Pros and cons of processing aluminum on a milling machine

This material is characterized by high ductility. This is good quality. But, when performing milling, it is precisely this that is a serious prerequisite for damage to the workpiece. The appearance of dents, scratches, and other defects that are very noticeable on the product.

It is possible to damage a metal workpiece even at the stage of fixing it to the workbench of the latter.

That is why it is recommended to fix all aluminum workpieces not with mechanical clamps, but with the use of special vacuum tables.

This solution has no alternative when performing engraving work and applying various images to thin and ultra-thin foil. It is physically impossible to secure it mechanically.

Due to the high probability of defects occurring on the workpiece during its processing, aluminum is very sensitive to the effects of the slightest vibrations of the machine and processing tools. This must be taken into account. Since, if the milling mode is incorrectly selected, or if incorrectly secured (unbalanced) collets or cutters are used, the finished surface of the cut may become jammed. The part will be rejected.

Table: cutting speed of materials

| Material | Speed (meters per minute) |

| Aluminum | from 200 to 400 |

| Brass | from 150 to 300 |

| Bronze | from 100 to 150 |

| Bakelite | from 50 to 100 |

| PVC | from 100 to 200 |

| Thermoplastics | from 300 to 500 |

| Various types of wood | from 300 to 500 |

| Stainless steel | from 50 to 90 |

The table contains general values for most machine tools, but they may go beyond the specified scope depending on the modification of the milling machines and the characteristics of the material. For example, plywood has a lower stiffness rating than wood, so standard speed values will not work.

Subtleties of milling modes

The pliability of Al, contrary to popular belief, does not mean that it is simple and easy to process at any selected cutting conditions, including extreme ones.

There is a high probability of situations occurring, even at moderate milling speeds, when metal shavings tightly clog the grooves of the cutter. The tool fails.

In order to eliminate the likelihood of such situations occurring, the following is required:

- perform work with the “correct” cutters, with the required number of teeth and grooves;

- use coolant;

- correctly select the required milling modes.

All this is achieved, first of all, by strictly following the recommendations of manufacturers of machines and cutters.

One more feature. By default, the definition of “aluminum” is collective. It applies to all alloys produced on the basis of this metal. The specifics of their processing can vary quite significantly.

Example. “Soft” AMG and duralumin require their own processing modes. The latter are selected taking into account existing requirements for the finishing quality of the manufactured part and machine parameters.

Heating and Lubrication

As the temperature rises and chips stick, the cutter loses its performance characteristics and works worse. To avoid breakage or damage to wood or other materials, it is recommended to lubricate the operating mechanisms.

Required for use:

- alcohol and special emulsions - when cutting or drilling aluminum and non-ferrous metals;

- soapy water - when processing parts that contain plexiglass.

In this case, it is necessary to control the feed and its speed. Determination of optimal values is carried out depending on the material and its thickness. To configure the desired indicator, use the values from the table.

High-speed processing of aluminum (HSO)

Aluminum milling is a popular and one of the simplest processing technologies. The installed cutter, removing a layer of metal of a given thickness, gives the workpiece the required shape and dimensions.

The use of modern CNC models ensures guaranteed processing with the most accurate implementation of the smallest elements, obtaining 2D or 3D relief of any degree of complexity. All images are processed in detail and clearly.

The economic efficiency of different technologies can vary quite significantly. VSO is, at the moment, the most effective method of processing aluminum workpieces. This is explained by the fact that a high spindle speed is organically combined with the possibility of increasing (in such modes) the depth of cut. Example. For steel this figure does not change.

In a number of situations, it is more economically feasible to manufacture one part (with a significant percentage of processing waste) than to cut out several parts from the same volume of material. This is precisely what explains the demand for processing VSO modes.

Selection of aluminum processing equipment

Aluminum parts produced using CNC machines are highly accurate and can be supplied to industries operating in the aviation, military or space sectors. Compact models that allow optimization of the technological process are often purchased by automobile workshops.

CNC milling machine SolidCraft CNC-3040 Light (300W)

- Power supply 110V/220V

- Dimensions, mm 610 x 490 x 390

- Software Mach3, Emc2

- Spindle speed 11000 rpm

- Spindle power 300 W

- Axes 3

- Repeatability 0.05 mm

- Working feed 4000 mm/min

- Working speed, mm/min 300-3000

- Working field 390 x 280 x 55 mm

- File format gcode, nc, ncc, tab, txt

- Motor type stepper 57/1. 8A

- Price 78,348 rub.

Go to product

A CNC milling machine is a high-precision device that can guarantee the most efficient processing of parts and ensure a perfectly smooth surface. The technology allows you to select the optimal processing speed by synchronizing the actions of the working tool. All this also allows you to reduce the time spent on performing operations (compared to standard methods).

An important structural part of the processing device when working with aluminum is the vacuum table. It allows for efficient fastening of parts and eliminates the risk of accidental shifting of workpieces under the influence of the cutter.

“It was smooth on paper...”

The unconditional attractiveness of tandem technology, VSO + increased cutting depth, contains its own “fly in the ointment”. This is a problem of increasing vibration. This phenomenon is inevitable and highly undesirable. And it will not be possible to fight it using traditional methods. Ensuring high rigidity of a four-link system, including a machine tool, a fixture for fixing, a processing tool, and a workpiece, is no longer enough.

It is necessary to take into account the harmonic law, according to which the cutter and spindle vibrate. Simply put, it is necessary to take into account, in addition to the static, also the dynamic characteristics of the resulting vibrations.

Example. Theoretical calculations, confirmed by practice, show that HCA machining of Al parts is best performed with an end mill having 3 spiral grooves. An increase in their number reduces the efficiency of chip removal due to a reduction in the cross-section of each groove in proportion to the increase in their number.

The reverse option, reducing their number to 2, also does not work. It will lead to an increase in unwanted harmonics. This is due to the following. The frequency with which the cutter oscillates no longer coincides with the number of blows that a pair of cutting edges make on the part (at spindle speeds reaching 20,000 rpm).

Special software products allow you to evaluate the optimal speed of its rotation. They allow you to evaluate the tonality of the device’s own vibrations. To do this, “listening” of the machine-tool system is carried out. The problem is solved by a specially designed microphone connected to the PC.

Factors affecting machine performance

The choice of appropriate modes depends on a number of factors. For a CNC milling type machine, the most important factors are:

- spindle feed and rotation speed - the permissible rate is calculated depending on the capabilities of the cutting machine, the type of material being processed, as well as the complexity of the part;

- milling width - this indicator is adjusted based on the dimensions of the workpiece (exact data can be found in the drawing);

- milling depth - depends on the number of passes of the cutter (for simple milling on a machine, one pass is usually sufficient);

- cutting speed - the indicator is calculated based on the distance that the cutter travels on wood or other material within one minute (the speed is also set depending on the technical parameters of the workpiece);

- feed – an indicator of spindle movement along three axes;

- feed per minute - calculated to determine the time it will take the spindle to complete the task.

To set up modes and obtain the necessary information, it is recommended to use the instructions for the machine, as well as the permissible values and characteristics of the processed materials in the tables.

Features of aluminum milling

With a large number of advantages, it also has several disadvantages, due to which aluminum and its alloys are among the most difficult to process on a milling machine.

- Firstly, despite its softness and pliability when cutting, it is prone to excessive chip formation. Long chips, which are formed during the milling process, clog the grooves of the cutter and wrap around the cutting tool. This can lead not only to disruption of heat flow from the cutting area, but also to blunting and breakage of the cutter/drill.

End mill wrapped with aluminum shavings

- Secondly, during milling of aluminum, so-called build-up occurs - the fusing of small particles onto the edge of the tool. This clogs the grooves and makes it difficult to remove chips. In addition, such surfacing causes overheating and imbalance of the cutting element, which can lead to jamming of the equipment and its failure.

Deposition of aluminum on the cutting edge of a cutter

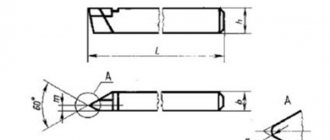

To minimize the consequences of milling aluminum, it is recommended to use only the most sharply sharpened two- and three-flush cutters made of carbide materials.

Cutter selection

Setting the required modes largely depends on the characteristics of the cutting mill used. The most suitable option is a large diameter solid carbide cutter. It is expensive, but has a number of advantages:

- high accuracy rate;

- high-quality heat dissipation;

- high cutting and feed speed.

For a specific machine model, it is necessary to use cutters made by the manufacturer. Less expensive manual options can only harm the machine tool.

Tables: feed speed

| Material | Speed for 3mm face tool (in millimeters per minute) | Speed for 6mm face tool (in millimeters per minute) |

| Soft woods | from 1 to 1.5 thousand | from 2 to 3 thousand |

| Solid wood | from 0.5 to 1 thousand | from 1.5 to 2.5 thousand |

| Double layer plastic | 2 thousand | absent |

| Acrylic and different types of polystyrene | from 0.8 to 1 thousand | from 1 to 1.3 thousand |

| PVC | from 1.5 to 2 thousand | from 1.5 to 2 thousand |

| Aluminum alloys | from 0.5 to 0.8 thousand | from 0.8 to 1 thousand |

The values in the table indicate the minimum and maximum values at which milling machines can cut properly without risk of failure.