From this article you will learn how to saw with a grinder without dust; a total of 3 simple methods are described.

When sawing concrete, brick, stone or tile with an angle grinder, a large amount of dust is generated.

Dust not only pollutes a room or work area, but also has a detrimental effect on human health.

In addition, it is much more difficult and inconvenient to work in dust, because... it's hard to breathe and you can't see anything.

To carry out dust-free work, you can use three reliable methods.

How to connect a vacuum cleaner to an angle grinder: options, tools and materials

When carrying out any repair and construction work, the appearance of small particles of debris and dust is typical. They get stuck in the most remote areas of the room, from where they are then difficult to remove. Large amounts of dust ultimately have a negative impact on human health, in particular on the respiratory system. A particularly dangerous tool in this regard is the grinder, after using which a real dust cloud is formed. It is not possible to get rid of it immediately.

As an option, you can pre-wet the sawn wood or concrete. However, this method is not always convenient and effective; it requires the constant participation of a second person who will carry out the humidification using a sprayer. The second method is more convenient; it involves connecting an angle grinder to a vacuum cleaner. You can do this yourself, the main thing is to have construction equipment on hand for cleaning, since ordinary household appliances are not very suitable for connection with a cutting tool.

Algorithm for connecting a vacuum cleaner to an angle grinder

The main principle of instant collection of dust when cutting is based on the creation of a special casing in which debris will accumulate, which will later be pulled out by the vacuum cleaner hose.

The algorithm for how to connect a vacuum cleaner to an angle grinder with your own hands using improvised means provides for the presence of the following materials:

- Scotch. It is advisable to take the reinforced version, since it is considered the most reliable and durable.

- Retraction. This part is used in plumbing work; it is important to use the polypropylene version, it is lightweight and quite durable. The outlet parameters are a bend of 45 degrees and a diameter of 45 mm.

- Scotch tape used for painting.

It is not at all necessary to use exactly these consumable spare parts; you can replace them with suitable analogues.

Step-by-step process on how to connect a vacuum cleaner to an angle grinder:

- Place the tool on a hard, stable surface with the blade facing up. It is important to securely fix the angle grinder to prevent injury during work.

- Use pliers to secure the outlet at one end, turn on the grinder and carefully cut out a small pipe along its body in the plumbing part. The length of the cut should be approximately 3-4 centimeters.

- Without removing the plumbing outlet from the disk, you should securely fix it with reinforcing tape. It is important that the winding is tight and tight. You can make a short approach to the grinder disc itself.

- Next, use masking tape to wrap the entire side of the casing covering the disk. It is important to continue the winding to the tap, connecting both parts.

The last step is to connect the hose from your cleaning appliance directly to the plumbing outlet. You can only use a construction vacuum cleaner; ordinary household models are not suitable. To collect dust while working with an angle grinder, it is enough to turn on the vacuum cleaner, which will draw out the dust that appears during cutting.

Other options for housings for a vacuum cleaner for an angle grinder

In addition to using a plumbing outlet, which is the simplest option, you can use other materials to create the casing. An interesting and quite affordable option is a plastic canister. The thick walls of narrow oil containers hold their shape well and do not deform. In this case, the neck of a standard canister usually matches the diameter of the vacuum cleaner hose.

Algorithm for how to connect a vacuum cleaner to an angle grinder using a plastic canister:

- Make a cut in the canister in such a way that the immersion depth of the cutting disc is taken into account. At the moment of cutting, the casing is “fixed” to the cutting disc.

- Attach the neck of the canister to the vacuum cleaner hose. If the diameters do not match, you can use special clamps.

There are other options for connecting a vacuum cleaner to an angle grinder. You can use an old saucepan or even a five-liter water bottle as material to create the casing. The most important point is to make sure that the neck of the container you are using matches the diameter of the hose of the construction vacuum cleaner.

The third method is a special attachment for an angle grinder

Using special attachments for angle grinders is the best option for sawing with a grinder without dust.

To do this, it is enough to purchase a universal dustproof cover, install it on the angle grinder instead of the standard protection, then connect a vacuum cleaner and after that you can safely work with the angle grinder without dust.

It is advisable to use a construction vacuum cleaner, or one that you do not use for regular household cleaning.

You can purchase a universal dustproof cover for angle grinders using this link

Installing the dust cover takes literally a few minutes; see how to do it in the diagram:

This dust-proof attachment is made from high-quality plastic; in addition to dust protection, using a special scale on this casing you can adjust the depth of the saw, which is very convenient.

See detailed description and reviews here

Budget construction vacuum cleaner with dust extraction for an angle grinder (useful collective farm)

Do you need to change the wiring in your house, but don’t have the money for tools or a crew?

Then this post may be useful to you.

I’ll tell you right away that you will need to at least purchase/take:

- an empty bottle of motor oil

-cylindrical container with a lid, preferably 30-50 liters

-plastic plumbing angles 45 and 90 degrees (2 of 40 mm in diameter and one for your vacuum cleaner, in my case 32 mm)

- corrugated pipe 40 mm 2 meters minimum

-oil filter (in a car store)

We make a dust extractor from a plastic canister ourselves

The easiest and most economical option to make a casing for an angle grinder under a vacuum cleaner is to use a plastic canister as a base. To implement this version of the casing, you will need to take a canister of the appropriate volume. Usually a one- or five-liter canister is enough, but it all depends on the size of the tool itself.

The principle of manufacturing the casing is quite simple, and to implement it you first need to prepare a drawing according to which the dust removal nozzle is made. When manufacturing, the following factors must be taken into account:

- The size of the nozzle is taken into account, which depends on the depth of immersion of the cutting disc. The larger the size of the nozzle, the shallower the depth of the resulting cut.

- Holes of the required diameter are cut depending on the size of the bushing to install the device on the shaft of the power tool and secure it

- A hole is made on one side to secure the device to the shaft of the power tool. On the other hand, it is not at all necessary to make a hole, since dust can leak through it, which will reduce the effectiveness of the nozzle

- The neck of the canister is used as a bracket for connecting the hose from the vacuum cleaner. To connect the neck of the canister with the hose from an industrial vacuum cleaner, use a tie or clamp

To make such a device, you will need a minimum of time, effort and money. The result should be a device for removing dust when cutting concrete, tiles and wood.

How to connect a vacuum cleaner to an angle grinder

Users appreciate angle grinders and are constantly trying to refine and improve the set of functions and capabilities. Let's consider one of these options that can make using the tool clean and comfortable.

Purpose of the dust collector for angle grinders

Homemade vacuum cleaner: example Using an angle grinder (grinder) to carry out repair work on concrete at home creates a large amount of dust.

If you need to level a wall, sand it for painting or applying other types of finishing coating, all irregularities or bumps become tiny particles of concrete suspended in the air.

Despite the personal protection used, they penetrate the mouth, eyes, and respiratory organs.

In addition, dust settles on all pieces of furniture, walls, ceilings and other surfaces, requiring labor-intensive and time-consuming cleaning. Dust from brick walls eats into surfaces and irreversibly spoils their appearance.

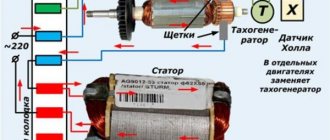

There are several designs of casings with a pipe for connecting a vacuum cleaner, which significantly improve the process. They are purchased in a store and installed on an angle grinder, connected to a vacuum cleaner. Working with such devices almost completely eliminates the spread of dust and can significantly reduce the pollution of the room and indoor air. Outwardly, they resemble conventional protection, but with a closed housing and an outlet for connecting a vacuum cleaner hose.

Purpose of the casing

As you know, any angle grinder has a standard protective cover. Its main task is to protect the operator from particles flying from under the tool and from flying debris in the event of a possible disk failure. If you make an angle grinder casing for connecting a vacuum cleaner with your own hands, then the standard casing is either used as a supporting base or removed from the machine.

The casing for connecting a vacuum cleaner to an angle grinder is used in many cases.

- “cutting” a groove in concrete;

- sanding the rough coating of walls or floors for subsequent finishing;

- cutting finishing tiles or building stones (brick, cinder block);

- sawing wood or other non-sparking materials.

- When cleaning surfaces from rust;

- Removal of old paint and varnish coatings;

- Sanding the material before painting.

Both lists are incomplete, and the need to simultaneously use an angle grinder and a vacuum cleaner is determined when planning the work.

Plastic canister model

The device is created from an old plastic canister of a suitable size. For manufacturing, select a canister of such a size that its width is 1-1.5 cm wider than the working body of the angle grinder. To connect a vacuum cleaner to an angle grinder using such a device, you need to prepare tools and materials.

- Plastic canister.

- A piece of plastic equal to the size of the side wall of the canister.

- 1 large clamp for securing the casing to the body of the angle grinder.

- 1 medium size clamp for fixing to the hose housing of a vacuum cleaner.

- 4 self-tapping screws of the shortest length, for example, 3x10 mm.

- Shoe or segment knife.

- Marker.

- Ruler.

- Screwdriver.

Manufacturing begins with cleaning the container from the remnants of the liquid stored in it. With a marker and a ruler, mark a hole in the center of one of the side walls of the canister with a diameter equal to the diameter of the standard clamping nut of the angle grinder. Cut a hole and transfer its center to the other sidewall. A hole is marked on it, the diameter of which is equal to the outer diameter of the seat of the support bearing of the angle grinder. The end wall of the canister is cut off opposite to the wall on which the neck of the canister is located. For greater strength, you don’t have to cut off the end wall completely, but cut out a “window” in it, stepping back 1-1.5 cm inward from each edge of the end wall.

Attaching a dust collector from a canister to an angle grinder is done like this: after removing the disk and support washer, put the casing on the angle grinder with the side on which the hole for the support bearing is cut. Next, if the height of the support bearing seat allows, a clamp is put on this seat and tightened. The wall of the device is sandwiched between the front plate of the angle grinder gearbox housing and the clamp. If the height of the bearing seat does not allow the “device” to be secured with a clamp, the wall of the former canister is pressed against the gearbox housing and the points of contact with the coupling bolts are marked on it. Having removed the casing from the machine, holes are made in the marked places with a diameter equal to the diameter of the bolts. They unscrew the gearbox bolts, and without disassembling it, put on a new device and, together with it, screw the bolts into place. After securing the device to the body of the angle grinder, put the support washer and working disk in place and secure it with a nut. The hole remaining on the front side is closed with a shield cut from existing plastic, securing it to the dust collector body with self-tapping screws.

A hose from a vacuum cleaner is attached to the neck of the former canister, securing it with a clamp - the tool is ready for work.

Before starting work, on the outside of the device body, you can apply a line corresponding to the mowing line of the working disk with a bright marker - it will be easier to control the evenness of the cut.

How to connect a vacuum cleaner to an angle grinder: options, tools and materials

The grinder is a universal tool. With its help, using various attachments, you can cut metal, stone, porcelain stoneware and tiles, process wood and other materials. But one of the disadvantages is the formation of a huge amount of dust. Work that causes the formation of large amounts of small debris:

- Grooving grooves on walls. The work is carried out using plaster, and cement and sand have a fine fraction. The height of the passage of the channels is at the level of one and a half or two meters. From such a height, dust settles evenly over the entire area of the room.

- Sanding of wooden structures. Before painting or varnishing, wooden products must be removed from the cellulose fibers that form during the sawing process. Cellulose is thin, light and hangs in the air for a long time.

- Removing old paintwork. Before applying fresh paint, the old paint must be removed. A flap sanding wheel is used. The paint it removes is fine.

- Cutting floor and decorative ceramic tiles. Sintered ceramic has a fine grain structure and it penetrates everywhere.

- Sanding parquet or wooden floors. Floor leveling occurs by removing the top layer. The irregularities have different heights and therefore, in addition to shavings, a lot of wood dust is formed.

What is the casing for?

Before you start working on concrete and wood, you will need to have a good idea of what the end result will be. When cutting with a grinder, dust is generated, which settles not only indoors, but also enters the human respiratory system. That is why work with the tool should be carried out exclusively in a respirator and safety glasses. To protect the room from excess dust, you will need to carry out work using a special attachment to which the hose from the vacuum cleaner is connected.

The attachment should be used on an angle grinder in the following cases:

- When chipping concrete, brick, cinder block, slate and other similar materials. If gating is carried out during the construction stage, then the settling of dust in the room is not as dangerous as during repairs. When cutting durable materials, they are crushed, which causes the formation of dust that settles throughout the room

- Cutting tiles and ceramic tiles - when processing these materials, dust is also formed, which is especially dangerous to human health. Tiles can be cut with special tile cutters, and no dust is generated, but if the work is done with an angle grinder, it is better to install a special attachment

- Wood processing - when sawing wood, not only dust is formed, but also sawdust, which can be eliminated very easily and quickly using a casing mounted on the grinder

Manufacturers make special casings for angle grinders with disc diameters of 125, 150 and 230 mm. These are the most common types of cutting tools, which is why manufacturers produce special housings for dust removal specifically for them.

This is interesting! If you don’t have an industrial vacuum cleaner, then it is not recommended to use a household one to remove dust when working with an angle grinder.

Craftsmen and specialists do not even doubt that a casing is needed on an angle grinder, since it is enough to try cutting concrete once to be convinced of the need to purchase or manufacture a dust collector. What is better, to buy or make a cover for collecting dust on an angle grinder with your own hands, everyone must decide for themselves. After all, the protective casing is relatively inexpensive, but in order to avoid costs altogether, you should make the nozzle yourself.

Making a fixture

With dust extraction from the pan

When it is possible to find an old aluminum pan, you can make a dust collector without using a welding machine. The main part of the casing is cut out and fits well to an angle grinder. When performing this work, it is necessary to accurately calculate in advance the maximum penetration depth of the cutting disc, because the height of the cross cut from below directly depends on this.

A seat for mounting on an angle grinder is cut out of another part of the aluminum pan. The hole diameter must be measured directly on the power tool. The size of the dust extractor must be as accurate as possible so that the casing cannot come off due to strong vibration when performing work.

In a similar way, you need to make a pipe for a vacuum cleaner. The protruding edges of the casing should be folded inwards as carefully as possible along a single line to secure the side wall, which can be made from any type of material. For example, a wall can be easily made from thin metal sheet. If there is a desire, then it is worth giving the device a more aesthetic appearance, treating the joints and painting them with enamel.

From a plastic canister

Next, we will consider another economical option for dust removal. In any person’s pantry you can find empty plastic containers for various technical liquids. This container holds its shape well and is quite easy to process. And also such a container has a convenient outlet pipe of the required size.

First, fitting is done, the main purpose of which is to ensure the required immersion depth of the cutting disc. Using a construction knife, cut out the required through holes. Their diameters are chosen in such a way that the homemade structure retains its rigidity. It is worth making special seats on both sides. This will make it possible to change the direction of rotation of the cutting disc.

Next, the vacuum cleaner hose must be connected to the neck of the canister and secured well with a metal clamp. Reliable fastening of the casing to the angle grinder is carried out using an adapter ring and a metal clamp. The assembly of this unit should be approached very responsibly. The second hole must be tightly closed with a lid. When changing the direction of rotation of the cutting disc, the lid is transferred to the other side of the canister.

Such hand-made devices are low cost, but their benefits are very great. A vacuum cleaner complete with an angle grinder will help you perform almost any type of work in rooms with minimal dust emissions. To sand wood, you need a slightly different form of attachment for the grinder. However, it is not very different from the products described above. It can be made in the same ways, using almost any materials.

Popular models

Protective covers for vacuum cleaners for angle grinders are available in a huge range. Moreover, each type can differ not only in design, but also in functionality. Several models of attachments are extremely popular among craftsmen.

Bosch 2605510224. This casing is suitable for angle grinders of various brands with 115 and 125 mm discs. It is equipped with a special ring brush, which allows you to perform work with a fiber attachment and a grinding wheel. The size of the nozzle is 200×190×80 mm, its weight is 0.3 kg. The cost is low.

- STOMER 98299441. This device is made in the shape of a semicircle. It is installed on angle grinders with 230 mm discs. The main advantage of the nozzle is the presence of a guide, which is responsible for adjusting the depth of the storm. The casing size is 320x160x240 mm, weight is 2.71 kg. It can also be purchased at an affordable price.

- Mechnik Air Duster. This option is suitable for tools with diamond blades with diameters of 125 and 230 mm. It is distinguished by its low price and the ability to connect to medium-power vacuum cleaners (up to 1.6 kW). The casing is lightweight and easy to install.

- Blastrak. This is a professional protective cover for a vacuum cleaner that can be attached to sanding tools with 125 and 180 mm discs. The attachment has variable elasticity, is more rigid in the places where it is attached to an angle grinder and is soft at the edges in contact with the floor.

- Metabo GED125. This casing deserves special attention. It is recommended to purchase it for processing concrete and stone. The nozzle is equipped with a special pipe that allows you to attach it to a vacuum cleaner.

Every craftsman, whether he is a professional or an amateur, cannot imagine his work life without an angle grinder, or popularly “grinder” or “ushma”. It is practically the main power tool in most jobs and many people try to buy it first. An angle grinder is not the safest type of tool, so its operation requires knowledge of safety regulations and special parts.

They are designed to ensure the personal safety of the worker himself and those around him, as well as to quickly and efficiently complete assigned tasks. What is meant by the phrase "special parts"? Various types of protective covers with dust extraction.

When purchasing an angle grinder, you can find a protective cover included, but this accessory, if you can call it that, will not be able to protect the room where the work is being done from dust. For this reason, many people buy or make a casing for an angle grinder under a vacuum cleaner.

When purchasing this attachment, you will need to familiarize yourself with information about what type of work it is intended for and what size disk the casing is made for. The advantages of such a purchase include adjustability of the depth of penetration of the disk, reliability and durability of the casing. The downside is that this accessory is by no means cheap.

Application of cover for cutting tiles

The manufacturing options for the casings under consideration are suitable for removing dust when processing concrete, brick, cinder block and wood. When cutting tiles, one important condition must be taken into account - the accuracy of the cut. When working, you need to see the mark along which the power tool is guided, thereby making the cut. It is impossible to see the disk through steel or plastic casings, so when using a device for tiles or ceramics, it is important to make it from transparent materials. The easiest option for this is a plastic bottle.

It is not difficult to make a casing from a plastic bottle, and to do this you will need to make one hole in the wall for installation on the shaft, and connect a hose from a vacuum cleaner to the neck. It does not matter for which brand of angle grinder the device is made - Bosch, Interskol, Makita, Diold and others. All tools from different manufacturers have a similar design, so the manufacturing principle is the same for all.

Through the transparent cover you can control the movement of the rotating diamond disk. Moreover, it is recommended to use solid discs for ceramics, since segmented ones contribute to the formation of chips, and as a result the material may be damaged. Moreover, cutting must be done in one pass, otherwise the cut of the tile will turn out uneven. Having made a homemade casing for an angle grinder under a vacuum cleaner, you can test it in action, making sure of the usefulness of such a device.