Choosing a lathe is an individual task. In this case, it is important to take into account several factors, for example, the purpose in production. The weight and dimensions of the machine will depend on the size of the workpieces, the number of operations and the length of the processed parts. When purchasing it for processing large batches, it is better to prefer equipment with CNC and a multi-spindle head, which is especially important when the part must be processed with several cutters.

In order to make the right choice, you should consider several options; you need to start with one of the many, which is represented by the modern assortment of relevant stores. Among others, the “Corvette 403” should be highlighted, which will be discussed in the article.

Information about the manufacturer of the Corvette-403 screw-cutting lathe

The supplier of the Corvette-403 table-top screw-cutting lathe is Enkor-Instrument-Voronezh, LLC , founded in 1992. Website address: https://www.enkor.ru/, online store website www.enkor24.ru.

Manufacturer: Shanghai Joye Import & Export Co., Ltd. , China, Shanghai, founded in July 2003.

Machine tools manufactured by Enkor-Instrument-Voronezh

- Corvette-10

– portable woodworking circular saw - Corvette-21

- portable woodworking thickness planer - Corvette-24

- portable woodworking planing machine - Corvette-27

- portable woodworking thickness planer - Corvette-31

- portable vertical band saw for wood - Corvette-42

- tabletop drilling machine Ø 6 x 60 - Corvette-51

- portable belt grinding machine - Corvette-71

- wood lathe Ø 250 x 420 - Corvette-82

- portable woodworking milling machine - Corvette-88

- electric jigsaw - Corvette-320

- multifunctional portable woodworking machine - Corvette 400

- tabletop screw-cutting lathe Ø 180 x 300 - Corvette 401

- tabletop screw-cutting lathe Ø 180 x 300 - Corvette 402

- tabletop screw-cutting lathe Ø 220 x 500 - Corvette 403

- tabletop screw-cutting lathe Ø 220 x 750 - Corvette 407

- tabletop turning and milling machine Ø 220 x 750

Related Posts via Categories

- Characteristics of 1K62 - features of the machine in numbers

- 1M63 - a solid tool for a turner and carving master

- School lathe - why is it popular not only in labor lessons?

- Mini lathe - indispensable equipment for miniature machining

- DIP-500 – screw-cutting lathe for single jobs

- JET BD-7 lathe – desktop unit for home use

- Accessories for a lathe - how to make the unit more functional?

- IZH-250 - the legendary lathe of Izhmash

- TRENS SE 320 and other machines from a famous European manufacturer

- DIY machine 0714 – inexpensive table lathe from China

Corvette-403 tabletop screw-cutting lathe. Purpose, scope

The Corvette 403 metal lathe is designed for processing workpieces made of metal, wood, and all types of plastic by turning.

Corvette 403 machine is a desktop universal screw-cutting lathe and is intended for all kinds of turning work:

- grooving and boring of cylindrical, shaped and conical surfaces

- drilling, chamfering

- boring

- segment

- metric thread cutting

- inch thread cutting

- trimming ends

- for machining large-diameter workpieces, it is possible to install return jaws in a self-centering chuck

- for processing long workpieces, it is possible to install a movable and fixed steady rest

- when installing the faceplate, you can perform a turning operation offset from the center of rotation

- a wide range of adjustment of the rotation speed and longitudinal feed speed increases the arsenal of the cutting tools used

The traditional visual layout of the machine in combination with a proven kinematic diagram allows you to confidently provide turning with accuracy class “H” over a long service life.

Compared to small-sized machines offered on the market, it is easy to operate, reliable and durable.

The Corvette 403 lathe operates on a single-phase alternating current network with a voltage of 220 V and a frequency of 50 Hz.

Corvette 403 machine can be operated under the following conditions:

- ambient temperature from 1 to 35 °C

- relative air humidity up to 80% at a temperature of 25 °C

Corvette 403 metal lathe :

- An asynchronous motor is installed on the machine

- The belt drive makes the machine operate quietly and protects the motor from overload

- Magnetic starter eliminates spontaneous start-up after a temporary power outage

- Spindle rotation reverse

- Stepwise adjustment of spindle speed

- Gearbox for changing the speed of automatic caliper feed

- A set of replaceable gears makes it possible to cut metric and inch threads with almost any pitch

- The machine has a table for setting up the machine when cutting threads

- For precise placement of the cutter into the groove of the previous pass when cutting threads, there is a thread cutting indicator

- For precise feeding of calipers there are dials with scale divisions of 0.025mm

- Longitudinal and transverse movement of the calipers on a dovetail slide with the ability to adjust the smoothness of the ride and eliminate backlash

- Rotary support for conical turning of short parts

- For conical turning of long parts, the tailstock has a lateral offset, which is set on a scale

- The machine is equipped with a pallet

- For safe operation there is a protective casing with a limit switch

- Large selection of equipment

Safety precautions

It is important to ensure that all tools are removed from the equipment before turning on the machine. The work area should be kept clean and the unit should be fenced off while the equipment is in use. It is important to avoid cluttering the work space with foreign objects. You should not start operation if the floor in the room is slippery, for example, covered with grated wax or sawdust. You can ensure that the relative humidity is no more than 80% if you plan to turn on the equipment.

It is important to ensure good lighting in the workplace. There should be freedom of movement around the machine. The device should not be overloaded. After reading reviews of the Corvette 403, you will understand that it is important to monitor the serviceability of parts and the correct adjustment of moving parts and connections. The defective part must be repaired or replaced. Before performing any adjustment or maintenance work, disconnect the power plug from the electrical outlet. The components must be recommended by the manufacturer.

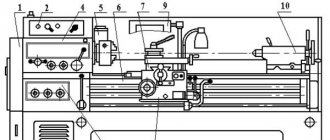

Location of components of the Corvette-403 screw-cutting lathe

Specification of components of the Corvette-403 screw-cutting lathe

- Automatic feed direction switch knob

- guitar cover

- Guitar Tuning Chart

- Belt tension lever

- Headstock

- Spindle rotation direction switch

- Emergency switch

- Three-jaw chuck jaws

- Three-jaw self-centering chuck

- Tool holder

- Toolholder fixing handle

- Rotary caliper

- Cross caliper

- Tailstock center

- Tailstock quill

- Quill position fixing handle

- Tailstock

- Quill movement flywheel

- Tailstock position fixing nut

- bed

- Chip tray

- Carriage feed screw

- Thread cutting indicator

- Carriage

- Lead screw split nut control handle

- Automatic feed lever

- Slewing Caliper Feed Handwheel

- Cross caliper feed flywheel

- Carriage manual feed handwheel

- Spindle

- Protective shield

- Automatic Feed Speed Shift Knob

- Thread cutting table

Safety precautions during operation

If something seems abnormal in the operation of the machine, you should stop using it. It is necessary to protect the cord from heating and contact with water and oil, as well as from rubbing against sharp edges. Once the machine is started, it should be allowed to idle for a while. If at this time you hear extraneous noise or feel excessive vibration, the machine must be turned off by connecting the plug from the outlet.

The equipment should not be turned on until the cause of the malfunction has been identified and eliminated. The instructions for the Corvette 403 state that turning operations cannot be performed unless the rotating assembly covers or protective covers are installed. You cannot turn deeper than 0.3 mm in one pass. The cutters in the holders must be well secured. There should be no chips wrapped around the cutter, nor around the workpiece being processed. Chips must not fall on the lead screw. The workpiece must be securely strengthened before starting work. The machine must be stopped to check the position of the mating parts and the condition of the fasteners, as well as mechanisms and components after 50 hours of operation.

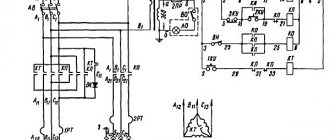

Description of the operation of the electrical circuit of the Corvette-403 lathe

The machine is connected to a 220V, 50Hz power outlet using a plug with a grounding contact. Before connecting, you must check the reliability of the connection between the machine and the grounding pin of the plug.

To turn on the machine you must:

- install the protective shield in the working position (at the very bottom) SB2

- release the emergency shutdown button of the machine SB1 by sliding the cover to the side

- select the direction of rotation of the jaw chuck using switch SA1

- turn on the machine by pressing the green SB button

There are four ways to turn off the machine:

- set switch SA1 to neutral position

- fold the protective shield to the upper position

- press the emergency shutdown button

- unplug the power plug from the socket

Installation and assembly

The characteristics of the Corvette 403 are not everything you need to know before starting work. For example, the device should be installed on a heavy, durable workbench that is of sufficient height. The operator should not bend over while working. It is important to be careful when moving the machine based on its weight. The equipment must be well secured to a sturdy workbench. This will guarantee security and stability of operation. It is necessary to drill 4 holes on the working surface of the workbench, fastening them with bolts and washers, which are not supplied in the kit. The machine is attached to a workbench with a pallet.

Technical characteristics of the Corvette-403 machine

| Parameter name | Corvette-400 | Corvette-401 | Corvette-402 | Corvette-403 |

| Basic machine parameters | ||||

| The largest diameter of the workpiece above the bed, mm | 180 | 180 | 220 | 220 |

| The largest diameter of the workpiece above the support, mm | ||||

| Maximum length of the workpiece at centers (RMC), mm | 300 | 300 | 500 | 750 |

| Recommended turning depth per pass, mm | 0,1 | 0,1 | 0,2 | 0,2 |

| Maximum turning depth in one pass, mm | 0,2 | 0,2 | 0,3 | 0,3 |

| Maximum cutter holder size, mm | 8 x 8 | 10 x 10 | 13 x 13 | 13 x 13 |

| Maximum weight of the workpiece processed in the chuck, mm | 123,5 | |||

| Maximum weight of workpiece processed in centers, mm | 120,5 | |||

| Spindle | ||||

| Diameter of through hole in spindle, mm | 20 | 20 | 20 | 20 |

| Morse taper spindle | Morse 3 | Morse 3 | Morse 3 | Morse 3 |

| Number of speed steps for direct spindle rotation | B/s | B/s | 6 | 6 |

| Spindle direct rotation frequency, rpm | 0..1100, 0..2500 | 0..1100, 0..2500 | 100, 250, 350, 500, 900, 1800 | 100, 250, 350, 500, 900, 1800 |

| Number of spindle reverse rotation frequency steps | B/s | B/s | 6 | 6 |

| Spindle reverse rotation frequency, rpm | 0..1100, 0..2500 | 0..1100, 0..2500 | 100, 250, 350, 500, 900, 1800 | 100, 250, 350, 500, 900, 1800 |

| Diameter of lathe chuck, mm | 80 | 80 | 100 | 100 |

| Maximum radial runout of the spindle, mm | 0,01 | 0,01 | 0,01 | 0,01 |

| Caliper. Submissions | ||||

| Maximum longitudinal movement of the caliper carriage, mm | 405 | |||

| Longitudinal movement of the caliper by one dial division, mm | 0,025 | 0,025 | 0,025 | 0,025 |

| Maximum lateral movement of the caliper, mm | 65 | 65 | 110 | 110 |

| Transverse movement of the caliper by one division of the dial, mm | 0,025 | 0,025 | 0,025 | 0,025 |

| Maximum movement of the upper (incisor) slide (rotary support), mm | 35 | 35 | 50 | 50 |

| Movement of the cutting slide by one division of the dial, mm | 0,25 | 0,025 | 0,025 | 0,025 |

| Angle of rotation of the cutting slide, degrees | ±45° | ±45° | ±45° | ±45° |

| Number of stages of longitudinal feed of the caliper | B/s | B/s | ||

| Limits of longitudinal working feeds of the caliper, mm/rev | B/s | B/s | 0,12..0,33 | 0,11..0,30 |

| Limits of working cross feeds of the caliper, mm/rev | No | No | No | No |

| Number of metric threads to be cut | 9 | 9 | 12 | 12 |

| Limits of pitches of cut metric threads, mm | 0,4..2,0 | 0,5..2,5 | 0,5..3,0 | 0,5..3,0 |

| Limits of pitches of cut inch threads | No | No | 8..56 | 8..56 |

| Limits of pitches of cut modular threads | No | No | No | No |

| Limits of pitches of cut pitch threads | No | No | No | No |

| Tailstock | ||||

| Morse taper tailstock | №2 | №2 | №2 | №2 |

| Maximum movement of the quill, mm | 40 | 40 | 40 | 40 |

| Electrical equipment | ||||

| Rated supply voltage, V | 220V 50Hz | 220V 50Hz | 220V 50Hz | 220V 50Hz |

| Main drive electric motor, kW | 0.4 collector | 0.5 collector | 0,75 | 0,75 |

| Dimensions and weight of the machine | ||||

| Machine dimensions (length width height), mm | 770 x 330 x 330 | 850 x 305 x 320 | 1030 x 480 x 475 | 1250 x 480 x 475 |

| Machine weight, kg | 37 | 38 | 105 | 120 |