Pressure gauges (devices for measuring pressure), like all precision instruments, must be monitored and verified. This is important because they are used on units that pose a danger if used incorrectly: gas cylinders, boilers, production equipment. The serviceability of the pressure gauge is monitored using specialized metrological systems; It is important that the procedure is carried out by a competent specialist. The pressure gauge is verified by an accredited organization in laboratory conditions using certified standards.

How and why to believe

Verification of pressure gauge readings consists of an external examination (presence of glass cracks, chips and dents on the body, etc.) and comparison of the device readings with the reference ones.

If the device is used in one of the areas falling under GROEI - state regulation in the field of uniformity of measurements, then regular verification of the pressure gauge is mandatory.

As for private houses and in other areas not included in the GROEI list, the verification of pressure gauges here is carried out on the initiative of the owners or managers to make sure that the device is in order.

Catalog

We invite you to familiarize yourself with the state standard’s answers to frequently asked questions.

QUESTION : What measuring instruments fall within the scope of legal metrology? and which ones are outside the sphere?

REPLY from 12/28/2012:

The scope of legal metrology extends to measurements performed during:

- carrying out trade and settlements between buyer and seller;

- determining the tax base;

- carrying out customs and banking operations;

- ensuring the protection of human life and health;

- conducting state technical inspection of vehicles, diagnosing the technical condition of vehicles;

- ensuring industrial safety of hazardous production facilities, fire safety and radiation safety;

- carrying out geodetic and cartographic activities;

- carrying out hydrometeorological activities;

- provision of postal and telecommunication services;

- conducting tests and monitoring the compliance of products and raw materials with the requirements of the legislation of the Republic of Belarus;

- conducting examinations;

- ensuring the defense and security of the state;

- ensuring environmental protection;

- ensuring labor protection;

- implementation of state metrological supervision;

- implementation of metrological control;

- monitoring compliance with the requirements for packaged goods;

- carrying out laboratory diagnostic studies by the veterinary service;

- production and use of slot machines and devices with monetary winnings;

- registration of international and national sports records.

Legislative acts of the Republic of Belarus may extend the scope of legal metrology to measurements performed in other areas of activity.

If the measuring instrument in question falls into one of the above areas, an analysis should be carried out:

– requirements of regulatory legal acts and technical regulatory legal acts relating to the specific field of application of the measuring instrument and other administrative documents governing the use of measuring instruments.

Comment: When classifying a measuring instrument as an SPM, one should check for the presence of direct instructions from normative legal acts and technical regulations, etc. for the verification of these measuring instruments by the bodies of the State Metrological Service (SMS). Such a requirement implies the use of measuring instruments in the SPM and its withdrawal from the SPM is possible only after changing the relevant requirements of normative legal acts and technical regulations. For example, the Resolution of the Ministry of Agriculture and Food requires verification of thermometers in vegetable storage facilities by the State Medical Migration Service. In this case, temperature control is a technological operation that does not fall into any of the areas of the SPM, and verification could be done by other legal entities.

– the presence of duplicate measuring instruments and devices that perform the same function and are subject to metrological or other type of control;

Comment: As a rule, at hazardous technological facilities (see areas 4, 6, 14) redundant circuit solutions are provided that ensure safety with a probability of 99.9%. For example, in water heating boilers, along with pressure gauges, pressure safety valves are installed. In this case, paragraphs 4, 6, 14 are provided precisely by valves, which undergo separate testing, and pressure gauges play a secondary role - monitoring temperature changes and can be removed from the SPM. Indicating pressure gauges can also be derived from the SPM.

– the ability to perform metrological control of the measuring instrument.

Comment: A measuring instrument, for example, a vibration sensor, thermocouple, pressure sensor, etc., intended for monitoring critical loads (see areas 4, 6, 14) is installed in a location of the process equipment that does not allow its metrological control. In this case, it is necessary to determine whether the equipment a) has measuring instruments that duplicate the specified functions and ensure the safety of the process equipment as a whole. For example, a non-contact thermometer or a patch-on thermocouple is installed on the bearing assembly of a steam generator, which makes it possible to correlate the temperature values recorded by a thermocouple that cannot be removed and generate a control signal. In some cases b) it is possible to carry out external periodic monitoring of the operating conditions of process equipment. In these cases, measuring instruments installed in hard-to-reach places may be excluded from the list subject to control in the field of legal metrology.

QUESTION : We ask for clarification on the legality of applying the term “verification” to measuring instruments used outside the scope of legal metrology, operated at an enterprise, in the event that these works are carried out by the enterprise’s employees (verifiers) without accreditation of a verification (calibration) laboratory; or in accordance with clause 4.1 of TCP 8.003-2011, the term “verification” is applicable only to measuring instruments verified in accredited calibration laboratories. Some enterprises designate the above procedure in their STP as, for example, “verification”, performing virtually all technical operations according to verification methods. Is it correct?

REPLY from 08/05/2013:

In accordance with the definition given in the Law of the Republic of Belarus “On ensuring the uniformity of measurements” (as amended by the Laws of the Republic of Belarus dated July 20, 2006 No. 163-Z, dated November 9, 2009 No. 53-Z, dated January 4, 2010 No. 109-Z), verification is a set of works during which the metrological characteristics of measuring instruments are confirmed and the compliance of measuring instruments with the requirements of the legislation of the Republic of Belarus on ensuring the uniformity of measurements is determined.

Verification of measuring instruments used outside the scope of legal metrology is carried out for measuring instruments for which the type of measuring instruments has been approved (they are included in the State Register of Measuring Instruments, there is a verification methodology). Verification of the specified measuring instruments is carried out by legal entities accredited for its implementation, or by legal entities and individual entrepreneurs engaged in the production of measuring instruments, their repair, sale, use, lease (rental), as well as on the basis of an agreement by other legal entities and individual entrepreneurs (Article 25 of the Law of the Republic of Belarus “On Ensuring the Uniformity of Measurements”). Verification must be carried out directly by verifiers under the conditions determined by the methods of verification of measuring instruments, using standards verified by legal entities of the state metrological service.

TCP 8.003-2011 (clause 4.1) states that Gosstandart, if necessary, may grant accredited verification laboratories of other legal entities the right to verify measuring instruments specified in the List of areas in the field of legal metrology in which the use of measuring instruments is permitted after their verification with at established intervals by legal entities included in the state metrological service.

The Law of the Republic of Belarus “On Ensuring the Uniformity of Measurements” (hereinafter referred to as the Law) determines that measuring instruments used outside the scope of legal metrology may be subject to verification or calibration, or in relation to these measuring instruments other methods of ensuring the uniformity of measurements may be applied, determined by a legal entity, an individual entrepreneur or other individual using these measuring instruments (Article 13 of the Law), while another method of ensuring the uniformity of measurements can be called, among other things, “verification”.

Once a year or once every five years?

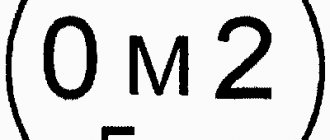

The frequency of checking pressure gauges is indicated in their technical data sheet. It depends on the design and model of the device. Typically, the timing of calibration of pressure gauges is once a year for older models and once every 2-5 years for models developed after 2000. This is due to the fact that new devices are more technologically advanced.

The frequency of checking pressure gauges is set by the manufacturer and must be strictly observed if the organization falls under the GROEI. The verification period may be shorter if the scope of application of pressure gauges falls under various safety regulations or internal regulations of the enterprise.

Procedure

If, as a result of checking pressure gauges, a Verification Certificate or a device verification protocol is required, it can only be carried out by a certified specialist. The organization providing services must be included in Rosreestr.

Verification of pressure gauges is carried out in the laboratory under normal environmental conditions using certified metrological equipment in compliance with the requirements of the Verification Methodology.

The procedure for checking the pressure gauge:

- Appearance.

- Testing: The pressure gauge to be verified is installed on the equipment, maximum pressure is applied, the pressure gauge is maintained at maximum pressure, then the pressure is gradually reduced to 0.

- Control of readings: The readings of the standard and the pressure gauge being verified are compared.

- Based on the procedures performed, a conclusion is drawn about the suitability or unsuitability of the application.

How to determine who can be trusted to verify household meters

Rosakkreditatsiya strongly recommends that all consumers, before applying for verification of metering devices to the selected company, carefully check the information about it in the Register of accredited persons

on your website. Moreover, it is quite simple and easy - you just need to clarify the exact name of the company or find out its TIN. After this, you need to go to the Register of Accredited Persons, which is open and accessible to every citizen of Russia. Next, the relevant information is entered into the “name” fields and after that the consumer receives all the information he needs, which must be correctly “deciphered”. If there is a green icon next to it, then this mark indicates that the accreditation is valid. A red pictogram indicates termination of accreditation, and if suddenly a yellow icon appears nearby, this means that the company’s activities have been suspended. Accordingly, having such important information, deciding on a company that can be trusted to verify metering devices is not a problem at all. It is important to know that only a company with valid accreditation has the right to enter data into the unified electronic Register of Rosstandart.

Self-check of the pressure gauge

If your task is not to document the timing of checking the pressure gauge, but to verify its operation, then you can check the pressure gauge yourself. For this you will need a control device.

Checking the serviceability of the pressure gauge:

- Install a pressure gauge into the container to check. Wait until the arrow stops.

- Remove the device. Install a control pressure gauge there.

- Compare the received readings.

- If they do not match, the pressure gauge must be repaired or replaced.

The frequency of checking pressure gauges in households and enterprises not from areas falling under GROEI should also be established in accordance with the technical data sheet of the devices.

Advantages of the new meter verification rules

The introduction of electronic document management makes it possible to simplify the verification procedure for the consumer, but not only that. Also in this case, the possibility of using various fraudulent schemes is eliminated and, in addition, if necessary, the data reconciliation procedure does not present problems and is carried out promptly. But you definitely need to know that the requirements for inspectors remain the same, that is: they must provide an official document

, confirming their identity and authority. You also need to pay attention to the behavior of specialists: their actions should be clear and understandable to the consumer, the questions asked should not go beyond their competence, and they also do not have the right to demand additional payment. It is important to remember about your personal safety. Therefore, it is not recommended to accept inspectors alone; it is preferable to involve close relatives and neighbors. This advice is especially important for lonely older people.