Protect your eyes | 04/08/2017

The oxygen in the cylinder used in gas-acetylene welding is under a pressure of 135...150 atmospheres, so the gas pressure should be significantly reduced before work. This role is performed by the oxygen reducer. This device not only reduces the oxygen flow, but also ensures constant operating pressure throughout the entire welding process.

Oxygen reducer characteristics and design features

In addition to the key parameters in the form of flow and pressure, the reducers have the following additional characteristics:

Oxygen reducer characteristics

Number of pressure reduction stages. Manufacturers produce devices with one or two stages of regulation. In the first, the main role is played by the spring. In models with two stages, adjustment is carried out using intermediate air chambers. These products guarantee the operation of the gas welding workplace in conditions where the temperature is below zero. In addition, these reducers guarantee a stable gas supply. But they differ in design complexity and, accordingly, cost. All oxygen reducers are connected to the gas source using a union nut. Clamps and other fastening devices must not be used. This is caused primarily by the explosive properties of oxygen, which require high-quality sealing of the connection. Another parameter of oxygen reducing devices is the climatic version

This indicator is important. The fact is that a drop in pressure leads to an increase in its volume

This leads to overcooling of the reducer and gas, which can lead to damage to the device.

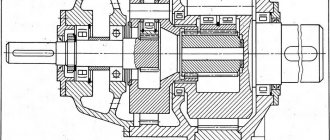

Oxygen reducer device features

The two-stage oxygen reducer is distinguished by a valve manufactured with high precision and a membrane assembled from two layers of material. Synthetic rubbers are used for its manufacture. This allows the device to remain operational at temperatures below 0 and pressures up to 200 atm.

Tips for selection and rules of use

When choosing a gearbox, the placement point should be taken into account. No special explanation is needed; it is clear that a ramp or network reducer cannot be installed on a cylinder. You cannot install an argon or carbon dioxide reducer on an oxygen cylinder. Make sure that the possible maximum gas inlet pressure does not exceed that allowed for this type of reducer. If this condition is violated, preconditions are created for emergency destruction of the product. Select the device according to the required operating voltage.

Making a choice between a single-stage and a two-stage gearbox is easy. In 99% of cases, one step is enough for you. And only under specific operating conditions may two stages of pressure reduction be necessary. This will necessarily be specified in the technical documentation for the technological process. The same is with the climatic version: if you work in a normal climatic zone, then the climatic version will not interest you at all.

To avoid running into a fake, carefully read the markings on the case. The manufacturer's logo, product brand and production date should be clearly visible here. Compare this information with that specified in the device documentation.

Issues of setting up and preparing for operation of the equipment were described above. Let's add a few more simple rules necessary for safe work. During operation, it is necessary to constantly monitor possible leaks and freezing of the gearbox.

When stopping work for a short time, it is enough to close the valve on the cutter. When stopping for more than 15 minutes, you need to unscrew the adjusting screw; this will protect the adjusting spring from damage. At the end of the working day, it is recommended to remove the reducer from the cylinder and place it in a box.

Design and principle of operation of an oxygen reducer

The direct purpose of the reducer is to ensure a constant ratio between the inlet gas pressure from the cylinder and the output, working, which enters the welding torch.

The simplest oxygen reducer consists of the following elements:

- Locking spring.

- Inlet valve.

- Pusher.

- Membranes.

- Pressure disk.

- Pressure spring.

The inlet valve is the most critical component of the oxygen reducer. He is constantly under the influence of two forces acting in opposite directions. One of them is created by the initial pressure of oxygen, which is in the cylinder. This pressure tends to push the locking spring upward and allow gas flow to flow to the pusher. However, the second pressure from the membrane prevents this. As a result, the reduced pressure chamber always maintains a balance of forces that are created by the shut-off spring and the membrane, which is ensured by the adjustment of the gearbox. In principle, the device is similar to an acetylene gearbox.

The oxygen reducer operates in the following sequence. When you try to lift the shut-off valve plate up, the force transmitted to the membrane from the pressure spring tends to prevent this. If the operating oxygen pressure is reduced, the pressure spring begins to move upward and move the membrane in the same direction. The pusher overcomes the resistance of the locking spring and opens the inlet for the passage of gas contained in the oxygen cylinder. Oxygen consumption increases accordingly. And vice versa, as the working pressure increases, it acts on the pusher, which moves down and blocks part of the inlet hole. With a properly adjusted oxygen reducer, dynamic equality is constantly maintained between these two processes.

Adjustment of the oxygen reducer consists in the fact that the tension force of the lower pressure spring can be changed. In most cases, a screw with a fine thread pitch is used for this. If this screw is removed, the spring tension weakens and the operating oxygen pressure decreases. As the screw is screwed in, the pressure increases.

The set of conventional gearboxes that are required to perform gas welding work includes two pressure gauges. One of them controls the pressure at the inlet to the reducer, and the second controls the pressure after reduction.

Structurally, oxygen reducers are produced in two versions - direct and reverse. In direct-pressure reducers, the initial oxygen that comes from the cylinder tends to open the valve, and in reverse-acting reducers, it tends to close it by pressing the pusher against the seat.

The dependence of the oxygen pressure in the cylinder, which is equipped with a reducer, changes according to a parabolic dependence: it is maximum in the initial period, and over time it decreases to the level of the operating pressure of the welding process (in this case, the reducer is actually no longer required). In practice, a reverse-acting reducer turns out to be more efficient, since it can ensure constant operating pressure values (regardless of the initial oxygen pressure in the cylinder) until the cylinder is completely emptied. At the same time, the direct-acting oxygen reducer reduces the working pressure when the cylinder is half empty, since the ratio of forces acting on the pusher is disrupted. Therefore, such devices require constant adjustment by the welder.

Why is a gas reducer used?

In any vessel, gas is under high pressure. This simplifies its transportation and operation. However, it must be supplied to the consumer, be it a stove, boiler, welding or gas-flame equipment, under low pressure. For such a transformation, there is a special mechanical device - a gas reducer.

The figure shows a diagram of the internal structure

Take, for example, a propane-butane mixture. In order to store it in a liquid state, a pressure of about 16 bar is created. At the same time, in most cases, a few tens of millibars are enough for the consumer. In addition, the outlet pressure must be maintained at a certain level while the tank is being emptied. It is for such purposes that a gearbox is needed. Any cylinder installation is equipped with a similar device, without which its safe operation is impossible, regardless of whether it is used for industrial or domestic purposes. You can learn more about the operation of gas cylinder equipment in the article: operation of cylinder units in an autonomous gas supply system.

Adjusting the device

Adjusting the gearbox for a carbon dioxide cylinder begins with the fact that it is necessary to adjust the tension of the main spring. For this, there is an adjusting screw, and the tension force depends on what initial pressure is observed in the cylinder with the volatile substance. This spring will lower along with the membrane under the influence of carbon dioxide, passing this substance into the chamber to reduce pressure. This chamber is connected to a shut-off valve, as well as a hose through which the gas flow will reach the welding machine torch.

Which carbon dioxide reducer should I choose? When choosing this device, it is very important to pay attention to the fact that the membrane must be made of oil-resistant rubber, and it must also be very accurately positioned relative to the outlet. It is worth adding here that you can use this type of gearbox manually. To do this, you need to screw in or, conversely, unscrew the adjusting screw, based on the pressure gauge readings

Since a sharp increase in pressure in the chamber is possible, the carbon dioxide welding reducer has a safety valve that protects the main membrane from rupture during a sharp increase in pressure. The safety valve will operate at the moment when the adjusting screw for any reason loses its tightness and more carbon dioxide begins to enter the chamber than expected

To do this, you need to screw in or, conversely, unscrew the adjusting screw, based on the pressure gauge readings. Since a sharp increase in pressure in the chamber is possible, the carbon dioxide welding reducer has a safety valve that protects the main membrane from rupture during a sharp increase in pressure. The safety valve will operate at the moment when the adjusting screw for some reason loses its tightness and more carbon dioxide begins to flow into the chamber than expected.

Oxy-fuel cutting safety: check valves and fire stop valves

Check valves and fire arrester valves are necessary to ensure the safety of workers who use oxy-fuel welding, cutting, heating (pre-heating or auxiliary heating) in the production process and to protect equipment such as furnaces, pipelines, discharge ramps.

A check valve is a device designed to prevent the unintentional backflow of gas.

The fire arrestor valve (fire arrester) prevents the spread of flame upstream of the gas.

Please note that these devices reduce the volumetric flow of gases.

Nature of the danger

Always check that there is enough gas in both cylinders to complete the operation before starting work. Gas backlash typically occurs when one cylinder becomes empty during operation, creating a pressure imbalance in the system. A clogged (clogged) or blocked (crushed) tip or torch can also cause backflow. An extremely dangerous situation can develop when oxygen and flammable gases mix inside hoses. Backflow check valves alone cannot stop the spread of flames in a system. When oxy-fuel processes (welding, cutting, heat treating, etc.) are conducted, operators may experience kickback or backfire.

How to work with an oxygen reducer?

First of all, you should check the position of the arrows on the pressure gauges - they should be at zero. You also need to make sure that the valve is closed, for which you check the adjusting screw to see whether it is turned out or not. Next, a hose is connected to the reducer, the valve on the burner is opened and the required pressure in the working chamber is adjusted.

Before work, the tightness of all connections is checked. To do this, the burner valve is closed and the adjusting screw is unscrewed. If at the same time the needle of the working pressure gauge rises up and stops, then the tightness is ensured. You can also check for leaks in the gearbox using soap foam. To do this, it is applied to the opening of the fitting. If bubbles have formed, this indicates the presence of a leak, and their absence indicates the serviceability of the oxygen reducer and its tightness.

Rules for safe operation

Considering the explosion and fire hazard of oxygen, such products, in accordance with GOST 12.2.008-75, must be periodically subjected to thorough routine maintenance. In relation to oxygen reducers of type BKO 50-4 and BKO 50-5, maintenance rules include:

- Checking the movement of the adjusting screw/flywheel from one extreme position to another: it should be smooth and without jamming.

- The connecting elements must not have external mechanical damage - cracks, scratches, and also be cleaned of oil, grease and dirt.

- Periodic checking of pressure gauges should not be less than once a year. The criterion for the need for verification is considered to be increased inertia of the instrument needle.

- Parts that do not meet the operating conditions of oxygen reducers cannot be used as sealing elements - gaskets, nipples, etc.

- Before each use, the tightness of the connections is checked (using a pressure gauge); leakage of oxygen from the cylinder is unacceptable.

- When an oxygen cylinder is connected to the reducer, it is prohibited to make any adjustments.

- According to labor safety rules, it is necessary to provide for the installation of safety devices between the reducer for the oxygen cylinder and the rest of the gas welding equipment, including those for extinguishing the flame. These can be check valves designed for the pressure in the cylinder, as well as safety valves.

The price of an oxygen reducer is determined by its design and operational capabilities. For single-stage gearboxes, the price ranges from 1800...2000 rubles. (BKO 50-4) and 1100...1200 rub. (BKO 50-5). Two-stage devices (for example, BKD-25 or Multi-Stage RG S2 O2 made in Czech) are much more expensive - 11,000...12,000 rubles.

Operation of the gearbox.

Before connecting the oxygen reducer, you must carefully check whether there are any traces of oil, etc. on the fitting and union nut. If traces of fatty substances are found, the reducer must be washed in some solvent (for example, aviation gasoline).

Next, you need to check the serviceability of the thread of the union nut, clean it from dirt and dust, and also check the presence and serviceability of the fiber (for oxygen gearboxes) or leather (for acetylene gearboxes) gasket, on which the tightness of the connection between the gearbox and the valve depends.

After blowing out the oxygen valve of the cylinder or line to remove dirt or chips from them that could get into the reducer and damage its valve, the union nut of the oxygen reducer is screwed to the valve fitting and secured with a wrench.

In the same way, it is necessary to purge the valve of the acetylene cylinder before attaching the acetylene reducer to it.

Before releasing gas into the reducer, its adjusting screw must be turned out until the pressure spring is completely weakened, so that when opening the cylinder valve, the reducer cannot be damaged. The shut-off valve on the gearbox must be open. A hose is attached to the hose nipple of the gearbox and secured firmly with clamps or soft wire.

To release gas into the reducer, you must smoothly open the cylinder valve half a turn of the handwheel. If no abnormalities are observed, then the cylinder valve should be opened all the way and by rotating the pressure control screw of the gearbox clockwise, set the required operating pressure using the pressure gauge. The operating oxygen pressure is set when the cutter valve is open.

When, due to the presence of oil or a sudden release of oxygen, a flash or strong heating of the gearbox occurs, it is necessary to quickly close the cylinder valve, and remove the gearbox and send it for repair.

After establishing the operating pressure, it is necessary to check whether there are gas leaks at the joints, along the threads of pressure gauges, etc. Gas leaks are dangerous, since acetylene and other flammable gases form explosive mixtures with air.

After checking, the torch is ignited and the flame is adjusted.

During operation, it is necessary to ensure that there are no leaks, freezing, etc. in the gearbox.

When you stop working for 2-3 minutes. Only the valves on the cutter can be closed. If work stops for 10-15 minutes, then in addition to the cutter valves, close the gearbox shut-off valve without changing the position of the control screw. During breaks in work for more than 10-15 minutes. You should additionally loosen the pressure spring by unscrewing the adjusting screw.

During long breaks and at the end of work, the valve of the cylinder or line is closed and the gas remaining in the reducer is completely released. Then, by turning the adjusting screw counterclockwise, the pressure spring is weakened.

Cylinders for storing and transporting oxygen

Oxygen cylinders must be manufactured in accordance with GOST 949-73. It provides volumes of 50, 40, 10 and 5 liters. This GOST also stipulates what the pressure in the oxygen cylinder should be. If the volume of the cylinder is 40 liters, and such cylinders are used most often, the working pressure can be 150 and 125 atmospheres. This pressure is measured at +20° Celsius. It may vary depending on the ambient temperature.

Example of pressure change in an oxygen cylinder:

| Ambient temperature | -30 | -20 | -10 | 0 | 10 | 20 | 30 |

| Pressure in the cylinder, no more than P kg/cm | 110 | 120 | 130 | 135 | 140 | 145 | 150 |

The pressure that a cylinder can withstand also depends on the type of steel from which it is made. It can be alloy steel or carbon steel.

If we consider the weight of an oxygen cylinder, it does not depend on temperature. A 5 liter cylinder weighs 5.8 kg, a 10 liter weighs 15 kg, a 40 liter weighs 77 kg, a 50 liter weighs 95 kg. Naturally, GOST also provides for smaller volumes of cylinders that are used in medicine. If necessary, you can look at GOST.

Design of an oxygen cylinder according to GOST

The height of the cylinder and the thickness of its wall depend on its volume and the metal used. By design:

- 1 – support shoe;

- 2 – body;

- 3 – cylinder neck ring;

- 4 – valve;

- 5 – safety cap for the valve.

If we are talking about oxygen cylinders for medical purposes, they can be used not only within the walls of a hospital, in ambulances, but also individually, according to a doctor’s indications. Typically these are cylinders with a capacity of 4 liters, but there are also smaller volumes. There are replaceable cylinders, and there are disposable ones, for example Atmung 12L. Or there may be other manufacturers.

| Attention Bearing Buyers Dear customers, send your questions and requests for the purchase of bearings and components by email or call now: Delivery of bearings throughout the Russian Federation and abroad. Bearing catalog on the website |

Attention Bearing Buyers

Dear customers, send your questions and requests for the purchase of bearings and components by email or call now: +7 [email protected] Delivery of bearings in the Russian Federation and abroad. Bearing catalog on the website

themechanic.ru

Design and principle of operation of a carbon dioxide reducer

The carbon dioxide reducer supplies gas at the required pressure, as well as shuts off the CO2 supply valve from the cylinder when welding stops. The design of the unit includes:

- Inlet valve.

- Sealing elements.

- Chamber with a regulating membrane.

- Release valve.

- Upper spring.

- Control spring.

- Connection fitting.

- Frame.

- Two pressure gauges that control the carbon dioxide pressure at the inlet and outlet.

- Shut-off valve.

A conventional single-chamber carbon dioxide reducer works as follows. Gas under pressure (which is controlled by a pressure gauge) from the cylinder enters the inlet fitting. Having passed into the chamber, the CO2 flow overcomes the resistance of the spring and presses it down, as a result of which the gas enters the cavity of the chamber. Since its cross-sectional area is significantly larger than the flow area of the fitting, the gas pressure in the chamber decreases. This change is recorded by a second pressure gauge.

Carbon dioxide reducer: purpose

The carbon dioxide reducer is designed to regulate and reduce the gas pressure that comes from the network or cylinder, as well as to maintain a constant value of the operating gas pressure.

According to GOST 6668-78, carbon dioxide gearboxes are classified into the following types:

- central (C) – CDC;

- universal (U) – UVN, UKN;

- network (N) – SAO, SKO, SMO, SPO;

- balloon (B) – BKD, BKO, BPO;

- ramp (R) – RPD, RKZ, RAD.

According to GOST 13861-89, carbon dioxide gearboxes for gas-flame processing of metals are classified:

- according to the operating principle: direct-acting gearboxes;

- reverse action gearboxes;

- single-stage with spring pressure setting (O);

Carbon dioxide reducers are black in color and differ from each other in the way they are connected to the cylinder or network.

Carbon dioxide reducer: operating principle and design

Carbon dioxide gearboxes used in modern industry for gas welding and metal cutting differ in their operating principles.

Direct-acting gearboxes have a decreasing characteristic (the operating pressure decreases as gas is consumed), while reverse-acting gearboxes have an increasing characteristic (the operating pressure increases as the gas pressure in the cylinder decreases).

To carry out the work, carbon dioxide reducers are connected to a gas cylinder using a union nut.

During operation, the gas, passing through the inlet filter, enters the high-pressure chamber. Adjustment of the working gas pressure during welding is carried out by rotating the adjusting screw. When it is turned clockwise, the force, through the pressure spring, sequentially acts on the pressure disk, diaphragm, pusher and pressure reducing valve. The reducing valve, as a result of this force, begins to move and opens the access of oxygen to the working chamber through the resulting gap between the valve and the seat.

Thus, the operating pressure is automatically maintained in the required range.

Modern balloon carbon dioxide reducers are available in various models and configurations. Depending on the model, some of them can be equipped with special devices - pressure gauges (low output and high input) pressure, which determine the gas pressure respectively leaving and entering from the reducer and into the reducer.

Carbon dioxide gearboxes are also produced without the specified measuring instruments.

Gas is drawn into the carbon dioxide reducer using a nipple attached to the reducer with a nut. A special sleeve is attached to the nipple itself, which goes directly to the gas cutter or gas burner.

Operation and checking the serviceability of the carbon dioxide reducer

Before operation, the carbon dioxide reducer must be checked for operability. The check includes:

- checking the serviceability of pressure gauges, the needles of which should be at zero; checking the adjusting screw, which must be turned out (valve closed);

- checking the pressure in the working chamber (checked after connecting the hose to the reducer);

- checking the tightness of the closure of the gearbox valve and the tightness of all connections (checked by closing the burner valve and unscrewing the adjusting screw);

- checking for possible leaks in the gearbox (checked with soap foam applied to the hole in the outlet fitting with the adjusting screw fully turned out).

Proper operation of a carbon dioxide gearbox ensures that no oils, grease or other contaminants come into contact with the gearbox.

Gas carbon dioxide reducers supplied by industry must have the following markings:

- trademark of the manufacturer;

- gear brand;

- year of issue.

Components for carbon dioxide welding

Cylinder for storing carbon dioxide. Wire for semi-automatic welding.

Used as an electrode. For each case, depending on what metal we will solder, the wire must be selected individually. Based on the thickness of the metal being welded, the power of the semi-automatic machine and its other features, the diameter of the wire can vary in the range from 0.5 to 3 mm. In practice, copper wire shows the best results, and we recommend using it.

It is necessary to use only clean material, without traces of rust, corrosion, or contamination, which has been stored in proper conditions.

Otherwise, this wire cannot be used unless you want to end up with a poor quality connection. It is recommended to soak the wire in sulfuric acid and then hold it at high temperature for several hours.

Carbon dioxide CO2. Actually, our main highlight of the program and the most important component. Carbon dioxide for semi-automatic welding is harmless to humans and colorless.

CO2 is transported and stored, as a rule, under pressure in special black containers and marked with the same name. Here are some practical and simply useful operating tips:

- for particularly important and complex work, use a container with a 99% carbon dioxide content; in other cases, containers with a 98% content will be sufficient;

- Please note that excess moisture will negatively affect the overall quality of welding. To get rid of it, place the container in a vertical position for one hour, during which time the moisture will settle to the bottom;

- Before starting semi-automatic welding, release a little gas from the container to get rid of nitrogen impurities contained in it that are harmful to welding.

Features of the device UR 6-6

This model has certain features that make it so popular:

- Firstly, the body of this device is made of a special alloy, which provides a certain resistance to various thermal influences and mechanical loads.

- Secondly, the minimum pressure unevenness does not exceed 0.3.

- A fairly low pressure indicator is 1.2 MPa, at which the safety valve will operate.

- Like other devices, it has two pressure gauges, which greatly simplifies the process of adjusting gas pressure.

- The throughput capacity of this type of gearbox is much higher. It is capable of passing up to 6 m3 of gas per hour.

- The cost of this device is about 1,100 rubles, while BUO-5-4, for example, costs 1,700-1,800 rubles.

Despite such differences, the process of selecting a gearbox is quite simple, since there is not much difference between them if you do not have to weld or cut metal at low temperatures. Any device is suitable for working in moderate conditions.

Overpressure protection

Compliance with safety standards is one of the main components of the gas supply system. Exceeding pressure levels several times higher than the nominal value can create an emergency situation with any possible consequences. In order to prevent an accident, some models are equipped with an additional safety valve, which releases excess gas if the nominal values are exceeded by 2.5-3 times.

When organizing gasification based on a group cylinder installation, it is advisable to equip each unit with a similar device. For more information about the principle of operation and compliance with safety precautions in an autonomous gas supply system, read the article: autonomous gasification - gas cylinder installations.

This is how the reducer is connected in a cylinder installation

How to choose?

As you already understand, a certain reducer is used for any type of gas. For your comfort, these devices are marked with a set color, which indicates the purpose of the device:

- black mark with yellow text – the reducer is intended for carbon dioxide (also known as a CO2 reducer);

- the label is blue and the text is black for oxygen;

- white mark and red text – acetylene;

- A black mark with blue or white text is intended for acetylene or argon, respectively.

Another way to distinguish the reducer you need is to learn the colors of the cylinders, since they are also marked by color. For example, a blue-colored cylinder is for oxygen, and a black-painted cylinder is often used for argon. And exactly the same with other colors.

There is an opinion that for welding work at home (short, irregular operations) any device whose threaded connection coincides with the connection on the cylinder will do. For example, for an event such as welding a brazier for a summer cottage, even a CO2 reducer screwed onto an oxygen cylinder (when using gas welding) or onto a cylinder with a technical mixture consisting of 20% carbon dioxide and 80% may be suitable. argon. However, after this you will have to throw away such a device.

In theory, an argon welding reducer and an oxygen reducer are equivalent. However, oxygen will function worse as the pressure in the cylinder decreases to a critical point of approximately 1 atm.

An example of an argon welding device is the Russian-made AR-40-2. There is also a truly universal device for reducing pressure - U-30\AR-40 (CO2 reducer\argon). It is able to withstand both temperature changes and high pressure.

If there are no difficulties with money, and the scale of welding work is planned to be large, then you should choose a device not with an additional pressure gauge, but with a device for displaying the volumetric flow rate of the mixture - a rotameter. This device reflects the consumption of the technical mixture much more accurately, since it operates according to a different scheme - it takes measurements in the current time mode. These devices are used by specialists in their work.

7 main mistakes that electric welders make when buying a gearbox for welding machines are in the video below.

Selecting a gearbox for welding

A reducer, in the global sense of the word, is a device that changes any physical indicator, usually in the direction of decreasing or lowering it (reduction).

A welding reducer is a device that is designed to release gas from a nozzle under reduced pressure, since it is highly compressed in the cylinder. Specific pressure indicators depend on the type of gas or gas mixture.

Color coding

Essentially, a reducer is a pressure regulator for a welding mixture. It is a mandatory part of the equipment for semi-automatic welding machines that use the principle of welding in a protected gas environment. At least two gearboxes (each connected to its own cylinder) are used in a gas welding and cutting installation.

Of course, the best solution would be to choose only a reducer specifically designed for it for a cylinder with a certain gas. There is a strict color coding system:

- blue color with black inscription - oxygen;

- white with red text - acetylene;

- black with blue inscription - technical argon;

- black with white lettering - raw argon;

- black with yellow inscription - carbon dioxide (CO2).

How to work with an oxygen reducer

When working with oxygen reducers, it is necessary to carry out several preparatory operations.

- Check the serviceability and integrity of the pressure sensors. The arrows must be set to zero and not change their position when turning the gearbox.

- Before connecting the gas supply hoses, it is necessary to check whether the operating screw that regulates the closing of the valve is turned out.

- After connecting the hoses, it is necessary to configure the device to supply the pressure necessary to perform the work.

Working with an oxygen reducer

In addition to the above operations, it is necessary to check the gearbox for leaks. To do this, the screw must be unscrewed completely.

Check the threaded connection for traces of oil and grease; if found, they must be removed immediately using a solvent.

By the way, you can check the tightness by applying soap foam to the threaded connections. If bubbles appear, work must be stopped and the gearbox must be sent in for repair.

Application area

Gearboxes of this type are used in almost all sectors of the national economy. In industry - for assembling and cutting metal structures, in medicine, for organizing the supply of gas to wards and operating rooms.

Performing gas-flame work

Oxygen reducers are used in various industries. In particular, when performing gas-flame work. The reducer ensures a constant supply of gas. In medicine, reducers are installed in the oxygen supply system throughout the wards. Air supply systems in aviation and maritime transport cannot do without such devices.

Oxygen reducer: purpose

The oxygen reducer is designed to regulate and reduce the gas pressure - oxygen, which comes from the network or cylinder, as well as to maintain a constant value of the operating gas pressure.

According to GOST 6668-78, oxygen reducers are classified into the following types:

- central (C) – CDC;

- universal (U) – UVN, UKN;

- network (N) – SAO, SKO, SMO, SPO;

- balloon (B) – BKD, BKO, BPO;

- ramp (R) – RPD, RKZ, RAD.

Oxygen reducer: operating principle and design

Oxygen reducers used in modern industry for gas welding and metal cutting are blue in color.

To carry out the work, propane reducers are connected to a gas cylinder using a union nut.

During operation, oxygen, passing through the inlet filter, enters the high pressure chamber. Adjustment of the working gas pressure during welding is carried out by rotating the adjusting screw. When it is turned clockwise, the force, through the pressure spring, sequentially acts on the pressure disk, diaphragm, pusher and pressure reducing valve. The reducing valve, as a result of this force, begins to move and opens the access of oxygen to the working chamber through the resulting gap between the valve and the seat.

Thus, the operating pressure is automatically maintained in the required range.

Modern cylinder oxygen reducers are available in various models and configurations. Depending on the model, some of them can be equipped with special devices - pressure gauges (low output and high input) pressure, which determine the gas pressure respectively leaving and entering from the reducer and into the reducer.

Oxygen reducers are also produced without the specified measuring instruments.

Gas is drawn into the oxygen reducer using a nipple attached to the reducer with a nut. A special sleeve is attached to the nipple itself, which goes directly to the gas cutter or gas burner.

Technical characteristics of some models of oxygen reducers

| Indicators | BKO - 50 mini | BKO - 50-4 | BKO – 50 MG | SKO - 10-2 | RK - 70 | RKZ - 500-2 |

| Maximum throughput V, m3/h | 50 | 50 | 50 | 10 | 100 | 500 |

| Maximum gas pressure at the inlet, P1, MPa (kgf/cm2) | 20 (200) | 20 (200) | 20 (200) | 1,6 (16) | 20 (200) | 20 (200) |

| Maximum working pressure, P2, MPa (kgf/cm2) | 1,25 (12,5) | 1,25 (12,5) | 1,25 (12,5) | 0,5 (5) | 7 (70) | 1,6 (16) |

| Weight, kg, no more | 0,85 | 1,5 | 1,2 | 1,5 | 12,2 | 10,0 |

Operation and checking the serviceability of the oxygen reducer

Before operation, the oxygen reducer must be checked for functionality. The check includes:

- checking the serviceability of pressure gauges, the needles of which should be at zero; checking the adjusting screw, which must be turned out (valve closed);

- checking the pressure in the working chamber (checked after connecting the hose to the reducer);

- checking the tightness of the closure of the gearbox valve and the tightness of all connections (checked by closing the burner valve and unscrewing the adjusting screw);

- checking for possible leaks in the gearbox (checked with soap foam applied to the hole in the outlet fitting with the adjusting screw fully turned out).

Proper operation of the oxygen reducer ensures that no oils, grease or other contaminants come into contact with the reducer.

Gas oxygen reducers supplied by industry must have the following markings:

- trademark of the manufacturer;

- gear brand;

- year of issue.

The most popular regulators for gas cylinders, their characteristics, photos are considered

What is a gas cylinder reducer, its functions, operating principle, types and applications. Brief technical characteristics of the most popular types and approximate prices. This article is about all this.

A gas cylinder reducer is a device designed to reduce or maintain a given pressure when gas is supplied from a cylinder.

How gearboxes work

The reducer is attached to the cylinder. The gas passes through the inlet filter and is supplied to the increased pressure chamber. As the screw rotates clockwise, the pressure spring strengthens. The force is transmitted to the membrane and the pusher, which moves the pressure reducing valve. The valve moves and a gap opens to allow gas to pass through.

Types of gearboxes

Depending on the type of gas in the cylinder, there are several types of reducers, and they also differ from each other in the way they are connected to the container and in color.

In general, pressure regulators for reducers of flammable gases (hydrogen, propane, methane) and inert gases (nitrogen, argon, helium).

Characteristic

- Oxygen - designed to regulate the supply of oxygen in the cylinder. Common markings: SKO - 10-2, BKO - 50 mini, RK-70, RKZ - 500-2. Painted blue, secured with union nuts. Capacity from 10 to 500 m3/hour. The price varies from 1600 to 21500 rubles.

- Propane - regulates the supply of propane. Markings: BPO - 5, SPO - 6, RDSG-1-MTL (frog). Painted red, secured with union nuts. Throughput from 1.5 to 1.6 m3/hour. Price – from 400 to 1600 rubles.

- Carbon dioxide - to regulate the supply of carbon dioxide. Markings: UR-6-6, BUO-5-4. Can be painted black or red and blue. Fastened with union nuts. Capacity 5-6 m3/hour. Price 900-1500 rubles.

- Acetylene - regulate the supply of acetylene. Markings: BAO-5-4, RAO-30-1, SAO - 10. Fastened with clamps. Painted white. They pass from 5 to 30 m3/hour. Price from 1600 to 14300 rubles.

- Argon. Markings are: AR-40-4DM, AR-40-KR1-mr. Color white or black. They pass 1.8-5.4 m3/hour. Price 1400-1750 rubles.

- Helium. For helium regulation. Marked: G-70-KR1, G-70-KR1-m. Fastened with nuts. Color white or black. Bandwidth 4.2. Price about 1500.

| Characteristics, name | color | Mounting method | throughput (highest value) m3/h | gas pressure at the inlet, (maximum value) MPa (kgf/cm2) | operating gas pressure, (maximum value) MPa (kgf/cm2) | Weight no more, kg | Price, rub.) |

| Oxygen species | |||||||

| SKO - 10-2 | blue | Union nuts | 10 | 1.6 (16) | 0.5 (5) | 1.5 | 2600 |

| BKO - 50 mini | 50 | 20(200) | 1.25 (12.5) | 0.85 | 1600 | ||

| RK-70 | 100 | 20 (200) | 7 (70) | 12.2 | 5910 | ||

| RKZ - 500-2 | 500 | 20(200) | 1.6 (16) | 10 | 21500 | ||

| Propane types | |||||||

| BPO-5 | red | Union nuts | 5 | 2.5 (25) | 0.3 (3) | 2 | 1300 |

| SPO - 6 | 6 | 0.3 (3) | 0.15 (15) | 1.8 | 1400 | ||

| RDSG-1-MTL (frog) | 1.5 | 1.6 (16) | 0.2-0.36 (2-3.6) | 0.2 | 400 | ||

| Carboniferous species | |||||||

| UR-6-6 | black | Union nuts | 6 | 10 (100) | 0.6 (6) | 0.61 | 900 |

| BUO-5-4 | Red Blue | 5 | 10 (100) | 0.35 (3.5) | 1.3 | 1500 | |

| Acetylene species | |||||||

| BAO-5-4 | white | Slip clamp | 5 | 2.5 (25) | 0.15 (1.5) | 0.6 | 1600 |

| RAO-30-1 | 30 | 2.5 (25) | 0.1 (1) | 10 | 14300 | ||

| SAO - 10 | 10 | 0.12 (1.2) | 0.1 (1) | 0.8 | 2600 | ||

| Nitrogen species | |||||||

| A-90-KR1-m | White and black | Union nuts | 5.4 | 20 (200) | 1.0 (10) | 0.74 | 1900 |

| A-30-KR1 | 1.8 | 20 (200) | 2.2 (22) | 0.8 | 2600 | ||

| Argon species | |||||||

| AR-40-4DM | black | Union nuts | 2.4 | 20(200) | 0.8 (8) | 0.78 | 1750 |

| AR-40-KR1-m-r | white | 2.4 | 20 (200) | 1.0 (10) | 0.78 | 1400 | |

| Helium species | |||||||

| G-70-KR1 | white | Union nuts | 4.2 | 20 (200) | 1.6 (16) | 0.8 | 1500 |

| G-70-KR1-m | black | 4.2 | 20 (200) | 1.6 (16) | 0.74 | 1200 |

Application of gearboxes

- Oxygen reducers are used in metal cutting, soldering and gas welding. Used for scuba diving and in medical institutions.

- Acetylene – used for cutting pipes and gas welding. Used in auto repair shops for body repairs.

- Propane - for cutting, for gas welding, heating work. Used to supply gas to gas stoves, as well as in construction.

What else you should know when working with a gearbox

As you know from a school chemistry course, oxygen is a strong oxidizing agent and therefore work with it must be carried out in strict accordance with the requirements of safety and labor protection rules. In particular, oxygen and oils must not be allowed to come into contact; such contact will result in an explosion.

Gas is often delivered to workplaces in cylinders with a pressure of 14.7 MPa. Therefore, when handling them, certain safety rules must be observed. In addition, the cylinder must not be dropped, hit, stored from fire, etc. The oxygen reducer installed on it must be covered with a durable casing.

Is interchangeability possible?

Some types of welding gears are interchangeable, but not all. So, instead of a specialized CO2 reducer for welding, it is permissible to use an oxygen one, but a reverse replacement is absolutely forbidden.

Oxygen is a chemically active substance, a strong oxidizing agent, so special metals and alloys are used to work with them. In addition, oxygen is pumped into gas cylinders under pressure that exceeds the same parameter for carbon dioxide by more than 2 times.

A welding reducer for carbon dioxide screwed onto an oxygen cylinder can last, depending on its quality, from several hours to a couple of weeks. But the sealing membranes, the main structural element, will inevitably be completely destroyed, as a result of which the device will begin to etch.

Similar threads are found in cylinders for cutting and welding. In this case, the oxygen reducer has a right-hand thread. Oxygen does not burn on its own, but supports combustion. It is explosive under certain conditions.

The oxygen reducer used during welding with a carbon dioxide cylinder faces another threat. Carbon dioxide causes parts in contact with it to freeze to -60 °C. Since the pressure regulator designed for oxygen is not supposed to withstand this operating mode, it will also begin to deteriorate.

Purpose of the oxygen reducer

Oxygen is an integral component of the so-called gas welding or metal cutting. It is delivered to the work site in cylinders made of steel and painted blue.

To ensure the supply of oxygen under operating pressure, reducers are used. In accordance with GOST 13861-89, these devices are marked as follows - BKO, SKO, RKO. The first abbreviation means that the reducer is used for installation on oxygen cylinders, single-stage (D - two-stage). The second is a network Product, and the third is a ramp Product.

Several types of these devices are produced - BKO 25 and BKO 50. The first type provides oxygen supply up to 25 cubic meters per hour, the second 50. The maximum operating pressure parameter of the first model is 0.8 MPa, for the second 1.25 MPa.

A union nut is used to connect the oxygen reducing device.

The gearbox uses the following principles in its operation:

- The gas passes through the filter and is supplied to the high pressure chamber. Rotation of the regulator transfers the force of the installed spring through the disk, diaphragm and pusher directly to the valve. It is he who regulates the flow of oxygen into the working volume.

- The unit in which the pressure changes occurs is a separate assembly unit consisting of a seat, a valve with a spring and an EF-5 filtration device. To increase safety, a valve is mounted on the device body, designed to release gas when a critical pressure level in the working chamber is reached from 16.5 to 25 kgf per square centimeter.

Oxygen reducer pressure gauge

As part of the oxygen reducer, pressure gauges are used, one shows the pressure value in the cylinder (network), and the second shows its output parameter. The oxygen mixture is supplied to the welding zone through a hose with a diameter of 6 mm or more. The hose is connected to the fitting, and a cutter or burner is installed at the other end.

Kinds

Depending on the installation location, they distinguish between BKO and BKD cylinder reducers, which means single-stage cylinder oxygen and two-stage cylinder oxygen with mechanical pressure regulation. To ensure welding, the BKO 50 - 4 reducer is most often used. The marking indicates the device’s ability to pass 50 m3/hour of gas at a pressure of 4 atm.

When powering welding stations from the gas main, SKO network reducers are used. They are used in cases where the gas pressure in the network exceeds the pressure acceptable for consumers. A distinctive feature is the presence of only one pressure gauge, which shows the gas pressure at the outlet of the device.

Centralized gas supply, carried out at high pressure, requires the installation of ramp reducers (RKZ). Their distinctive feature is their large throughput capacity up to 125 m3/hour. They are installed on the high pressure rail directly on the pipeline. Can be operated at oxygen pressures up to 300 bar. They have a built-in inlet filter and a valve to relieve excess pressure.

There are two types of oxygen reducers, differing in operating principles: direct action and reverse action. We will look at the features of their work below. For those who do not want to delve into the intricacies of the operation of these devices, we note that reverse-action reducers are considered more reliable, have a simpler design and allow you to maintain normal operating pressure until the gas in the cylinder runs out.

Design features and maintenance

There are 2 types of gases used in industry and everyday life:

- inert;

- flammable.

The adapters on them are fundamentally different, so as not to confuse them. For inert gas cylinders, the connection between the reducer and the cylinder is made with a right-handed, standard thread. Oxygen, propane, carbon dioxide, methane and other flammable gases are connected to the reducer by screwing it into a hole with a left-hand thread - counterclockwise.

Multi-directional threads eliminate the possibility of filling the container with the wrong type of gas and using the cylinder for purposes other than its intended purpose.

Gearboxes have a membrane inside that wears out. The gearbox must be tested every 5 years. In this case, the membrane is replaced with a new one. In reducers for composite cylinders - made according to European standards, the membrane is designed to operate for at least 10 years, but the equipment must be tested after 5 years.

There is a marking on the top of the case indicating the year of manufacture of the unit and the first verification. During the subsequent test, the next date is entered.

The gearbox must be lubricated regularly and checked for leaks. If necessary, the gaskets must be changed.

Instructor, college teacher at the Donmet plant P.V. Sarkizov: There is an opinion among amateurs that a gearbox with a rotameter allows you to use gas economically. In practice, the devices differ only in their readings. The second pressure gauge on the reducer shows gas flow per minute. This value is inherent in the welding modes. The rotameter shows the actual pressure in the working chamber at the moment. To set operating parameters, you need to recalculate the rotameter readings using a coefficient or use a conversion table.

Gearboxes with 2 rotameters are designed for welding refractory metals and with high heat transfer. A welding torch is connected to the first, and a nozzle for heating the back side of the seam is connected to the second. You cannot connect 2 devices."

Application of equipment for different types of gas

According to the type of gas being reduced, reducers are divided into the following types:

- acetylene;

- hydrogen;

- oxygen;

- propane-butane;

- methane.

At the same time, all options can be divided into devices for flammable and non-flammable gases. Cylinders with a flammable gas mixture have a left-hand thread, while containers for inert gases and oxygen are equipped with a right-hand thread. This is done in order to prevent accidental connection of a reducing element, intended, for example, for methane, to an oxygen cylinder. By the way, you will find more information about autonomous gasification in this section.

For liquefied hydrocarbon gases, the design of gas reducers may have one design feature. In order to prevent freezing of the gas at the outlet, the body of the device is made with developed fins.

The quality of the gas plays a big role in the longevity of the gearbox. Therefore, tanks must be refilled from reliable ones, where, in addition to good service, you can get professional advice on working with any gas equipment.

The equipment used to reduce the oxygen pressure at the outlet of the storage vessel to the operating level and maintain it at the required level is called a reducer.

For each type of technical gas used in industry and everyday life, there are different equipment designs: for carbon dioxide one type, for acetylene another, for oxygen a third.