A spring is considered a fairly common product that is used in a wide variety of mechanisms. To create them, a project is developed, of which the diagrams are part. The schematic display is characterized by a fairly large number of features, only when taken into account can the development of the project be carried out. Let us consider all the features of its image in the drawing in more detail.

Types of springs and their designation in the drawings

There are quite a large number of different types of parts, and they are displayed differently on the document. The following have been distributed:

- Screw type is the most famous type, which is used today to create a wide variety of devices. An example is a car suspension. This design option is available in cylindrical and conical form. This drawing of a spring is very common and can be displayed in a simplified or other version.

- Torsion versions resemble the previous one, however, they can work simultaneously in torsion and bending. This type of part is used to create suspensions for heavy vehicles, measuring and many other instruments. On the document this option is depicted somewhat differently, it all depends on the specific variety.

- Spiral ones are used to create a wide variety of mechanisms, for example, wristwatches. The key feature is that a wire of a certain diameter is wound in a spiral. The distribution of a product can be associated with the possibility of accumulating and storing potential energy.

- Disc-shaped ones only partially resemble the classic version, but they are used quite often. They are represented by several disks that are located among themselves. The main advantage of this proposal is the insignificant deformation of the structure when exposed to large forces. Most often, poppets are used to create safety valves and

- Wave structures, which are characterized by their specific key features, can also be used. An example is that the coils have a strong curvature, due to which the dimensions of the device are significantly reduced.

Classification is also carried out according to the intended purpose of the product. The following main groups are distinguished:

- Sprains. In this case, adjacent rings are without clearance relative to each other.

- Compression. During manufacturing, a certain gap is left, which allows the last two rings to be brought closer to each other.

- Torsion and bending.

Many design options are displayed on the document taking into account established standards. At the same time, we should not forget that various parts are characterized by their specific performance characteristics.

Displaying the technical parameters of the spring in the drawing

Designation can be made on a drawing using a variety of methods. An important point is that the applied standards are specified in GOST 2.401-68. The applied scheme and established standards determine the following points:

- All product types must be displayed in exempt condition only. It is characterized by the fact that there is no pressure on the wire from the external environment.

- It is worth considering that for all products an additional note is created, which indicates all the main technological features.

Download GOST 2.401-68

There are quite a large number of different parameters that are important. An example is the number of turns, stiffness coefficient and much more.

Manufacturing

The production of torsion springs requires special equipment and careful calculations. To obtain a high-quality result, we use ready-made standard projects or create new ones in accordance with the customer’s individual criteria. Making a spring is a simple process, provided that projects are developed in advance, drawings are available and modern production equipment is available. All operations today are automated and practically do not require constant monitoring by operators.

After the production of the first batch, the products are necessarily tested for compliance with the declared properties and general standards for this type of product, and only after that the finished order is shipped to the client.

For the production of springs, stainless steel and steel wire, alloy steel, and various high-temperature and corrosion-resistant alloys are used.

Compression spring drawing

Executions designed for compression have become quite widespread. They are used to create a wide variety of mechanisms, and at the same time are characterized by their own specific features. Considering the drawing of a compression spring, we note the following points:

- In the case where the part has more than 4 turns, only 1-2 turns are drawn on both sides.

- Due to the large length, all rings are not shown. However, the latter are displayed as a dashed line and an axial line is created.

- If a wire is used in the manufacture of a product, which has a thickness of no more than 2 mm, then it is displayed by lines with a thickness of 0.6-1.5 mm.

Do not forget that all dimensions must be displayed on the document. The most important are:

- Diameter of the wire used. It can vary over a fairly large range.

- Ring spacing. Another determining parameter that must be taken into account.

- Average diameter, as well as internal and external. They determine the main dimensions.

- Free length of the product. The free state is considered to be when there is no load on the part.

In general, we can say that the task of displaying the part is quite difficult to perform.

1.5. Fonts

GOST 2.304-81* defines the style, dimensions and rules for making inscriptions on drawings and other design documents.

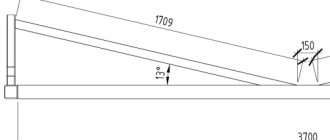

The inclination of letters and numbers to the base of the line should be about 75°.

Font size (h) is a value equal to the height of capital letters in mm.

The height of capital letters h is measured perpendicular to the base of the line. The height of lowercase letters c is determined from the ratio of their height (without extensions k) to the font size h, for example, c=7/10*h.

Letter width (q) - the greatest width of a letter is determined in relation to the font size h, for example, q=6/10 h, or in relation to the line thickness of the font d, for example, q=6d.

Font line thickness (d) - thickness determined depending on the type and height of the font.

Auxiliary grid - a grid formed by auxiliary lines into which letters fit. The pitch of the auxiliary grid lines is determined depending on the thickness of the font lines d (Figure 1.4).

When preparing drawings and other design documents, it is recommended to use type B font with a slope of 75° (d=1/10h) with the parameters given in Table 5.

Table 5 - Fonts

The following font sizes are set: (1.8); 2.5; 3.5; 5; 7; 10; 14; 20; 28; 40.

Figure 1.4 – Type B font with slant

For questions regarding tutoring in engineering graphics (drawing), you can contact us in any way convenient for you in the Contacts section. Full-time and distance learning via Skype is possible: RUB 1,000/academic hour.

Tension spring drawing

A part that is intended to be stretched is characterized by its own specific characteristics. It also occurs quite often, but special properties are also reflected in the schematic display. The extension springs under consideration are depicted as follows:

- In the free state, all the turns are close together, there is no gap. This point largely determines the difficulties in displaying the product.

- The pitch in the case under consideration is equal to the width of the wire.

- All turns, except the outer ones, which are intended for engagement, are in operation during operation.

- The document shows the toe rings in expanded form. They are an important part of the stretching mechanism and are designed for fixation.

As in the previous case, in this case the main dimensions except the step are displayed. Examples include the outer and inner diameters, as well as the free length.

Cold coiling technology without hardening

First you need to do preparatory operations. Before a workpiece is wound from wire, it is subjected to a patenting procedure. It consists in heating the material to the plasticity temperature. This operation prepares the wire for the upcoming change in shape.

During the winding operation the following parameters must be maintained:

- External diameter of the product (for some parts the internal diameter is standardized).

- Number of turns.

- Winding pitch.

- The total length of the part, taking into account subsequent operations.

- Compliance with the geometry of the end turns.

Cold coiling without tempering

Next, the end turns are ground down to a flat state. This must be done to ensure high-quality support for other structural parts, to prevent their destruction and the spring from slipping out.

The next stage of the technological process is heat treatment. Cold coiling of springs involves only tempering at low temperatures. It allows you to increase elasticity and relieve mechanical stresses that arise during winding.

After heat treatment, it is necessary to carry out test and control operations.

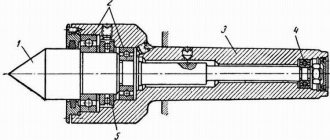

Torsion spring drawing

As previously noted, the design option designed for torsion is quite difficult to display. The key points are the following:

- Two types are often depicted.

- If a part has a large number of turns, then a certain part is not displayed.

- The main dimensions can be called the diameter of the wire used in manufacturing, the diameter of the created rings and the central bend.

The considered version of torsion is very common. It is used in the manufacture of various mechanisms.

Calculation

When making springs, the first step is to make a calculation. If the calculations are made incorrectly, the element will not cope with the load or will fail prematurely.

The following values are used for calculation:

- highest torque;

- twist angle;

- diameter of wire and spring;

- material strength – nominal and ultimate.

If you are not an engineer, you should not carry out independent calculations of torsion springs - the probability of error is too high. But to facilitate calculation work, you can find special calculators on websites.

Most often, for the manufacture of springs, standard designs are used, drawings for which are already available, but if it is necessary to make a batch according to an individual order, specialists come into play and develop new documentation.

The torsion spring drawing includes the following information:

- winding direction (in technical requirements);

- dependence of load on deformation and vice versa;

- hardness value (for products with further heat treatment).

If the number of turns is more than 4, then they may not be fully displayed on the drawings; all necessary information is in the accompanying documentation and technical requirements.

Wire product drawing

All types of mechanisms are made using wire. That is why the following information is indicated when displayed:

- Diameter.

- Length.

- Type of material used in manufacturing.

Some details cannot be displayed in a simplified form. This is why quite a lot of difficulties arise when creating a document.

How to draw a spring?

There is practically no single and universal algorithm for displaying the product in question. That is why you can draw a spring using a variety of methods. In addition, there is a unified design documentation ESKD drawing. The algorithm of actions is as follows:

- The axis is displayed. Established standards determine that the axis is displayed as a dash-dotted line.

- The main parameters are determined. An example is the pitch between individual turns, as well as the diameter of the wire used.

- Circles are displayed with a certain step. To do this, axes are drawn, the distance of which is determined by the pitch, as well as the diameter of the turns. Initially, the circles are drawn with a thin line.

- The circles are connected to each other by lines. Due to this, the main part is formed. Where the turns intersect, the lines are drawn with strokes.

- The next step is to break the central part in the case of a large length of the part in the free state.

- Next, the main dimensions are applied. As previously noted, this is the free length, the average, minimum and maximum diameter of the turns, the diameter of the wire used in manufacturing, the pitch and some other parameters. It is worth considering that if there is not enough free space to display all sizes, they are entered into a special table.

The depiction of springs in the drawings involves the creation of a fairly large number of auxiliary lines, which are required for the precise positioning of the main elements. The cable suspension of some other mechanisms is also displayed in a similar way.

In conclusion, we note that today you can draw a sketch manually or using special programs. More often than not, special software is used recently. This is due to the fact that the electronic form of the product is the easiest to transfer and correct. In addition, when using the program, you can increase the accuracy of the finished result and speed up the process itself.

Equipment and fixtures used

To make an elastic element, specialized equipment is required.

These are winding machines. You can make a part on a regular lathe, but it will require additional equipment with special equipment. Medium and large series are produced on semi-automatic machines that operate with minimal operator intervention. You can also make a spring from wire by hand. This will also require special equipment. At the next stage of machining, the ends are ground on face grinding machines. For single production or small series, this can be done with a grinding wheel.

Heat treatment is carried out using mandrels that prevent product deformation in specialized furnaces for hardening and tempering. Both operations can be done in a universal oven.

Equipment and fixtures used

For quality control, load installations and measuring systems are used. In case of single production, measurements can be made with a universal tool.

If you find an error, please select a piece of text and press Ctrl+Enter.

In November 2022, the production facilities of LLC "PRUZHINA.RU" were modernized. In 2022.

Due to the expansion of production capacity, the list of open vacancies in ours has been updated.

Please accept our sincere congratulations on the upcoming New Year 2017! May the coming year.

A new section “Drawings of springs and wire products” has been created on our website, we hope that it will.

Flat springs are plates of a given shape (curved or straight) that work in bending (elastically bending under the influence of external loads). Used when the device is exposed to forces in small ranges of travel.

Flat springs - all types:

According to their shape, flat springs are divided into straight and spiral. According to the methods of fastening and places of application of loads, flat springs are divided into those that work as: • a cantilever beam. Free end load. • beams on two supports. Load on supports. • beams with a fixed end and a second freely lying one. Load on the second support. • beams with a hinged end and the other freely lying on a support. Load on the second support. • Round plates, with fixed edges and load in the middle (diaphragms)

Design and production of flat springs:

When designing sheet flat springs, it is desirable to select the simplest forms to facilitate their calculations. Installation of flat springs involves pre-tensioning them.

Flat Coil Springs:

The action of this type of spring is based on the occurrence of a bending moment in the plane normal to the axis of the spring. Application - watches, mechanisms, recorders and similar devices as winding springs - energy accumulator. Placed in drums to provide lubrication and fixation of external dimensions.

Efficiency:

The efficiency of spiral flat springs is the ratio of the work of the spring performed during deployment to the amount of work spent on winding. The efficiency ranges from 0.7 to 0.85, the limit value is up to 0.9.