Today, knitted knitted gloves are a very popular product. They are necessary in any type of production, for working in fields and garden plots. In everyday life, ordinary minor repairs around the house are also not complete without protective cloth gloves.

Cotton gloves are knitted in a special way on special equipment for the production of cotton gloves.

You can choose machines for the production of cotton gloves based on their cost. There are electric and electronic devices, both options have their advantages. There is only one drawback - a significant difference in price. Everything will depend on the amount of initial investment. At the beginning, it makes no sense to buy very expensive equipment; it is better to improve production as the business develops.

Another option for cotton gloves is knitted products with polymer impregnation. Manufacturers of cotton gloves have further strengthened them by covering them with a PVC compound. This coating is used to extend the life of the glove and also reduces friction and stress on the palm. Various additives, special heat-resistant and especially strong threads used in the production of cotton gloves not only extend the service life of the product and protect hands. Changing the knitting composition expands the scope of use of gloves.

It is not necessary to rent production space in a city or urban area. Rural areas may also be suitable. At the initial stage, this will significantly reduce the cost of producing cotton gloves. The production of knitted gloves is a popular business.

Business plan for the production of knitted gloves

Why do you need a business plan? A business plan is a documentary representation of the strategy of a future enterprise for the production of cotton gloves. In short, your cheat sheet to action. It is provided to financial institutions as one of the documents if you apply for a loan to start or develop your business.

To develop a business plan for the production of cotton gloves, there are many different teaching aids, but they are all very specific and understandable only to accountants and economists. Meanwhile, any person who decides to open their own business should be able to independently model a business strategy for the near future. You can resort to the help of ready-made business plans for the production of cotton gloves.

Registration

In order for an enterprise to operate officially, you will need to register with the local branch of the Federal Tax Service as an individual entrepreneur. This form is better suited in this case than LLC. Completing the documentation takes a couple of days; you need to bring the following documents to the tax office: an application, a passport of a citizen of the Russian Federation, a receipt of paid state duty. We recommend choosing the simplified tax system 6%, it is the most profitable and convenient.

Do not forget to indicate the OKVED codes that correspond to the selected activity. For the production of gloves, code 13.99 “Production of other textile products not included in other groups” is suitable.

Introduction

The production of cotton gloves is considered a promising and profitable business. The market for the products ranges from small shops and market stalls to supermarkets and other large stores. Everyone needs household gloves.

In addition, gloves are products that have a short service life, which means they will always be needed. Such products are purchased in small quantities, even just for home use. This fact suggests that there will always be a need for gloves.

The material used is cotton or wool - natural, hypoallergenic, easily disposed of or recycled. The equipment (various machines for knitting gloves) is compact, low noise and has high productivity. Products have no shelf life if storage conditions are met.

Advertising and Marketing

Business practically does not need advertising. It is planned that the owner himself will visit construction and hardware stores in the region and negotiate cooperation with their owners. It is most profitable to work with large networks, construction companies and municipal institutions, since they provide regular orders, but it will be difficult to get them as partners. At the first stage we will do without this.

It is planned to offer volume discounts. 5% - for a batch of more than 500 pieces, 10% - for a batch of more than 1000 pieces, 15% - for a batch of more than 10 thousand pieces.

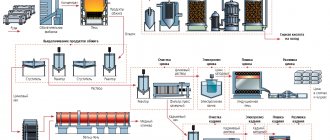

Organization of production of construction gloves

production technology:

A. Knitting gloves without finishing the edges of the cuffs

b. Knitting an edge on a serger

V. Special PVC composition on the palm side

d. Drying and packaging of finished products

technical equipment of production:

A. Electric machine for knitting gloves Aurora 12 in the amount of 7 pieces. The total cost is 750,000 rubles. Productivity of one machine is 15 pairs per hour

b. The Salyut 2 edge processing device is designed for overcasting the edge of a knitted product. Price per piece is 32,000 rubles. Productivity: 180 pairs of gloves per hour

V. Device for applying PVC coating, PPM - 1, in the amount of 1 piece. Cost 225,000 rubles. Productivity 250 pairs per hour

Drying apparatus. Used to dry fresh PVC coating. Cost 50,000 rubles. Dries up to 100 pairs at once

d. Packaging machine, designed for packaging finished products. The cost is 18,500 rubles. Packs 400 pairs of gloves in one hour

Raw materials for the production of cotton gloves are supplied in thread spools protected with film. Threads can be very different in composition and weight. Usually it is wool or cotton thread, sometimes artificial fibers. For intermediate braiding, latex fiber braided with cotton is used by an automatic machine for overcasting the edge of the product.

It is possible to weave a special, especially strong thread into the glove; this will make it possible to protect the palm from serious cuts and significantly extend the service life of the knitted product. Also, to protect the hand from fire, Teflon thread is used in the production of gloves. Such products will cost much more than the original ones, not 11-12 rubles, but about 28-30 rubles per pair.

Approximate consumption of raw materials:

- latex thread 240 rub. per reel - 1 gram per pair;

- thread for overcasting the edge of the product 220 RUR. per reel - 0.3 grams per pair;

- yarn, thread 100 rubles per unit - 40 grams per pair;

- thermoplastic polymer PVC - consumption 6 grams.

The required amount of spare raw materials for the first three months of work totaling 180,000 rubles.

How to register?

The production of work gloves, as a business, requires official registration with the relevant government agencies. If the products will be sold at retail (to ordinary citizens), registration of an individual entrepreneur is sufficient. If you want to expand your sales market and cooperate with companies, you will have to register an LLC. The next stage is choosing the form of taxation. Here, options with the simplified tax system or UTII are possible. The main volume of finished products will go to companies, so it is worth choosing a form of taxation with VAT (when registering an individual entrepreneur, 4-NDFL is suitable).

Staff

The machine for cotton gloves Aurora 12 automatic is a full cycle equipment. The knitter monitors the timely change of the spool, and also takes out ready-made gloves from special storage units.

To service 7 machines for the production of gloves, you will need 3 people, subject to a shift work schedule.

- an accountant, he can also be a merchandiser;

- manager for searching and attracting clients;

- marketer - may be needed at the initial stage of developing a business project;

- advertising specialist;

- one worker monitors the timely replacement of thread on the machine, services 7 machines, the maximum number of machines for 1 person is 60 pieces;

- one employee operates the machine for overcasting the edge of the product, threads the rubber thread, and controls the process;

- employee involved in drying gloves;

- one employee coats gloves with PVC mixture. He can also perform the additional function of a foreman - a machine operator for the production

x gloves.

Accountant, manager, marketer, advertising specialist - these people can be hired for a short period of time through companies that provide special services for regulating business processes.

Purchase of raw materials

It is important to buy high-quality and inexpensive raw materials from which the gloves will be made. For production we will need cotton yarn, latex threads, overlock threads, plastisol and elastic. It is worth entering into long-term contracts with suppliers to avoid production downtime due to a lack of raw materials. Moreover, for a large and long-term order, many suppliers are ready to give good discounts. You will have to spend money on raw materials right away, and then make new purchases every month. The monthly purchase of raw materials will cost approximately 60 thousand rubles. This will be enough to produce 60 thousand units of gloves. It is worth choosing Indian yarn, its quality indicators are the best at the moment.

Production room

To provide technically comfortable equipment with an area of 7 machines for making gloves x b, you will need a room with an area of 50 to 80 square meters. The room may not have special technological solutions, the main thing is that it is dry, warm in any season and has electrical wiring capable of withstanding the existing load (approximately 380 kW).

Such sites can be found in urban industrial areas. zones, or even closer to the center in old factory areas. The cost of monthly rent of the premises will cost 200-400 rubles per square meter.

Production may be located on the outskirts of the city, but if you are a future large manufacturer of cotton gloves and are launching a large project designed for wholesalers, it is better to look for suitable premises closer to the city.

Step-by-step launch instructions

- The type of gloves you plan to produce is determined - the most popular and affordable in comparison with competitors.

- Perform market analysis to determine competitive pricing and distribution channels. These can be wholesale and retail stores with an assortment of construction and gardening equipment, as well as large manufacturing, construction, installation and other companies - including municipal ones - to which you can sell goods at more favorable prices.

- A business plan is drawn up taking into account the seasonality of sales: in the warm season it is obviously larger.

- Investments are attracted: own funds, investor funds, credit or through government subsidies.

- Formed as an individual entrepreneur or LLC. OKVED in this industry is 19/14/13, and the taxation system can choose a “simplified” profit tax, since the flow of money will not be stable, if only because of seasonal fluctuations in sales.

- A suitable premises is located and rented/purchased, the necessary repair work is carried out, and areas of the area are fenced off for various needs.

- Purchase of equipment.

- Hiring staff.

- Start of production.

- All the nuances are honed in direct work.

Promotion of goods and organization of sales of cotton gloves with PVC coating

As already noted, knitted cotton gloves reliably and for a long time enjoy great consumer interest. Workers of construction companies, owners of gardens, vegetable gardens, people employed in the agricultural industry are interested in them. The sales market for this product has every opportunity to grow due to large-scale construction throughout the country.

Gloves specially reinforced with various fibers will be in demand by port and shipbuilding organizations.

Directions for selling knitted gloves with PVC coating

- construction markets and supermarkets;

- auto markets;

- sawmills;

- large wholesale companies supplying consumables to enterprises;

- agricultural stores;

- municipal offices, housing and communal services and other budgetary organizations willingly enter into contracts for the purchase of such gloves.

Search for sales channels for finished products

This type of business requires almost no advertising campaign. Usually, the owners independently visit stores selling cotton gloves and offer cooperation. The most profitable buyers are large retail chains, municipal institutions and construction organizations that are ready to regularly purchase gloves in large quantities.

Since products are in demand in a wide variety of areas, it makes sense to produce products in several versions: different densities, colors, sizes, as well as with or without PVC coating. This solution will allow you to gain a significant competitive advantage.

Calculating the payback period for the production of cotton gloves

Estimated price of consumables (quantity/price/consumption per pair)

- latex thread, braided - 2.5 kg / 1000 rubles / 1 gram;

- thread for processing the edge of the cuff - 1.5 kg / 500 rubles / 0.3 grams;

- yarn and thread mixtures, cotton, wool, artificial - 150 kg / 22,500 rubles / 40 grams.

Cost of material for one pair of gloves (weight in grams/cost/one pair)

- wool, artificial fiber, cotton yarn, mixture - 40 grams/4.60 rubles;

- latex fiber - 0.7 grams /0.43 rub.;

- stitching thread - 0.3 grams / 0.1 rub.;

- PVC mixture - 6 grams/0.6 rubles;

- needles as needed.

The total cost of one pair of gloves is 5 rubles 63 kopecks.

Amount of electrical energy consumption to produce one pair of gloves

- The Aurora 12 glove machine will produce 15 pairs of gloves / hourly service cost will be 0.21 rubles.

- The Salyut 02 automatic glove edge processing machine produces 187 pairs per hour, the amount of energy consumed is 0.001 kW per pair

- Machine for applying PVC film, 250 pairs per hour, energy consumption 3 kW

- Packaging machine, 400 pieces per hour of operation, with a consumption of 0.18 kW.

Total energy costs for the production of one pair of gloves will be 0.21 rubles or 21 kopecks. The total cost of a pair of gloves will be 5.84 kopecks.

Calculation of profitability, payback

The main investment for the purchase of equipment is 1,140,500 rubles, of which:

- expenses for equipment will amount to 1,080,500 rubles;

- a three-month supply of raw materials for the production of 48,000 pairs of cotton gloves for a total amount of 180,000 rubles;

- production area 50 square meters;

- rental cost 250 rubles per sq.m., total 12,500 rubles per month;

- working hours from 8.00 to 17.00, or from 20.00 to 4.00;

- number of workplaces:

- knitters - 3 people, with a salary of 10,000 rubles per month

- one foreman - adjuster (part-time) -12,000 rubles per month

- accountant - 1 person 12,000 rubles per month

- marketer (for three months) 10,000 rubles per month

- advertising specialist (for three months) 10,000 rubles per month

Approximate revenue on seven machines in 21 working days

Production at the final stage will be 15,000-15,500 thousand pairs of gloves. To calculate, let's take the approximate cost of a pair at 12 rubles. We get 15500 x 12 = 186000 rubles.

Based on the above calculations and electricity costs, the price will be 5.84 kopecks.

With the listed costs, the cost of running the enterprise per month will be:

Expenses - 69,500 rubles

- salary 44,000 rubles;

- rent 12,500 thousand rubles;

- utility bills, electricity 8,000 rubles;

- taxes 12,000 rubles;

- other expenses 5000 rubles.

Profit

Possible profitability of your enterprise:

- profit - 186,000 rubles;

- capital investments - 90,520 rubles;

- monthly expenses - 69,500 rubles;

- gross profit - 95,480 rubles;

- net profit amounted to 25,980 rubles.

Approximate calculation of return on fixed capital

Net profit is 25,980 rubles, main investments in the amount of 1,040,500 rubles, we get the figure 40 (months). That is, your enterprise will pay for itself within three years. Let's make small adjustments to the fact that accounting can be done independently and there will also be no need for some specialists, since they have already completed their stage of work.

The more specific the numbers, the greater the likelihood of success.

To make gloves, it was necessary to purchase glove machines. Manufacturers in China wrote that the machine is configured in such a way that it does not require any special actions.

The glove will be made independently. In general, production will be fully automated; only packaging is required.

If you wish, of course, you can purchase a special packaging machine for gloves. You can search for information on YouTube yourself; there are many videos about these machines. But I considered the purchase of this equipment to be overkill, since this packaging machine costs a lot of money.

Purchase of equipment

At the first stage, we planned to purchase five machines. I would like to say that the cost of a new machine is about 190,000-210,000 rubles. Production machines are divided into classes (in fact, like gloves), we settled on the 10th and 7.5 classes. These gloves are in greatest demand.

And by the way, the yarn must also correspond to the class of gloves:

- 7.5 class is a rougher glove, it is used when working with rough surfaces, the structure of the glove itself is looser;

- 10th grade - on the contrary, a thinner glove, but thanks to the knitting structure it is stronger.

At cost, class 7.5 gloves are more expensive. Regarding the performance of automatic knitting machines, after the launch of the line, I had great doubts. When launched, the machines did not dispense more than 120 pairs per day each. It makes no sense to work around the clock on such equipment, since the equipment is expensive, so we did not resort to this method.

However, here we decided that we were in a hurry with the purchase of new glove machines. If the equipment has already been used, then the cost is correspondingly reduced by almost half. You can verify this by looking at advertisement sites for the sale of these machines.

In addition to the machines themselves, it is necessary to purchase a compressor. We took it for about 10 thousand rubles.

Machines may also differ in how they process the top of the glove:

- The machine is fully automatic. Processing – x-thread. No additional action is required.

We had three tenth grade looms with x-thread.

- Machines without x-thread. The top is additionally processed with a manual overlog.

For such machines, a manual overlog is required (specifically for work gloves). We took it for 48,000 rubles. A glove of this treatment can be sold at the highest price and with the help of this treatment a double winter glove can be knitted.