Radial drilling machines are used to drill through and blind holes in metal or wooden parts, as well as to perform a number of auxiliary operations - countersinking, boring, reaming and threading.

Radial drilling machine

This article provides information about radial drilling units. We will study their functional purpose, scope of application, design features and consider popular equipment models.

Purpose, functionality

Radial drilling machines are widely used in both mass and individual production to form holes in parts made of metal, cast iron and non-ferrous alloys. The main movement in equipment of this class is the rotational movement of the working tool - the drill, and its reciprocating feed.

Radial units are designed to work with large parts that are unsuitable for drilling on conventional vertical machines due to the laboriousness of moving the workpiece across the work table. Unlike standard equipment, in radial mechanisms the part fixed on the table plane remains motionless, and the spindle with the working tool moves to the required position.

The functionality of the unit directly depends on the type of working tool mounted on the spindle. Thus, modern radial drilling machines can perform the following operations:

- drilling;

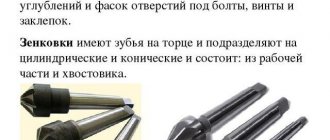

- countersinking;

- countersinking;

- deployment;

- boring;

- trimming ends;

- thread cutting (metric, inch)

The key characteristics of the equipment are three parameters: the maximum drilling diameter, the spindle overhang in relation to the bed and the dimensions of the work table, the last 2 determine the dimensions of the parts that a particular unit can process.

1.1 Radial drilling machine in operation (video)

1.2 Design features

Depending on the design features, all radial units are classified into three groups:

- universal (stationary);

- portable (used for processing large-sized workpieces, to which the equipment is supplied by a crane);

- self-propelled (moved on trolleys along rail tracks, fixed to parts using shoes).

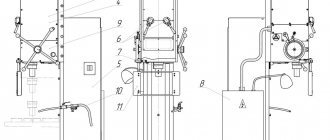

Design diagram of the radial machine 2E18P

The design of the machine consists of the following components:

- Foundation slab.

- Load-bearing column.

- Hydraulic clamp.

- Rotary sleeve.

- Traverse.

- Drilling head.

During processing, the drilling head can move both along the guide traverse and rotate within 360 0 due to the movement of the rotary sleeve. The part itself is installed on the workbench or directly on the foundation plate (depending on the design of the particular machine).

The column mounted on the foundation slab is made of a metal pipe. A lifting mechanism is installed on its upper part, moving the traverse in a vertical plane. The drilling head is a separate structural unit consisting of a speed unit, feed mechanism and spindle.

The drilling head in such equipment has a design similar to vertical drilling units, however, it has an increased number of feeds and revolutions. The increased spindle speed requires effective lubrication, which is provided by an automatic coolant system (a fluid reservoir is usually located inside the base plate).

Torque is transmitted to the spindle from the engine through a gearbox consisting of gears. Asynchronous motors are used as a drive; 3-8 motors can be installed in one machine, each of which is responsible for the movements of a specific structural unit. For example: the common 2A553 machine has 7 engines (the electrical diagram shows the location of each drive):

Electrical circuit of the machine 2A554

- M1 - coolant pump motor;

- M2 - spindle motor;

- M3 — motor for accelerated spindle retraction;

- M4 - traverse motor;

- M5 — traverse hydraulic pump motor;

- M6 - speed dial engine;

- M7 - feed set motor.

This is interesting: Drill chucks for drills and adapters: types, features

Technical capabilities of the device

Thanks to a well-thought-out design and the use of high-quality components in its creation, the machine model 2A554 is distinguished by decent technical characteristics, ease of operation and high efficiency. Weighing 4700 kg and dimensions 266.5x103x343 cm, the radial drilling machine of this model corresponds to the “H” accuracy category, which is a good indicator.

Kinematic diagram of the machine

Using this device, you can drill holes with a diameter of up to 50 mm in steel and up to 63 mm in cast iron workpieces. As stated above, using the 2A554 machine you can cut internal threads with a diameter of M52x5 for steel and M54x4 for cast iron.

The passport for the machine also indicates such parameters as the distance from the column to the spindle axis (375–1600 mm), as well as the distance from the end of the spindle to the work table (450–1600 mm). It is these characteristics that mean that it is permissible to process fairly large parts on this machine.

A notable characteristic of this device is the lifting speed of the traverse along the equipment column, which is 1.4 m/min. The machine crossbar together with the column can be rotated through an angle of up to 3600.

The dimensions of workpieces that can be processed on a 2A554 radial drilling machine are determined by the dimensions of the work table (102x255.5 mm). To expand the functionality of the machine, you can install an additional tool on the drilling head, the weight of which should not exceed 15 kg.

Workspace dimensions

The performance and functionality of this radial drilling machine is determined by the characteristics of the spindle head.

- The spindle rotation speed is in the range of 18–2000 rpm.

- Number of speeds – 24.

- Maximum torque – 710 Nm.

- Feed can be carried out in the range of 0.045–5.0 mm/rev.

- When performing a feed, a force of up to 20 kN can be created.

- The mounting hole in the spindle (Morse taper) is KM5.

Radial drilling machine 2A554 as part of a production line

To fix the moving elements of the machine in a certain position, two types of clamps are used:

- hydraulic (to stop the rotation of the column and move the drilling head along the traverse);

- electric (for braking the traverse as it moves along the column in the vertical direction).

The design of the radial drilling machine of this model is equipped with several electric motors responsible for the various movements of its elements: 5.5 kW – rotation of the spindle with the cutting tool; 2.2 kW – movement of the drilling head along the traverse. Five additional motors, which operate the coolant pump, are necessary to accurately fix the structural elements of the machine relative to each other and the workpiece.

Electrical diagram of the power part of the machine (click to enlarge)

A friction clutch is installed between the gearbox and the main engine of the machine, which is responsible for turning on, off and changing the direction of rotation of the spindle.

Design of radial drilling machine model 2A554

The elements that make up the design of the 2A554 radial drilling machine are:

- a foundation plate that serves both as the base of the machine and as a base for placing the workpiece being processed (to ensure fixation of the latter, there are several T-shaped grooves on the upper surface of such a plate);

- a column that ensures rotation of the traverse and its movement along a vertical axis (for easy, smooth and accurate rotation, a bearing unit is mounted at the base of the column);

- traverse mounted on a column;

- a working head that moves in a horizontal plane along the traverse guides;

- a mechanism that ensures rotation of the traverse and its fixation in a certain position;

- main electric motor, drive mechanism, feed control box.

Main components of the machine (click to enlarge)

The controls are located on the side of the drilling head of the 2A554 radial drilling machine, which makes working on it convenient and efficient. The operator sets the modes before starting processing, which makes it possible to increase not only its productivity, but also the accuracy of execution.

Purpose of controls (click to enlarge)

The design of the machine is designed in such a way that the working head, no matter what position it is in, is always in a balanced state, which significantly expands the technical capabilities of the device.

Machine 2A554 radial drilling type: functions and device

The Odessa ZRSS 2A554 model is a classic representative of radial drilling equipment, effective when it is necessary to metalwork large and medium-sized metal parts. These machines are large-sized and professional and have an appropriate price; they can be purchased at a price of 1,500,000 rubles and above; in used condition they are also expensive. The need for their installation must be justified; all design features and characteristics should be familiarized with in advance.

Device functions and tasks

A distinctive feature of the 2A554 radial drilling machine is the presence of a rotating column with a multifunctional working head, rotated 360° and processing stationary workpieces fixed on a heavy and stable base with dimensions up to 1600 mm, that is, medium and large. The high number of degrees of freedom of the spindle, coupled with good overload protection, reduces the time of drilling operations and increases their productivity significantly; in terms of saving energy costs, the 2A554 compares favorably with models that move massive parts on the work table.

The technical capabilities of the machine allow you to perform a variety of operations with fairly high accuracy (class H according to GOST 8-82): drilling through and blind holes, countersinking to improve roughness parameters, drilling and boring previously created, including those obtained by casting, rolling threads using taps . Provided that additional devices are attached and a special cutting tool is used, the functions of the model expand to preparing grooves, cutting round plates from thin sheets of metal, forming holes with a square cross-section, grinding in cylinders and valves, and performing other actions inherent in boring-type models.

Application area

The radial drilling machine 2A554, depending on the equipment, can be used for a wide variety of work. Examples include the following operations:

- Reaming holes.

- Drilling holes of various diameters.

- Countersinking.

- End processing.

- Cutting in the inner surface of a thread.

The radial drilling machine under consideration differs from the standard design in that most of the controls are concentrated on the body of the working head.

Setting up and setting up a radial drilling machine 2N55

The workpiece, depending on its overall dimensions, is mounted on a plate or on the machine table. The fastening of the part must be reliable, since during drilling the part can turn and cause injury to the worker and damage to the machine.

In accordance with the operation performed on the machine, auxiliary and cutting tools are selected and installed in the spindle. When working sequentially with several tools, use a quick-change chuck. In case of thread cutting, a safety cartridge must be installed.

When using heavy tools, the counterweight spring should be adjusted. The counterweight is adjusted in the lower position of the spindle.

The sleeve is installed at such a height that processing is carried out with the spindle quill minimally extended.

When choosing cutting modes, you should keep in mind the dynamic parameters of the machine (see section “Brief instructions for using machines”).

However, the choice of modes that exceed the specified parameters will not lead to the destruction of machine parts, since its power units are equipped with safety devices that protect the machine mechanisms from overload. When the fuses trip, you need to reduce the modes.

The set of speeds and feeds is carried out as follows:

Case 1 – the spindle does not work, the friction clutch control handle is in the middle fixed position. Turn the handle for setting speeds or feeds until the desired number on the handle aligns with the index rod. At the same time, a signal lamp on the remote control lights up with the inscription “set of modes”. After the lamp goes out, turn on the spindle using the friction clutch control handle.

The direction of spindle rotation corresponding to the position of the handle is indicated by an arrow on the plate next to the handle.

The mechanical feed is activated by moving handle 19 (see Fig. 15) up. Before turning on the friction clutch control handle, handle 19 must be lowered.

Case 2 - the spindle is working, the friction clutch control handle is in one of the extreme positions.” Turn the dial handle to the desired position, after the “mode set” signal light goes out, move the friction clutch control handle to the middle fixed position, then turn on the control handle again friction clutch,

During operation, the mechanical feed can be turned on and off using handles 25 (see Fig. 16). Turning on the mechanical feed with handles 25, move them away from you.

Functions performed by the RSS

The improved model has a maximum list of functions that previous versions could not accomplish:

- drilling;

- thread cutting;

- trimming ends;

- countersinking;

- boring;

- deployment.

When processing parts, especially oversized ones, the following parameters are taken into account:

- minimum and maximum drilling diameters;

- spindle overhang length;

- surface dimensions.

How to ensure high-quality and uninterrupted operation of the machine

In order for the technical capabilities of the 2A554 radial drilling machine to be fully realized, it is necessary to properly prepare it for work. Such preparation consists of arranging a level platform for installing the machine, which should be able to support its weight. All structural elements of the device must be checked for visible defects. Only after this can you begin installing the equipment. The electrical network must be designed for the power consumption of the radial drilling machine, which is indicated in the technical data sheet.

Installation dimensions of the machine and foundation diagram

There are several simple rules, following which will allow you to work effectively and safely on such a device, maintaining all its original characteristics for a long time.

- Any emergency situation that arises when working on a radial drilling machine must be accompanied by its complete disconnection from the power supply. Only after this can you begin to diagnose and repair equipment.

- Cleaning the machine, changing the position of the workpiece, tightening threaded connections and other auxiliary operations can only be performed after it is turned off.

- During operation of the machine, it is necessary to regularly monitor the condition of the counterweight, which is responsible for the performance and precise functioning of the spindle assembly.

Naturally, only operators who have the appropriate qualifications and are familiar with safety requirements can be allowed to work on a radial drilling machine.

This is interesting: Collet chuck for a machine tool: types, design, principle of operation

Technical characteristics of the machine 2A554

All main technical characteristics of the 2A554 machine are presented in the table below.

Machine characteristics

Below you can download for free the complete technical documentation for the 2A554 machine, namely the machine passport and the operating manual for its electrical equipment.

Passport for radial drilling machine 2A554 (+ manual for electrical equipment)

Design features

This 2A554 radial drilling machine has a classic layout, which is represented by the following components:

- Foundation slab. This element is the base of the 2A554 machine, which distributes the load and receives the pressure coming from all components, the workpiece and the pressure created at the time of processing the workpiece.

- Column. On the machine in question, a column is installed, which is needed to ensure rotation of the traverse and movement of the head in the vertical axis. In the manufacture of the column, cast iron is used, which copes well with vibration and other loads. In addition, cast iron does not react to moisture, which significantly extends its service life.

- Traverse. It is located on the column and is designed to move the cutting tool with control elements.

- The working head is designed directly to feed the cutting tool. For this purpose, vertical guides are located on the traverse.

- The operating instructions provide the ability to rotate the head around an axis, which can significantly speed up work.

- This model's electrical circuit provides for the transmission of forces from various motors. The spindle gearbox receives force from the main motor through the drive mechanism. Drilling can take place at a wide variety of speeds, for which it is enough to switch on the required gear. The spindle drive, if the device is in good condition, does not produce much noise, but there is a possibility that if the drive is heavily worn, there will be problems with operation. The model can have quite a lot of malfunctions; it is important to carry out maintenance in a timely manner.

- The box table allows you to fasten a wide variety of workpieces, which may differ in shape and size.

- The main electric motor is installed on the traverse, another on the column.

- Control elements are represented by handles and buttons.

- Electrical wiring is hidden in special flexible pipes that can protect them from mechanical and other impacts.

Electrical circuit of the machine 2A554

When considering the information that the manufacturer included in the passport, attention should be paid to the fact that the controls are located on the side of the drilling head. The operation of switching spindle speeds in the 2A554 machine, as well as other functions, is based on setting all parameters immediately before starting drilling. During drilling or other operation, you cannot set other parameters.

Drilling machine gearbox 2A554

Main technical characteristics

Decoding the name of the machine can indicate a fairly large amount of information, but most of it is entered in the passport.

The manufacturer included the following information in the passport:

- The accuracy class of the 2A554 radial drilling machine is N. This point determines that this model can be used to obtain very precise parts.

- The operation of this equipment determines that the largest diameter of the resulting hole is 50 mm. When drilling cast iron, the figure increases to 63 mm.

- All components of the 2A554 radial drilling machine are designed to withstand the load that occurs when producing such holes.

- The distance from the spindle axis to the workpiece is adjustable in the range from 375 to 1600 mm. Along the sleeve, the drilling head moves a distance of about 1225 mm.

- The design of the 2A554 radial drilling machine also provides for rapid movement of the hose along the column at a speed of 1.4 m/min.

- To ensure high functionality, the sleeve can be rotated around the axis of the column by 360 degrees. This feature of the 2A554 radial drilling machine allows you to process workpieces without reinstalling it.

- Technical characteristics determine that the size of the surface plate is 1020 by 2555 mm. These parameters determine what dimensions the workpiece can be installed.

- The spindle sleeve has a size of 90 m.

- The maximum spindle speed varies from 18 to 2,000 rpm. The design allows you to set the desired speed by selecting one of 24 gears. There are special handles for changing speeds.

- A hole can be created when a force of 20 kN is reached.

- The 2A554 radial drilling machine has a very complex kinematic diagram; several electric motors are installed to transmit movement. The main movement is transmitted from a motor with a power of 5.5 kW, the hose drive has a power of 2.2 kW. In addition, the 2A554 machine has a cooling system, the pressure in which is created by a motor with a power of 0.125 kW.

Kinematic diagram of the machine 2A554

When considering the features of the 2A554 machine, it is worth considering that the total power of all installed motors is 8.9 kW. The weight of this model is 4,700 kilograms, which makes installation significantly more complicated.

How to extend the life of the device?

If you follow some recommendations, you can significantly extend the life of the device. Let's take the following recommendations as an example:

- A level area should be constructed that must withstand the pressure created by equipment, tools and workpieces. Taking into account the fact that the weight of the machine is several tons, it is necessary to prepare the base.

- Before installation and operation, the structure should be checked for visible defects.

- When installing, take into account the high load placed on the electrical network. Thus, the total power of installed electric motors reaches 9 kW.

In addition, there are several recommendations that should be taken into account when operating this device:

- If any emergency occurs, the device should be completely disconnected from the power supply. Repairs and maintenance should only be carried out under conditions of complete blackout. This is due to the fact that during operation the device may move.

- Maintenance, repair, and adjustment work can only be performed when the machine is completely turned off.

- The design has a counterweight, which is responsible for the performance and precise positioning of the cutting tool. During operation, you should constantly monitor the condition of the counterweight, otherwise problems may arise.

You should also pay special attention to the selected cutting modes. So the cutting speed and feed rate determine the load experienced by the main components. As previously noted, all units are designed to withstand a load of no more than 20 kN. Otherwise, dimensional accuracy and surface roughness will deteriorate. The 2A554 radial drilling machine may have malfunctions related to the drives, coolant supply system, and the integrity of the electric motor device. Also, the fact that the workpieces are heavy determines the possibility of deformation of the body. In such cases, the positioning accuracy of moving structural elements significantly deteriorates.

Main common models

Among the models that are most similar in functionality to PCC are:

- GS535;

- 2K550;

- 2L53;

- 2N55.

The above list is far from complete; there are other units with a drilling diameter of 5 cm or more for metal and 6.3 cm for cast iron. Modern analogs of RSS are products of the Sterlitamak plant, Gomel hub plant, and Astrakhan plant. The passport and indicators of models may change; it is necessary to clarify the indicators in each specific case.