One of the most popular power tools in the household is an angle grinder (angle grinder), popularly called an angle grinder. Despite the fact that its main purpose is grinding, it is more often used as a tool for cutting various materials. This is primarily due to the abundance of types of disks that can be installed on it.

The main disadvantage of an angle grinder when performing such work is the low cutting accuracy, because while holding an angle grinder in your hands, it is extremely difficult to maintain the exact angle and direction of the cut. It is rarely possible to trim any material strictly at a given angle. Especially if you have to prepare parts of the same type of any design, and even with specified cutting angles. This disadvantage can be minimized by using a special stand for the angle grinder.

There are such factory-made devices for various models of angle grinders, some of them are quite universal. But the relatively high cost makes them out of reach for most home craftsmen. Meanwhile, most of these craftsmen are able to make a stand for their angle grinder with their own hands, without spending a lot of money or time on it.

Drawings of a stand for an angle grinder

There are not many drawings of such racks on the Internet. Basically, these are primitive sketches that illustrate the principle of operation of the device rather than the exact dimensions and order of its assembly. And even those that exist do not have all the necessary information.

And the very design of such devices quite often raises doubts about the use of such a drawing without some correction.

Therefore, we advise you not to waste time searching for them, but to carefully consider the options for implemented projects to create homemade stands for angle grinders and choose the one that suits you. Or, taking into account their shortcomings, implement your own.

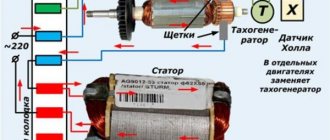

Electrical part

Since the angle grinder is attached to the bottom, you cannot turn it on as usual. You will need to install:

- A clamp that will hold the control key in the “on” position.

- Socket for angle grinder.

- A control station that turns on/off the electricity in the outlet.

Using an industrial station is an excellent solution, the device has a couple of keys, the start button is tight, which will protect against accidental activation. A large and convenient “stop” button will allow you to quickly turn off the device if necessary.

Do-it-yourself stand for an angle grinder - overview of options

The main tasks of this rack:

- securely attach the instrument to the console;

- ensure minimal deviations from the cutting plane during operation;

- hold the tool securely in the up position.

To attach the grinder to the console, threaded fastenings of the handle on its head are suitable. There are 3 of them, and this is more than enough for reliable fixation.

Sometimes not everyone uses them.

And sometimes, to secure the grinder, they use a protective casing that is quite rigid and securely attached to its head.

For small grinders working with discs up to 125 - 150 mm, sometimes it will be sufficient to fasten the body to the console using powerful clamps, but to prevent axial rotation of the tool, the stop pad of the grinder head must be used.

Angles that work with large-diameter cutting discs (200 - 230 mm), in addition to securely attaching them to the console, must have a good support base for attaching the console itself to the work table.

This ensures minimal deviation from the cutting plane.

Many DIYers ensure the oscillatory movement of the console by installing one or two bearings to attach it to the desktop. For this purpose, ready-made bearing units for cars or bicycles are often used. However, sufficient mobility will be provided by a simple bolted connection, the parts of which, if well lubricated, will work as ordinary plain bearings.

So, as shown in the video describing the simple design of a metal angle grinder stand:

True, we would not rely on such reliability of fixing the tool in the upper position, as the author of the video recommends, but would install the tension spring in a convenient place.

It is clear that repairing such a console mount comes down to replacing the bolt, or, in extreme cases, simply increasing its diameter or installing a bushing if the mating parts are worn out a lot.

A similar principle of ensuring compliance with the flatness of the cut is also ensured when making a stand not from corners, but from profile pipes. Watch a short video about a simple homemade metal drain for an angle grinder:

Few people decide to make a wooden stand for an angle grinder, but this does not mean that it cannot be made. But some design solutions that we want to show you may well serve as a source of ideas for creating a rack of your own design, incl. and from this material.

To enlarge the picture, click on it:

Sometimes, to ensure that the tool returns to the upper position after making a cut, instead of a tension spring, a conventional counterweight is used to compensate for the weight of the tool itself.

What may be needed to make a bed

Drawing of a metal frame

Before you start making a frame for an angle grinder, you should decide what types of work this machine will perform. A self-made angle grinder stand can be much more functional than industrial products. The type of attachment of the angle grinder to the frame is of great importance - vertical or horizontal. The depth of cut largely depends on this. The type of fastening also depends on the nature of the work performed.

To cut materials on a stationary work table, the grinder is mounted on a pendulum bracket made of angles or profiled pipes. If it is necessary to cut large sheets of steel, textolite, or plywood, then the angle grinder is mounted on a movable carriage that moves along guides made of angles or channels. Having decided on the design, you should prepare the necessary tools and materials in advance.

Tools:

- Bulgarian;

- drilling machine;

- welding machine;

- grinding wheel;

- pliers;

- Screwdriver Set;

- a set of keys;

- measuring instruments.

Materials:

- steel corner 40×40;

- steel corner 50×50;

- channel 5U or 6.5U (for guides of a moving carriage);

- water pipe cuttings;

- profile pipes 15×15, 20×20, 25×25;

- bearings;

- hardware;

- tin trim;

- textolite

Features of using an angle grinder as a saw

For your safety, it would be useful to remind you that not all types of discs can be directly used for an angle grinder. First of all, this concerns disks for sawing wood, which have significantly lower speeds than are used in almost all grinders.

The exception is special wood discs designed for standard angle grinder speeds.

It's good if your tool has speed control. And if not, then before using your angle grinder as a miter saw for wood, make a simple speed controller based on the KR1182PM1 microcircuit, or one similar in performance, according to such a scheme.

You should not use a simple rheostat for this. Along with the reduction in speed, it will also proportionally reduce the power and torque of the tool. And for the grinder itself, using it in such operating modes is harmful.

We strongly recommend that your rack be equipped with an emergency shutdown button for the tool, because access to the shutdown button after installing the angle grinder in the rack can be difficult. And even an angle grinder securely fastened in the device is a rather traumatic tool.

You can place such a button in the cut of its power supply wire, but it is better to break the supply line with it, because when removed from the stand, the angle grinder becomes an ordinary mobile tool with all its advantages.

High quality counterweight with shock absorber

The safety of using the bed largely depends on the counterweight. The most practical option is considered to be when, at the moment of lowering the tool, it will automatically move to a vertical position, thereby stopping any cutting manipulations. It will not only be very convenient, but also safe. The easiest way is to install a spring mechanism, which must be selected in accordance with the characteristics of the angle grinder. The design itself will be compact and efficient.

The simplest device for an angle grinder stand

Actually, this device cannot be called a stand, but the work with it can be done almost the same as that provided by the most technologically advanced stand. The principle of its operation is clear from the short video:

But if instead of a strip you use a corresponding corner with a sawn-off part of one of the shelves, as one of the authors of a similar design did, then there will be no need to drill a blind hole in the head of the angle grinder.

In this case, the tool will be fastened with two screws into the threaded holes for the handle existing on the head of the angle grinder. But the principle of operation of the sole will not change - only its rigidity will increase.

The method of using an angle grinder as a kind of circular saw using the same sole, shown in another video by the same author, will also not change:

We recommend other articles on the topic

Hand router for wood, accessories for hand router

Screw mechanical jack and more - we choose for your tasks

Hydraulic jack - its design and principle of operation

Renovator - a multifunctional tool

Selecting material for the bed

In this case, the capabilities of the angle grinder are significantly expanded. By installing the grinder on a stationary structure, you can make a cutting machine that will accurately and at the desired angle cut any profiles - angles, I-beams, metal pipes.

To cut metal, wood, and plastic sheets of large sizes, you should install the grinder on a moving carriage moving along guides. In this case, it is advisable to use metal corners as guides.

Stand for grinder

The angle grinder stand comes in a variety of designs. A variety of materials and components can be used for its manufacture. It makes no sense to recommend a specific design, since each owner of an angle grinder will adapt the angle grinder to his own requirements.

Profiled pipes can be used as starting materials for the device, as they are the most durable and reliable for this type of work. For guides, you can use corners, 5U or 6.5U channels.

For complex structures you will need a welding machine, but it is easier to get by with screw connections. If the work does not require special precision, then the grinder can be used simply as a portable tool.

To perform precise work, for example, with a grinding attachment, you may need a stationary device - a stand for an angle grinder (you can assemble a simple collapsible machine with your own hands, which after use will be folded and hidden in the designated place). Such a frame is sometimes also made of wood. It is advisable to make a wooden frame if frequent and prolonged use of an angle grinder is not expected.

Scope of application of cutting machines

The use of additional accessories for angle grinders provides a very wide range of their use, but the main task remains cutting materials such as metals, wood, and stone.

A do-it-yourself cutting machine from an angle grinder is made for the following purposes:

- Control of cutting thickness.

- Evenness of the cut.

- Possibility of setting different cutting angles.

All these criteria give the homemaker the opportunity to use a cutting machine to produce parts of a more complex design, as the quality of workmanship improves.

Attention! Without a machine, you can perform these tasks at home, but it will take more time, since you will have to ensure the evenness of the cuts. At the same time, it will be important to double-check the correctness of the angles for identical workpieces several times.