A vacuum gauge is a device designed to measure the pressure of gases or vacuum in a vacuum environment. A vacuum gauge is often called a vacuum pressure gauge. Today, manufacturers offer the consumer a huge number of varieties of vacuum gauges that allow you to measure the size of the vacuum, both in a point method and in general. In addition, it is possible to determine the absolute value of the vacuum or determine the difference between the pressure in the process flow and atmospheric pressure.

Classification of vacuum gauges depending on the type of device

- This category includes:

- liquid;

- mechanical: membrane, deformation, etc.;

- thermal: thermocouple, thermoelectric;

- compression: McLeod vacuum gauge;

- ionization;

- magnetic;

- viscous;

- electric discharge;

- radiometric.

You can use the vacuum gauges presented above to measure total pressure.

However, there are often situations when it is necessary to measure other types of gas. For example, in the case of partial pressure, it is necessary to work with special meters and mass spectrometers. In this regard, we get another classification of vacuum pressure gauges.

A little theory about the principles of measuring vacuum levels

Pressure is the effect of gas particles on a certain area. In many areas, small pressure values, such as in industry and scientific research, cannot be measured directly. In high and ultra-high vacuum, gas particles have a sufficiently large free path. Therefore, pressure can be determined by ionizing gas particles as a result of their collision with accelerated charged particles directed by an electric field to the electrodes and measuring the current value. Depending on the ionization method, two types of ionization vacuum gauges are distinguished: the particles necessary for ionization are emitted as a result of high voltage and discharge of particles from the cold cathode, or they are formed as a result of incandescence of the filament (hot cathode).

Classification of vacuum gauges according to operating principle:

Classic vacuum gauge

Measured pressure limits: 10 (0.075) – 100000 (750) Pa. (mmHg.).

Operating principle. A classic vacuum gauge is a typical pressure gauge (liquid or aneroid) that can be used to measure low pressures.

A liquid vacuum pressure gauge is characterized by the use of oil with a previously known density in the measuring elbow. This ensures that conditions for vacuum exist. Typically, “nitrogen traps” are used to isolate from another part of the vacuum system at the same time as the vacuum gauge. They are devices that are filled with liquid nitrogen and serve to freeze out the vapors of the working substance of the pressure gauge.

An aneroid is characterized by the absence of liquids when measuring pressure. Such a vacuum gauge consists of a metal box in the shape of a cylinder with a vacuum created inside it. A spring (membrane) is attached to it outside, which moves depending on the atmospheric pressure. If it rises, the box compresses and the spring tightens; if it decreases, the box expands and the spring is repelled. As a result, the movement of the spring in the lever system moves the needle on the scale, where the level of measured pressure is shown.

Capacitive vacuum gauge

Measured pressure limits: 1 (0.0075) – 1000 (7.5) Pa. (mmHg.)

Operating principle. A capacitive vacuum gauge is designed to measure pressure up to a high vacuum; the type of gas does not matter. Such pressure gauges are used to determine relative pressure. The operating principle is based on the reaction of the capacitance of the capacitor, the size of which changes depending on changes in the distance between the plates. One of them is a flexible membrane, which affects the change in capacitance of the capacitor when pressure changes. If you measure this membrane lining and carry out the calibration, then you can use the device to determine the pressure.

Thermocouple vacuum gauge

Measured pressure limits: 10−1 (10−3) – 103 (10) Pa. (mmHg.)

Operating principle The key element of a thermocouple vacuum gauge is a thermoelectric converter, since thermal conductivity and cooling due to the thermocouple are important in this mechanism. These vacuum pressure gauges are considered the most budget devices (among analogues), with which you can measure medium and low vacuum.

Pressure is created around the thermocouple, which is in contact with the heated wire. It directly depends on the thermal conductivity of the rarefied gas, since the heating of the thermocouple depends on the temperature in a vacuum. When the thermal conductivity of the gas is low, the temperature of the conductor increases, and with this change the pressure can be determined. Examples of a thermocouple vacuum gauge are the domestic PMT-2 and PMT-4.

Thermistor vacuum gauge

Measured pressure limits: 10−1 (10−3) – 1.013 (760) Pa. (mmHg.)

Operating principle. The operation of a thermistor vacuum gauge is based on a bridge circuit, the task of which is to constantly maintain the resistance of the thermistor (it can be a platinum thread - a Pirani pressure gauge). There is a directly proportional relationship between the voltage on the sensor and the pressure: if the gas pressure increases, then the power supplied to the thermistor also needs to be increased so that the temperature remains unchanged.

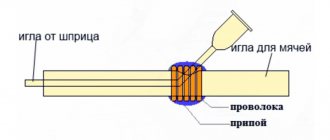

Like a thermocouple vacuum gauge, a Pirani gauge uses a filament to convert thermal energy into voltage. However, the Pirani sensor is more accurate because an electrical circuit is soldered into its mechanism.

In addition to the Pirani sensor, domestic PMT sensors - 6-3 can be cited as an example.

Ionization vacuum gauge

Measured pressure limits: 10−10 (10−12) – 10 (10-1) Pa. (mmHg.)

Operating principle. The operation of such a vacuum gauge is based on gas ionization. The ions are influenced by the magnetic field and electric discharge. Under such influence, atoms must gain speed depending on the degree of compression of the vacuum. If the gas pressure decreases, the number of particles that can undergo the ionization process will decrease. Consequently, the ionization current that flows between atoms at such a voltage will also decrease.

An ionization vacuum gauge can be used to measure pressure in a high vacuum. The main examples of such gauges are the Bayard-Alpert vacuum gauge and the cold cathode vacuum gauge.

Alphatron

Measured pressure limits: 10−1 (10−3) – 103(10) Pa. (mmHg.)

Operating principle. Alphatron is a subtype of ionization vacuum gauge. The difference lies in the particles used for ionization - here, instead of electrons, α-particles are used, which are emitted by a source of radium or plutonium (approximately 0.1-1 mCurie).

Advantages over a vacuum gauge with a cathode: simplicity, reliability, accuracy. Disadvantage: they cannot give accurate measurements due to low sensitivity, which makes it difficult to determine ultra-low currents.

Exemplary vacuum gauges

The reference vacuum gauge is intended for carrying out verification tests of other vacuum gauges. Most often, the scale of this vacuum gauge has two zones - MO and VO.

Exemplary vacuum gauges

Main technical characteristics of the standard vacuum gauge:

- The measuring device is manufactured subject to mandatory compliance with technical specifications;

- The unit of measurement is taken to be a conventional value;

- The accuracy class ranges from 0.4 to 250 conventional units;

- The operating temperature range is from 5 to 40 degrees;

- At an average working environment temperature of +25 degrees, relative humidity does not exceed 80%;

- The weight of the device directly depends on the accuracy class. With an accuracy class of 0.4 conventional units, the mass of the device is 1.8 kilograms;

- At the customer's request, it is possible to manufacture a vacuum gauge for use in any climate zone.

Results

Currently, there is a huge variety of vacuum gauges, each of which differs in its advantages and technical characteristics, as well as design features. When choosing sensors for installations, it is worth considering that modern manufacturers strive to improve the performance of devices by combining the advantages of different devices, so class boundaries are often blurred. This affects the cost of the vacuum gauge and its durability.

When purchasing a vacuum pressure gauge, pay attention to the technical characteristics of the device and its sensitivity.

Description and technical properties of a digital vacuum gauge

This type of device is increasingly used in industrial production. It is worth recognizing that these sensors are highly accurate and also provide a wide range of capabilities for long-term monitoring of readings.

As an example, consider the Meta-Chrome device. The device belongs to a rare subclass of ionization-thermocouple devices. It is capable of measuring pressure continuously.

The design uses an automatic sensor switching circuit. The software part is responsible for current control. The data obtained as a result of monitoring is displayed on the built-in display.

Attention! The device can be controlled either from the built-in keyboard or using a remote computer.

"Meta-chrome" makes it possible to always know the pressure inside the vacuum system. Now it doesn't matter where you are. The RS-485 operating interface provides ample opportunities for remote monitoring.

The device has the following technical parameters:

- The measurement limit is from 0.8 to 10 millimeters of mercury.

- Two channels for measurement.

- The design has two lamps, ionization and thermocouple.

- There is the ability to work with converters of different classes.

- Response time 0.1 s.

With all these characteristics, the weight of the device is three kilograms.

Equipment use

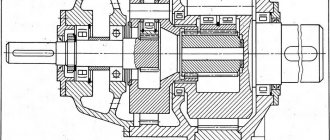

Measurements using a pointer vacuum gauge do not require complicated steps. The design includes two main elements - a measurement unit and a pressure transducer. The transducer transmits all changes that occur to the sensing element into a signal or movement. The measuring unit evaluates the signals and converts them into understandable units. This element consists of electrical circuits and a power supply. An important component of the block is the mechanism of the device. In modern equipment, this mechanism looks like a liquid crystal display.

A pointer-type vacuum gauge is a traditional unit that is used in various industries, as well as in experimental conditions.

Equipment use

Cold cathode ionization vacuum gauge

In the cold cathode, the gas is ionized by collision with electrons moving in crossed electric and magnetic fields along spiral trajectories. When the voltage between the cathode and anode is high, all electrically charged particles in the residual gas are accelerated and move towards the corresponding electrode. At the same time, they themselves can ionize other molecules by colliding with them, or cause the formation of secondary electrons. Electrons moving towards the anode and ions rushing towards the cathode cause a gas discharge process. The residual gas in the cold cathode is ionized by electrons. At low pressures it is very important that they remain in the ionization region for as long as possible. Thus, the probability of ionization and the duration of the gas discharge increases. An additional external magnetic field enhances the effect of the process.

Hot cathode ionization vacuum gauge

Thermal emission is the simplest way to produce the electrons needed for ionization. The cathode (filament) is heated by high electric current. At elevated temperatures, electrons are stripped from the atoms, accelerated by the electric field, and used to ionize the gas. In addition to the filament, a hot cathode vacuum gauge usually also consists of a lattice-shaped cylindrical anode and an ion trap. The filament and anodes are at different positive potentials, the collector is at ground. The measurement value of the hot cathode sensor is the discharge current that occurs when positively charged particles exit the collector. The cathode/filament itself is used exclusively for the production of electrons. The Bayard-Alpert sensor is considered the most common type of hot cathode sensor.

Equipment selection

Before you buy a pointer vacuum gauge, you need to decide on the basic characteristics. There are several important criteria for choosing a device - size, reproduction of results, exact parameters and cost.

An effective device for monitoring and measuring in vacuum systems is a pointer device. It is used in laboratory and industrial systems.

Selecting a pointer vacuum gauge

The following advantages of the equipment are highlighted:

- A universal device that is suitable for different types of gases and mixtures;

- High level of accuracy;

- No influence of atmospheric pressure;

- Easy to install in different systems;

- Convenient measuring scale;

- Long service life and reliability.

The pointer device allows you to study parameters in a rarefied air environment.