A mandatory type of measuring instrument for completing heating networks, water supply, gas supply and other engineering systems is a pressure gauge.

It allows you to measure the excess pressure of the working medium in the pipeline, inside vessels and equipment.

In addition, using special formulas, you can obtain the values of flow rate, medium velocity and other parameters. Accurate measurements can only be ensured if the device meets operating conditions and technological requirements.

Therefore, it is important to have an idea of how to select a pressure gauge for installation in the system.

How to choose a suitable pressure gauge

When choosing a pressure gauge, it is important to consider the following basic characteristics of the device:

- Measuring range - it must be selected so that the expected operating pressure falls within the range between 1/3 and 2/3 of the maximum value measured by the pressure gauge. If the operating pressure is less than 1/3 of the scale, a large error is possible. If it exceeds 2/3, then the device will operate in overload mode, which can lead to damage.

- Accuracy class - the higher the accuracy class, the more correct the device’s readings will be, but the higher its price will be and the worse it will withstand overloads. Therefore, the accuracy class should be chosen based on what measurement error is suitable for your conditions.

- Diameter – this parameter should be selected based on how much free space there is to install the device. Devices with larger diameters take up a lot of space, but are easier to read readings.

- Fitting placement – the most common models are those with a vertical fitting and a fitting located at the rear. The choice between them is based on the geometry of the place where the device is planned to be placed.

- The thread on the pressure gauge fitting must match the thread on the pipe where it will be installed.

How to find out the accuracy class of a pressure gauge

The accuracy class is indicated on the instrument scale; the letters KL or CL may be placed in front of the numerical value.

Calculation of the accuracy class of the device

Let's assume that the scale indicates an accuracy class of 1.0, and the measuring range of the device is 250 Bar. When comparing the pressure measurement results with the readings of a standard pressure gauge, it turned out that the error was 2 Bar. Does the pressure gauge comply with the specified accuracy class?

In order to answer this question, we will calculate the accuracy class; to do this, we will correlate the measurement error with the measuring range of the device and express the result as a percentage.

The result obtained does not exceed 1, which means that the pressure gauge corresponds to the specified accuracy class of 1.0.

Rules for operating pressure gauges

In order for the pressure gauge to last as long as possible and show the correct values, it is important to observe the temperature regime recommended by its manufacturer, use it to work with exactly the environment for which it is intended, and prevent the pressure gauge from being exposed to excess pressures that go beyond its measurement scale. Pressure on the device must be applied smoothly - sudden surges in forward or reverse pressure can damage the pressure gauge mechanism.

To ensure the correctness of readings, pressure gauges must undergo mandatory annual verification (some models allow verification once every 2 years), which must be performed by a representative of a licensed metrology center. Based on the verification results, the body of the measuring device must be sealed or branded.

The use of pressure gauges with the following defects is not allowed:

- Damage to the glass behind which the instrument needle is located.

- There is no seal or verification stamp, the verification period has expired - without regular verification, the pressure gauge can only be used as an indicator; its readings cannot be considered reliable.

- The arrow of the device does not return to the zero mark after removing the pressure.

- When applying or removing pressure, the needle does not move or moves in sharp jumps.

Top 10 rating according to KP

Editor's Choice

BERKUT ADG-031 (from 1390 rubles)

Analog pressure gauge BERKUT ADG-031.

Photo: BERKUT From the manufacturer’s description it follows that the BERKUT ADG-031 dial pressure gauge is used not only to measure the pressure in car tires, but also to reduce it, if necessary. The model has a special valve designed to release excess air in case of emergency. Owners of all-wheel drive cars who like to drive off-road should pay attention to the device. The device also claims to have increased accuracy. To avoid contamination and damage, the pressure gauge is equipped with a special protective cover.

Characteristics:

| Pressure gauge type | analog |

| Maximum measurement value | 2.5 bar |

| Additional Information | division value: 0.1 Atm/1 Psi |

| Equipment | bag-case |

Reliability, accuracy

Not attuned to real values

show more

Wester MTG-100 (from 569 rubles)

Wester MTG-100. Photo: Wester

This digital pressure gauge can perform several functions at once. Thus, it is used to measure and control the pressure in car tires, and is also suitable for working as a portable flashlight. The device has LED backlighting. It is also equipped with an emergency hammer head for emergencies and a blade for cutting seat belts.

Characteristics:

| Pressure gauge type | digital |

| Minimum measurement value | 0.21 bar |

| Maximum measurement value | 6.9 bar |

| Weight | 130 g |

| Additional Information | Built-in LED flashlight, emergency hammer, seat belt cutter |

Measurement accuracy, functionality

Uncomfortable shape

show more

STARWIND CM-130 (from 840 rubles)

STARWIND CM-130. Photo: STARWIND

This device is rightfully in the ranking of the best pressure gauges. It has most of the necessary measurement scales: PSI, Bar, kPa. The error of the first is 0.5 psi, the second is 0.05 Bar, and the error of kPa is 1. This indicates the accuracy of the device. The model is comfortable to hold in your hands. It is powered by AAA batteries. Additional features include a built-in seat belt cutter and glass hammer. Such additions are designed to help in emergency situations.

Characteristics:

| Pressure gauge type | digital |

| Minimum measurement value | 0.2 bar |

| Maximum measurement value | 10.2 bar |

| Maximum operating temperature | + 50 degrees |

| Additional Information | graduation value: 0.05 bar, 0.5 psi, 1 kPa |

| Measurement limits | 3-150psi, 50-1055kPa |

Functionality, reliability

Dimensions

show more

Where to buy a pressure gauge and how much does it cost?

You can purchase a reliable and inexpensive pressure gauge for a domestic or industrial water supply or heating system in the MILLENNIUM online store. The cost of pressure gauges depends on their design and operating pressure range. Thus, the option with a rear connection and a maximum pressure of 6 bar has a price of 180 rubles, while a vertical pressure gauge with a maximum measured pressure of 10 bar costs from 220 rubles.

The MILLENNIUM company offers favorable terms for delivery of orders. You can receive the ordered goods:

- pickup from company stores or warehouses;

- via courier delivery service;

- at the branch of the selected transport company.

What other pressure gauges are worth paying attention to?

Heyner 564100 (from 379 rubles)

Heyner 564100. Photo: Heyner

An inexpensive device designed to monitor car tire pressure. It copes with its functions perfectly. Users note that the model is distinguished by the accuracy of its readings. This is where the nice design catches your eye. When measured, the arrow stands up straight and does not bounce—not all devices can boast of this. The product does not slip in the hands and does not create unnecessary inconvenience for car enthusiasts.

Characteristics:

| Pressure gauge type | analog |

| Device type | deformational |

| Principle of operation | pneumatic |

| Minimum measurement value | 0.5 bar |

| Maximum measurement value | 4.4 bar |

Compact, convenient

Few measurement scales

show more

Vympel MN-01 (from 202 rubles)

Pennant MN-01. Photo: Vympel

This representative of the rating of the best pressure gauges is designed for measuring air pressure in tires of cars, trucks, as well as on bicycles, motorcycles, ATVs and other types of transport. It works using a pointer-analogue system. The metal body makes the device reliable. There is a reset button, which is also convenient. A plastic case is included.

Characteristics:

| Pressure gauge type | analog |

| Device type | deformational |

| Principle of operation | pneumatic |

| Maximum measurement value | 7.2 bar |

Iron case, case included

There may be errors in readings

show more

Airline APR-D-04 (from 380 rubles)

Airline APR-D-04. Photo: Airline

The model is designed to measure pressure in car tires. Among the advantages that the manufacturer names is a liquid crystal display that shows data and also allows you to measure pressure in three units: ATM/PSI/KPa. Maximum measured pressure: 7 ATM / 100 PSI / 700 KPa. All readings are recorded.

Characteristics:

| Pressure gauge type | digital |

| Device type | piezoelectric |

| Principle of operation | pneumatic |

| Maximum measurement value | 7 bar |

Measurement accuracy, sturdy

Equipment

show more

Digital pressure gauge Golden Snail GS 9203 (from 365 rubles)

Golden Snail GS 9203. Photo: Golden Snail

Model made in China. But there is no need to be afraid, its characteristics and qualities are acceptable. The manufacturer calls this pressure gauge a portable, high-precision device. Like many other devices in this series, it is used to measure and control tire pressure. The maximum measurement value here is 7 bar.

Characteristics:

| Pressure gauge type | digital |

| Additional Information | there is a digital indicator |

| Maximum measurement value | 7 bar |

Turns on quickly, accurate readings

Not the most convenient

show more

Dollex MSC-20 (from 589 rubles)

Dollex MSC-20. Photo: Dollex

Good quality model. Works with car tires. Among the advantages here is the ability of all digital meters of the brand to show the result on any scale for determining pressure. The cost of the device is affordable, which also attracts car enthusiasts. The pressure gauge is very strong and can work at temperatures up to 40 degrees.

Characteristics:

| Pressure gauge type | digital |

| Additional Information | there is a digital indicator |

| Maximum measurement value | 7 bar |

| Maximum operating temperature | + 40 degrees |

| Weight | 68 g |

| Measuring range | 0-100 psi/0-7.0 Bar/0-7.0 kg/cm/ 0-700 kpa |

| Nutrition | 3V,CR2032 |

| Working temperature | 0°C - 40°C |

| Instrument error | +/- 0.5 psi |

Measurement accuracy, backlight

Fragile design

show more

Daewoo DWM7 (from 759 rubles)

Daewoo DWM7. Photo: Daewoo

The DAEWOO DWM 7 digital pressure gauge is another device designed to measure and monitor tire pressure. The device has a stylish design. All the information drivers need can be easily read on the LCD display. You can also work with this device at night - an LED flashlight will help.

Characteristics:

| Pressure gauge type | digital |

| Minimum measurement value | 0.2 bar |

| Maximum measurement value | 6.9 bar |

| Maximum operating temperature | + 50 degrees |

| Weight | 56 g |

| Units | atm,psi,kPa,kgf/cm² |

| Battery Type | 4xLR44 |

| Additional Information | backlit display; built-in LED flashlight; rubberized shock-resistant housing |

Convenience, design

Plastic quality

show more

Muscle M10 (from 480 rubles)

Jock M10. Photo: Jock

This digital pressure gauge is aimed at timely determination of car tire pressure. It's easy to use. The owner must attach the device to the tire valve, look at the screen and record the readings. Errors, according to the manufacturer, can be minimal, for example, 0.5 bar. The screen is backlit, which will help you see the data even in the dark. The device works even at high temperatures.

Characteristics:

| Pressure gauge type | digital |

| Minimum measurement value | 0.15 bar |

| Maximum measurement value | 7 bar |

| Maximum operating temperature | + 40 degrees |

| Units | psi/bar/kPa |

| Equipment | batteries 5xLR44 (L1154) (inside the device), blister packaging with instructions for use |

| Additional Information | there is a digital indicator |

Can be used instead of a flashlight, convenient digital screen

No reset button

show more

Importance and relevance of pressure gauge classes

When selecting a pressure gauge (the device is usually abbreviated as “DM”) for ordinary living conditions, users rarely pay attention to its error group.

As we have already said, accuracy is not particularly important for such purposes as monitoring mPa (bar, atm) in tires, when it is enough for the user to know the approximate value, or deviations of fractions of divisions or even several marks will not affect the overall picture and condition of the equipment. But high accuracy of readings is always desirable for boilers, heating, water supply, pumps of this equipment and for similar purposes.

And also the accuracy group is one of the parameters that must be paid attention to when the correctness of measurements is especially necessary. For housing and communal services, industry, production, for pressure-sensitive equipment, where a deviation of even one division leads to wear and tear of the equipment, accidents (central water supply systems, heating systems, boiler rooms).

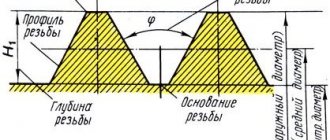

How to read labels, calculations

The more insignificant the deviations of the DM, the lower the number in its class designation (numerical expression). The range varies, but the most common is 0.4–4.

GOST 2405 defines how it is recommended to designate the device:

Relationship with dimensions

Device type according to class. exact usually associated with the diameter of its graduated part (with the dial). This refers to mechanical devices with an arrow-pointer running along the divisions painted on a given segment.

More details according to GOST 2405:

The same document contains data on the connection between the dial and accuracy classes:

There are also drawings of scales and graduation options:

The diameters of the scales of pressure meters are usually within the following range (in mm): 40, 50, 63, 80, 100, 150, 160, 250.

The values may be different and depend on the standard size according to the agreed specifications with the licensing authorities.

The larger the scale diameter, the smaller the deviations and the lower (better) the accuracy class. The pattern can be traced from the table (see above), for example, a device with Ø50 has groups 2.5 and 4, and a DM with Ø250 has the best (high) accuracy of readings and characteristic smaller values of error groups.

So, the lowest accuracy is for products with a dial Ø40–50, the highest is for standard sizes with a dial Ø160–250.

Dependence on measuring range

Errors depend not only on the classes, but also on the measurement range for which the pressure gauge is designed.

The limits of the pressure gauge's capabilities in terms of the measured value can be any - different manufacturer decisions are allowed. For standard instruments they are extended. But the most standard, statistically average are the following:

Recommended measurement ranges are indicated in GOST R 8.905 in table. adj. A.

How to calculate and determine the class (error) of pressure gauges

Initial data: we have a DM with a range of 10 mPa, group KL 1.5. This means that the greatest possible error of the meter should not be higher than the test result. You can calculate it using the following algorithm:

10×1.5/100=0.15 mPa

You can also find out the maximum deviation as a percentage, this method is consistent with the above formula (0.15 in the example described above is 1.5%). This can be done simply by looking at the class marking number. The number means the following: the greatest error in the pressure gauge readings will be 2.5% of its measurement range.

How to Determine If a Pressure Gauge Is Out of Class

To check whether the level of error is within the assigned class, it is necessary to compare the experimental product with the reference one.

Order:

- Take 2 devices: the reference and the one being tested.

- Measurements are taken with two meters under similar conditions, especially temperature.

- Record the readings. They look at how the readings differ, draw a conclusion about the magnitude of the deviation, and whether it is within the permissible error for the assigned class.

- Carry out the above several times and find the maximum deviation.

The above procedure allows you to assign the meter to a certain accuracy class. In a similar way, manufacturers verify products at factories, but to make the results official, the algorithm is more complex, taking into account many factors, with additional tests. Displayed in journals, procedural acts, certified by seals, signatures of responsible persons, regulated by GOSTs and other regulatory documents. An example of groups of such norms:

We have already described how to calculate the percentage of deviation; here it is also performed as the last step of the verification procedure. For example, the scale range of the test sample was 300 bar, revealing deviations of 3 bar from the reference device. Let's calculate the % error:

3×100/300=1. The result does not exceed 1.

Accuracy class for the above case is 1. If the figure is higher, even by a fraction, then this is the next group.

Regulations

An explanation of what the accuracy class of a pressure gauge is given by GOSTs, in particular R 8.905:

The main acts on accuracy for pressure gauges are GOSTs R 8.905 and 2405. Documents related to them and those to which they contain links also serve as sources of standards. Further, we will illustrate the article with excerpts of text in the form of images from these two regulatory documents.

For specific areas, the level of correctness can be established by the standards in force for it, including labor protection and safety, for example, for pressure vessels (cylinders and the like) there are the following standards.

The issue of errors is regulated and specified by acts for certain narrow areas, for example, for well pumps: