Rating of the best welding electrodes in 2022

Welding electrodes are metal rods with or without special coating. Each type of electrode is used for its own purpose.

Coated consumable electrodes are used for welding steel, cast iron and stainless steel. Non-consumable electrodes, such as tungsten, are used to form the edges of welded parts.

This site review will present a rating of the best welding electrodes in 2022.

Types of electrodes

The manufacturer of Arsenal electrodes, a plant under the same name "Arsenal", presented them in only two versions - MRZ ARS and ANO-4. However, each of them deserves close attention, including for home welding.

Arsenal welding electrodes have the following advantages:

- easy arc ignition;

- the constancy of its combustion;

- easy re-ignition of the arc after it has died out;

- minor metal spattering;

- melting uniformity;

- formation of an even seam;

- easy removal of slag.

In addition to electrodes, the plant produces filler wire. Arsenal electrodes, like all manufactured products, comply with international standards, which is combined with their low cost.

Core

Consumable type metal rods used when working with an inverter are selected in accordance with the type of metal of the parts and structures being welded. The welding wire from which the electrode core is made must comply with state standards.

There are three types of electrodes for inverter devices: alloyed, highly alloyed and carbon. Each of them is made from a corresponding type of welding wire. When working with high-alloy and stainless steel, experts recommend using rods TsL-11, carbon steel - ANO-21, UONI-13/45, MR-3S, cast iron - OZCH-2, low-carbon steel - ANO-4 and ANO-6.

Electrodes ANO-4

Arsenal welding electrodes of the ANO-4 brand are used for welding work using the manual arc welding method. Can be used by professional craftsmen and beginners. They are most suitable for welding carbon steels. Welding electrodes Arsenal brand ANO-4 have different diameters - from 2.0 to 6.0 millimeters, which allows you to weld products from 3 to 20 millimeters.

Their main advantage is the rutile coating. It ensures rapid ignition of the arc and its further stable combustion. This makes the job easier and results in a high-quality seam.

The possibility of being in space depends on the size of the diameter of the consumable. Electrodes having a diameter of less than four millimeters can provide the ability to weld in a variety of existing positions. If electrodes whose diameter exceeds this value are used, then the limitation is the direction of movement of this consumable element during vertical welding - it should be carried out from the bottom position to the top, and not vice versa.

When welding, alternating current is used. To use a permanent one, you will have to use a transformer. No preliminary preparation is required. The undemanding nature of the surfaces being welded allows for rust residues and minor contamination.

When using ANO-4, the seam is of high quality and durable. There are practically no defects such as cracks and pores. Welding of critical structures is acceptable. Before starting welding, it is recommended to calcinate the electrodes for at least one hour, especially if they were stored in a damp room.

Welding with an inverter machine

A characteristic feature of any type of inverter is the constant performance and stability of the welding current, which guarantee the quality of the resulting seam and the formation of alternating voltage that forms the welding arc. The connection of the surfaces to be welded is carried out by the melting method.

The qualitative indicators of the reliability of the unit are due to its design feature. Each device, regardless of type, consists of the following elements:

- frequency converter;

- control systems (center);

- transformer;

- power rectifier;

- network filter.

All of them form the general circuit of the inverter, and the main tool for welding is the electrode.

Electrodes MP-3

In terms of their advantages, MRZ and ARS electrodes are similar to ANO-4 brand electrodes, but there are still some differences that make them even more popular. The welding workflow with this type of electrode is much easier than when using other models. Arsenal MP-3 electrodes can be used in industrial production and for domestic use.

One of the main features is that there is no need to remove slag residues from the surface of the seam, since it separates on its own. All that remains is to remove him from the place of work.

Another undeniable advantage is the ability to use MP-3 Arsenal electrodes for surfacing metal with gaps of a sufficiently large size. Their use allows welding not only on a short arc, which is still difficult, especially for beginners in this matter, but also on a long one.

The rutile coating, which includes titanium dioxide, provides strength and resistance to the formation of defects such as pores and cracks, and also reduces the susceptibility to corrosion. The coating has a slightly greenish color.

Arsenal 3mm electrodes allow you to work with a long arc, which is important when the surface is of poor quality and there are oxides on it. Arsenal 3 mm electrodes allow you to fill cracks and gaps of any size. The resulting seam is of high quality and even. The average consumption of electrodes for one hour of welding work is 1.7 kilograms, that is, in order to weld one kilogram of metal, 1.7 kilograms of MP-3 welding electrodes will be required.

The diameters are as follows: 2.5; 3.0; 3.2; 4.0; 5.0 millimeters. Such a large selection simplifies the welding conditions. Depending on the diameter of the electrode, the current value is set. If you have to work with structures that have walls of medium and large thickness, then the mode is set to the maximum, and the electrode is moved along the welding process with a slight inclination. You can weld using the short tack method.

If thick-walled parts are welded, then a reinforced seam is applied and the current size is increased. Electrodes with a diameter of 5.0 millimeters are used for work in the lower and vertical positions. Ease of use allows you to perform various types of welding work.

Protective covering

Electrodes differ in the type of coating used. There are four types of coatings:

- main or SSSI;

- cellulose;

- rutile;

- sour.

Rods with cellulose and base coating create elastic, reliable, impact-resistant seams when carrying out welding work with direct current. Rutile with acid coating are universal. Coatings are used for welding with both direct and alternating current.

Electrodes coated with acidic coating are toxic. Work with them is carried out in closed spaces only when the rooms are equipped with good forced exhaust. Rods coated with rutile, which has a bluish or greenish tint, are easy to ignite. This parameter remains unchanged when operating the inverter at low open circuit voltage.

Electrodes ANO-21

Arsenal ANO-21 electrodes are used for welding parts with a thickness of one to four millimeters made of low-alloy and carbon steels. This model is available in diameters 2.0; 2.5; 3.0 and 4.0 millimeters.

For their manufacture, wire is used containing additives that increase the value of the surface tension coefficient of the formed deposit. This makes it possible to work on seams located in the ceiling and vertical positions without fear of metal leaking out of the weld pool.

The advantages of ANO-21 electrodes include: easy ignition of the arc, stability of its combustion, formation of easily removable slag, strength and durability of the seam, which is sealed. However, they cannot be used when it is necessary to weld parts of large thickness and pipeline joints under high pressure. If vessels operate under low pressure, then it is possible to use this type of electrodes.

Areas of application

The product is used during manual electric arc welding (MMA) of workpieces made of carbon alloys. The most common areas of application are the following:

- installation and field repair of pipelines and vessels operating under low pressure;

- assembly of critical structures with butt, corner and overlap seams;

- welding root seams on thick workpieces.

ANO-21 is used at industrial enterprises in the field of shipbuilding, mechanical engineering, distribution networks in housing and communal services . Both repair shops and home craftsmen use electrodes with pleasure.

Decoding the brand of electrodes Uoni

- Electrode brands

- Types of electrodes

- Questions and answers

Many people want to know the full decoding of the brand of Uoni electrodes, to find out what the abbreviation Uoni means, as well as what the letters mean and how Uoni differs from Uoni, and therefore here we will reveal all the secrets of these letters and numbers.

What does the abbreviation uoni 13 and uoni-13 stand for?

- U - Universal

- O - Coating

- N - Scientific

- I - Research

- I - Institute

- 13 — №13

And here’s how the abbreviation uoni 13 came about.

This is an excerpt from the report which is located at the bottom of this page.

Apparently this means

- U - Universal

- O - Coating

- N - Scientific

- I - Institute

- 13 — №13

It's back to 1940.

What is the difference between SSSI and SSII?

At first the name was simply uoni, but later, according to GOST 9466-75, everything changed.

UONI-13/45 electrodes should be designated UONII-13/45 and belong to the E46A type, and in the future, various versions of Uoni electrodes will be called Uoni.

You can look it up in the book (Sapiro L S Welder's Handbook, page 53 in the note.) Open the book.

Excerpt from GOST 9466-75.

The whole point is that on the labels or in the markings of boxes, packs and boxes with electrodes, both uoni and uonia can be written, but in the documentation the uoni must be specified.

How to determine high-quality UON electrodes

About how the quality of the same electrodes differs depending on the manufacturer who has been tested and who simply makes them according to GOST.

The same electrodes are subject to different manufacturing requirements and different materials used in manufacturing.

GOST and certified by NAKS (National Agency for Control and Welding).

Let's compare electrodes that are very similar to each other, but with different quality. (The quality varies quite a lot, as does the price)

To compare prices in the Yandex store and in Uonia and Uonia. As you can see, the difference is quite noticeable.

Link to the report https://cniim.com/files/doklad_2012_1.pdf

Link to report in pdf (Open)

The page decoding the electrodes will help you for complete clarification down to each letter and number of UONII -13.

If you have any questions or would like to supplement this material, please write to us using the feedback form located on the questions and answers page.

If you have a desire to buy high-quality welding electrodes, this can be done through the contact page

- What to do if the electrodes get wet

- What does changing polarity give when welding with electrodes?

- How many times can electrodes be calcined?

- Electrode sticks when welding

- Difference between UON and MR electrodes

- Difference between ANO and SSNI electrodes

- What are Uoni electrodes needed for?

How to choose a welding electrode?

Dear novice welders, in this article we will briefly talk about electrodes and give practical recommendations on their use.

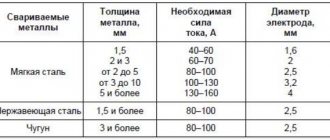

- Metal thickness - (the thicker the metal, the larger the diameter of the electrode).

- Steel grade - (ferrous metal, stainless steel, heat-resistant, etc.).

- We determine the current by the electrode!

- Welding position - (bottom, horizontal, bottom T, vertical - welding from bottom to top, ceiling, ceiling T).

Which welding electrode to choose?

MP-3 and ANO - these electrodes are best used on alternating current. They are not picky about dampness. These electrodes are not for critical structures; they are never used to weld bridges and load-bearing roof beams; they are used to weld fences, gates and greenhouses in the country, fences, and small metal structures for domestic use. If there is no overload, these are the electrodes for you. The most popular brands among amateur welders and summer residents.

UONII 13/55 are excellent electrodes, but very “specific”. UONII 13/55 is brewed by professionals. You have to cook on a short arc! These are electrodes for critical structures. They burn only on direct current, they like a stable arc and do not like voltage surges. Start working with UONII 13/55 only when you learn how to cook MP-3 and ANO.

LB-52U - we recommend buying these electrodes from the Japanese company KOBELCO. These electrodes are used for welding pipes under high pressure. Very high quality seam. LB-52U electrodes are one of the most expensive; as a rule, they are purchased by enterprises and structures involved in the repair of urban heating/water networks.

We introduced you to the most popular electrodes. Below we will briefly describe the electrodes of the ESAB Concern (Sweden), perhaps you will find exactly what you need. All ESAB electrodes begin with the letters OK - in honor of the founder of the Concern, Oskar Kelberg.

OK 46.00 ESAB (Russia) – metals can be welded with these electrodes using direct and alternating currents. Often these electrodes are called UNIVERSAL or ELECTRODE FOR STEEL. If you don’t know what to choose, take these electrodes – you won’t go wrong. Electrodes are good because they have a wide range of diameters. You can always choose the one you need.

OK 48.00 ESAB (Sweden) - DC only. Ideal for critical structures.

OK 61.30 ESAB – stainless steel/stainless steel welding (steel grades 304, 308L, 03Х18Н11, 06Х18Н11, 08Х18Н10, 08Х18Н10Т, 12Х18Н10).

OK 67.60, OK 67.62 ESAB - stainless steel/steel welding.

OK 63.30 ESAB (Russian analogs of ANV-26) - (steel grades 316 , 03Х17Н14М2, 10Х17Н13М3Т, 06Х19Н11Г2М2) are ideal for welding thin-walled pipes and thin-sheet products.

If you don’t understand what kind of steel is in front of you, you don’t know its composition - your choice is OK 68.81, OK 68.82 - these electrodes can be used to weld dissimilar steel products and steels of unknown composition.

There are many nuances when welding cast iron!

Welding cast iron steel ESAB OK 92.18 (new name OK Ni-Cl) - designed for welding thin cast iron (no more than 3 layers).

Welding cast iron; cast iron steel ESAB OK 92.60. (new name OK NiFe-Cl) - they can just cook cast iron of any thickness and cast iron with steel

Aluminum welding. Aluminum is a very complex metal, it requires heating before welding, it melts quickly and hardens quickly. Aluminum is usually welded using TIG or MIG welding. It is very difficult to weld aluminum with an electrode, but if you succeed, you can consider yourself a master!

OK 96.20 ESAB - it can be used to weld a very limited number of grades of aluminum. Study the composition carefully.

The most universal electrode for aluminum is OK 96.40 . IMPORTANT that the aluminum electrode must be used in one ignition. An unfinished electrode must be replaced with a new one. Plus, unlike steels, you need to make circular movements with the end of the electrode.

Why do you need to calcinate the electrodes?

The electrodes are calcined in order to remove moisture from them. If the electrode is damp, during welding, defects may occur in the weld seam or the electrode will constantly stick to the product.

Please note that in our online store all the electrodes are “fresh”, we purchase them from suppliers who have special heated warehouses, the electrodes are not stored in warehouses for more than a month, all packs are sealed.

Features of work

The main feature of ANO-21, like other products with rutile coating, is the ability to work in difficult conditions, on wet workpieces with traces of corrosion. However, the electrode itself must be almost completely dry. To do this, they are stored in sealed packaging, and if moistened, they must be calcined for 40 to 60 minutes at a temperature of 120 o C.

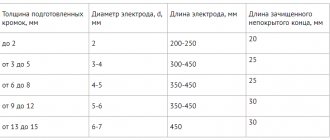

Welding modes depend on the diameter of the product:

Diameter, mm

You should not try to weld workpieces thicker than 5 mm or pipe joints that must work under pressure with such electrodes. Such attempts will not lead to anything good. It performs the work for which ANO-21 was designed almost flawlessly

To come in

Already registered? Sign in here.

There are currently 0 users on the page

There are no users viewing this page.

| Length, mm | Quantity per 1 kg, pcs. | Operating current, A | |||

| Lower | Vertical | Ceiling | |||

| 2 | 300 | 95 | 60-100 | 70-80 | 80-100 |

| 2,5 | 300 | 58 | 70-120 | 70-100 | 90-110 |

| 3 | 350 | 40 | 100-150 | 90-110 | 110-140 |

| 4 | — | — | 160-190 | 150-170 | 150-180 |