The 2M112 drilling machine, whose compact dimensions allow it to be installed on a desktop surface, belongs to the equipment of the middle price category. The optimal ratio of affordable cost and decent technical characteristics makes the machine of this model a leader among similar equipment of domestic and foreign production.

Small-sized desktop drilling machine 2M112

What is the 2M112 machine and where is it used?

The 2M112 machine, which belongs to the vertical drilling category, began production in 1980. Over a fairly long period of its existence on the market, this device has gained enormous popularity when used in home workshops and workshops of small manufacturing enterprises. 2M112 machines, designed for desktop use, are also included in the equipment of training workshops of schools and vocational educational institutions, where young specialists are trained on them.

The technical capabilities of the drilling machine in question allow you to perform a number of technological operations:

- drilling holes;

- reaming;

- deployment;

- countersinking;

- internal thread cutting.

You can install a rotary vice on the machine's work table

The material used to manufacture the parts processed on such a drilling machine can be metal, plastic or wood.

Despite the simplicity of the design, the 2M112 desktop drilling machine provides the ability to change the rotation speed of the working chuck in 5 steps. To implement this function, the position of the belt on the belt drive pulleys changes on the unit, which is done very quickly thanks to the special design of this unit. The drilling depth when working on the 2M112 drilling machine is also adjusted quite simply - a flat scale (or stops) is used for this.

Belt drive under raised machine guard

The simple design provides the main advantages of the 2M112 vertical drilling machine - exceptional reliability and ease of use. This machine is distinguished by such characteristics as compact dimensions (795x390x950 mm) and low weight (120 kg), which makes it easy to move such equipment to any place. Due to its compactness, the model 2M112 vertical drilling machine can be installed both on the surface of a mechanic’s table and on a special drilling column or stand.

Transportation.

To transport the unpacked machine, a steel rod Ø 6-17 mm is used, which is passed through the hole provided in the body.

When gripping the machine with ropes by the rod, care must be taken not to damage the lining of the machine. In this case, the spindle head of the machine must be moved to its lowest position and securely fastened.

When transporting to the installation site and when lowering onto the foundation, the machine should not be subjected to strong shocks.

Before installation, the machine must be thoroughly cleaned of the anti-corrosion coatings applied to the machine’s open and covered surfaces with casings and shields, and to avoid corrosion, coated with a thin layer of I-ZOA oil GOST 20799-88.

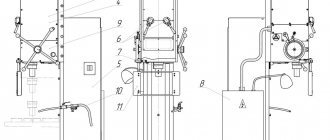

Installation diagram of the 2M112 machine

Cleaning is first done with a wooden spatula, and the remaining lubricant from the outer surfaces is removed with clean napkins moistened with gasoline B-70 GOST 511-82. When re-opening the machine, comply with the safety requirements in accordance with GOST 9.014-78.

Machine characteristics and documentation

The main characteristic of any drilling machine is the maximum diameter of the hole drilled with it. Using the machine model 2M112, according to the passport, it is possible to produce holes in the workpieces with a diameter of up to 12 mm. Holes of this diameter are quite sufficient to carry out drilling work in a home workshop, but in production conditions, larger diameter drills are installed on these machines.

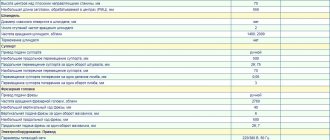

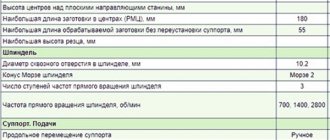

Machine Specifications

Below you can download free technical documentation for the 2M112 machine, namely the machine passport or operating manual.

Data sheet of the tabletop drilling machine 2M112:

The chuck of the 2M112 drilling machine, according to the passport, can rotate at a speed of 450–4500 rpm, and the rotation speed of this unit can be adjusted in 5 steps. The machine is equipped with a B-18 class spindle, the distance from the end of which to the surface of the work table can vary in the range of 0–400 mm.

The dimensions of the work table, on the surface of which there are three T-shaped grooves for fixing the workpiece or a machine vice, are 250x250 mm.

The surface of the machine's work table allows the clamping fixtures to be fixed

To expand the functionality, the drilling machine can be installed on a special stand, which allows the equipment to be used for drilling holes in the ends of parts whose length reaches 1000 mm. An electric motor with a power of 550 W is used as the main drive device on the 2M112 machine.

Despite its small dimensions and not too high power, the tabletop drilling machine of this model can be subjected to long-term and intensive use. Such worthy characteristics are ensured by the simple but effective design of the device.

In a home workshop, the 2M112 machine can be placed on a homemade metal stand

Operating rules

The drill model 2a112 requires compliance with a number of rules before starting work and when performing operations on it.

A preliminary check of the strength of the drill fastening is required. During the work process, a smooth approach of the drill to the workpiece is necessary. The transmission is engaged until the drill comes into contact with the workpiece. The feed rate decreases as the drill exits the hole formed in the part.

Removing short chips that wrap around the drill is done with a hook. Long chips are removed only after the machine stops. Maintenance of the device includes:

- changing the oil in the gearbox after 90 hours of operation;

- removal of coal dust from the electric motor after 90 hours of operation;

- complete cleaning of the unit after each start-up;

- after disassembling and assembling the device, it must be checked for electrical safety;

- Constant inspection of brushes and their replacement if the height is less than 8 mm.

Machine design features

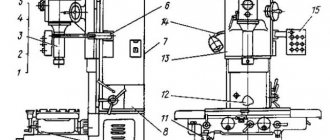

Even from the photo of the 2M112 vertical drilling machine you can understand how simple its design is. So, the components of this unit are:

- a column along which the spindle head moves in the vertical direction;

- a device that ensures clamping of the spindle head in the required position;

- drive motor;

- mechanism responsible for raising the spindle head;

- base plate, the upper part of which is used as a work table;

- a casing that protects the drive mechanism;

- spindle head;

- a mechanism responsible for tensioning the drive belts;

- bracket in which the base of the column is fixed.

Main parts of the 2M112 machine

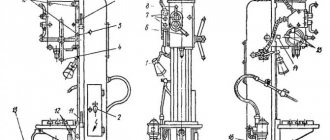

Structural elements that provide convenient and efficient control of the operating parameters of the 2M112 drilling machine are:

- handle responsible for manual spindle feed;

- a handle that ensures the required belt tension;

- a handle used to secure the headstock to the column;

- electric buttons, with the help of which the drive motor is started and stopped;

- handle responsible for fixing the sub-motor plate.

Machine controls

Spindle assembly of tabletop drilling machine 2M112

The manufacturer of the 2M112 drilling machine specially mounted all the main mechanisms (spindle assembly and belt tensioning mechanism) in a cast iron body to ensure their reliable protection from mechanical damage.

To ensure greater operator convenience, the machine design includes a lighting system for the processing area.

Machine control buttons can be located on the spindle head or at the bottom of the desktop, depending on the model modification

Device

One of the important advantages of the drilling machine is its simple and reliable design. It has gone through several modernizations, but has retained a number of important components.

The modern 2M112 machine is a massive steel column with a work table at the bottom and a horizontal bracket at the top. A vertically moving spindle head is mounted on the bracket at the front, and a drive motor is installed at the rear.

The power unit shaft is connected to the spindle module by a drive belt (V-belt drive), and the entire drive is protected by a cast metal casing. The motor shaft is equipped with a pulley with five stages of belt installation (splines), which allows you to adjust the spindle rotation speed when working with parts made of different materials.

The spindle head is a tool movable head with a rotating spindle (quill). It is equipped with mechanisms for fixing on the bracket and moving along the bracket (back and forth), as well as mechanisms for spindle feed (up and down) and tension of the drive belt (adjusts the distance between the transmitting and receiving pulleys), which are controlled using handles.

To adjust the position of the work table, which is a massive thrust plate made of tool steel with T-shaped slots, a mechanism with a handle is also used. To precisely control the movement of the spindle head and the drilling depth, a clamp with a flat measuring notch is installed on the tool head.

The spindle is mounted in a special sleeve with two ball bearings, and its clamping device (Morse taper) is adjusted by a rotating head with a lock, which makes it possible to quickly install and change drills of different sizes to drill holes of the required depth and diameter.

To illuminate the working area of the machine, an electric lamp is attached to the body. The electric drive is started by the start button, which is located on the body of the machine column.

In addition, when working with the machine, you can use additional equipment: a support stand (for face machining of parts with a diameter of up to 120 mm), a cross table for ultra-precise drilling, a replaceable turret, a vice for securely fastening parts on the work table and a cooling unit for long-term drilling superhard materials.

Advantages and disadvantages of the device

The fact that the model 2M112 tabletop drilling machine, the design of which was developed more than thirty years ago, can still be found in the equipment of many manufacturing enterprises and home workshops, indicates that specialists value this equipment for its characteristics and advantages.

The popularity of the 2M112 vertical drilling machine is also evidenced by the fact that even after a complete breakdown (which happens extremely rarely), users try to find a unit of a similar model, rather than purchasing cheap and low-quality devices from Chinese manufacturers or expensive European equipment.

In the electrical panel of the machine (combined with the control panel) everything is simple and minimalistic

Among the most significant advantages that the drilling machine model 2M112 has, it is necessary to highlight the following.

- Thanks to its long service life, the machine is characterized by exceptionally high endurance and is able to be successfully operated even in the most severe conditions.

- Due to the simplicity of the design, the device does not require complex care and special maintenance. Even disassembling such equipment yourself does not cause any particular difficulties.

- On the modern market you can easily find any spare parts and components for the 2M112 machine, so there are no difficulties with the repair of such equipment.

- The power of the electric motor with which this machine is equipped is quite enough to satisfy the needs of both a home craftsman and a small manufacturing enterprise.

- A significant characteristic of the 2M112 machine is its affordable price, which is optimally combined with its reliability, efficiency and ease of use.

Connection diagram of the machine to a 220 volt power supply network

The vertical drilling machine of the model in question is not without its shortcomings, which are not mentioned in the passport. The main disadvantage of this equipment is that it is already obsolete. Modern devices of this category, the production of which uses new technological approaches and innovative kinematic schemes, surpass the 2M112 in processing accuracy, efficiency and productivity.

The kinematic diagram of the machine consists of a minimum number of parts

Schematic diagram of 2M112

This machine is also inferior to new models in its compactness and ease of use, but such minor shortcomings are compensated by its affordable cost, reliability and ease of maintenance.