Mechanical wear is so merciless that it does not spare even high-strength metal alloys . Over time, the sharpest edges of any cutting tool become dull. It is for this reason that an integral attribute of every more or less serious workshop is a sharpening machine . The review will tell you how to choose a sharpening machine

The basis of a sharpening machine is a grinding wheel, which is made of an abrasive material, most often corundum.

A sharpening machine (electric sharpener) is a device for restoring sharp edges on a cutting tool, all kinds of devices and equipment. An electric sharpener consists of a motor with a grinding wheel attached to its shaft. When a rotating wheel comes into contact with a dull cutting edge, friction occurs .

If you bring the cutting edge at the right angle, then under the influence of friction the abrasive will restore the edge.

The sharpening machine is used for processing:

- Drills, countersinks and reamers

- Knives and cutters

- Chisel, pick and impact bits

- Spatulas and trowels

- Hacksaw blades, saw chains and band saws

- etc.

In fact, the scope of application of sharpening machines is truly limitless . Almost every day some cutting tools and specialized power devices appear that need to be sharpened from time to time. The sharpener will be welcome everywhere, even in a production or repair area, even in the home tool corner.

Types of sharpening machines

Before buying a sharpening device, you should first find out what types of sharpening machines there are and where they should be used. For example, depending on the functionality and scope of application, machines of a universal type and machines of a special type are distinguished.

With the first type, various fasteners and attachments are used, which allows you to expand the scope of application, sharpen and grind a larger number of tools.

Special machines are suitable for working exclusively with workpieces of a certain shape. This limitation is compensated by the fact that a huge number of tools can be processed in a short time.

Productivity is due to the absence of the need to frequently change structural elements. Moreover, their distinguishing feature is the exceptional quality of processed parts. They are good for use in spare parts turning plants.

Among the special purpose machines there are:

- Sharpeners: These are good for working with cutting tools and also for finishing parts. Such machines are good in mechanics' workshops;

- Drill sharpening machines: These are used for grinding twist and feather drills. The main requirement is that the drill diameter should not be more than 18 mm. When using additional equipment, you can change the angle of the plane.

- Disc Saw Machines: Their job is to sharpen the tool and return it to cutting ability. Depending on what abrasive elements are used, you can change the sharpening angle of the working surface;

- Machines for sharpening cutters: process cutters of different shapes;

- Polishing and deburring machines: they are used to remove various defects.

It's difficult to say which sharpening machine is better. It all depends on their functionality and quality of work.

Additional "chips"

In sharpening machines

Of the additional “chips,” the most in demand is

speed control

, since this function expands the possibilities: you can sharpen hard steels and fine grind soft ones.

Wet sharpening

will be needed for working with hard steel to eliminate overheating, achieve higher quality and save working time.

Desk tilt

, as well as

adjusting the depth and angle of sharpening

allow you to achieve the desired result even without much experience. If on the machines of the “last century” you had to “train your hand”, then on modern ones you just need to adjust it correctly and you can sharpen like a real pro!

Backlight

can be carried out in two ways:

point

(diode) or

diffuse

(using a lamp on a leg). In the first case, the work table is illuminated, in the second, the light spot is manually directed to the desired location.

Some advanced models have the ability to protect the machine from unwanted startup

. The function is implemented by blocking the power key or in another special way. It will be useful at home if you have small children, or at work to prevent the use of the sharpener by strangers.

Benefits of using a sharpening machine

Now we should talk about what advantages can be found from using an electromechanical type sharpening machine:

- It is quite possible to do without the help and services of a specialist and restore the cutting properties of a particular tool on your own.

- This device has a fairly long service life of up to 15 years.

- Due to the mechanized process, less time is wasted, which allows you to modernize the work and make it easier.

- This device is quite easy to use, and even an untrained person can handle it.

- Such a machine can be made completely independently.

- Higher productivity and more efficient operation.

Types of tabletop sharpening machines - distinctive features and useful properties

Despite the simple design and principle of operation, the hero of our review has its own classification. This is due to the abundance of cutting tools used in modern construction and industry.

Specialized sharpening machine

This modification only works with certain surfaces, but allows you to achieve better results when processing. Such equipment most often refers to professional equipment rather than household equipment - this affects both the range and the price. Among specialized grinding machines, several subtypes can be distinguished:

| Machine type | Description |

| Sharpening machine with engraver | Allows you to give metal and other materials a certain shape and apply inscriptions to their surface |

| Device for sharpening knives and scissors | Works only with the specified devices, they must be sharpened strictly at a certain angle in relation to the abrasive |

| Device for working with chains of electric and gasoline saws | Serves for processing teeth of chain saws with various power sources, also requires a certain skill |

| Drill sharpening machine | Makes it possible to restore the former cutting properties of drills of any diameter, very popular in mechanical engineering |

The option for processing the edges of knives and scissors is the simplest and most affordable, but its functionality is not so wide.

Material for machines

The machine body, together with the frame and casings, is made of metal. The protective shields are made of plexiglass.

The disk used to sharpen parts (it is also called the working element) is made solid or coated with a special powder. Emery itself (the material from which abrasive wheels are made) is a type of special granular structure, the elements of which are iron, silicates and crystals.

The grinding wheel can be:

- Diamond: the coating includes a powder from a mixture of carbonates and beads. Diamond is considered one of the strongest materials, and its properties are good for grinding stones, razors and tools made from carbide;

- Vulcanite: This wheel will require vulcanized rubber. It is advisable to add special additives to it to improve its performance properties. Its purpose is to clean and polish metals;

- Felt: discs of this type are good for polishing metal surfaces, because with their help you can achieve a mirror shine. Thick felt is not suitable for working with edges.

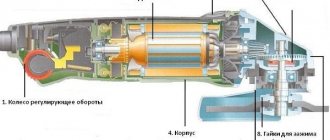

Typical design

Grinder

is

an electric motor

mounted

on a frame

. As a rule, there are shafts on both sides of the engine for attaching abrasive wheels. One of them has a coarse grain for rough sharpening, the other has a fine grain for finishing the tool.

Abrasives must be covered with protective covers.

. They ensure the safety of the worker, extinguish sparks, and prevent the scattering of waste. Some enclosures even have waste storage compartments.

It is important to know:

Guards that have a perforated or other hole in the bottom are safer because during operation most of the sparks and waste come out through them rather than the working top hole.

For ease of work, hand rests (work tables)

, which can move in the longitudinal direction. This adjustment is necessary to move the table as the circle is erased. Hand rests that are attached not to the drive, but to the frame, are more stable, since they are less affected by vibration.

A transparent shield is mounted on top of the casing

made of plexiglass. It allows you to monitor the process and at the same time protects you if a splinter flies off from a tool or abrasive. Some shields have a magnifying glass, through which it is easier to see small details and perform jewelry sharpening.

Lifehack:

When choosing an electric sharpener, manually turn the circle; if it turns independently and smoothly, it means you have a quality tool.

Sanding sizes

Emery cloths intended for household use are relatively small in size and weigh up to 14 kg. For industrial use, larger machines are used, the weight of which reaches 100 kg by average standards.

The dimensions of such devices directly depend on the size of the electric motors and what maximum permissible disk diameter is permissible for working with a particular machine.

If the dimensions of the machines do not have some common standard, the same cannot be said about the working elements. Since their replacement occurs much more often than replacing the entire machine, therefore, there is no reason to manufacture any unique molds.

Characteristics of abrasive consumables

A wheel can be used as an abrasive on a sharpener.

or sanding

belt

. Not only the quality of sharpening, but also the safety of the budget, as well as health safety, depend on their correct selection.

Circles come in a variety of colors. White

Made from electrocorundum and designed for sharpening soft steel. They serve for a long time and do not overheat the material being sharpened. Typically, table saw wheels have a 32 mm bore and an outer diameter of 125 to 200 mm. The thickness of such a disk can reach 25 mm.

Green

the color is characteristic of silicon carbide wheels. They are characterized by low abrasion and high operating temperature when sharpening. Designed for processing materials made of tool steel and hard alloys. The size range is identical to the white circle.

Hardness index

is a property that reflects the resistance of abrasive grains to external influences. A universal option is wheels with medium hardness. They last a long time and can be used to work with various materials.

When choosing an abrasive based on hardness, they are guided by the following rule: soft material - hard abrasive, hard material - soft abrasive!

Grain

- a characteristic for both circles and skins. Their markings are different, but the essence is the same: the smaller the grain, the cleaner the processing of the material.

Interesting to know:

Some manufacturers add a coloring pigment to electrocorundum discs. The main goal is to differentiate the product from competitors!

Engine power

Asynchronous motors are used to operate electrical machines. Thanks to their features, it is possible to achieve the ideal balance between acceptable spindle speed and relatively low noise level.

- Speaking about the power of such engines, we can say that elements with a power of up to 1000 W are suitable for domestic use models.

- The most frequently sold models have up to 450 W.

- In industrial environments, motors are used whose power reaches 5 kW.

Spindle speed

The speed of operation directly depends on how many revolutions per minute the spindle makes.

The speed of conventional models reaches three thousand revolutions per minute, provided that there is no contact with any surface.

For some machines, an additional disc is specially installed to allow wet sharpening.

- The lower part of such a circle must be lowered into a container of water.

- The speed of work is noticeably reduced.

- The maximum number of revolutions is less than 150.