The smallest equipment designed for forming holes in parts made of various materials is considered to be a mini drilling machine with a vertical layout of the working head. Using such a machine, you can create small-diameter holes in compact parts, cut threads in them and perform a number of other technological operations.

Proxxon TBM220 85 W desktop mini machine

Significant advantages of such a device include its small dimensions, due to which it takes up very little space in a workshop or production workshop, low energy consumption and affordable cost.

Areas of use of miniature drilling machines

A miniature drilling machine, despite its rather modest dimensions, allows you to effectively perform drilling operations and achieve high processing accuracy. On many of the modern models of such machines, due to their functionality, they not only carry out drilling operations, but also mill oversized parts.

A radio amateur or modeler cannot do without a lightweight drilling machine

One of the most common areas of application for mini drilling machines is the formation of holes in printed circuit boards, without which not a single electrical and electronic device is created today. It is impossible to make holes with a very small diameter in such products using conventional drills, so it is simply impossible to do without mini drilling machines in these situations.

PCB drilling

To drill holes in printed circuit boards, radio amateurs use various DC motors, usually with a collet chuck. By mounting such a motor on a special tripod, we get a micro-drilling machine.

The photo shows one of the simplest options. Such a tripod made of plastic and frail metal tubes is a waste of money. And the motor itself is not bad.

Another option for a drilling stand. Shown with electric motor DP-2-26. No cartridge yet.

This tripod is better than the first, but still requires preliminary fine-tuning with skilled hands. In addition, the tripod parts are made of aluminum alloy and, of course, will not last long.

To clamp thin drills, collet chucks are usually used, but there are also small drill chucks, such as in the photo (clamping up to 3.5 mm). Note Translator: People from Moscow (and not only) can buy a similar cartridge at the Moscow representative office of Proxxon - Paradox LLC on the street. Marxist. Price list item (28941) “Cartridge for the Mikromot machine” price as of 09/05/08 - 157 rubles. It must be said that the quality of collet chucks included in the equipment set of sold power tools (for example, electric tools of the “Mikromot” series, or (28620)-Flexible shaft MBW 110/P) and those sold separately are completely different! The latter are clearly inferior to those that come complete with power tools - in terms of the material from which all the parts are made and, less obviously, in terms of accuracy.

Design features of the equipment

Like any device in this category, a micro drilling machine performs its functions through two movements: rotation of the drill fixed in the spindle head and its movement in the vertical direction (feed movement). In this case, the part in which the holes are drilled is fixed on the surface of the work table.

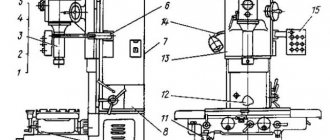

Typical design of a mini drilling machine

The basic element of a tabletop machine, like any other drilling equipment, is the base support on which the vertical stand is fixed. Guides are mounted on the outer surface of the rack along which the working head moves in the vertical direction. The drive motor of a mini drilling machine is mounted on the back side of the working head, and in its inner part, if provided for by the design of the device, there is a box for adjusting the rotation speed of the spindle assembly.

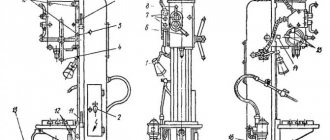

Drive mechanism of mini drilling machine ZB2506-1

Modern models of desktop machines provide automatic supply of oil to the equipment mechanisms and coolant to the processing area, for which special pumps are responsible. Inside the working head, in addition to the gearbox, there is also a feed switch box. Both of these mechanisms operate through a set of gears with different parameters, which are engaged using control handles.

Electric motors installed as a drive on small tabletop machines operate from an electrical network with a voltage of 220 V, and their power can vary between 150–300 W. Most mini drilling machines are equipped with a protective screen made of transparent plastic, which ensures the safety of the operator during operation.

Drill manufacturing technology

The technological process for manufacturing spiral drills for metal with conical shanks consists of the following sequence of operations.

- A piece of workpiece for the tail section.

- Cutting the workpiece for the working part.

- Cleaning the ends of the tail section.

- Cleaning the ends of the working part.

- Cleaning the workpiece using a sandblasting machine.

- Welding.

- Annealing.

- Peeling the bead at the weld.

- Straightening the workpiece after welding.

- Trimming the end from the shank side.

- Drilling and countersinking the center hole from the shank side.

- Turning of the outer center from the side of the working part.

- Turning of the working part in diameter, preliminary and final.

- Taper turning of the shank, preliminary and final.

- Turning the shank for the foot and trimming the end.

- Foot milling.

- Spiral groove milling.

- Milling the back of the tooth.

- Heat treatment and cleaning using a sandblasting machine.

- Polishing of spiral grooves.

- Center grinding.

- Grinding the shank to a cone.

- Grinding the working part along the diameter with a reverse cone.

- Drill sharpening.

- Control and branding.

How does a miniature drilling machine work?

When starting, the rotation from the electric motor shaft is transmitted to a gear (for the smallest models) or belt drive. The rotation speed of the spindle assembly and the tool fixed in it is changed by means of the equipment gearbox, which is controlled using a special handle.

A jaw chuck or collet chuck can be used to hold the drill bit in the spindle assembly of a small bench saw. To secure the tool in the jaw chuck, a special key is required (in a collet device this process is performed automatically).

A special handle located on the right side of the working head body is responsible for the vertical movement of the spindle assembly with the drill (feed movement). Automatic return of the working head to its original state is ensured by a special spring built into the feed mechanism.

Micrometer scale on the feed handle helps you drill holes to the desired depth

Some models of mini drilling machines are equipped with a mechanism that allows you to automatically adjust the drilling depth. In order to use such a mechanism during the drilling process, it must first be configured, which is done as follows. The tip of the drill is lowered to a mark on the side of the part corresponding to the required drilling depth. In this position, the handle of the drilling depth limiting mechanism is tightened, which will prevent the tool from falling below the required hole depth during processing.

Features of drill manufacturing, additional methods for improving tool performance

We will talk about the features of performing the most important operations included in drill manufacturing technology, and describe the methods that are used to improve the basic characteristics of tools.

Heat treatment

It is very important. The wear resistance of the tool and the quality of the steel directly depend on the correctness of the heat treatment.

Hardening is carried out in baths with molten salts or in furnaces (electric and gas). In some cases, equipment with a vacuum or a reducing atmosphere is used to make drills.

For tempering, oils, alkalis, salts and water are used. Often the workpieces are cooled in air.

Note! Heat treatment modes are of particular importance. Therefore, all processes are controlled automatically.

Resistance butt welding

Performed on special electric welding machines. There are three technologies.

- Continuous flash welding without heating. The technology is highly productive. The disadvantage is the high consumption of metal for melting and upsetting.

- Heated intermittent flash welding. Takes a little longer. Metal consumption is significantly reduced.

- Heated resistance welding. Almost no metal is consumed, but the operation requires highly qualified workers.

The second method is most often used.

Photo No. 3: contact butt welding

Additional methods for improving the basic characteristics of drills

Let us list the technologies that are used in the manufacture of drills to further improve their properties.

- Cyanidation. The surfaces of the working parts are saturated with nitrogen and carbon. Cyanidation increases the strength of tools by 2–3 times.

- Sulfidation. The surface layers of drills are saturated with sulfur. Sulfur compounds reduce friction and increase the wear resistance of tools by 1.5–2 times.

- Steam treatment. After this, the instruments are placed in oil. Black oxide films form on surfaces. The strength of drills that have undergone this treatment is doubled.

Parameters of mini drilling devices

Mini drilling machines are characterized by a number of parameters, which should be taken into account when choosing such equipment:

- power (not only the technical capabilities and productivity of the machine, but also the amount of electricity that it will consume during its operation depend on the value of this parameter);

- rotation speed of the spindle assembly, which can vary between 200–3000 rpm (on modern mini drilling machines, gearboxes are installed that allow the rotation speed of the spindle assembly to be adjusted in 12 steps);

- the distance from the lower end of the spindle assembly to the surface of the work table (this parameter determines the maximum height of the part that can be processed on a mini drilling machine);

- the minimum and maximum diameter of the hole that can be drilled using the machine.

Technical parameters of some mini drilling machines

Despite the fact that the weight and dimensions of the frame of mini drilling equipment are not as important as those of conventional machines, it is necessary to pay attention to these parameters. The weight of the base plate of the desktop machine determines how stable it will be during processing and, accordingly, how accurately the holes will be located on the surface of the part.

Criterias of choice

How to choose the right drilling machine if you decide to make a mini-workshop in your garage or plan to carry out a number of works in the country or at home? To choose the optimal model, you will have to take into account a number of factors:

- The first step is to take into account the size of the room intended for the workshop, as well as the expected operating mode. As a rule, in domestic conditions such a machine is not used constantly, but periodically. But sometimes prolonged operation of the device is required. In general, in these cases, a household or semi-professional option, which does not have great productivity, is sufficient. You should only think about a professional machine if the machine will be used actively every day. This device is more expensive, but it has high performance. And it usually allows you to create holes that are quite large in diameter. The holes after the drilling machine are accurate and neat

- How often will the machine be used : more than 2 hours a day (long-term frequency) or less (repeatedly short-term, usually in this case the device is used for only a few minutes). Remember that household appliances should “rest” for 5 minutes every 20 minutes.

- The next important criterion is power . If the machine will be used constantly, then its power should be more than 600 W, or better yet, at least 1000 W. For domestic purposes, a unit with a power of up to 600 W is sufficient. Machines designed to be powered from a 220 V network are somewhat weaker than those designed for other indicators.

- Drill bits for a drilling machine. Next, consider what size holes you will create. Household options are unlikely to allow you to use a drill with a diameter of more than 16 mm (in rare cases there are exceptions). But for professional ones you can use 60 mm. For small holes, you need to buy a modest-sized machine for drills up to 6 mm - it will be more accurate.

- It is also important to consider what material you plan to work with. So, on machines you can create holes in metal, wood or plastic. But remember that to work with wood or iron sheet you need a machine with a power of at least 600 W, but in order to make holes in thick, durable metal you need a device with a power of at least 1000 W.

- The depth of the holes also matters. It depends on the spindle stroke. This indicator is important if you have to work with thick workpieces. And, accordingly, the thicker they are, the more powerful the device should be and the greater the spindle stroke should be.

- Think about the size of the machine . So, if you have to work in a modest-sized room (like a garage), then choose a small, compact unit. It is also desirable that it does not make much noise during use. The smallest machines are tabletop. But they usually do not allow the use of drills larger than 16 mm in diameter and are not very powerful. But they are lightweight and operate relatively quietly. The best option is a vertical type of machine. It can be installed on almost any workbench and securely fastened to it using a special footrest.

Types of drills used

The vast majority of mini drilling machines are used to make holes in printed circuit boards, which are made of fiberglass. Conventional drills become dull very quickly when working with such material; they are enough to process no more than a hundred holes. It is not possible to sharpen miniature drills, given the very small diameter of such a tool. The solution is to use drills made of carbide materials that interact well with fiberglass laminate.

Micro drills for making small diameter holes

Microdrills made of carbide materials, the diameter of which can vary in the range of 0.5–2 mm, are capable of withstanding several thousand drilling cycles without losing their geometric parameters. However, such a tool should be protected from significant lateral loads, which could cause it to break.

The short video below will help you decide on the choice of drills for a miniature drilling machine.

Drills for mini machine

mini drilling machine with console

In most cases, microboards for radio devices are made using such equipment. The board is located on fiberglass, which is destructive to drills. It is enough to make no more than a hundred holes and the drill must be sharpened or thrown away. It is not possible to sharpen a micro drill with a diameter of 0.5 mm with your own hands. There are drills made of hard alloys that can withstand work on fiberglass. You can find micro diameters from 0.5 to 2 millimeters, the diameter of the tail section is standard for all - 2 mm. This drill is enough for several thousand micro holes. But they need to work very carefully, avoiding lateral pressure, which instantly breaks the fragile instrument.

Attempts to install a micro drill in a hand drill lead to its failure. It will serve well in a drilling machine for many years.

Videos on how to make a mini drill yourself:

Operations performed

Using drilling equipment you can do everything related to making a hole:

- Drilling is the rough creation of a hole in solid material.

- Reaming is an increase in the diameter of a previously created hole.

- Countersinking is a semi-finish processing of a hole in order to increase its accuracy.

- Reaming is the finishing of a hole that comes after countersinking.

- Countersinking is the creation of recesses for the heads of bolts, screws and rivets.

- Countering is the finishing treatment of the flat bottom of the recess, comes after countersinking.

- Threading – creating a threaded surface.