Pulley hoists: from calculations to reeving

A chain hoist is a portable block system designed for lifting and moving loads of varying degrees of severity. This device is used in the construction industry, logistics, mountaineering and during rescue operations. To make a chain hoist with your own hands, you need to know the design features of this device, methods of attaching ropes to a forklift, and reeving technology.

Simplifying device assembly

At home, you can use improvised materials and ready-made transfer units. For example, the ratchet used in a KAMAZ vehicle to equalize the braking force is a ready-made worm gear mechanism.

You can get rid of manual lifting for a long time if you assemble the motorized winch system with your own hands for work once. To do this, you need to put a gear on the winch drive axis, connecting it with a chain to the chainsaw drive sprocket on a rigid housing structure.

By combining block mechanisms with drum winches, you can work to compensate for the shortcomings of each type of lift. For example, pulley hoists do not provide a lock that prevents reverse movement of the hoist, but drum swans eliminate this very simply. But the angle between the lifting force vector and the weight vector of the pulley can be almost anything, which winches cannot boast of.

You can use purchased lifts on the farm, but, as a rule, winches are needed where stores are far away - and always urgently. It's worth looking in the garage for some parts to get out of the situation.

General information about pulley hoists

A pulley block consists of 2 or more pulleys (blocks) connected using rope ropes or chains:

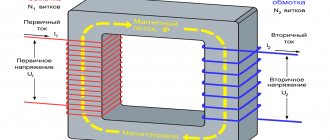

Simple pulleys can consist of 1 pulley and rope. In them, the roller is located above the load: on the ceiling, beam or support. The first end of the rope is connected to the hook and goes down to the load being lifted. A man pulls on the other end of a rope, lifting a heavy object. Complex lifting devices include several simple pulleys and provide greater gains in strength.

The operating principle of pulley blocks is based on the rule of leverage. A rope is thrown over a stationary pulley. The load is raised to a height by applying forces commensurate with the weight of the object being lifted. The length of the rope or chain should be comparable to the height to which the load is lifted. To reduce the amount of effort required, it is necessary that the moving block moves parallel to the load.

There are the following types of pulleys:

Pull blocks are used for the following operations:

Various types of cranes, hydraulic and electric drives are equipped with pulleys. They were also used in older elevator prototypes.

Design features of modern pulley hoists

The main area of application of such systems remains jib mechanisms of tower, bridge, and truck cranes. With the help of pulleys you can significantly increase force or, conversely, speed. The first is used in cranes, and the second in lifts. Structurally, they include the following elements:

- movable and fixed blocks;

- bypass drums;

- bypass blocks.

The traditional layout of pulley blocks remains vertical, and the location of the drum is determined by the presence of bypass blocks. If the latter are absent, then the drum is at the top and vice versa. At the same time, the number of blocks (for the power type) determines the degree of growth of the total force, and the number of similar elements with a fixed axis is 1 less than with a movable one.

Calculation of the chain hoist

Before manufacturing a chain hoist, it is necessary to calculate the main technical characteristics of the load-lifting structure. Calculations are required for drawing up drawings and are made according to the parameters of the working premises and the weight of the load.

To determine the loads affecting the block system during operation, it is necessary to calculate the parameters acting on individual blocks:

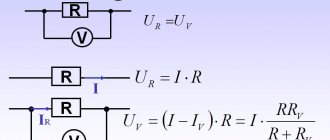

The equation used to find the moments of force is as follows: SM * R = SC*R + l*SC*R + N* g*d/2, where:

The efficiency of the pulley is determined by the following formula: η = SC/SM. This parameter is influenced by the quality of the blocks and the complexity of the circuit. There are the following efficiency levels of the block system:

When calculating, it is also recommended to determine the efficiency of the remaining bypass rollers, depending on the design features of the lifting mechanism.

How to calculate a winch for a car?

If we recall physics again, then to calculate the traction force of a winch, the formula should look like this: required traction = vehicle mass × (friction factor + lifting factor).

Interesting materials:

Should I wash off tea tree oil from my face? Do I need to remove my ankle brace at night? Do I need to peel the ginger? Do I need to create a staffing table every year? Is it necessary to take into account the minimum wage when calculating vacation pay? Do I need to withhold personal income tax from my salary for the first half of the month? Do I need to cover clematis? Is it necessary to maintain a cash book with an online cash register? Is it necessary to maintain personal accounts for employees? Do I need to enter an invoice without VAT?

Methods for attaching a rope to a lifting mechanism

The cargo rope allows you to automatically fix the lifted load, which affects the passage of knots. It must be filled in such a way that there is no possibility of chafing due to frequent contacts with other parts of the lifting structure. There are 3 main methods of attaching a rope to a pulley system:

To secure crane ropes, you need to secure 1 end of the rope with a lock or cable clamp. On winches, the cable is fixed to special fastenings using a wedge and a clamping bar.

Manual drum winches

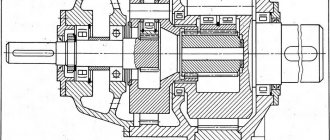

The principle of operation of winches resembles a simple lever fixed at a fulcrum. If the short arm of the lever is the surface of the cylinder, and the load is attached to it by a cable, you will get a winch with a gear ratio equal to the ratio of the length of the lever and the radius of the cylinder. To prevent reverse rotation, a ratcheting mechanism with a spring-loaded pawl is installed on the axis - a ratchet. You can assemble such a hand winch with your own hands according to the drawing:

However, the high gear ratio of the system will require a very long handle, which is inconvenient. The solution is found in two types of drum winches, which increase the gear ratio using gears or a worm gear.

How to make a winch with your own hands using a worm gear can be seen in the drawing:

A ratchet is not needed in this design; the gear ratio, when the worm flange passes over each gear tooth, is equal to the number of gear teeth multiplied by the ratio of the length of the handle to the radius of the worm. But a significant disadvantage will be the friction between the teeth and the comb. The mechanism requires constant lubrication.

A gearbox made of gears operates with much less friction. When using the principle of transmitting force through a pair of gears of different diameters, the easiest way to make a manual drum winch with your own hands is this:

The simplest do-it-yourself lifting mechanism

In home workshops you can make a simple chain hoist from scrap materials. It is capable of lifting light loads and can only be used for occasional jobs. To make a chain hoist with your own hands, you need to purchase the following components:

A bearing is installed on a steel stud, a nut is screwed on and locked. A hook is attached to the stud to reduce the effort required to rotate the homemade shaft. The first end of the rope is located on a static platform. To lift the load, you need to pull the second end of the cable up. For ease of operation, it is recommended to make an additional block and pass a rope through it. This will allow you to connect the rope to the winch and fix the transported object in an intermediate position.

Types of lifting devices

What the pulley for lifting loads and the construction crane have in common is the use of the idea of increasing force - the rule of leverage.

In order to balance the load on the short side of the lever, you need to apply less force to its long side to the extent that the short arm is less than the long one. The ratio of forces at the ends of the lever is called the gear ratio. You can balance and even lift a weight with an effort less than its weight, but the path made by the end of a long lever will be longer than that of a short one, just as less force was applied to lift it. There is no gain in work (F1*L1=F2*L2), but this is not required.

The use of Archimedes' principle is implemented in different lifting mechanisms, and how depends on the purpose of the lift. Designs differ in gear ratio, principle of force transfer, mobility, strength, and energy used. The most popular types for self-production:

- chain hoists;

- drum structures;

- lever mechanism.

To choose the type of device needed for specific work, it is worth familiarizing yourself with their capabilities and limitations.

Refilling chain hoists

Reeving is a procedure for changing the location of pulleys and the distance between them. The purpose of this operation is to regulate the speed and height of lifting loads in accordance with a certain pattern of cable passage through the blocks of the lifting mechanism. There are the following types of reserve:

There is also variable reeving. It can be either double or quadruple. The movable rollers are mounted on several movable cages held by a rope. The reeving ratio is changed by lowering the hook suspension onto the support while reeling in the rope.

Source

Pulley hoist or how to get more traction from a winch

September 14, 2022 root root

Those who have used car winches or were interested in using these devices know how to select them. First of all, you should pay attention to models whose traction force is 2-2.5 times the weight of the car. Otherwise, at a critical moment, the power of the winch may not be enough.

An example would be the situation with a tow truck called to transport a faulty vehicle. If this is a passenger car, and everything happens on an asphalt highway, there will be no problems. Let’s imagine that the driver of a tow truck sees in front of him a heavy SUV that has turned over on its side in the mud, and, moreover, due to a malfunction, its axle is jammed. And the tow truck driver realizes with annoyance that his car is not capable of the task.

The fact is that the winch develops maximum traction at the beginning, and the more cable is wound on the drum, the smaller the traction force becomes. In addition, the resistance of the swamp in which it is stuck and objects falling under the wheels (logs, stones, etc.) is often added to the weight of the car. Therefore, the winch should be “with reserve”.

But what to do when this “reserve” is not enough?

If your traction device fails, just add a pulley to it - a lifting device consisting of a wheel through which a rope is passed. Its name comes from the Greek Polyspastos, which means “stretched with many ropes.”

The principle of operation of this device is the same as that of a simple lever - we lose in distance, we win in strength. A chain hoist is used wherever a large weight needs to be moved when there is a shortage of labor or production capacity.

It is used by tourists and rock climbers, rescuers and builders. And the equipment of sailing ships - rigging - is generally impossible to imagine without this device.

The effectiveness of this design is ensured by the fact that the rope is divided into two parts by a block. The force applied to each of them is divided by 2. At the same time, the length of the cable that must be chosen to lift the same load to the same height also increases by 2 times.

In industry, chain hoists of complex design, consisting of several blocks, are used. Each subsequent block built into the circuit almost doubles the load-carrying capacity, while increasing the distance the rope must travel by the same factor.

You may ask what to do if you don’t have a block with a wheel like in the diagram? In this case, you can use a simple metal ring or even a piece of cable or rope instead.

True, when using them instead of a block with a wheel, friction losses inevitably increase. They can be reduced by lubricating the rope or halyard with some slippery substance. eg soap.

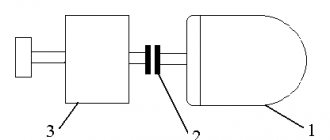

So, one end of the cable is attached to the winch drum. We hook the other one to the towing hook of the car, passing the cable through the pulley wheel. The wheel block, in turn, is attached to a tree, large stone or some other fairly massive object. We received a simple single-stage chain hoist and, having spent a little more time, we confidently pull our vehicle out of any trouble.

Another angle from which it is advisable to look at the device described in this review is unloading the traction unit. For a winch, in principle, like for any other electrical mechanism, one of the most destructive factors is overload. Accordingly, using the block makes it possible to avoid this problem with a high degree of efficiency. Therefore, using a chain hoist even when the goal is not to overcome extreme efforts will be 100% justified. Your winch will thank you for this.

In the PRAGMATEC online store you can find useful solutions for increasing the traction power of the winch, as well as other components that increase the overall level of benefit from the winch.

Go to section Blocks for winches >>>

We also suggest that you familiarize yourself with two videos about the design, use and application of the pulley block.

Inexpensive mini lift

Practice shows that when building a private house, a real crane is not always needed. Often, a developer can get by with “little expense” and make a small lift based on an electrically driven hoist.

My design is simpler than the authors above, but it suits me quite well. I bought a hoist with a load capacity of 300 kg without a block and 600 kg with a block. Tests have shown that the device can lift a load weighing 250-270 kg, then the engine protection is triggered. During the construction season, I used it to lift about 40 pallets with building blocks, a 6-meter beam for the mauerlat, rafters, mortar for masonry and concrete for the reinforced belt.

The lift, again to save money, is made from used pipes, angles and channels.

All rust was cleaned off with a grinder, and the pipes were sprayed and then painted with paint with a rust reducer.

In order to be able to assemble the lift on the ceiling of the second floor, all components (where welding is not needed) are made dismountable - with bolted connections.

A hoist is installed on the stand using clamps.

In case of rain, a plastic bottle with the bottom cut off is placed on the control panel.

The telpher covers a canopy made of used roofing iron.

When lifting a pallet, two boards are placed under it, and the pallet is lowered onto them.

The entire structure is fixed to the floor with clamps.

Drawing with dimensions of the lift.

These are topics that describe in detail how to make a lift for aerated concrete, and provide dozens of options for mini-cranes, from simple to the most complex designs.

Lift for laying aerated concrete blocks

Abroad, during the construction of private houses, cranes and various lifts are often used. This way construction goes faster, which means the “box” is cheaper, because It is more profitable to use small-scale mechanization tools than to hire laborers. Our developer relies on himself and often builds a house “with one helmet.” Therefore, the urgent question is how not to physically overstrain yourself when laying a wall from aerated concrete blocks weighing 35-40 kg.

An interesting option is the unusual homemade “assistant” of the FORUMHOUSE user with the nickname Krestik. First, let's show what he took as a basis.

German mini crane with retractable central post

A special feature of the lift is the original folding “arm-boom”, with the help of which the crane, moving on wheels, can reach two opposite walls.

I am building a house myself and, in order to be able to lay aerated concrete blocks, I built a lift according to the above model. The crane was made completely collapsible, except for the base. I didn’t measure the maximum load on the hook, but it easily lifts me (weighing 95 kg).

Technical characteristics of the lift:

- width – 2200 mm;

- height – 4200 mm;

- boom radius – 4200 mm;

- load capacity of electric hoist – up to 800 kg;

- total weight of the crane with ballast is approximately 650 kg;

- lift weight without ballast – about 300 kg;

- The maximum lifting height of the masonry block is 3500 mm.

The working height of lifting blocks is adjustable in two ranges. The first is 1750 mm. The second is 3.5 m, for which the structure is raised, sliding upward along the supporting “legs” using a hydraulic jack lined with spacers made of GB blocks.

To make the lift, the user needed:

- swivel wheels;

- profile pipes for the mast, “legs” and boom with a section of 12x12 cm, 12x6 cm, wall 6 mm;

- pipe-jibs – 63x3 mm;

- powerful gate hinges;

- The boom rotating mechanism is made of ST45 steel and “205” bearings.

During operation, the design was modified. For example, the user laid the cable for the winch in a corrugated pipe and extended the cable for the control panel.

The design has a number of shortcomings that I would like to correct. For example, I’m thinking about making wireless control, replacing the gate hinges with bearings. Increase the number of “joints” in the boom at the same reach. Instead of a temporary counterweight - bags of sand concrete, pour concrete ballast.

Important nuance : in order for the lift to move around a construction site or, for example, on a concrete floor slab on the second floor, you need to keep the workplace clean, because GB fragments and debris interfere with the relocation of the tap.

Types of homemade winch

The main elements of the winch are the cable, the drive drum and the handle. For various specific types of work, models of lifting devices equipped with additional elements, removable and stationary, have been developed.

Removable winches are used for household and household needs, and for towing cars.

Stationary devices are used in factory workshops and construction sites and are equipped with electrical and hydraulic mechanisms.

Types of winches:

- manual;

- mechanical;

- electric;

- hydraulic.

Each type is used for specific work (weight of cargo, its location, environmental conditions). This specificity must be taken into account when creating a winch yourself.