gas in Stainless Steel Welding

When we use a semi-automatic machine for welding stainless steel, the following question arises: “What gas to use?”

There are 3 gas options that can be used:

Argon

Semi-automatic welding of stainless steel in an argon environment is widely used due to the aesthetics of the resulting seams, but has disadvantages such as an abundance of spatter, arc instability and high cost.

Carbon dioxide

Semi-automatic welding of stainless steel in a carbon dioxide environment is the cheapest option, but due to even more splashes than with argon, the seams turn out to be very rough.

A mixture of argon and carbon dioxide

Basically, these mixtures contain 98% argon and 2% carbon dioxide, or 95% and 5%, respectively. This is the best option, because... it combines both affordable cost and good seam quality. If there are no high requirements for the type of seam, the percentage of carbon dioxide can be increased to 30.

But is shielding gas always necessary?

The answer is no. A protective environment can be achieved without the use of gas. In this case, an analogue of solid wire is used - flux-cored wire. It is a thin-walled tube, which is filled with flux and gas inside. The top is covered with a metal protective layer, which, when melted, releases flux, which in turn blocks the access of oxygen to the welding site.

At the same time, flux-cored wire is not used so often due to the inability to provide the necessary protection for the welding zone. This, in turn, reduces the quality of the seam - it becomes less durable and strong.

| Welding stainless steel using filler material and shielding gas (compared to MMA and TIG) | |

| Advantages: - Reduced splashing - High performance | Disadvantages: - Limited outdoor use - Appearance inferior to TIG welding |

| Semi-automatic welding of stainless steel with flux-cored wire | |

| Advantages: - ability to perform welding work outdoors - no need to use a gas cylinder | Disadvantages: - high cost of flux-cored wire - formation of slag on the surface of the weld - after welding, additional protection against corrosion is required |

How long do the consumables of a semi-automatic machine last?

When thinking about semi-automatic welding of stainless steel, it is worth knowing how long the consumables will last. The most quickly worn element is the current collecting tip. Through it, voltage is transmitted to the wire. The outlet hole in the mouthpiece breaks, causing the wire to start “walking.” This complicates manipulations to control the electric arc and reduces the quality of the seam.

When working with a semi-automatic device for 6-8 hours every day, 1-2 current-collecting tips will have to be replaced per shift. The welder should always have such parts in stock. Moreover, each wire diameter has its own mouthpieces. When welding is carried out either with 0.8 mm or 1.2 mm wire, the mouthpieces also change.

The wire feed channel lasts for several years. Then it gets clogged with dirt and the wire starts to get stuck. The pressure rollers of the pushing mechanism “live” up to 5 years. With active use of the equipment, the mass clamp gradually wears out - the grip weakens, the clamping “lips” burn. The service life depends on the original quality of the element. For amateur devices, the clamp will last for a couple of years, for professional ones - up to 7-10 years.

Materials and equipment required for welding

- Semi-automatic welding machine as a power source

- Gearbox

- Solid or cored wire (material identical to the parts being welded to improve the quality of the seam)

- Shielding gas cylinder

- Means of protection:

Necessary for semi-automatic welding to regulate the gas pressure coming from the cylinder. Each type of gas has its own reducer.

To exclude point 4, it is necessary to choose a flux-cored wire, and it is necessary to remember about the reduction in the quality of the seam.

- A welding mask is a mandatory means of protecting the eyes and face during welding work.

- Gaiters are a necessary attribute to protect the welder’s hands

Welding helmets are produced in several types: with a small area covering the face and head, with a large protective covering including the neck and hair, and also with a rising light filter.

They are made from split wood or canvas. In addition, they differ in the number of finger compartments.

What is needed for the process

Required attributes include:

- MIG/MAG welding machine (semi-automatic);

- steel brush (to remove coarse splashes after finishing work);

- gas cylinder;

- solvent (anti-corrosion);

- filler wire intended for welding stainless steels in accordance with GOST 2246-70.

Of course, it is worth remembering about personal protective equipment - a welder’s mask, mittens, canvas workwear and the like.

Examples of filler wire are products from the domestic company BARS (for example, BARS ER-309LSi) or foreign manufacturers (BRIMA, ESAB, Linkoln Electric and a number of others).

If you are going to weld metal without using gas, be sure to purchase cored wire with a self-protection function.

Welding wire selection

Solid wire

It gives good seam quality, despite the fact that it has a low cost.

Cored wire

It produces a lower quality seam, but allows welding work to be carried out without the use of gas cylinders.

Copper-plated

It is mainly used for welding in carbon dioxide and its mixtures. The use of this type of wire leads to an increase in arc stability.

Filler wire is produced from 0.13 to 6 mm in diameter.

Preliminary work before welding begins

Immediately before starting the welding process, the following steps must be performed:

- Clean the surface on which welding will take place until it shines with an abrasive material.

- Remove chamfers if the wall thickness of the workpieces being welded is more than 4 mm

- Degrease the surface with alcohol, acetone, gasoline or solvent

- Remove moisture by heating the edges with a burner to 100⁰C

- To eliminate internal stress, the metal is heated to 200⁰ before welding.

Start of the welding process

Before starting, it is necessary to process the edges of the parts to be welded.

- The joint between the edges of the parts being welded should have a gap of 2-3 mm to ensure free shrinkage of the seams.

- The surfaces of the edges are cleaned to a shine using a special metal brush or grinder.

- Then the surfaces are treated with a solvent, which is acetone or aviation kerosene. The solvent will ensure the removal of fat from the future welding site. Which, in turn, will prevent the further formation of pores in the weld seam.

Preliminary work before welding begins

Regardless of the type of gas providing the protective environment (argon or carbon dioxide), the rules for semi-automatic welding are the same:

- The current must be of reverse polarity

- The burner must be tilted in such a way as to ensure sufficient penetration depth and the correct seam width

- It is enough to make the wire overhang up to 12 mm

- Gas flow can be adjusted from 6 to 12 mᶾ/hour

- The shielding gas is passed through a drying agent (usually copper sulfate) to remove moisture. Before use, it must be calcined at 200 ⁰C for about 20 minutes.

- To protect against hot splashes, surfaces adjacent to the joint must be treated with chalk dissolved in water

- To avoid the formation of hydrogen cracks, welding should be started approximately 5 mm from the edge of the workpiece

- Welding must be performed with a smooth movement of a semi-automatic torch along the seam. If you make transverse movements, the molten metal may go beyond the protective environment

Some features of the technology

The use of special semi-automatic welding machines mentioned above can significantly improve the quality of stainless steel welding, as well as simplify the process of its implementation. The use of such equipment allows you to solve several technological problems at once, including:

- supply of filler wire to the joint formation zone;

- supply of shielding gas to the welding zone;

- cooling of the welding torch;

- ensuring the convenience of making welded joints in hard-to-reach places.

Semi-automatic welding equipment

In products made of stainless steels, during the welding process, significant internal stresses are formed, which are removed by their further heat treatment - heating to a temperature of 660–760° and slow cooling in the open air.

Preparation for welding work

Before welding products made from stainless steel using a semi-automatic machine, they must be properly prepared in order to obtain a high-quality and reliable connection. The process of such preparation is as follows.

- The surface of the parts to be joined is thoroughly cleaned using a metal brush and then degreased, for which the most common solvents can be used.

- To remove residual moisture from the surface of the product, it is heated to a temperature of 100°.

Preparing stainless steel for welding the manifold

Welding rules and methods

As mentioned above, in order to qualitatively weld stainless steel using a semi-automatic machine, it is necessary to correctly select the filler wire from which the weld will be formed. It is optimal if the degree of alloying of the wire exceeds that of the base metal. This is explained by the fact that alloying elements contained in the chemical composition of the wire will burn out of the metal during its melting, therefore their content must be taken into account with a reserve.

For semi-automatic welding of stainless steel, wire with an ultra-low carbon content and high silicon content, resistant to oxidizing environments, is used

For welding products made of stainless steel, three main methods are used:

- short arc method (used in cases where small thickness products are welded);

- jet transfer method (allows you to weld parts even of very significant thickness);

- pulsed (the most universal technology that allows you to perform welding work with high productivity and at the same time save wasted resources).

Each of the listed methods has certain features, but there are also general rules that should be followed when using each of them. Let's look at these rules.

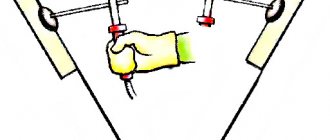

- The torch body is located at the opposite angle to the progress of the seam to provide a high-quality overview of the latter.

- The torch nozzle, through which shielding gas and welding wire are supplied, is located at a distance of approximately 12 mm from the surface of the products.

- The filler wire, melted as a result of the burning of an electric arc, is fed into the zone of the weld being formed in small drops.

Burner position: approximately 11 o'clock

In addition, there are general recommendations for welding work that uses shielding gas.

- Stainless steel should only be cooked with reverse polarity.

- The angle at which the welding machine nozzle is located should ensure good penetration of the joint and a small width of the seam being formed.

- The protrusion of the wire from the nozzle of the welding machine should not exceed 12 mm.

- The gas flow rate that forms the protective environment should be in the range of 6–12 m3/min.

- The gas supplied to the welding zone must first be passed through a drying agent, which is copper sulfate.

- To minimize the splashing of molten metal from the welding area, the surface of the products to be joined is treated with an aqueous solution of chalk.

- To get a beautiful and high-quality weld, it should not start and end at the very edge of the parts being joined. It's better to retreat some distance. The welding itself, which is important, is performed without oscillatory movements to the sides of the seam being formed.

Elimination of deformations

During the welding process, stainless steel products can become deformed, which is associated with their significant heating during this procedure. In order to correct such defects, you can use one of two methods.

- Using a hammer and a smoother, the “bubble” formed on the surface of the stainless steel is simply tapped, moving from the edge of the part.

- Straightening the formed warping by tapping will be more effective if you combine it with heating the parts, for which you can use a regular gas burner.

In order to cook stainless steel with high quality using a semi-automatic machine, it is not enough just to get acquainted with the theoretical basis; it is very advisable to watch a training video on this topic.

Semi-automatic welding of stainless steel with other types of metals

Today's semi-automatic welding technologies make it possible to join stainless metal with aluminum, high and low alloy metals, as well as other alloys.

Distinctive features of semi-automatic welding of stainless steel with other metals:

- When welding ferrous metal with stainless steel, the yield strength of the metal decreases, protecting the surface from the effects of the environment

- when we weld St40 to stainless steel, we use 08G2S wire, which helps to avoid rupture of the seam at the junction of two types of metal after cooling

- to weld stainless steel with copper it is necessary to use low-melting solders and flux

- The pulse mode is used for welding stainless steel with aluminum and other metals, resulting in increased resistance to corrosion and improved quality of penetration.

- Argon is used for welding aluminum to stainless steel using the pulse mode. Copper cored wire is recommended.

Tables with semi-automatic welding settings

Butt bottom position

| Workpiece thickness, mm | Gap, mm | Wire diameter, mm | Welding current, and | Welding voltage, V |

| 0,8 | 0 | 0,8 | 50-80 | 16 |

| 1,2 | 0 | 0,8 | 70-80 | 17 |

| 2,0 | 0,5 | 0,8 | 70-80 | 17,5 |

| 3,0 | 1 | 0,8 | 80-90 | 18 |

| 4,0 | 1,5-2,5 | 0,8 | 100-110 | 20 |

| 5,0 | 2,5 | 1,0 | 135-145 | 21 |

| 6,0 | 2,5 | 1,0 | 140-150 | 22 |

Vertical spatial position

| Workpiece thickness, mm | Wire diameter, mm | Torch direction | Welding current, and | Welding voltage, V |

| 0,8 | 0,8 | down | 50-80 | 16 |

| 1,2 | 0,8 | down | 70-80 | 17 |

| 2,0 | 0,8 | down | 70-80 | 17,5 |

| 3,0 | 0,8 | up | 80-90 | 18 |

| 4,0 | 1,0 | up | 100-110 | 20 |

| 5,0 | 1,0 | up | 135-145 | 21 |

| 6,0 | 1,0 | up | 140-150 | 22 |

Corner connection lower position

| Workpiece thickness, mm | Wire diameter, mm | Welding current, and | Welding voltage, V |

| 0,8 | 0,8 | 60-70 | 15 |

| 1,2 | 0,8 | 70-80 | 16 |

| 2,0 | 0,8 | 80-90 | 17 |

| 3,0 | 0,8 | 90-100 | 19 |

| 4,0 | 1,0 | 130-140 | 22 |

| 5,0 | 1,0 | 155-165 | 24 |

| 6,0 | 1,0 | 175-180 | 26 |

Final work after welding

- Mechanical processing - removing bubbles by tapping them with a heavy object through a smoothing iron and splashes resulting from melting the metal

- Pickling - removing scale that causes corrosion from seams with a special compound

- Passivation is the application of agents to the weld to form a chromium oxide film on it, which protects against corrosion.

Useful tips

At the end of the article I would like to share a few useful tips for welding stainless steel that will help improve the quality of the final weld:

- during welding in a protective atmosphere (a mixture of argon and carbon dioxide), reverse polarity is established, and when using flux - direct polarity

- for the distance between the wire and the joint, it is recommended to take a value not exceeding 12 mm

- you need to move the burner from left to right with an inclination away from you so that it does not cover the seam from us

- the connection of thick-walled parts is performed at an angle of 5 - 10⁰ to ensure deep penetration, as well as a strong and reliable seam

- when welding thin stainless steel, the torch is tilted forward, thus reducing the depth of penetration and minimizing the risk of burn-through

Methods for processing welds

Unlike the TIG method, semi-automatic welding of stainless steel results in black seams. These are oxides from the melting of metal, gases, and the combustion of protective sprays. To keep the seam white, cleaning with a metal brush is required. Then the scales will be visible and the connection will become more beautiful.

If necessary, the seams can be sanded if this is the front side of the product. A mirror effect, like TIG welding, cannot be achieved without additional processing. To do this, the seam is cleaned with flap wheels, gradually reducing the grain size of the abrasive in order to remove all risks on the surface. Then the metal is polished with felt pads and paste.