Slotting, planing, broaching. Other machines. Groups 7, 8, 9

7210

longitudinal planer Ø 900 x 1000, Minsk

7212

longitudinal planer Ø 1120 x 1250, Minsk

7216

longitudinal planer Ø 1400 x 1600, Minsk

7B35

cross-planer Orenburg

7D36

cross-planer Gomel 7D37 cross-planer Gomel

7E35

cross-planer Orenburg

7M36

cross

736 cross-

planer

737

planer Gomel

7303

cross-planer Orenburg

7305

-

planer Orenburg 7307 cross-planer galny Orenburg

7307G

cross planer Orenburg

7307D, 7310d

cross planer Gomel

7A412

slotting Ø 360, Saraktash

7A420

slotting Ø 500, Saraktash

749

cross-planing Orenburg

7402

slotting Orenburg, Baku

7430

slotting Ø 650, Gomel

7D430

slotting Ø 630, Gomel

7M430

slotting Ø 630, Go Mel

7403, 7405

– slotting Ø 630, Gomel

7417

slotting Orenburg

GD200

slotting Ø 500, Gomel

GD320

slotting Ø 770, Gomel

GD500

slotting Ø 940, Gomel

7A510

broaching 98 kN, Minsk

7A534

broaching 250 kN, Minsk

7B55

broaching 100 kN, Minsk

7B56

broaching 200 kN, Minsk

7523

broaching 100 kN, Minsk

7534

broaching 250 kN, Minsk

8A531

vertical band saw Maikop

8B72

hacksaw-cutting Ø 250 Krasnodar

8B66

automatic cutting circular saw Ø 280, Minsk

8B66a

automatic cutting circular saw Ø 280, Minsk

8G240

abrasive cutting Ø 60

8G662

automatic cutting circular saw Ø 280, Minsk

8G6 63

automatic cutting circular saw Ø 285, Minsk

872A

hacksaw- cutting Ø 250 Krasnodar

872M

hacksaw-cutting Ø 250 Krasnodar

8725

hacksaw-cutting Ø 250 Orenburg

N-1

hacksaw-cutting Ø 250 Kaunas

Table of contents

The 2M55 radial drilling machine is widely used not only in repair shops, but also in large-scale production. The following types of work can be performed on the machine:

- Drilling;

- Reaming;

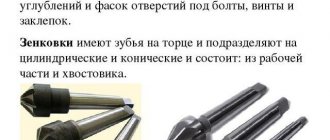

- Countersinking;

- Deployment;

- Tapping threads

Using fixtures and special tools, the machine can perform work typical of boring machines

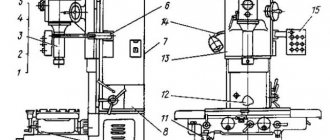

Design of a radial drilling machine 2M55

- Plate

- Base

- Cooling system

- Current collector

- Sleeve

- Lifting mechanism

- Sleeve clamp mechanism

- Gearbox

- Hydro station

- Clamp

- Drill head

- Friction clutch

- Machine speed box

- Machine feed box

- Worm shaft

- Feed mechanism of the machine

- Manual movement of the drill head

- Drill head clamp

- Hydro preselector

- Hydraulic preselector drive

- Hydraulic panel

- Command controller

- Headstock

- Counterweight

- Pump

- Master cylinder

- Hydrocommunications

- Lubrication system

- Electrical equipment for the column

- Electrical equipment for the hose

- Electrical equipment for head

Controls of the radial drilling machine 2M55

- Cooling pump switch

- Input switch from ABB catalogue;

- Accelerated approach of the spindle head and inclusion of mechanical feed

- Turning on the stop to adjust the required drilling depth

- Locking the feed mechanism when cutting threads

- Drill head release

- Column and head pressing

- Column and head clamp

- Connection of the dial with the machine feed mechanism

- Fine adjustment of the dial to the required drilling depth

- Load indicator

- Counterweight spring tension handle

- Signal lamp

- Sleeve lift control

- Disconnecting the spindle head from the gearbox

- Pre-speed knob

- Starting the main engine

- Control of lowering the sleeve and stopping the sleeve when lifting

- Pre-feed handle

- Community stop button

- Start reversing clutch control

- Light switch

- Mechanical feed switch handle

- Flywheel firebox manual feed spindle

- Coolant switch-on edge

- Drill head movement flywheel

Plate, base and column of a radial drilling machine

Foundation slab 1 is a rigid casting, reinforced with ribs in the longitudinal and transverse directions. On the surface of the plate there are T-shaped grooves that serve for fastening a table, workpieces or special devices.

A base 5 is fixedly mounted on the plate, in which a column 6 is installed on bearings 3 and 10. The column is the most loaded part of the machine, therefore it is made of a steel pipe and has a hardened working surface with a slight roughness, along which the sleeve moves.

Purpose of the unit

All equipment of this type is designed to work with large workpieces, whose free movement on the table is impossible or takes a lot of time.

If we delve even deeper into the information about the operation of the machine, it is easy to find out that it is used to produce a large or small number of parts, especially those of the same size range. This feature makes it easy to complete standard orders in a short time.

It is easy to perform the following types of work on the equipment:

- drilling;

- countersinking process;

- reaming;

- deployment;

- thread cutting.

There is a variation of this machine, it is called a radial drilling machine 2K52-1. The difference between these two units is the landing and secondary connecting bases. The location of these parts allows you to expand the range of use of the machine in the production of small-sized parts.

Radial drilling machines

What distinguishes radial drilling machines from vertical drilling machines is the design possibility of aligning the axis of the workpiece hole with the axis of the spindle by moving the spindle relative to the stationary workpiece to any location on the horizontal surface of the table. By design, radial drilling machines are divided into general-purpose machines, portable - for processing holes in large-sized workpieces (the machines are carried by a crane to the workpiece and machine vertical, horizontal and inclined holes) and self-propelled, mounted on trolleys with their fastening at the processing site with using shoes.

Radial drilling machine mod. 2554 (Fig. 7) is used when machining holes in medium-sized body parts. The machine allows you to perform drilling in solid material, reaming, countersinking, reaming and boring holes, tapping and other operations. On the foundation plate 1 of the machine there is a pedestal 2 with a fixed column 3, on which a sleeve 4 is mounted. The sleeve rotates around the column, ensuring the processing of holes anywhere in the part without moving it. A traverse 6 is mounted on the sleeve, which has horizontal guides along which the spindle head 5 can move. Inside the spindle head there is a gearbox, a gearbox and a spindle assembly 7. The controls are located on the front cover. The workpieces to be processed are installed on a side table or directly on the upper plane of the foundation slab 1.

Rice. 6.

Radial drilling machine mod. 2554: 1 - plate; 2 - cabinet; 3 - column; 4— sleeve; 5— spindle head; 6 — traverse; 7— spindle

The spindle 7 with the drilling head can move vertically along the guides of the sleeve 4, in the radial direction along the traverse 6, and also, together with the traverse 6 and sleeve 4, rotate around the axis of the fixed column 3. These three movements allow you to install the tool in any coordinates. The spindle is reversed using a friction clutch. The traverse 6 mechanically moves vertically along the sleeve 4 with automatic release at the beginning and clamping at the end of the stroke.

The drilling head is equipped with an automatic feed shutdown mechanism, which is triggered when the required drilling depth is reached. The machine is equipped with a system of safety devices that eliminate the possibility of its breakdown due to overloads.

Rice. 7.

Main parts of the machine mod. 1Н125 (2Н135): о - general view of the drilling head; b - kinematic diagram; 1 — gearbox; 2 — feed box; 3, 5, 14 — control handles; 4 — drill head body; 6, 7, 9, 13 — control mechanisms; 8 — spindle splines; 10, 11 — control panels; 12 - limb; 15 — electric drive for accelerated spindle movement; 16 - electric motor.

CNC drilling machine 2р135ф2: characteristics

- The maximum diameter of parts to be processed should not exceed 35 mm.

- The maximum size does not exceed 24 mm.

- The maximum milling width does not exceed 60 mm.

- The processing process involves 6 tools.

- Spindle speed 12.

- The working surface has the following dimensions - 710x400 mm.

- The spindle speed ranges from 35 to 1600 per minute.

- The number of feeds along the Z axis reaches 18.

- Working feeds along the Z axis range from 10 to 500 mm per minute.

- The table and slide move at speeds of up to 7000 mm per minute, and during the milling process 2200 mm per minute.

- The caliper movement frequency reaches 4000 mm per minute.

- In terms of dimensions, the machine has the following parameters: 1800 mm by 2400 mm by 2700 mm.

We buy Boards

We buy at the highest prices:

- Consumer electronics (boards must be cleared of metal, plastic, transformers larger than 3 cm in any direction and black monitor coils)

- Motherboards from laptops and motherboards up to the Pentium 4 generation (batteries, power supplies, metal parts, plastic fasteners, radiators, etc. must be removed), video.sound.set.

- Motherboards of the Pentium 4 generation and higher. Socket: 423, mPGA 478, 775, 1155 (batteries, batteries, metal parts, plastic fasteners, radiators, etc. must be removed)

- Imported boards (plastic, metal and aluminum elements must be removed)

- Computer component boards, RAM with yellow lamella

- Boards with valuable radio components (KM capacitors, microcircuits (yellow), connectors (yellow), transistors (yellow)) of domestic production

- Cell phone boards (without housing and display) 2SIM generation, touchscreen, smartphones

- Cell phone boards (without housing and display.) Up to the 2SIM and touchscreen generation

- Control boards for military and Soviet devices, made in the USSR (plastic, metal and aluminum elements must be removed) without valuable radio components

- Cutting from boards (unliquid stock of switches, transistors, microcircuits, etc.)

Features of the design of machine components

Desktop

The base plate is made as a modified cast iron casting. For reinforcement, the structure is provided with longitudinal and transverse ribs. Special T-shaped grooves allow the use of different methods of fixing workpieces. You can install:

- Three-jaw chucks, cylindrical parts are fixed in them. Then axial drilling will be performed with high precision.

- Four-jaw chucks are designed for fixing asymmetrical parts on the table.

- Pneumatic or eccentric clamps are used for positional fastening of a special shape.

Support column

A conical ring is used to fix the column. During axial movement, the cone clamps the cylinder, preventing it from rotating in the sleeve. Involuntary rotation of the column is impossible. It is firmly fixed.

To facilitate the movement of the cone ring, special flanges are used. To displace them, screw clamps are used, connected by control handles and corresponding longitudinal movement mechanisms.

Drive unit

The main mechanism for ensuring rotation speed, its switching during drilling and the operation of the gearbox is characterized by one feature. Having disassembled the gearbox of the 2K52 drilling machine, the passport of which includes its own electric drive, we can say that there are several similar mechanisms.

It is allowed to install 3 electric motors in accordance with the operating manual 2K52 and other regulatory documents. The power of the main drive is 1.5 kW.

The manual indicates the weight of the installation - 1250 kg, and also displays a full explanation of the name of the machine.

The kinematic scheme is based on four chains, the first of which is the rotation chain of the main spindle. When disassembling the installation, you can notice that the load when the spindle rotates is evenly distributed over the gearbox and U-type drive shaft.

Kinematic diagram of the 2K52 machine

The components of the kinetic scheme are also:

- Feed chain.

- Chain of vertical displacement of the main sleeve.

- Column clamping circuit.

During the assembly process, the designers equipped the 2K52 installation with the maximum set of additional modules. Expanded functionality allows you to increase the accuracy of all operations, it also becomes possible to work with complex workpieces, and productivity is accelerated.

As a result, the 2K52 drilling machine has parameters suitable for performing many jobs, the adjustment of which allows one to achieve fairly high accuracy. Each work operation is carried out without complex manipulations, which can be performed even by a worker with minimal qualifications. The resulting holes always have the correct shape.

2K52 portable radial drilling machine. Purpose and scope

Radial drilling machines model 2K52 were produced until 1990, then significant changes were made to the kinematic diagram of the machine. In particular, the number of teeth in almost all gears was changed, which led to the appearance of a machine with the index 2K522.

The portable radial drilling machine model 2K52 is designed for processing holes in medium and large parts in single, small-scale and mass production.

On the 2K52 drilling machine you can perform: drilling, reaming, countersinking, reaming, threading and boring holes. It can be used most effectively when processing holes located at angles in different planes of large parts in tool, repair, experimental, assembly and production shops.

Operating principle and design features of the machine

The 2K52 machine consists of the following main components: base, column, body, sleeve, carriage, drilling head, column clamping mechanism, coolant supply system and electrical equipment.

A column with a body and a sleeve is installed on the base, and a coolant tank is attached to it at the end.

The column is a steel pipe installed in a plinth on two bearings. The base contains part of the electrical equipment and the column clamping mechanism.

The housing is a cast iron casting of rigid shape and is the base part for assembling the gearbox, the mechanism for moving the housing along the column, and the mechanism for clamping the housing on the column.

Electrical equipment is installed in the housing niche.

On the front side of the case there are control handles for the gearbox, a mechanism for moving the barrel along the column and a control panel.

The sleeve is attached to the body with four clamps. A carriage with a drilling head attached to it moves along the guides of the sleeve. The sleeve is rotated around its axis by a handle through a worm gear.

The drilling head is a cast iron casting in which the spindle, feed box and steering device are mounted.

The machine spindle has a wide range of rotation speed control and can be spatially oriented by rotating the sleeve and drilling head.

The machine is equipped with a device for processing holes to a given depth and devices that protect against overloads in terms of torque and axial force. When processing large parts outside the working surface of the plate, the machine is aligned using screw supports. It is recommended to process small parts on a box-shaped table mounted on the table plate.

A distinctive feature of the machine of this standard size is the presence of a rotating column and mounting of the drill head carriage on sleeve guides on rolling bearings, which significantly increases the ease of operation of the machine.

The machine is manufactured for operation in temperate climates, on request for operation in tropical climates, as well as for processing parts in the inch measurement system.

The electrical equipment of the machine can be designed for supply current with a frequency of 50 and 60 Hz and a voltage of 220, 380, 400, 415, 440, 600 V.

On request, the machine is equipped with an electromechanical column clamp, as well as with a system for supplying coolant to the cutting zone.

Machine accuracy class N according to GOST 8-77.

The roughness of the treated surfaces, depending on the work performed, is R = 80-20 microns.

Arrangement of components of a radial drilling machine 2532l

Arrangement of components of a radial drilling machine 2532l

Specification of components of drilling machine 2532l

- Plate and sleeve – 2532l.00.10.000

- Barrel – 2l53u.00.11.000

- Electrical cabinet – 2l53u.00.82.000

- Electrical equipment of the machine – 2l53u.00.81.000

- Drilling head – 2532.35.20.000

- Command apparatus - 2l53u.00.19.000

- Cooling system – 2L53u.00.16.000

- Rotary table – 2L53u.00.15.000

List of controls for the radial drilling machine 2532l

- Barrel Clamp Handle

- Table turn square

- Remote Control:

- lamp “Live machine”

- lamp “The machine is ready for work”

- barrel lift button with turntable

- barrel lowering button with turntable

- “General stop” button

Cooling pump switch Input switch Sleeve clamp handle Sleeve stop handle Dial clamp handle Drill head clamp handle Handles for setting spindle speeds Handle for setting feeds Handle for turning on feeds Handle for command device Handwheel for fine manual feed of spindle Hard stop button Mechanical feed locking lock

How does the machine work?

Here are the main details of the machine:

- base;

- Column;

- frame;

- barrel sleeve;

- drilling head;

- electrical equipment;

- carriage.

Machine carriage

The body and sleeve are attached to the base, and a container for cooling liquid is attached to the end part.

The column is a large steel pipe, which is installed in the base and attached with two bearings. Electrical equipment and clamping mechanisms are also located there; it is worth knowing that clamps are not included with the original equipment, they must be ordered separately.

A densely shaped cast iron is the housing, which is the main part for the gearbox. It also has space for electrical equipment.

The sleeve is attached to the body part by means of four clamps. In the direction of this part, a carriage moves along with a drilling head.

The head itself consists of a spindle, a control device and a feed box.

The spindle is made of cast iron. Has a large range for drilling frequency.

Drill head

In the manufacture of the body, cast iron was used, which is resistant to vibration loads and is not susceptible to high humidity. Inside there is a system for switching spindle rotation or feed speeds. To significantly extend the service life of the structure, the contacting elements are lubricated with a special suspension. To do this, a lubrication pump, main motion drive or spindle brake are installed on the housing.

The gearbox is controlled through externally mounted handles. In the manufacture of gears, alloy steel is used, which has increased wear resistance.

Tantalum capacitors K52-1, K52-2

Capacitors K52-1, K52-2 are tantalum volumetric porous oxide electrolytic capacitors of constant capacity, accumulate charge from 1.5 µF to 470 µF at voltages from 3.2 V to 100 V.

The permissible deviation of the capacity is ±10%, ±20%, ±30%. Designed for use in DC or pulsating current circuits. Structurally sealed tantalum capacitors are produced in metal cylindrical (K52-1) or cup (K52-2) cases with flexible axial-type wire leads.

Capacitors have a polar type of design. An aqueous 35-38% solution of sulfuric acid is used as a working electrolyte.

Failure of an electrolytic capacitor is often accompanied by a characteristic explosion and possible release of liquid electrolyte, so you should pay special attention to the polarity of the capacitor when installing it in the circuit

On the side surface of the body of the volumetric-porous tantalum storage device there is a nominal marking indicating the capacity, permissible deviation, operating voltage and polarity of the terminals.

In the absence of polarity markings, the anode terminal of the K52-1 capacitor is determined by an end that is filled with epoxy resin, and the anode terminal of the K52-2 capacitor is determined by a welding unit (connection of a tantalum wire terminal and a tinned nickel terminal) or an end made of an insulating plug.

Installation of capacitors - at the terminals using soldering. Installation in a vertical position with the negative terminal down is allowed. When bending leads, the minimum distance from the capacitor body or lead welding unit is 2.5 mm, the height from the body to the soldering point is at least 5 mm, and the bending radius is at least one and a half diameter of the lead.

The elevated operating temperature of the environment is no more than +155°C, the reduced operating temperature is not lower than -60°C. Loss tangent tgδ from 5% to 30%, maximum leakage current – 30 µA. The operating time is at least 5000 hours.

Tantalum capacitors K52-1, K52-2 are resistant to vibration loads with a frequency of 1-5000 Hz with acceleration up to 20g and mechanical shocks of a single (acceleration up to 1000g) or multiple (acceleration up to 150g) action.

Tantalum oxide electrolytic capacitors K52-1, K52-2 are used in household, medical equipment, railway transport and other electronic equipment.

Detailed characteristics, labeling, overall and installation dimensions of tantalum capacitors K52-1, K52-2 are indicated below. Our company guarantees the quality and performance of capacitors for 2 years from the date of purchase; quality certificates are provided.

Specifications

- Drilling diameter in steel 45 according to GOST 1050-38, mm 32

- Drilling diameter in cast iron SCH according to GOST 1412-89, mm 40

- Distance from the spindle axis to the guide column (overhang), mm 1000

- Weight of 2L53U tool, kg, max 5

- Spindle travel, mm max 325

- Drill head movement along the sleeve, mm, max 710

- Max vertical movement of the hose along the column, mm 6251

- Angle of max rotation of the sleeve around the axis of the column, degrees. 330

- Spindle speed limits, min-1 35.5 - 1400

- Number of spindle rotation stages 8

- Number of working feed stages 6

- Overall dimensions, mm LxWxH, mm 2500x1070x2840

- Weight, kg 3500

The lightweight radial drilling machine 2L53U is used for single, small-scale and mass production. The equipment is actively used in small procurement enterprises, workshops and factories. The mechanism is capable of performing such technological operations as:

- countersinking;

- drilling;

- reaming;

- thread cutting;

- deployment;

- cutting planes with a cutter.

Before purchasing a 2L53U machine, it is worth preparing a concrete base for installing the equipment. The layer height must be at least 40 cm.

Main parts and components of the machine:

- cast iron work table with a rotating design that can be rotated around its axis by +90 and -80 degrees manually;

- coolant supply system;

- feed switching device;

- a drilling head, in the body of which there is a gearbox and a feedbox, a device for switching the feed and controls;

- electrical equipment, wiring and electrical cabinet;

- a barrel on which a rotary table is mounted, which moves vertically and around the column 360 degrees;

- controls;

- mechanism for moving and clamping the drill head.

- a sleeve on which the drill head mechanism is located;

- a foundation slab on which a vertical cast iron column is located.

To prevent breakage of electrical wires, the rotation of the hose relative to the column is constrained by rigid stops. The movement of the barrel along the column is possible due to the reliable connection of the screw with the bracket. To prevent overheating of the working tool and rapid wear of the equipment, a coolant is built into the 2L53U design, which supplies liquid using a cooling pump.

To switch the speed and feed, the operator needs to operate the handle, which is located on the right side of the drill head. The safety clutch is located in such a way that a specialist can make the necessary adjustments without dismantling the components.

The industrial machine tool 2L53U is equipped with three electric motors, namely:

- for supplying coolant to the working area - 0.125 kW;

- table drive – 0.56 kW;

- spindle drive – 2.2 kW.

The 2L53U machine is reliably protected from overloads and short circuits using a fuse and a thermal relay. Unauthorized movement of the table is not allowed if the spin handle and limit switch are locked. In addition, there is a special braking device, which is controlled by an electromagnet. In order for the spring brake to work, the handle must be set to the neutral position, which automatically turns off the electromagnet. The braking system also operates automatically in the event of intentional or accidental power outages.

The 2L53U radial drilling machine allows the operator to perform processing of various levels of complexity. This is possible due to the wide range of spindle speeds and feeds. The big advantage is that the specialist, working at the machine, makes a minimum of physical effort with smaller drilling radii, which allows increasing the efficiency of the work process. All types of technological operations are carried out strictly with international quality standards.

To improve the mechanism, the following is mounted into the structure:

- protective screen for the drilling and cutting area;

- air cooling system for working equipment;

- swivel or standard cabinet.

This machine model is considered indispensable if the enterprise constantly needs to process metal parts. The equipment is quite easy to use and can easily act as an independent production unit.

Unit differences

Design features include:

- It is easy to choose a model with different energy ratings for connecting to the network: standard 220, industrial 360 and non-standard 600 volts.

- The spindle rotates over a wide range.

- The system control is located on the front side of the device, this allows you to quickly switch between different options.

Technical characteristics of the unit:

- Weight is 1 ton 250 kilograms.

- Dimensions: length – 1 meter 76 centimeters; width – 92 cm; height – 1 meter 96 centimeters.

- The power of the main engine for operation is 1.5 kW.

- The cooling system is powered by a pump whose power is 0.125 kW.

- The drilling diameter has a limit; it is 3.5 centimeters.

- The spindle head moves along the sleeve within the range of 40–90 centimeters.

- The machine rotates with a frequency of 60 to 1.6 thousand revolutions per minute.

- Speeds for work: 6.

- The number of working feed stages is 3.

- Work table: 80 cm long and 63 cm wide.

The device rarely breaks down, so repairs are an infrequent task. The unit easily adapts to the dimensions of the room; the unit does not require special lighting or ventilation.

Mechanical components are used to brake and stop the spindle head.

The machine is easy to use, despite its apparent complexity. Before starting work, you should read the instructions for use.

2N55 radial drilling machine. Purpose and scope

The radial drilling machine model 2N55 replaced the outdated model of the machine of the same series 2A55.

The machine is designed for drilling holes in steel with a diameter of up to 50 mm using drills of medium hardness (tensile strength σ = 55..65 kg/mm²).

The 2N55 radial drilling machine is designed for drilling, reaming, countersinking, reaming, boring holes, tapping threads, trimming ends with a cutter, as well as performing other similar operations when processing various body parts in machine shops of single, small-scale and mass production, as well as in assembly shops of heavy transport engineering factories. When equipped with fixtures and special tools, the machine can be used for high-performance processing of large parts in large-scale production.

The 2N55 radial drilling machine has a two-column layout of the machine part, which makes it possible to create a rigid unit structure that does not allow the spindle axis to shift when clamping the column. A special center-type column clamp creates a braking torque that guarantees high-performance drilling.

To rotate the column, little force is required at the smallest drilling radius, which also ensures high productivity and reduces operator fatigue. A wide range of spindle speeds and feeds ensures highly productive work with any combination of processed materials, tool sizes, etc.

Spindle balancing is ensured by a special counterweight, allowing convenient adjustment from the workplace if the tool weight changes.

The cutting modes allowed on the machine are determined by the dynamic parameters of the machine:

- Effective power on the spindle, kW - 4.0

- Maximum torque on the spindle kg*cm - 7100

- Maximum feed force, kgf - 2000

It should be borne in mind that the greatest power on the spindle can be used starting from the 7th speed level (80 rpm, see the section of the passport “Main motion mechanics”).

Low spindle speeds are used on a machine tool to perform operations that require less power but more torque. Therefore, in the first six speed steps, the power on the spindle does not reach its maximum effective value.

The maximum permissible feed force is determined by the strength of the machine parts and the rigidity of its structure. Exceeding the permissible value of the feed force causes the feed mechanism's safety clutch to turn off. Therefore, the mechanical feed amount should be selected so as not to exceed the permissible feed force. The feed force largely depends on the correct sharpening of the drill.

Wide ranges of spindle speeds and mechanical feeds allow you to increase machine productivity.

A preselective remote electro-hydraulic device allows you to change modes with their preliminary selection. The machine has an automatic shutdown mechanism when the specified drilling depth is reached.

The presence in the machine of preselective control of speeds and feeds, easy hydraulic control of the spindle friction, the ability to disconnect the spindle from the gearbox, the presence of reliable hydraulic clamps of the column and drilling head, working both together and separately, as well as the concentration of all controls on a small area of the drilling head allows you to minimize auxiliary time.

If you need to change tools frequently, it is recommended to use a quick-change chuck. A safety tap chuck should be used for cutting threads.

The machine has the following advantages compared to the previously produced model:

- tightening of the clamping of the column due to the developed cone, which allows working at high cutting conditions; increasing the volume of the working space by increasing the strokes of the hose along the column and the head along the hose;

- achieving the specified accuracy and achieving accuracy outside the slab thanks to the two-column layout and developed sleeve guides;

- reduction of time for re-aligning the hose in height due to the increased speed of its movement and the fast action of the clamp;

- increased maintainability thanks to a new design of column guides;

- the absence of mechanisms at the upper end that require maintenance, which ensures ease of operation of the machine and improves its appearance.

Developer - SKB APC, Odessa

The quality category is the highest.

Machine accuracy class N according to GOST 8-77.

Design features

With certain equipment, the 2l53u radial drilling machine is used in mechanical engineering, machine tool building and other industries. Radial drilling machine 2l53u technical characteristics has the following features:

- The layout allows processing of parts that are installed outside the slab.

- Accuracy class N.

- The limit on the diameter of the resulting hole when using a drilling machine is 35 mm.

- From the spindle axis to the direction of the column, the distance can vary from 290 to 1,000 mm.

- Along the hose in a horizontal plane, the drilling head can move 710 mm.

- The model also allows you to move the table, which makes drilling easier when the workpiece is small. The limit on the vertical movement of the drilling machine steel is 340 mm.

- The size of the plate on which the workpiece can be placed is 800 by 1500 mm.

- The passport of the radial drilling machine 2l53u indicates that the end of the spindle is in accordance with GOST 24644-81 Morse 4.

- The kinematic scheme provides for 8 direct rotation spindle speeds.

- The spindle speed can vary from 35.5 to 1,400 rpm.

- The number of working gear stages is 6.

- A fairly large number of different cutting tools can be installed on a radial drilling machine, some are attached through special equipment that is not included in the kit.

Download the passport (operating instructions) of the 2L53U machine

The model has an extensive electrical network. The lubrication system and specifications of the 2l53u radial drilling machine determine the presence of a fairly large number of electric motors.