Not so long ago, transformer welding machines were widely used. But today they are actively being replaced by compact welding inverters, which are easy to use and light in weight. Manufacturers of such equipment offer consumers dozens of models, which have different technical characteristics. If you also decide to acquire such a device, then you need to figure out what criteria to pay special attention to. Among others, it is worth highlighting the class of the unit, which can be:

- household;

- professional;

- industrial.

The first ones are intended for a small amount of work. Their operating mode is short-term. After a certain period of operation, the unit will require a long break. But the professional class of inverters is equipment for welding pipes and repairing communications without interruption. By purchasing professional equipment, you get high quality welding and a long period of operation.

Industrial inverters are used in relevant facilities. They are used continuously throughout the day and are not designed for long breaks. In order to decide which device to give preference to, you need to consider at least one of them. An excellent example would be Resanta SAI-190, reviews of which you should read before going to the store.

Main features of "SAI 190"

The cost of this equipment is 5900 rubles. It is used in manual arc welding. To work, you will have to purchase coated piece electrodes. The equipment has very compact dimensions and light weight. The device is characterized by high performance, does not require special technical care and is easy to use.

Reviews of the Resanta SAI-190 also indicate that the equipment is well protected from overheating and complies with IP21 protection class. The unit is built on IGBT type transistors. Before purchasing, it is also important to know that the welding current is adjustable up to 190 A. While its minimum value is 10 A. The manufacturer has supplemented the equipment with ANTI STICK and HOT START functions, the first of which provides anti-sticking, and the second - hot start.

Inverter Features

The use of modern technologies allows even the simplest inverters, which include the Resanta 190 model, to provide the highest quality welding; at the same time, such devices are compact and easy to use. Due to its high power, the device can be used to work with cast iron and non-ferrous metals. This unit converts the mains voltage into a pulsed current, which is subsequently rectified, and at the output we get a high-quality welding arc with even electric current power.

The SAI 190 inverter model has anti-sticking and hot start functions, which not only simplifies the use of such a device , but also prevents damage to the electrodes. This is typical when equipment is used by inexperienced welders. This reduces the consumption of expensive electrodes without losing the quality of the metal connection.

The automation used maintains an even electric arc. All work is regulated automatically, which allows even ordinary homeowners to use the unit. The inverter system allows the use of SAI 190 at unstable mains voltage, while guaranteeing good welding quality.

Inverter technology allows not only to optimally regulate the voltage at the output of the machine, but also guarantees high welding current. This model has the ability to adjust the welding current from 10 to 190 Amps. A power of 190 Amps will be enough to work with various refractory metals.

In terms of the duration of continuous operation, such installations belong to semi-professional models. With a current of 190 Amps, 7 minutes of continuous welding is allowed, after which the device requires a 3-minute rest to cool down.

The Resanta 190 welding machine is equipped with an overheating warning system, so as soon as the temperature reaches the limit, protection is triggered and the unit is turned off until it is completely cooled. Such emergency protection can be triggered if there is a short circuit in the network.

Model specifications

If you still don’t know whether you should buy the Resanta SAI-190 inverter, we recommend reading reviews about it. After reading the opinions of consumers, you can find out that the described equipment model belongs to the household class. There is no TIG welding in the device, which, according to buyers, limits the scope of use of the unit. Overall dimensions are equal to the following parameters: 180x300x280 mm.

Experts are often interested in open circuit voltage. In the case of this model, it is 80 V. The input voltage is 140 V. The maximum power reaches 5.5 kW. 70% - this is exactly the value of the duty cycle at maximum current.

After reading reviews of the Resanta SAI-190, you can understand that the equipment operates on a 220 V mains voltage. A power plug is included, which is very convenient. The maximum current is equivalent to 190 A. The manufacturer does not provide a case.

The diameter of the electrodes used reaches 5 mm. The minimum value of this parameter is 2 mm. Consumers like that the inverter is lightweight, weighing 4.7 kg. The welding wire used with the unit is DX25.

Review of the device Resanta SAI 190 PROF

This model is more popular among professional welders. The principle of operation is similar to the model we have already considered, but there are also some additions in the form of the ARC FORCE function. It allows you to regulate the change in current strength during the welding process. Before work, the types of metals to be welded and their thickness are taken into account, then the required value is selected from 0 to 100% based on the previously determined welding current. In this case, the arc will have durability, and the metal will gain fluidity.

See also: Resanta SAIPA 165

Technical indicators:

- Housing protection - lP21;

- Adjustable welding current from 10 to 190 A;

- Arc voltage - 26 V;

- Electrodes d - 5 mm;

- Mon — 70%

- Operating voltage - 100-260 V;

- Maximum current consumption - 33 A;

- Idle speed - 65 V;

Advantages of the model

First of all, the modern appearance of the device catches your eye. The control panel has a protective transparent cover made of durable plastic. The digital display will show all values and set indicators for ease of operation. The number of ventilation holes has increased. There is a special handle on top for easy movement; the unit weighs about 4.8 kg. All measures taken made it possible to save consumed electricity by 30%. A power factor corrector was installed; it will ensure stability when operating with voltages from 100 V. The device also maintains its functionality when connected to many autonomous power sources.

Interesting! If the Resanta SAI-190 apparatus requires a generator with a power of at least 5.5 kW, then for the PROF model, 4.6 kW will be sufficient. In this case, the stability of operation will not be affected.

Instructions for use of the Resanta SAI 190 inverter

Connecting a device to the network occurs without special rules and requirements. The device is grounded through the plug-in cord, so the outlet must be grounded. The instructions state that for successful connection it is appropriate to install circuit breakers with a value of at least 16 A.

No work should be carried out with tools that create a dusty atmosphere at a close distance from the unit. These include grinders, electric saws or grinders. If Resanta is operating in normal mode or even idling, you should not cover it, creating restrictions on heat conduction; to ensure stable operation, the cooling system should not be irritated.

Welding is strictly prohibited in the rain or in areas with high humidity. Work with the device does not begin immediately, if it was brought in from the street, where the temperature is currently below freezing, the inverter must stand indoors without operation for at least 2 hours.

Recommendations

Do not turn off the equipment too often; if the indicator lights up, it is appropriate to simply wait a little over 15 minutes until it cools down. When work occurs in intermittent mode for 7-9 minutes, welding does not turn off, you need to wait about 3 minutes of idle operation. A harmless shutdown is only possible if no work is carried out for one hour.

To care for equipment, it is recommended to clean the internal surfaces from possible dust and dirt. The frequency depends on the degree of pollution or the time spent working in dusty areas.

What are the most common causes of device failure?

The first and simple rule that should be followed in order for the welding machine for welding Resanta SAI 190 to serve for a long time and without problems is periodic cleaning and compliance with operating rules, but there are other factors that can lead to repair of the model:

- Fast heating if the fan fails;

- An open circuit or cable malfunction will not allow the device to turn on;

- Due to a cable break, there is no arc, this leads to the burning of the printed circuit board or loss of ground.

Positive Features

Before choosing one or another inverter, you should consider its features. The positives in the case of the described equipment option are:

- convenient control;

- ease of transportation;

- high reliability.

The manufacturer managed to achieve convenient control thanks to the ability to adjust the welding current. This allows for a smooth weld seam and ensures precise work. From reviews of the Resanta SAI-190 welding inverter, you can also understand that it is very easy and convenient to transport. This feature is ensured by the presence of a practical belt that allows you to move the device from place to place or load it into the trunk of a car for transportation.

We can’t help but mention reliability. It guarantees a long service life, which is ensured by a durable metal housing. It reliably protects the device from external mechanical influences. Additional advantages include the mobility of the device, which is ensured by its low weight. The service life is also extended thanks to forced tunnel cooling. The equipment does not require special technical maintenance. It is highly productive and equipped with the necessary functions for comfortable work.

Feedback on operating features

Before installing the equipment, you should evaluate the impact of electromagnetic interference from the equipment on the surrounding area. The manufacturer recommends paying attention to:

- radio and television transmitters and receivers;

- network cables;

- computers and office equipment;

- devices related to human health;

- equipment responsible for the safety of facilities;

- electronic control measuring instruments.

Consumers emphasize that the unit can be dangerous. Arc radiation sometimes causes damage to the skin as well as the eyes. The closer a person is to the arc, the more serious the injuries may be. They are caused by hot metal, slag and sparks. The welder and other people in the work area should have appropriate personal protective equipment.

After reading the reviews about the Resanta SAI-190 inverter, you can understand that it is better to use it after putting on a welding mask, special boots and a hat. It is recommended to wear a fire-retardant jacket and pants that cover all areas of the body.

Features of the inverter brand "Resanta SAI-190 PN"

An alternative offer from the manufacturer is an inverter at a higher cost of the SAI 190 PN brand. You can buy it for 9,000 rubles. The equipment is intended for the manufacture of structures, pipelines and containers, as well as the repair of products using manual arc welding.

Reviews of the Resanta SAI-190 PN will help you understand which device to give preference to. The one described in this section ensures stable operation at mains voltages from 140 to 242 V. As a bonus, the same functions of arc force and anti-sticking are provided. Additionally, the manufacturer has equipped the device with a hot start option.

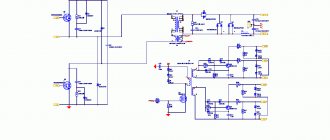

Circuit and faults

Below we have attached several images with SAI 190 diagrams. Open them in new tabs to view them in full resolution.

And this is a list of the most common malfunctions that occur during operation of the SAI 190. They can be corrected on their own. If more serious damage occurs, we recommend contacting a service center.

Working range and weight information

For easy control of operation, the inverter has LED indicators on the front panel. Thanks to them you can prevent overheating. The equipment operates over a wide temperature range. The maximum value reaches +40 °C. The reviews and price of the Resanta SAI-190 PN welding machine should interest you. After reviewing them, you will be able to understand that the equipment is lightweight, which allows the welder to move the device around the job site.

Advantages and disadvantages

The first obvious advantage of the Resanta model SAI 190 is its ease of connection. Insert the plug into a household outlet and you can get to work. The main thing is that the voltage in the network is sufficiently stable and is not less than 200V.

The second plus is the “filling” of this inverter. It is designed based on IGBT type transistors. It is thanks to IGBT transistors that the manufacturer managed to make such a compact and lightweight device, which at the same time has additional functionality.

Specifications

The described equipment belongs to the semi-professional class. At maximum current, the PV reaches the same 70%. The equipment does not have a case. You can use electrodes or wire with the unit, the diameter of which can reach 5 mm. The equipment weighs 6.4 kg.

Reviews and characteristics of the Resanta SAI-190 PN indicate that the maximum current of the unit reaches 190 A. The consumer will not have to spend money on purchasing a power plug, since it is supplied included.

Characteristics and Features

The inverter welding machine SAI model 190 can be used in conjunction with electrodes with a diameter of up to 5 mm. The maximum welding current that can be squeezed out of this device is 190 Amperes. At least according to the manufacturer