Metal spraying is a technology for changing the surface structure of a product in order to acquire certain qualities that increase performance characteristics. Processing is performed by applying a homogeneous metal layer to a part or mechanism. Special powder compositions are used as consumables, which are subjected to heat treatment and give them significant acceleration. Upon impact contact with the surface, particles are deposited on the plane.

The technology appeared at the beginning of the 20th century as an alternative to traditional methods of surface modification of metals. As methods of spraying metal products were studied and developed, a separate industry was formed - powder metallurgy. This is a technology for producing powders for making various products from them.

In modern industry, metal spraying is considered one of the most economical processing methods. Compared to bulk alloying, the technology makes it possible to obtain the necessary performance properties of the surface at lower costs.

Why galvanizing

Zinc differs from iron by a higher negative potential (0.2-0.3 mV).

Therefore, the zinc coating acts as an anode and protects the steel at the electrochemical level. This metal dissolves very slowly in electrolytes contained in urban and industrial atmospheres, sea water, and wet concrete. Therefore, it plays the role of an effective protector, applied in a thin layer over the surface of the structure that requires protection. The thickness of the layer is determined based on the degree of aggressiveness of the environment in which the product must be used. Additional anti-corrosion resistance is obtained using a paint coating laid on a layer of zinc. This solution greatly increases protection and provides an attractive appearance.

Scope of application of laser surfacing

By fusing using laser welding, it is possible to eliminate damage caused by chips, crushing, wear, and fracture:

- edges of casting molds, including those used for working with rubber and plastic;

- bearings on shafts, gears, teeth in splined fastenings;

- elements of hydraulic systems: valves of suction and discharge lines, spools in hydraulic distributors;

- in the end part, in the area of the base and rib of the airfoil of gas turbine engines;

- turbine compressor rotors;

- products of their alloys of increased strength, operating under conditions of shock and shock-abrasive loads: hydraulic drills, vibratory hammers, cutting dies, etc.;

- large-sized metal products weighing tens of tons.

These are not all cases where laser cladding technology will be the optimal solution for restoring metal products. It will find worthy use in both small workshops and large enterprises.

offers specialized systems for laser cladding with reliable guarantees and delivery throughout Russia. If necessary, consultants will come to the rescue and help you select equipment for the specific features of the upcoming work. To contact them, use the feedback form or call us.

Why do most people prefer gas-dynamic spraying?

- Cheapness. The price of the Dimet metal spraying machine is perhaps the biggest expense. Because the consumption and cost of applied metals (taking into account the durability of the installation and the number of operating cycles) are minimal.

- Convenience and practicality. The metal layer is applied without damage to the workpiece, which practically does not heat up, does not oxidize, and there is no burning of alloying alloys or warping.

- Completely harmless to humans and the environment, as it does not form toxic compounds during operation.

- Does not require the creation of certain conditions for operation.

These advantages make Dimet units convenient, practical and very efficient to use.

Features of laser metal deposition

Due to the precise direction of the laser beam, during surfacing, a uniformly dense conglomerate of powder and base material is formed. The thickness of the metal liquefaction ranges from 0.2-1 mm; it is possible to create several such layers, located one above the other.

For drawing lines, edges or contours, the installation is equipped with an optical device with the ability to automatically move. The uniform distribution of layers is ensured by an intelligent sensor system. Progressive surfacing technology is implemented using two types of laser radiation – pulsed and continuous.

Metal spraying - all methods and necessary equipment

Metal spraying makes it possible to improve the characteristics of parts operating under conditions associated with severe wear and concentrated mechanical loads. Metallization of surfaces increases stability and increases service life.

In addition to solving technical problems, spraying is used during the production of decorative items, jewelry, in the food, pharmaceutical and chemical industries.

Various metals can be used for spraying; the specific choice depends on the technical specifications.

Chemical chrome plating

Used for processing parts with complex geometric shapes, the process is based on the reduction of chromium from salt solutions using sodium hypophosphite. The sediment is gray in color, the shine is acquired after polishing. Chemical chromium plating takes place in baths with this composition of solutions.

Composition of solutions for chemical chromium plating

- Chromium fluoride, g - 17

- Chromium chloride, g - 1.2

- Sodium citrate, g - 8.5

- Sodium hypophosphite, g - 8.5

- Water, l - 1

- Temperature, °C — 70-87

The speed of the chrome plating process can reach 2.5 microns/hour; resistant plastic is used to make the baths. Metallization is accompanied by the release of toxic chemical compounds; solutions have a negative effect on human skin.

During work, safety regulations must be observed; forced ventilation is installed to clean the air environment.

The ventilation power is calculated based on the volume of the room or work area, taking into account the minimum exchange rate.

At industrial enterprises, plastic ventilation is installed; it allows you to maintain the recommended technological parameters with minimal financial losses. For industrial chromium plating using the chemical method, specially developed solutions with improved performance are used.

When preparing solutions, chromium chloride dissolves first. Then, according to the scheme, sodium citrate and chromium fluoride can be dissolved. To speed up chemical processes, oxalic acid is added to the composition.

Chromium ions form a chemically active ion with it, the coating speed increases to 7 µm/h or more. The percentage of ingredients is adjusted by technologists taking into account the final tasks for processing the parts.

To obtain calculated coverage, the following requirements must be met:

- High-quality surface preparation. Parts are cleaned mechanically and chemically, and if necessary, surfaces are ground.

- The equipment must ensure maximum automation of the process to eliminate the harmful influence of the human factor.

- Constant monitoring of the state of the solution, filtering, maintaining a given concentration, timely replacement of the cathode.

Violation of the recommended technology can cause peeling of coatings or the formation of deep cavities. The need to correct defects leads to a significant increase in production costs.

Visual control of chemical processes is carried out by determining the amount of hydrogen released; to improve the process, technologists recommend simultaneously coating parts made of several metals. Too intense release of hydrogen can cause the appearance of shells; the speed of the process is adjusted in each specific case.

Gas plasma spraying

Gas plasma spraying allows you to obtain a clean coating with high adhesion rates. The process takes place at temperatures up to +50,000°C, the jet speed is 500 m/s, the surface temperature of the workpiece is no more than +200°C.

The surface roughness of the sprayed parts is up to 60 Rz, the blowing zone should be 2–5 mm larger than the nominal size of the sprayed area. For work, powders of the same size fraction are used, untreated areas of the part are covered with special screens. Before the process, the surface of the parts is preheated to operating process temperatures.

Equipment for powder spraying consists of a gas supply (1), plasmatron cathode (2), cathode housing (3), heat insulator (4), anode housing (5), powder feeder (6), carrier gas supply (7), plasma arc (8) and power source (9).

High pressure devices

High-pressure apparatuses are used to spray not only polyurethane foam, but also polyurea. Polyurea processing technology requires high component supply pressure, from 180 bar or 18 MPa. N/A installations are not capable of producing such pressure. Due to the high speed of supply of components, mixing is better than in low-pressure machines.

Spraying process with high pressure apparatus

Spraying is carried out using an airless method: only due to the pressure created by the device itself, without the participation of air from the compressor. The air here is intended only for purging the mixing chamber.

Examples of high pressure installations

Graco Reactor EXP 2

Maximum operating pressure: 240 bar (24.0 MPa, 3500 psi). Flow rate: 7.6 l/min (2.0 gpm). Heater power: 15,300 W. Maximum hose length: 94 m (310 ft). Network connection: 380 V. Weight: 198 kg.

PROton E-6

Working pressure: up to 200 bar. Productivity: 6.5 kg/min. Built-in flow heaters: 3.5 kW. Supply voltage: 220 V. Max. hose length: 75 m. Weight: 75 kg.

Interskol 5N200

Maximum pressure: 210 bar. Productivity: 5 kg/min. Heaters power: 6 kW. Max. hose length: 93 m. Supply voltage: 380V/50Hz, 3 phases. Weight: 152 kg.

High-pressure washers have 10–15% lower flow rates than low-pressure washers. The cost and costs of insulation work are reduced. High-pressure cleaners produce homogeneous foam without inclusions or roughness.

On the left is a sample sprayed at low pressure, on the right at high pressure.

Sputtering process technology

The starting material is fed into the plasma column in the form of a powder or wire. Ionized gases release active gas molecules, some of which (for example, hydrogen) further raise the temperature inside the plasma column, accelerating the process of converting the molecules of the original material into a vapor state. As a result, the settling of moving particles onto the substrate is accelerated. Ionization is possible not only from gas, but also from liquid evaporating in the arc column.

Spraying powders diversify the composition and properties of coatings, since a wide range of metals can be processed into a finely dispersed state.

Plasma spraying is carried out as a result of:

- Plasma is initialized by a high-voltage discharge, which forms a direct current electric arc formed between two electrodes - a copper anode and a metal cathode (usually tungsten). The electrodes must be constantly cooled;

- Generating a stream of high temperature ionized plasma gas, which usually consists of argon/hydrogen or argon/helium;

- Heating the gas, followed by acceleration of its movement through a tapering nozzle;

- Transfer of fine powder in a plasma jet to the substrate.

A high-quality coating is formed due to the combination of high temperature (up to 15,000°C), the concentrated thermal energy of the plasma jet, the inert atomization environment and particle velocities reaching 300 m/s.

Impact of Particle Velocity on Coating Quality and Efficiency

- The coating particle has reached the minimum impact speed, which is necessary to excite the mechanism of interaction with the surface of the substrate (processed sample). This so-called “critical speed” affects the properties of the coating material.

- As the impact velocity is higher than the critical velocity, the deformation and quality of particle adhesion increase.

- If the impact velocity is too high (the "erosion rate"), more material is destroyed than added. No coating is formed.

- To form a dense and well-formed coating, the particle impact velocity must be between the critical velocity and the erosion rate.

The main advantages of the method

The advantages of the technology include:

- performing work under any climatic conditions (pressure, temperature, humidity);

- the possibility of using stationary and portable equipment, which in the latter case allows for work to be carried out at the location;

- possibility of applying coating to local areas (defective areas);

- the ability to create layers with different properties;

- the ability to create a layer of the required thickness or different thicknesses in multilayer coatings;

- the process does not affect the structure of the product being sprayed, which is an important advantage;

- safety;

- environmental friendliness.

The disadvantage of this type of spraying is only one fact. The layers can be applied to ductile metals such as copper, zinc, aluminum, nickel and alloys based on them.

Manufacturers from different countries produce stationary and portable equipment for manual and automated application of coatings of varying productivity on different metals.

General form

"Plasmacenter" offers

- services for size restoration and application of functional coatings;

- supply of equipment and materials for the processes of welding, soldering, surfacing, spraying, deposition, additive technologies (for example, flame, plasma, high-speed and detonation spraying, plasma surfacing, electric spark alloying, powder dispensers, control devices);

- conducting R&D in the field of surface engineering, coating tribology, plasma processing methods, selection of optimal coatings and methods of their application;

- training, consulting in the field of surfacing, sputtering, hardening, modification, hardening.

Contact us by phone: +7 (812) 679-46-74, +7 (921) 973-46-74, or write to us by email.

Our managers will tell you in detail about the technologies we have for coating, hardening, restoring, imparting surface properties, as well as the cost of the company’s services.

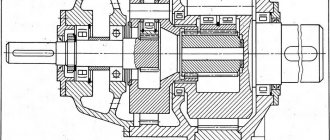

Plasma spraying equipment

For diffusion metallization, three types of devices are produced - with the combustion of an oxygen mixture, with the supply of an inert gas, and with thermal decomposition of a liquid. The coating thickness reaches 100…120 microns.

Plasma spraying installations using the energy of high-speed oxygen plasma operate at hypersonic gas velocities, reaching 1600...1800 m/s at the moment the jet hits the substrate. This is how plasma spraying of wear-resistant metal carbides is carried out when complete melting of ionized particles is not required.

Equipment where a plasma stream is formed in a jet of inert gas is used to produce coatings that require a combination of good wear resistance and impact resistance. Heating causes the gas to reach extreme temperatures, dissociate and ionize.

Installations of the third type perform metallization at the final moment of shaping the surface or cavity by an electric arc discharge compressed by the transverse flow of the working medium. Such installations are the most productive. As an example, consider a machine of the “Duga-8M” type, consisting of the following components:

- Tool head with electrode holder.

- Sealed working chamber.

- Pumping station.

- Reservoir with dielectric.

- Plasma generator.

- Control and tracking units.

Operating principle of vacuum spraying units

Operating principle of vacuum spraying units

Vacuum spraying by specialists is carried out using an installation consisting of several elements, each of which can be considered as an independent device. The operating principle of the installation as a whole assumes:

- Creating a vacuum in the chamber, producing steam from particles of the substance that forms the spray.

- Transportation of parts or products to the working chamber, where they are placed in a strictly defined position.

- Spraying the material from which the film will be created. During this process, steam condenses on the substrate, and ultimately a coating with the desired properties is formed.

Installations can be either periodic or continuous. In the first case, the equipment carries out one spraying cycle and then turns off. But continuous equipment is used mainly in mass production, for mass processing. The specific number of loaded products is set in advance. These installations can be multi-chamber or have several positions (spraying stations) located in one chamber. This is convenient when using a conveyor feed of processed products.

Application of galvanizing

Galvanizing of metal structures is necessary in the production and processing of the following structural elements:

- Concreted steel structures, which, according to SNiP and GOST, must have additional protection against corrosion. Before laying, such parts are galvanized by thermal spraying, thermal diffusion or hot galvanizing, or by coating with zinc-rich paints (cold galvanizing).

- Surfaces, components and parts of special equipment. Due to the high degree of adhesion, zinc adheres firmly to the surface, and the paint coating applied to it does not peel off or crack.

- Technical pipelines, the surface of which improves the degree of protection against corrosion.

- Gate valves, valves and other locking elements of hydraulic structures.

- Bridges and other important structures exposed to aggressive environments.

- Ship hulls.

- Monuments and architectural structures.

- Piles, pillars and other load-bearing elements that are buried in the ground.

Metal spraying technology: main methods of metallization of products

The production of metal products is being modernized with the development of advanced technologies.

Metal is more susceptible to moisture, therefore, to ensure a long service life and give parts, working mechanisms and surfaces the required properties, metal spraying is widely used in modern industry.

Powder processing technology consists of applying a protective layer to the base metal base, which provides high anti-corrosion characteristics of the sprayed products.

Spraying tasks and options

After powder treatment, the metal surface acquires important protective properties. Depending on the purpose and area of application, metal parts are given fireproof, anti-corrosion, and wear-resistant characteristics.

The main purpose of spraying a base metal base is to ensure a long service life of parts and mechanisms as a result of exposure to vibration processes, high temperatures, alternating loads, and the influence of aggressive environments.

Metal sputtering processes are performed in several ways:

- Vacuum processing - when the material is strongly heated in a vacuum environment, it is converted into steam, which, during the process of condensation, is deposited on the surface being treated.

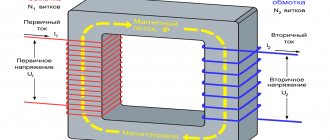

- Plasma or gas-plasma spraying of metal - the processing method is based on the use of an electric arc formed between a pair of electrodes with injection of inert gas and ionization.

- Gas-dynamic processing method - a protective coating is formed by contact and interaction of cold metal microparticles, the speed of which is increased by an ultrasonic gas jet, with the substrate.

- Sputtering with a laser beam - the generation of the process occurs using optical-quantum equipment. Local laser radiation allows processing of complex parts.

- Magnetron sputtering - performed by exposure to cathode sputtering in a plasma environment to deposit thin films on the surface. Magnetron processing technology uses magnetrons.

- Protection of metal surfaces by ion-plasma method is based on the sputtering of materials in a vacuum environment with the formation of condensate and its deposition on the treated base. The vacuum method prevents metals from heating up and deforming.

The technological method for spraying parts, mechanisms, and metal surfaces is selected depending on the characteristics that need to be imparted to the sprayed base. Since the method of volumetric alloying is economically expensive, advanced technologies of laser, plasma, and vacuum metallization are widely used on an industrial scale.

Sputtering in magnetron installations

Metallization of surfaces using magnetron sputtering technology is based on melting the metal from which the magnetron target is made. The treatment occurs in the process of impact action by ions of the working gaseous medium formed in the discharge plasma. Features of using magnetron installations:

- The main elements of the working system are the cathode, the anode, and the magnetic medium, which contributes to the localization of the plasma jet at the surface of the sputtered target.

- The action of the magnetic system is activated by the use of constant field magnets (samarium-cobalt, neodymium), installed on a base made of soft magnetic materials.

- When voltage is applied from the power source to the cathode of the ion installation, the target is sputtered, and the current must be maintained at a consistently high level.

- The magnetron process is based on the use of a working medium, which is a combination of inert and reaction gases of high purity, supplied into the chamber of vacuum equipment under pressure.

The advantages of magnetron sputtering make it possible to use this processing technology to obtain thin films of metals. For example, aluminum, copper, gold, silver products. Semiconductor films are formed - silicon, germanium, silicon carbide, gallium arsenide, as well as the formation of dielectric coatings.

The main advantage of the magnetron method is the high speed of target sputtering, particle deposition, accuracy of reproducing the chemical composition, absence of overheating of the workpiece, and uniformity of the applied coating.

Purpose

Manufacturing of parts and products with functional surface properties, for example, wear resistance (except for parts experiencing impact-abrasive wear), anti-friction, corrosion resistance, heat resistance, cavitation resistance, erosion resistance, electrical insulation, resistance to fretting corrosion, decorative characteristics, etc. Use for restoration sizes of worn and defective surfaces, application of retention coatings in dentistry.

Subsequent treatment of the coating

The plasma atomization process is limited to materials that have a higher melting point than the flame. At lower temperatures and speeds (up to 40 m/s), the energy characteristics of moving particles decrease, which leads to oxidation, porosity and the presence of various inclusions in the finished coating. The strength of adhesion and adhesion between the coating and the substrate decreases. Such coatings are sanded or polished. In justified cases, heat treatment is provided - hardening, tempering, normalization.

Sources

- https://master-pmg.ru/raboty-po-metallu/gazodinamicheskoe-napylenie-metalla-svoimi-rukami.html

- https://ometalledo.ru/plazmennoe-napylenie-metalla-svoimi-rukami.html

- https://svarkaprosto.ru/tehnologii/plazmennoe-napylenie-metallov

- https://WikiMetall.ru/metalloobrabotka/gazodinamicheskoe-napylenie-metalla.html

[collapse]

Modern version

Various enterprises use production plants equipped with metal parts, which wear out and suffer from corrosion under conditions of significant loads. To increase the wear resistance and strength of mechanisms, their surface is completely or partially covered with a layer of molten metal. The influx obtained in this way is firmly connected to the surface material, forming a single conglomerate.

To restore the functionality of an old part, a similar type of metal is fused, which allows the product to return its shape and integrity. If it is necessary to improve the quality of the top layer, it is coated with another material that gives the mechanism new properties.

Principle of technology

Laser surfacing (laser metal deposition technology) is one of the most effective methods for restoring coatings with increased wear resistance. The process involves modern laser systems equipped with powerful diodes and specialized nozzles. What's happening:

- Using a laser, a kind of melting bath is created on the surface of the selected area. The container is filled with metal powder entering through the nozzle opening.

- During laser processing, a short-term melting of the base material occurs. All stages are carried out with automatic regulation of the melting zone parameters.

The principle of laser cladding is the same as with electric arc and powder plasma additive bonded to the metal. The disadvantage of traditional types of surfacing is the submelting of the base under significant thermal influence on it. Processing of powder material with a locally directed beam of a powerful laser eliminates heating of the melting surface at a high deposition rate.

Advantages

- The ability to use different powders to create multilayer structures of your own alloys;

- ease of replacement of consumables, which is performed without stopping the work process;

- the ability to create three-dimensional structures on uneven surfaces with modified geometry;

- control of the degree of penetration with high-strength adhesion of the powder mixture to the top layer of the base;

- minimizing the influence of heat treatment on the local impact zone, eliminating the likelihood of deformation;

- high speed of creation of coarse and very fine structures, which is inaccessible to other types of melting;

- the ability to access any areas of large-sized products with rapid heating and cooling of the working area.

Laser surfacing of a metal surface is not without some disadvantages, the main one of which is the need to use complex and expensive equipment. Disadvantages of melting also include low productivity with low efficiency.