The Russian housing construction market is again moving towards stable growth - and it seems that even the experiment with the introduction of escrow accounts will not significantly affect its development. Thanks to this, the production and sale of fastening materials is becoming an increasingly promising business area.

Self-tapping screws are used both by private individuals during repairs and by large construction organizations. The production of self-tapping screws is a profitable business idea, the implementation of which will allow the entrepreneur to receive a stable income.

1. Application of self-tapping screws 2. Production technology 3. Investments 4. Registration 5. Preparing the premises 6. Equipment 7. Raw materials 8. Personnel 9. Ways of implementation 10. Payback calculation

Use of self-tapping screws

The official name of the self-tapping screw is self-tapping screw element. The material has a high fastening ability (due to the thread), which determines its popularity in the construction industry. There are many types of self-tapping screws: they differ in material and features of the structural elements (head, slot, end).

| Thread pitch | Application area | Diameter, mm | Lengths, mm |

| Average | Universal, for different types of fastening | 3.0; 3.5; 4.0; 4.5; 5.0; 6.0 | 12; 16; 20; 25; 30; 35: 40; 45; 50: 60: 70: 80: 90:100:120:140; 160; 180; 200; 220 |

| Frequent, carving in 2 passes | Metal sheets up to 0.9 mm thick without dowels. You need to drill a hole first | 3.0; 3.5; 4.0; 4.5; 5.0; 6.0; 8.0 | 12 — 200 |

| Rare | Soft materials without dowels (wood, plastic, plaster) | M | 16 — 150 |

| Medium, herringbone profile | Concrete, brick, hammered into dowel | 3.0; 3.5; 4.0; 4.5; 5.0; 6.0; 8.0 | 12 — 200 |

| Asymmetric | Elements of modern wooden furniture. Chipboards, plywood. You need to drill a hole with a diameter of 4.5 or 7 mm. | 5.0; 7.5 | 40 — 70 |

| Variable with notch | Concrete, brick, without dowels (dowels). It is screwed into a hole 15 mm longer than the self-tapping screw. | 7.5 | 70 — 200 |

Self-tapping screws are used to work with:

- metal products;

- wood products;

- plasterboard sheets;

- sandwich panels;

- window profiles.

Requirements for premises for the production of self-tapping screws

To produce self-tapping screws, a small room with an area of 50-70 m2 is sufficient. The basic requirements for such premises must be observed. First of all, it should be taken into account that the volume of the production premises must be at least 13 m3 and at least 4 m2 per worker. The height of the premises is calculated based on the dimensions of the equipment; in our case, the equipment is not large, but the regulated ceiling height must be at least 3.2 m.

It is undesirable to locate a workshop for the production of self-tapping screws in a basement or semi-basement; this may raise questions from regulatory authorities. Pay attention to the need for adequate lighting and ventilation for production areas.

If you use galvanic baths to increase the resistance of self-tapping screws, then the requirements for the premises will be more stringent. You can familiarize yourself with the operating requirements when choosing specific items of equipment.

Of course, in practice, all of these requirements are not always met, but if your employee receives a work-related injury, rest assured that all of the specified parameters will be checked and if it is proven that the production premises do not meet the necessary parameters, then you will be held criminally liable.

You can rent or build the necessary premises. In our opinion, when starting any business, it is better to minimize investments in it, which will reduce financial risks in the event of unfavorable market conditions. Therefore, at the initial stage, it is better to rent production premises.

Average rent for renting industrial premises in Russia, rub.*

| ROOMS 50-60 SQ. M | ROOMS 70-80 SQ. M. |

| 22 284 | 25 326 |

*according to analysis of Avito advertisements as of September 12, 2018

However, if you have the necessary funds, you can build your own workshop premises. For the production of self-tapping screws, the easiest way to build a production facility is from sandwich panels. Providing fairly low heat loss rates, such structures are characterized by low cost and short installation time. The cost of such a structure starts from 900 – 1200 rubles per square meter. The building is being assembled within a few days.

Pay attention to such an important point as the availability of communications on the site for the construction of buildings. If the building itself can be assembled within a few days, the process of connecting communications will take several months. The process of connecting natural gas is especially long, which can be used both for heating and for some stages of the production process in the production of self-tapping screws. Such a connection may take you at least six months and will require several hundred thousand rubles, even if the gas pipe runs in close proximity to the industrial premises being built.

Market situation

The self-tapping screw business is directly related to the construction sector, since its participants are the main consumers of screws.

Due to the difficult international situation and problems in the economic sphere (domestic and global), the last few years have been marked by a crisis in many industries in Russia, including construction.

Now the situation is returning to normal. The construction market fully recovered by the end of 2022. According to data for the first quarter of 2018, 19.6% more apartments were commissioned compared to the same period in 2022. During this period, 72.5% more residential buildings were commissioned. The general situation, the macroeconomic environment, indicates an increase in the consumption of building materials - that is, in favor of the business of producing self-tapping screws.

Production technology

The process of manufacturing self-tapping screws is automated. The equipment is responsible for the entire production process. The required raw material is steel wire (rolled metal).

Let us describe the process of manufacturing products using the cold stamping method:

- We make preparations. We cut pieces of equal length from rolled metal (blanks).

- We form the caps and apply the carvings. In fact, you get ready-made self-tapping screws.

- The products are placed in an oven, where they are hardened to increase their strength.

- We wash the screws to eliminate interference during further processing.

- We spray anti-corrosion coating on clean screws.

The finished product becomes highly durable, capable of withstanding the negative effects of the environment for a long time.

Types of machines

Depending on the control method, you can purchase the following unit:

- Semi-automatic.

- Auto.

According to the principle of operation, equipment is distinguished:

- Cold heading . Cuts blanks and forms heads. It is divided into units with semi-protective and fully protective casing. Needs adjustment and special technical care.

- Thread rolling . It has a replaceable die that rolls threads.

Based on size and power, the following models are distinguished:

- Mini machines.

- High-power installations.

Depending on the technical condition, you can purchase the machine:

- New.

- Used.

According to the country of manufacture, the unit can be:

- Imported.

- Domestic.

You can buy a machine for making the following self-tapping screws:

- On wood.

- For metal.

- Universal.

Depending on the manufacturing company, you can take a machine of the following brand:

- LianTeng.

- SAMSTAL.

- INNOR.

- FOB.

- Candid.

At the place of purchase, the equipment may be:

- Purchased from a local specialty store.

- Ordered from an online trading company.

- Taken from a private advertisement.

- Purchased directly from the manufacturer's warehouse.

Machine WN0564 - price 727,250 rub.

Investments

The main cost item for starting a business is the operating line for the production of screws, which operates automatically. Automation is more expensive, but more profitable in the long term. You don't have to hire a large staff.

| Expense item | Cost, rub. |

| Registration | 10 thousand |

| Premises for rent, 100 sq. m | 50 thousand |

| Equipment | 2 million |

| Raw materials, months norm | 150 thousand |

| Salary, 4 people. | 100 thousand |

| Additional expenses | 200 thousand |

| Total | 2.51 million |

The cost of renting premises is indicated subject to working in a city with a population of up to 500 thousand people. We rent premises that are ready for use and do not require major repairs. The costs of all preparatory work are included in additional costs.

How much money is needed to open a company producing self-tapping screws?

Entrepreneurs who have been producing self-tapping screws for a long time and know all the nuances of this business well, claim that you will need 250-350 thousand rubles to start. This amount is enough to register a company, purchase mini-machines, rent premises, purchase raw materials and pay staff until the enterprise reaches self-sufficiency. If you are planning to create a real plant for the production of self-tapping screws, then you will need an amount of at least 1 million dollars.

Are you thinking about where to invest and what business to start? Watch our free courses on investing and making money. Perhaps they will help you choose the right path or suggest a new idea for making money.

Registration

A business producing self-tapping screws can be organized as an individual entrepreneur or a legal entity. However, LLC opens up great opportunities for selling products, allows you to increase sales, production capacity, and financial and economic indicators of the business.

Construction companies and large retail chains prefer to cooperate with legal entities. Working as an LLC, you can find regular large customers, develop stable sales channels and gain a foothold in the market.

An individual entrepreneur is much easier to register and maintain documentation.

Business registration

You can open a production workshop either as an individual enterprise or a legal entity. Both options have their merits. An entrepreneur should remember that if they plan to cooperate with large companies, they should form an LLC. It is this legal form that suppliers of raw materials, retail chains, and machine-building plants trust most of all.

The production of self-tapping screws is not a licensed activity. There is also no need to obtain special permits to conduct business.

When filling out registration documents, select 25.94 “Production of fasteners” as the OKVED code and choose a simplified taxation system with a rate of either 6% of total income or 15% of net profit.

Preparing the premises

You need a room of about 100 square meters. m. There will be a production workshop with equipment, warehouses for raw materials and finished products, staff premises, and a place for loading/unloading goods.

The premises may be located on the outskirts of a populated area. It must be connected to the electrical network, a power cable (the equipment will consume a lot of energy), and must comply with fire and sanitary safety conditions and be connected to communications. An important condition is the availability of automobile access to the site.

Production premises should not be rented far from sales markets, since costs for fuel and fuels and lubricants increase unjustifiably. It is better to rent equipped empty space at a large enterprise.

Equipment

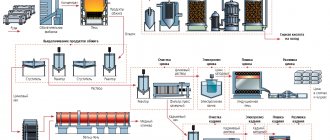

The operating line for the production of screws consists of several machines:

- Drawing machine.

- Cold heading unit.

- Thread rolling machine.

- Tempering furnace.

- Galvanic bath.

- Drying centrifuge.

The drawing machine draws the wire, heats it, and cuts the blanks of the required size and diameter. The point and heads of the screws are formed on a cold heading machine. A thread of the specified size is cut on a thread rolling machine. The self-tapping screws are hardened in a hardening furnace. In a galvanic bath, an anti-corrosion coating and zinc anode are applied to them. The finished screws are dried in a centrifuge. Next, it remains to check the quality of the output material and package it. The cost of such a line according to the terms of the business plan is 2 million rubles. Productivity 180-200 pcs./min.

Raw materials

The starting material is steel or brass wire. The material must be selected based on the final purpose of the screws. For example, screws from:

- stainless steel - used when working with wood;

- high-carbon steel - used where a high hardness coefficient is needed;

- brass - for finishing work.

We deliver spools of rolled metal wire to production. It is easy to get it in Russia. One reel produces approximately half a million self-tapping screws. It is better to purchase it directly from the manufacturer at wholesale prices. This will reduce costs.

Staff

The advantage of automation is that you don't have to hire many workers. After delivery, the manufacturer performs the initial setup of the machines. The craftsmen are left to monitor their work and ensure the continuity of the production process.

No more than two or three people will be required per shift. They must undergo special training and be able to operate machines. They can also be storekeepers, deliver raw materials to the workshop, store finished products, and load them into vehicles.

You will also need a driver with a car, an accountant (can be hired through outsourcing), a sales representative who will negotiate with networks and construction companies (the entrepreneur himself can take on this work at first).

Personnel

Naturally, a large workshop cannot do without workers and maintenance personnel. But small production is quite possible to carry out independently. Modern equipment is fully automated and does not require “manpower”. Installation, installation, and maintenance of machines are usually carried out by their manufacturer (you should immediately check when purchasing equipment). All other production processes are decided by the entrepreneur himself. It is advisable to outsource accounting and legal support for business.

Ways of implementation

It is recommended to use all possible implementation paths:

- enter into long-term contracts with construction companies;

- work with specialized organizations (for example, for the production of windows, doors, furniture);

- sell products to construction stores and networks;

- interact with private contractors.

Think over your pricing policy. Reasonably low prices for quality products are an obvious way to gain loyal customers. It is also recommended to think through various promotions that encourage customers to buy more and more often.

Develop an assortment. Start producing and selling several varieties of self-tapping screws, identify those that are in demand and focus on them. Nails and anchors can be produced as additional products.

Potential consumers of hardware products:

- construction organizations, including small teams for finishing work;

- enterprises producing household appliances;

- furniture workshops, up to private small workshops;

- manufacturing enterprises associated with the production of construction and finishing materials;

- markets with construction assortment;

- trade organizations, both large (wholesale) and small stores.

Large and medium-sized construction, industrial and furniture organizations, as well as wholesale trade enterprises and large construction stores will be the most likely and convenient for cooperation.

Advantages of working with them:

- work is carried out under long-term contracts;

- the opportunity to receive advance payment for the release of future products;

- constant source of sales;

Work with small enterprises at the stage of production formation should be based only on the principle of advance payment.

Sales and deferred payment are unprofitable for several reasons: small organizations will not bring in much revenue, but in case of delays in payments, a significant amount of time will be spent on collecting debts than on engaging in their main production.

Payback calculation

Let's calculate the payback and profitability according to the business plan for self-tapping screws:

- The amount of initial investment is 2.51 million rubles.

- The total amount of expenses per month is 350 thousand rubles.

- An operating line with a capacity of 180 - 200 screws per minute in 1 shift (8 hours) within 22 days (month) will produce 1.9 - 2.1 million pieces. self-tapping screws With an average price of 1 screw - 25 kopecks, monthly revenue will be 475 - 525 thousand rubles.

- Minus monthly costs, net profit is 125-175 thousand rubles.

- You can reach the break-even point in 15-20 months.

It will be possible to fully recoup the initial costs in about 1.5 years. Then the entrepreneur will begin to receive a stable high income. However, such a forecast will come true only with constant production and marketing of manufactured products.

With proper organization of the production process, you will be able to create a business as strong as the profiles assembled using your screws. The business plan for the production of self-tapping screws presented in the article will help you better understand the features of manufacturing fastening tools, we will tell you about the main stages of creating a mini plant and the nuances important for achieving success.

Approximate prices

In Russia, new machines for the production of self-tapping screws are sold for 170,000-2,570,000 rubles . Approximate prices for equipment depending on productivity and country of manufacture are shown in the table.

| Types of machines by country of manufacture | Productivity in pieces per minute | Minimum cost in rubles |

| Domestic | 50-70 | 170000-200000 |

| Chinese | 250-300 | 500000-700000 |

| German, Austrian | 300-500 | 1500000-2200000 |

The cost of units for the production of self-tapping screws of popular models is shown in the table below.

| Brand | Country of Origin | Unit type | Cost in rubles |

| 4R-40 | China | cold heading | 1112595 |

| CTR6HN | Taiwan | thread rolling | 954300 |

| FET-ID5x85 | China | cold heading | 1482300 |

| CTR8H | Taiwan | thread rolling | 1284630 |

| WN0564 | China | cold heading | 727250 |

| YH 1552 | Taiwan | cold heading | 2570000 |

| AS3016 | Russia | cold heading | 220200 |

Machine YH 1552 - price 2,570,000 rub.

Used machines for making self-tapping screws are sold at prices ranging from 100,000 to 1,200,000 rubles .