A two-stage planetary gearbox is a structure made up of gears and other working elements that are driven by a gear drive. At the same time, they move according to the principle that is inherent in the mechanics of planetary rotation - around one center. For this reason, the central gear is called the “sun” gear, the intermediate ones are called “satellites”, and the outer one with the internal gear clutch is called the “crown”. In addition, the simplest planetary gearbox consists of a carrier. It is designed to fix the satellites relative to each other so that they move together.

For proper operation of the device, it is necessary that one of its constituent parts be rigidly fixed to the body. In a planetary gearbox, which is equipped with a carrier, it is the static part. In addition, the ring gear or sun gear can be rigidly fixed. If none of the parts of this device are fixed, it is possible to split one movement into several, or merge two into one.

In this case, in coupling with the drive and driven shafts there can be both ring and sun gears, or satellites. This mechanism can increase the gear ratio and reduce the torque and vice versa.

This design ensures that the driven and drive shafts move in the same direction.

Purpose and design of the gearbox

The gearbox serves to provide a reduction in gear and at the same time increase the torque. To ensure the operation of this mechanism, a rotating shaft is attached to its driven element.

This device, in its classic design, consists of worm or gear pairs, centering bearings, various seals, oil seals, etc. An example of a planetary gearbox is a ball bearing. The device body is composed of two elements:

- covers;

- grounds.

All components of this device are lubricated by spraying oil, but in some special devices this is done by force using an oil pump.

Improving a mechanical concrete mixer or how to make a gearbox yourself

When building a house, non-residential structures, that is, a barn, a garage, a concrete mixer is always a necessary equipment. Buying it is really expensive, especially since the owner is not going to spend his entire life. But making it yourself is quite possible and not very difficult if you use the instructions. You can use a ready-made mechanical design, or you can make everything yourself. The design can be either for stationary use or mobile. Then you can use an old wheeled cart.

One example of making a homemade concrete mixer

It’s not difficult to make a planetary gearbox with your own hands that will rotate the container of a concrete mixer. The concrete mixing speed should not be high. He is an intermediary between the electric motor and our tank and will regulate the rotation speed through the gearbox shaft. In its manufacture, an important role is played by the gearbox housing, in which there will be shafts, axles with the necessary alignment, and gears must be set with the necessary clearance. If it is not possible to select the required housing size, you will need to either remake it from a ready-made one or weld a new one. When welding, it is necessary to take into account the deformation of the metal.

Some craftsmen advise welding the body completely and using pipe cutting supports as bearing housings, which can be set in the required position and secured either by welding or bolting. To make it possible to lubricate our gearbox, the cover is removable.

The shafts and axles that will serve as support for the gears are made from steel with good strength characteristics. The gears on them must be firmly fixed. The axle is used in the design when an intermediate gear is needed in the gearbox, which can be locked on the axle either with a locking split washer or a nut with a thrust collar.

Approximate set of shafts and gears

The shafts rest on support bearings and their correct selection affects the performance of the entire gearbox. It is best to choose a sealed bearing so that you do not have to frequently disassemble the structure and lubricate the bearings. The choice of bearing also depends on the type of tooth on the gear. Spur gears require conventional single-row, preferably double-row, ball bearings, while helical gears work better with an angular contact bearing, and it is better to choose a roller bearing.

Gears are quite difficult to make; the best option would be to remove them from old decommissioned equipment. The main thing is that they come in pairs and correspond to your idea in terms of the number of teeth. To do this you need to calculate the transmission. Let's say a concrete mixer should rotate at a speed of 35 revolutions per minute. The engine produces 1000 revolutions in one minute. We make the calculation: 1000/35 = 28. This means that the diameter of one gear and its teeth must also be related to the diameter of the other gear.

We lubricate them with liquid oil so that the lower teeth are covered with it and set the required gap, adjusting it in such a way as to reduce noise during operation and maintain the required load. It is also necessary to install oil seals to prevent oil leakage. It is also necessary to install bearing caps, which can also be selected ready-made.

Next, we weld the frame and install your container on it, after making sure that it is sealed if you are using improvised material. If we are making a movable version of a concrete mixer, we will weld the stands to the cart and install your container on the cart. You must ensure that the container can be tipped over to unload concrete. To do this, we make the mount on the frame movable using axles or bolts and attach the steering wheel on top. On the base we fix the frame with the attached engine and gearbox assembled into one unit and attach our unit to the middle of the bottom, onto which we first attach the so-called crown using welding or bolts. Basically, that's all.

| Attention Bearing Buyers Dear customers, send your questions and requests for the purchase of bearings and components by email or call now: Delivery of bearings throughout the Russian Federation and abroad. Bearing catalog on the website |

Attention Bearing Buyers

Dear customers, send your questions and requests for the purchase of bearings and components by email or call now: +7 [email protected] Delivery of bearings in the Russian Federation and abroad. Bearing catalog on the website

themechanic.ru

Principle of operation

How this unit will function depends on the kinematic diagram of the drive. Thus, the rotational movement can be applied to any element of this system, and removal can be done from any of the remaining ones. The gear ratio depends on the scheme according to which the supply and removal of the rotational movement is organized.

Understanding how such a gearbox works allows you to evaluate the complexity of repair and restoration.

Racks and Gears

Welcome to Apex Dynamics, a manufacturer of planetary and angular gearboxes

| Gear racks and gears. Accuracy class from Q4 to Q10, module from 1 to 12 | |||||

| Straight tooth slats | slats with oblique teeth | Straight tooth gears | Helical gears | Accessories | |

| Automatic lubrication system | |||||

| 2000 ml module, up to 40 lubrication points | 400 ml module, up to 16 lubrication points | Lubrication gears | Accessories | ||

| Coaxial planetary gearboxes | |||||

| AB series | AE series | AF series | AFX series | AD series | ADS series |

| Angular planetary gearboxes | |||||

| ABR series | AER series | AFR series | AFXR series | ADR series | |

| New generation: Coaxial planetary gearboxes (economy) | |||||

| PAII series | PEII series | PGII series | PSII series | PD series | PL series |

| Hypoid and multi-stage gearboxes | |||||

| KF series | KH series | AHK series | AH series | APK series | AP series |

| Angular planetary gearboxes with spiral bevel gear | |||||

| AT-L series | AT-L1/R1 series | AT-H series | AT-C series | AT-LM/RM series | AT-4M series |

| Angular planetary gearboxes with spiral bevel gear with flange for servomotor | |||||

| AT-FL series | AT-FL1/FR1 series | AT-FH series | AT-FC series | ||

| Specialized planetary gearboxes | |||||

| AM series (miniature) | L series (for plasma and laser cutting machines) | GL/GLS series for AGV pulleys and trolleys | |||

| Steel angular planetary gearboxes with spiral bevel gear | |||||

| ATB-L series | ATB-L1/R1 series | ATB-H series | ATB-C series | ATB-LM/RM series | ATB-4M series |

| Steel angular planetary gearboxes with spiral bevel gear with flange for servomotor | |||||

| ATB-FL series | ATB-FL1/FR1 series | ATB-FH series | ATB-FC series | ||

Welcome to the website of the Russian representative office of Apex Dynamics Inc. – the world leader in the production of planetary gearboxes! Apex Dynamics has over 20 years of experience in the development and sales of gearboxes and has achieved and maintained a high level of technical manufacturing capability.

We offer our customers advanced, high-speed, planetary gearboxes with low backlash (less than 1 arc minute!) and a wide range of reduction ratios (from 2 to 10 for single-stage planetary gearboxes and from 10 to 100 for two-stage planetary gearboxes), which allows them to be used in high-precision equipment together with servo systems (in coordinate systems, CNC machines, etc.). Gearboxes of any design are available: both axial and angular, T-shaped and cross-shaped gearboxes.

Apex Dynamics' unique patented technologies provide consumers with an optimal balance between high precision gearboxes and their reasonable price. In addition, we offer (the only one in this area!) a 5-year warranty, including on seals and bearings. Our company's motto: TRUTHFULNESS, RESPONSIBILITY, CREATIVITY. We focus on quality in our daily work. This is Apex Dynamics' top priority. We are constantly working on manufacturing processes, looking for more efficient methods and technologies to achieve high quality planetary gearboxes, developing new products (such as hypoid gearbox series or belt pulley gearboxes) to provide customers with solutions most suitable for their applications, no matter how complex and they were not diverse. Our goal is to find the optimal solution for you, to offer the best planetary gearbox specifically for your engine, for your machine, for your task.

If you need not only gearboxes, but also motors, drivers, gears, couplings and other components for machine tools, go to the website of our partner, Giden Electronics, which offers everything for the machine tool industry, including CNC systems and plasma sources.

Types of planetary gearboxes

Depending on the number of stages they have, planetary gearboxes are divided into:

- single stage;

- multi-stage.

Single-stage ones are simpler and at the same time more compact, smaller in size compared to multi-stage ones, provide greater opportunities for transmitting torque, achieving different gear ratios. Having several stages are rather cumbersome mechanisms, and the range of gear ratios that they can provide is significantly smaller.

Depending on the complexity of the design, they can be:

- simple;

- differential.

In addition, planetary gearboxes, depending on the shape of the housing, the elements used and the internal design, can be:

- conical;

- wave;

- globoid;

- worm;

- cylindrical.

Through them, motion can be transmitted between parallel, intersecting and intersecting shafts.

Video course on this topic

Video course “SOLIDWORKS Lessons to Improve Your Skills”

0 out of 5

Useful SOLIDWORKS tools and features not covered elsewhere.It is the depth of use of the program that gives you the status of a professional user.

2700 rub.

Add to cart Quick view

Characteristics of the main varieties of this device

Cylindrical

The most common. The efficiency of these devices reaches 95%. They can provide the transmission of sufficiently large powers. The transmission of motion is carried out between parallel and coaxial shafts. They can be equipped with spur, helical and herringbone gears. The transmission coefficient can range from 1.5 to 600.

Conical

They have this name because they use gears that have a conical shape. This ensures smooth coupling and the ability to withstand fairly large loads. I can have one, two or three stages. The shafts in this type of gearbox can be positioned both horizontally and vertically.

Wave

They are a design with a flexible intermediate number. They consist of a wave generator, an eccentric or a cam, which ensures the stretching of the flexible wheel until it reaches contact with the stationary one. In this case, the flexible wheel has external teeth, and the fixed one has internal teeth.

The advantages of this type of gearbox include:

- smooth ride;

- high gear ratio;

- the ability to transmit movement through sealed and solid walls.

They can be single- or multi-stage. High-speed ones are equipped with plain bearings, and low-speed ones are equipped with rolling bearings.

What does a planetary gear consist of?

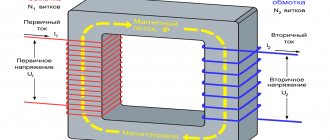

A planetary gearbox is one of the types of mechanical gearboxes. This type of gearbox, widespread in many industries, is based on a planetary gear. A planetary gear is a gear mechanism, the characteristic feature of which is that the axes of some gears are movable.

The most popular type of planetary gear consists of the following elements:

- Sun gear - a small gear with external teeth located in the center of the mechanism

- Ring gear (epicycle) – a large gear with internal teeth

- Carrier - this part of the planetary gear mechanically connects all the satellites. It is on the carrier that the rotation axes of the satellites are installed.

- Satellites are small gears with external teeth located between the sun gear and ring gear. The satellites are simultaneously engaged with both the sun and ring gears.