The use of natural stone in finishing has always been highly valued from an aesthetic point of view. This material is durable and reliable, and also has a diverse range. But these products are not used everywhere.

The main factor that slows down the spread of natural stone is its high cost, which is sometimes beyond the reach of the average developer. In addition, the extraction of such material is carried out only in some regions. But even if you have the funds to purchase, you should keep in mind that natural stone has an impressive weight. That is why, in order to install it on the wall, you will have to build a solid base or strengthen the old one.

Why is it better to replace natural stone with artificial one?

Additionally, you will have to carry out activities that are accompanied by material investments. And it’s impossible to process such samples without special tools in your arsenal. An alternative solution is materials that can be cast from the appropriate mixture yourself. The components are different, but one of the most popular is gypsum.

Why choose artificial marble

If you still haven’t decided whether to make artificial stone using gypsum, you should consider some features of the material, including:

- Possibility of use in any room;

- availability of technology;

- low costs for self-production;

- possibility of interior design in an unusual style.

This stone is no different from natural stone in terms of environmental friendliness; it is even capable of regulating the indoor microclimate. The surfaces that you finish with gypsum stone will not lose their ability to breathe.

Services for maintenance and restoration of stone surfaces

Specialists grind, polish and restore the appearance of surfaces, both natural and artificial stone. The work is carried out using modern imported equipment. We restore stone coverings of any size.

Repair operations are carried out by a team of tilers who have many years of experience. To submit an application for marble processing, please contact our manager by phone or email. The specialist will calculate the cost of the service and draw up an agreement on individual terms. All types of work are guaranteed.

Pay attention to the services of our company - we carry out turnkey stone restoration work!

Manufacturing technology

If you decide to make artificial marble from gypsum, the first step is to prepare a mold. The cost of such templates starts from 2,700 rubles. per piece, but making it yourself will cost 800 rubles. You can decide how much formwork you will need if you determine the time allotted for production. Having one shape will slow down the process, and the stones will turn out to be completely identical in shape. Therefore, the quantity will be determined by the texture and size of future products, as well as material capabilities.

Production technology

The method of producing artificial marble is simple, it is only important to follow the specified recommendations.

Preparation of the solution

Pour the dry ingredients into a clean container, mix them thoroughly with a mixer and add the dye. The latter is mixed in carefully to maintain the uneven color of the finished material.

Then the mass is diluted with water, shaken well or placed on a vibrating table - this will help get rid of air bubbles. Water is introduced in 2 steps: first, 80% of the liquid is added, then the plasticizer is added, and then the remaining water.

Preparation and filling of forms

The molds are placed in a strictly horizontal position, sprayed with gelcoat (polyester resin), and the solution is poured. Shake to get rid of excess air and leave to harden for at least a day under the film.

Advice! To enhance the strength of marble, reinforcement is made - a wire mesh is placed in the thickness of the solution.

Processing of finished slabs

After curing, the molds are turned over, the stone slabs are taken out and sanding begins. Such products can only be cut with equipment equipped with diamond blades.

Preparation of formwork

When artificial marble is made from gypsum, a sample is first found from which copies can be made. This can be natural material, including the one offered for sale. The dimensions of the mold should be slightly larger in relation to the future product. You can prepare the formwork from a piece of PVC panel, moisture-resistant plywood and similar materials. It is necessary to consider how many samples will be made, as well as whether the mold will support the weight of the material.

Preparing for pouring

When making artificial marble from gypsum, at the next stage you can begin preparing the solution. It is better to treat the inside of the formwork with grease, including the sample. To do this, you can also use Ciatim lubricant, but it will be expensive.

The frame should be placed on plastic film. The base should be as smooth as possible. In order to prevent the silicone from spreading, the edges of the formwork must be pressed tightly to the surface. To make templates, you should purchase silicone; you can also use sealant, but it costs much more.

During the pouring process, it is necessary to control how evenly the mass is distributed over the area. You can straighten it with a brush previously soaked in detergent. The latter should not contain alkali, so laundry soap is not suitable for this.

Technical characteristics of cast marble

These types of finishing tiles have a lot of attractive properties that make them very popular floor and wall coverings:

- Wear resistance and abrasion resistance due to the polymer-mineral structure.

- Frost and heat resistance - withstands temperature changes in the range from -50 to +900° C. Although this may affect the appearance of the material.

- Easy to care for – easy to clean from dirt.

- The impact resistance obtained through the use of polymer components exceeds that of the natural original.

- Water resistance, virtually preventing the absorption of liquids.

- Vibration resistance.

- Non-conductivity and fire safety.

- Inertness to chemical reagents - both household (vinegar, detergents, etc.) and technical (solvents, etc.).

- Hygiene (according to the results of a study by the Erisman Institute of Hygiene and the Research Institute of Plumbing).

- Maintainability.

Structural integrity allows cast marble to withstand severe loads - this makes it possible to reduce the thickness of the coating without losing its strength properties.

Features of mold manufacturing

The thickness of the template is selected taking into account the dimensions of the sample. Once the mass has dried, it can be removed from the formwork and inspected. The sinks are sealed with silicone, and the protrusions are smoothed or cut off. If you decide to make artificial marble from gypsum, you can first prepare a mold, which is usually cast from silicone. It hardens quite slowly. It will take a week for a centimeter layer.

Therefore, the template should be left in the formwork for this time. This period can be shortened by keeping the structure in a warm room. It should not be heated to achieve forced hardening. The cost of this form will be equal to the limit from 220 to 280 rubles. Using it, you can cast up to 40 stone samples, everything will depend on the accuracy of the master.

Pouring the mixture

When making artificial marble from gypsum with your own hands, you need to decide whether the material you will use is white or colored. Surface painting will be cheaper, but it will not be durable. The tinting method is of higher quality, but it is expensive; to implement it, dye is added to the mixture.

To reduce the cost of the process, pouring is carried out in two stages, for each of which its own composition is prepared. Dye is added to one, and first the colored mixture is poured in, which should be well compacted; this is most conveniently done with wire, which is used to pierce the mass over the entire area. It is necessary to carry out these manipulations to remove air.

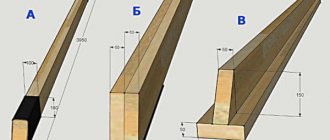

If you are thinking about the question of how to make artificial marble with your own hands, then at the next stage you can pour the second layer of the mixture. It will form the back of the product and the side edges. If it is necessary to give the samples increased strength, a reinforcing material is placed on the first layer of mass, which can be a mesh for plastering.

The mixture can be made not from pure gypsum, but with the addition of cement. When the brand does not matter, the ratio can be 2 to 1, where the first ingredient is gypsum, while the second is cement. To improve the quality of adhesion of the decorative stone to the surface to be finished, slits in the form of longitudinal strips must be made on the hardening base. This mixture will set quite quickly. Before making artificial marble, you should familiarize yourself with the technology. From it you can understand that the product will reach full readiness within an hour.

Useful tips for making stone

If there is no cement among the ingredients, then this stone is suitable for interior decoration. For cladding buildings, such material can only be used when certain measures are taken to protect against atmospheric influences. To do this, the stone is treated with a primer and the surface is varnished.

As an alternative solution, plasticizers in the form of polymers can be added to the composition. In this case, the solution will consist of one part cement and three parts sand. Coloring ingredients are substances that are added to gypsum in a ratio of 1 to 20.

After you manage to remove the template from the mold, you need to wash it with soapy water. Quite often, property owners wonder how to make artificial marble from gypsum quickly. To reduce the setting time, it is necessary to add citric acid to the composition; its volume in relation to the total mass should be 0.4%. When the stone is made at home, only four templates will be enough. This technology is suitable for the production of shaped products that can be used to decorate any room.

DIY cast marble

It is quite possible to make artificial cast marble yourself. You just need to purchase all the components of the material, molds for pouring and follow the instructions.

To make cast marble you will need:

- polyurethane casting mold;

- film;

- mixer;

- brush.

In production, the filler is CaMg(CO3)2, and the hardener is Butanox M-50. At home, pebbles and cement can be used instead of these substances.

Materials for making artificial marble:

- sand (river) – 2 parts;

- cement – 1 part;

- water – 0.2 parts;

- pebbles (as filler) – 25% of the total volume;

- pigment – 1% by weight of cement;

- plasticizer – 1% by weight of cement;

- gelcoat

Sequence of production of cast marble:

- A dry and clean mold is coated with gelcoat and allowed to dry.

- Mix sand, pebbles and cement. Add a plasticizer, coloring pigment and water (80%) to the mixture, mix with a mixer to obtain a plastic mass (about 30 seconds). Then add the rest of the water and stir the mixture again until smooth.

- The mixture is poured into a mold, excess is removed from the edges, covered with film and left to harden for 10 hours.

- The material is removed from the mold and left in the open air for some time.

In this simple way, you can obtain a material that can be used in its original form or subjected to further processing to give the desired shape.

Pros and cons, reviews

Although the composition of artificial marble is fundamentally different from its natural counterpart, it has the same technical properties. Moreover, the level of strength and wear resistance of artificially produced material is several times higher than that of natural material.

The main advantages of artificial marble:

- has a high level of mechanical strength and is not afraid of impacts;

- is durable and has a long service life;

- almost does not conduct heat and electricity, has a high level of fire safety. Therefore, it can be used to decorate heating radiators, electric stoves, etc.;

- the material does not heat up, does not delaminate, is not afraid of acids, alkalis, solvents, does not absorb fat, and does not leave stains on it. Due to this practicality, it is often used to decorate kitchens and bathrooms, and finish floors in residential, industrial and public spaces;

- does not emit harmful substances, is environmentally friendly;

- Thanks to the external gelcoat coating, it looks aesthetically pleasing and can be used for decorative purposes.

It combines the hardness of natural stone and ease of processing. Unlike natural marble, artificial material provides a greater degree of comfort and is always warm to the touch.

Among the disadvantages of artificial stone, many note that it cannot be considered a complete analogue of natural material. It feels more like plastic, and the top coating looks like polyurethane.

In addition, the gel coating often cracks over time. As a result, the material becomes discolored and destroyed.

Making stone from polished gypsum

Artificial marble made from polished gypsum is called oselkovy. It is a colored mass, which is prepared using an adhesive solution. This composition is applied to the base, and after drying it is brought to a mirror shine by grinding and polishing. The material can be tinted to match different types of marble, including lapis lazuli and malachite.

The main raw material for such a product remains gypsum, to which substances are added that slow down the setting. The advantages of this material are low weight and fairly high strength. Using this finishing, lightweight structures can be made. To improve the microclimate, marble is used for finishing residential premises. It absorbs excess moisture and releases it if the room is dry.

Manufacturing of artificial stone

Making artificial marble

Before pouring the solution, you need to decide what material to make the marble from. You can cast it in white and then paint it. But such a product will not be durable. A more durable, but also expensive method is tinting the solution. With this method, the dye is introduced directly into the gypsum mixture. The working mixture poured into the mold is filled with dye and compacted. To do this, it is better to use a wire with which you need to pierce the entire mass over its entire area. This will allow air to escape and the dye to penetrate into the solution. Next, you can apply a reinforcing mesh and fill in the 2nd layer of dye. Cement can be added to the gypsum solution in proportions of 2:1. For better adhesion, notches in the form of strips are made on the base of the artificial stone along the slab. An hour after pouring, the product will be ready for further work.

Stone made from a gypsum mixture, which does not contain cement, can be used for interior finishing work indoors. To carry out cladding work on the outside of the building, it is necessary to carry out several more operations to protect the material from natural phenomena. The artificial material is treated with a primer and then coated with varnish. You can prepare a solution using another technology:

- take 1 part of cement;

- mix cement with 3 parts gypsum;

- add 1/20 of the dyes;

- introduce a polymer plasticizer.

To speed up the drying of the solution, you can add 0.4% citric acid to it. In this case, 4 molds will be enough to produce any amount of material.

Artificial marble made from polished gypsum also has another name – oselkovy. This is a mass colored with the addition of glue. After drying, it is ground and polished to a mirror finish. This technology is used to make facing materials imitating marble, malachite, and other stones. The structures are light and durable. Artificial marble slabs can be obtained using one more method. To do this, acrylic or polyester resin and marble chips are mixed in a ratio of 4:1. Binders can be:

- building gypsum;

- cement mortar;

- solution of lime and cement.

The fillers in this solution are colored sand, pebbles and colored quartz. The finished products will not resemble natural marble; it will be a somewhat new facing material. The use of mineral coloring pigments allows you to obtain more natural veins in the solution layer.

Alternative marble compositions

The technology for producing artificial marble from gypsum may involve the use of a different composition of raw materials. To do this, polyester or acrylic resin is mixed with marble chips. The ratio will look like this: 4 to 1. The following are used as connecting elements:

- building gypsum;

- cement mortar;

- lime mortar with added cement.

The most common resins are those that guarantee high strength. Decorative materials such as colored quartz, colored sand and pebbles are sometimes used as filler. In this case, the finished products will not have the appearance of natural stone, they will become a completely new finishing material.

Artificial gypsum marble can be made at home using mineral pigments. When the product is introduced into the main composition, it is stirred a little, which allows you to get veins. Pigments can not only color the material, but also make it resistant to external influences. The top layer of gelcoat gives the coating a glossy finish.

Origin of natural marble

The history of marble goes back thousands of years. “Brilliant stone” (from the Latin marmaros) was discovered by the ancient Greeks - a beautiful, durable and easy-to-work material that was ideal for the construction of temples and palaces. The remains of majestic structures are still preserved in the territories where the ancient Greeks and Romans lived.

Durability, easy processing and unique patterns are due to the origin of marble. Under pressure from the earth's crust, carbonate rocks (limestone, dolomite and others) undergo metamorphism - they recrystallize and become harder. In this case, the grains of calcite, the main marble mineral, adhere closely to each other, so the material is well polished. Also, during metamorphism, calcite crystals grow together with mineral and organic impurities, which form the basic color and unique pattern of the marble vein.