Internal grinding machines

Internal grinding is the main method of finishing holes. This processing of parts is performed using an abrasive wheel.

The peculiarity of internal grinding is the ability to correct the axial displacement of the hole, which appears during previous operations.

Internal grinding

This processing is used for different holes: cylindrical, conical, blind and through.

Internal grinding is widely used in various fields of mechanical engineering. In particular, such processing is practiced when working:

- with smooth and splined gear wheels;

- with ball bearings and roller bearings (in particular with their inner rings);

- with roller tracks on the outer rings of roller bearings;

- with different tools for cutting (this includes: shaver, cutters, attachment reamers).

This type of grinding uses longitudinal feed and plunge grinding. During the process the following movements occur:

- rotation of the grinding disc;

- rotation of the workpiece (circular feed);

- feed of longitudinal and transverse type.

The internal grinding machine is classified as equipment that can reproduce the processing of parts with minor deviations from the shape and dimensions, with slight surface roughness. The characteristics indicated by the passport show its high performance capabilities. The passport also contains a complete description of the specific equipment.

Description

Internal grinding machines are divided into the following groups:

- Internal grinding equipment in which rotations of the workpiece and the grinding disk occur. Feeds of longitudinal and transverse types in this case are carried out by moving the spindle or the headstock located in front.

- Internal grinding models, on which the finishing part (usually a dimensional one) is placed motionless, and the disk performs orbital movement. It rotates along the circumference of its own axis and along the circumference of the hole axis simultaneously.

Internal grinding of workpiece

Production characteristics divide these machines into universal machines, automatic machines and semi-automatic machines.

Universal types (with cartridge clamp). Used when working with short and long holes. Processing on conical-shaped variants takes place by turning the headstock to the desired slope. These machines are widely used in auxiliary and main departments of a manufacturing enterprise. They are equipped with a face grinding device, and the processing is distinguished by a high level of accuracy in terms of the perpendicularity of the end to the hole.

Internal chamfer grinding scheme

Semi-automatic devices. They are widely used to produce a large number of parts. These types are equipped with measuring and control devices; they automatically control the progress of grinding. Processing stops when the product reaches the required dimensions.

Automatic machines. Both center and centerless options have an additional loading device. It delivers the workpiece to be processed into the grinding area. There is also a device whose purpose is to automatically fasten, remove the workpiece and control disk edits.

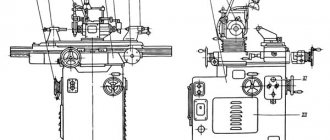

Internal grinding machine model 3K227A

The basis for a number of internal grinding equipment produced by domestic manufacturers are machines of the 3K line. The passport of these models confirms their purpose for finishing workpieces with a volume from 0.3 to 80 cm. Accuracy class - P, A and B. Each such machine has a face grinding device.

Internal grinding machine 3K722A

Model 3K227A began to be produced in the eighties. The 3K227A machine is used for grinding cylindrical, conical blind and through openings. The 3K227A unit with a face grinding device makes it possible to finish the outer ends of a part during one installation. These goods are supplied to domestic and foreign stores. Model 3K227A is distinguished by the highest quality indicator. Users leave only positive reviews about the 3K227A machine.

Features of model 3K227A:

- electrical adjustment of the number of revolutions of the part;

- equipped with hardened guides;

- the ability to grind the outer end with one installation;

- equipped with a set of spindles;

- cross-feed equipment for automatic return of the table to its initial location;

- wide range of rotation of grinding discs, spindle, transverse feed, speed of table movement.

Download the passport of the grinding machine 3K227A

Each internal grinding unit is supplied with a passport and instructions for use. The passport has all the necessary data and technical characteristics for a specific type. Here are detailed technical specifications, structure and diagram of the machine.

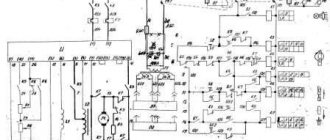

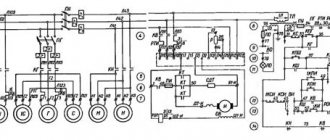

Hydraulic diagram of the 3K227A internal grinding machine Electrical diagram of the 3K227A internal grinding machine Technical characteristics of the 3K227A internal grinding machine

Before work, it is recommended to carefully study the passport, technical specifications and device. Internal grinding units may only be used in accordance with the manufacturers' recommendations. Otherwise, the equipment will not operate reliably and may cause serious injury to a person.

If you find an error, please select a piece of text and press Ctrl+Enter.

stankiexpert.ru

Description

Internal grinding machines are divided into the following groups:

- Internal grinding equipment in which rotations of the workpiece and the grinding disk occur. Feeds of longitudinal and transverse types in this case are carried out by moving the spindle or the headstock located in front.

- Internal grinding models, on which the finishing part (usually a dimensional one) is placed motionless, and the disk performs orbital movement. It rotates along the circumference of its own axis and along the circumference of the hole axis simultaneously.

Internal grinding of workpiece

Production characteristics divide these machines into universal machines, automatic machines and semi-automatic machines.

Universal types (with cartridge clamp). Used when working with short and long holes. Processing on conical-shaped variants takes place by turning the headstock to the desired slope. These machines are widely used in auxiliary and main departments of a manufacturing enterprise. They are equipped with a face grinding device, and the processing is distinguished by a high level of accuracy in terms of the perpendicularity of the end to the hole.

Internal chamfer grinding scheme

Semi-automatic devices. They are widely used to produce a large number of parts. These types are equipped with measuring and control devices; they automatically control the progress of grinding. Processing stops when the product reaches the required dimensions.

Automatic machines. Both center and centerless options have an additional loading device. It delivers the workpiece to be processed into the grinding area. There is also a device whose purpose is to automatically fasten, remove the workpiece and control disk edits.

3K227A machine characteristics

Buy this machine without intermediaries:

Specifications:

Model 3k227a machines are designed for grinding cylindrical and conical, blind and through holes, internal and external ends

The smallest and largest diameter of the holes being ground, mm 20-150 The longest grinding length (with the largest hole diameter), mm 125 The outer diameter of the workpiece installed on the machine, mm: without a casing 400 in a casing 250 The largest angle of rotation of the workpiece headstock (when grinding conical holes), deg. 45 Transverse movement of the product headstock (manual) per revolution of the flywheel, mm: coarse (adjustment) 2.5 fine 0.25 per dial division 0.001 from the dosed feed lever 0.001 Table speed, m/min: when dressing the wheel 0.1 -2 when grinding 1-7 with fast longitudinal approach and retraction 10 Maximum table stroke, mm 450 Limits of the number of revolutions of the product spindle (stepless adjustment), rpm 60-1000 Number of revolutions of internal grinding spindles, rpm 9000, 12000, 18000, 24000 Speed of the end spindle, rpm 5600 Total power of all electric motors (without converter units), kW 8.42 Required area for a machine with a hydraulic system tank, emulsion tank, electrical cabinet (length X width), mm 2815×1900 Total weight of the machine ( with electrical cabinet, emulsion tank and hydraulic pump station), kg 4050 Machine dimensions, mm Length 2500 Width 1470 Height 1560

Buy this machine without intermediaries:

mashinform.ru

Internal grinding machine 3K227A

The 3K227A internal grinding machine is used in various industries when working with blind and through holes of conical and cylindrical shape. An abrasive wheel is used as a tool for workpieces made of metal or other materials.

Design Features

- roller guides and helical rolling gear ensure smooth and precise movement of the grinding headstock

- a special device allows you to process the end and hole in one installation

- wide range of stepless control of workpiece rotation

- forced lubrication system for all mechanisms and components of the machine

- device for cleaning coolant from contaminants and impurities

| Specifications | 3K227A |

| Accuracy class - GOST 8-82 | IN |

| Hole diameter, mm | 20-200 |

| Maximum grinding length, mm | 200 |

| Largest diameter of the installed part, mm | 400 |

| Headstock rotation angle, degrees | 45 |

| Maximum longitudinal stroke of the table, mm | 560 |

| Table speed, m/min | |

| when editing a wheel | 0,1-2 |

| when grinding | 1-7 |

| with fast approach and retraction | 10 |

| Rotation speed of the internal grinding spindle, rpm | 5000-28000 / 48000-96000 |

| Transverse movement of the product headstock per revolution of the flywheel, mm | |

| thin | 0,25 |

| rough | 2,5 |

| one division of the dial | 0,001 |

| from the dosing lever | 0,001 |

| Parameters of cross feed per side, mm/double stroke | 0,001/0,002/0,003/0,004/0,005/0,006 |

| Number of revolutions of the product spindle, rpm | 60-1200 |

| End spindle rotation speed, rpm | 5600 |

| Total engine power, kW | 9,2 |

| Machine dimensions, mm | 2885 x 1900 x 1750 |

| Weight, kg | 4500 |

Accuracy

- end surface roughness - 0.32 µm

- hole surface roughness - 0.16 microns

- Constancy of hole diameter - 2 microns

- hole roundness - 1 micron

- flatness of the end surface - 3 microns

Completeness and equipment

| Basic | Additional |

|

|

Terms of delivery and payment

You can find out the cost and additional parameters for the 3K227A internal grinding machine by phone number: +7 (4852) 66-40-25, or make a request by email: This email address is being protected from spambots. You must have JavaScript enabled to view it. or through the order form on the website. We transport equipment to its destination. The warranty for the internal grinding machine model 3K227A is 12 months.

Internal grinding machines 3K227, 3K228, 3K229

The machine is designed for grinding cylindrical and conical, through and blind holes with a diameter of 20 to 150 mm, a length of up to 125 mm at the largest diameter of the hole being ground, with a cone angle at the apex of up to 90°.

The machine is equipped with an end grinding device that allows you to grind the outer end of the product in one setting with grinding the hole. The scope of application of the machines is machine-building plants with small-scale and mass production, as well as tool and repair plants and workshops.

SPECIFICATIONS

| Smallest and largest diameter of ground holes, mm | 20-150 |

| Maximum grinding length (with largest hole diameter), mm | 125 |

| Largest diameter of the installed product, mm: | 400 |

| The largest diameter of the installed product in the casing, mm | 250 |

| The greatest angle of rotation of the headstock of the product (when grinding conical holes), degrees. | 45 |

| Transverse movement of the grinding head (manual) per revolution of the flywheel, mm: | |

| rough (adjustment) | 2,5 |

| thin | 0,25 |

| one division of the dial | 0,001 |

| from the dosing lever | 0,001 |

| Amount of automatic cross feed per side, mm/double stroke. | 0,001; 0,002; 0,003; 0,004; 0,005; 0,006 |

| Table movement speed, m/min: | |

| when editing a wheel | 0,1-2 |

| when grinding | 1-7 |

| with fast longitudinal inflow and outflow | 10 |

| Maximum table stroke, mm | 450 |

| Limits of product spindle speed (stepless adjustment), rpm | 60-1200 |

| Speed of internal grinding spindles, rpm | 5000-28000 |

| End spindle speed, rpm | 5600 |

| Total power of all electric motors (without converter units), kW | 9,23 |

| Dimensions of the machine in plan with hydraulic system tank, emulsion tank, electrical cabinet, mm | |

| length | 2815 |

| width | 1900 |

| Weight of the machine with attached equipment, kg | 4300 |

Accuracy and cleanliness of the processed surface:

| 3K227VM | 3K227AM | |

| Constancy of hole diameter, µm | 3,0 | 2,0 |

| Hole roundness, microns, no more | 1,6 | 1,0 |

| Flatness of the end surface, µm | 4,0 | 3,0 |

| Surface roughness Ra | ||

| holes, µm | 0,32 | 0,16 |

| end, µm | 0,63 | 0,32 |

ESPECIALLY HIGH PRECISION INTERNAL GRINDING MACHINES 3K228, 3K229

The machines are designed for grinding cylindrical and conical (with an apex angle of up to 60°) through and blind holes: for the machine model ZK228A, diameter 50-300 mm, length up to 320 mm; for the machine model ZK229A diameter 100-500 mm, length up to 500 mm.

The machines are equipped with an end grinding device that allows you to grind the outer end of the product in one setting with grinding the hole.

Indicator of processing accuracy of the sample product:

- constant diameter in the longitudinal section 3 microns

- roundness 1.6 µm

Surface roughness of the product sample, no more than:

- cylindrical internal Ra 0.080 µm

- flat end At 0.32 µm

The machines have the following design features:

- Roller guides with hardened steel bars for the transverse movement of the grinding headstock together with the final link - a ball screw pair (screw-nut transmission) - provide minimal movements with high accuracy.

- Stepless regulation of the spindle speed of the product headstock

- The design of the product head allows the installation of a pneumatic or lever device and various cartridges for fastening products.

- A magnetic separator and conveyor filter provide high quality fine purification of the coolant, which improves the quality of the treated surface.

- Automatic cross feed

- Automatic termination of cross feed after removing the established (roughing) allowance allows the operator to simultaneously control several machines.

- Automatic lubrication system

- A device for grinding the ends of products allows you to machine holes and an end in one installation of the product.

- To reduce the heating of the bed and eliminate the transmission of vibration to the machine, the hydraulic drive is installed separately from the machine and connected to it with a flexible hose.

- Accelerated setup transverse movement of the grinding head reduces auxiliary time when readjusting machines.

SPECIFICATIONS

| Parameter name | 3K228A | 3K229A |

| Main settings | ||

| Accuracy class according to GOST 8-82 | A | A |

| Largest diameter of the installed product, mm | 400 | 800 |

| The largest diameter of the installed product in the casing, mm | 400 | 630 |

| Maximum length of the installed product, mm | 320 | 500 |

| Smallest and largest diameter of the hole to be ground, mm | 50..300 | 100..500 |

| The longest grinding length with a grinding diameter of at least 100 mm, mm | 320 | 500 |

| Maximum recommended grinding length at smallest diameter, mm | 125 | 200 |

| Distance from the axis of the headstock spindle to the base of the bed, mm | 1225 | 1300 |

| Distance from the axis of the headstock spindle to the table mirror (height of centers), mm | 340 | 410 |

| Distance from the supporting end of the product spindle flange to the end of the grinding headstock bracket, mm | 1335 | 1570 |

| Distance from the end of the new face grinding wheel to the supporting end of the spindle flange, mm | 150..400 | 250..550 |

| Machine work table | ||

| Maximum table movement length, mm | 800 | 800 |

| Manual movement of the table per revolution of the flywheel, mm | 25 | 25 |

| Table movement speed when grinding, m/min | 1..7 | 1..7 |

| Table movement speed when editing a wheel, m/min | 0,1..2 | 0,1..2 |

| Table movement speed with rapid longitudinal approach and retraction, m/min | 10 | 10 |

| Face grinding device | ||

| Face spindle rotation speed, 1/min | 4000 | 4000 |

| Longitudinal movement of the end grinding wheel is maximum adjustment, mm | 250 | 250 |

| Longitudinal movement of the end grinding wheel is greatest working (fine), mm | 4 | 4 |

| Longitudinal movement of the face grinding wheel per revolution of the adjustment movement handwheel, mm | 27 | 27 |

| Longitudinal movement of the end grinding wheel per revolution of the working (fine) feed handwheel, mm | 0,1 | 0,1 |

| Longitudinal movement of the end grinding wheel per division of the working (fine) feed dial, mm | 0,0025 | 0,0025 |

| Grinding head | ||

| Rotation speed of internal grinding heads, 1/min | 4500,5300,8200,12000 | 2500,4500,5250,8200 |

| The largest diameter of the grinding wheel according to GOST 2424-83, mm | 200 x 76 x 63 | 250 x 76 x 63 |

| Maximum peripheral speed of the grinding wheel, m/s | 35 | 35 |

| Diameter of the internal grinding head sleeve, mm | 125 | 125 |

| Diameter of the end of the grinding spindle according to GOST 2324-77, mm | 30, 40, 50 | At least 45 |

| Transverse movement of the grinding head | ||

| Movement per one revolution of the handwheel - rough (adjustment), mm | 5 | 5 |

| Movement per revolution of the handwheel - fine, mm | 0,5 | 0,5 |

| Movement by one division of the dial, mm | 0,002 | 0,002 |

| Movement per swing of the manual dosed feed lever, mm | 0,002 | 0,002 |

| The largest adjustment movement of the grinding head is backward (to the worker), mm | 10 | 10 |

| The largest adjustment movement of the grinding head is forward (from the worker), mm | 80 | 100 |

| Headstock (product headstock) | ||

| Nominal diameter of the end of the spindle of the product, according to GOST 12595-72 | 2-8M | 2-11M |

| Maximum angle of rotation of the headstock of the product, degrees | 30 | 30 |

| The largest adjustment movement of the headstock of the product is backward (to the worker), deg | 50 | 50 |

| The largest adjustment movement of the headstock of the product is forward (from the worker), deg | 250 | 300 |

| Product rotation speed (stepless regulation), rpm | 60..600 | 20..240 |

| Drive and electrical equipment of the machine | ||

| Number of electric motors on the machine | 7 | 7 |

| Grinding head spindle electric motor, kW | 7,5 | 7,5 |

| Electric motor drive of the face grinding device, kW | 2,2 | 2,2 |

| Electric motor of the product drive (product headstock) DC, kW | 1,6 | 1,6 |

| Hydraulic pump electric motor, kW | 3,0 | 3,0 |

| Electric motor of the filter-conveyor, kW | 0,09 | 0,09 |

| Electric motor of the cooling system pump, kW | 0,15 | 0,15 |

| Magnetic separator electric motor, kW | 0,09 | 0,09 |

| Total power of electric motors, kW | 14,63 | 14,63 |

| Thyristor converter ET1E2-10, kW | 1,3 | 1,3 |

| Overall dimensions and weight of the machine | ||

| Overall dimensions of the machine (length x width x height), mm | 3535 x 1460 x 1870 | 4165 x 1780 x 2000 |

| Weight of the machine with electrical equipment and cooling, kg | 6400 | 8300 |

stan-mash.ru

Internal grinding machine model 3K227A

The basis for a number of internal grinding equipment produced by domestic manufacturers are machines of the 3K line. The passport of these models confirms their purpose for finishing workpieces with a volume from 0.3 to 80 cm. Accuracy class - P, A and B. Each such machine has a face grinding device.

Internal grinding machine 3K722A

Model 3K227A began to be produced in the eighties. The 3K227A machine is used for grinding cylindrical, conical blind and through openings. The 3K227A unit with a face grinding device makes it possible to finish the outer ends of a part during one installation. These goods are supplied to domestic and foreign stores. Model 3K227A is distinguished by the highest quality indicator. Users leave only positive reviews about the 3K227A machine.