Situations in which adjustment is necessary

New chainsaws are supplied by the manufacturer with already adjusted carburetors. This is called standard adjustment. But for the normal running-in process, it is necessary to reduce the maximum engine speed and adjust the carburetor. After break-in, the chainsaw needs fine tuning to achieve maximum engine efficiency.

Also, a signal for cleaning and adjustment is increased fuel consumption, which negatively affects the operation of the exhaust system. Simply put, the chainsaw begins to smoke heavily and the muffler becomes clogged with carbon deposits, which in turn will lead to a decrease in power.

If there is too much fuel in the mixture, engine parts are poorly lubricated and premature wear occurs. Also, a poor quality mixture can cause the engine to jam due to overheating (this is one of the reasons why the chainsaw will not start).

This is what a jammed, overheated piston looks like from a disassembled chainsaw with an incorrectly configured carburetor.

Adjustment is necessary when the engine does not idle, stalls, or does not develop full power. Carburetor adjustment should be carried out with clean air and fuel filters. We also recommend reading an interesting article that details the main reasons why a chainsaw starts and immediately stalls.

Recommendations for use

To increase the life of the tool, you must follow some rules. This primarily concerns the saw chain and guide bars. It is recommended to replace the chain every three hours and turn the guides 180 degrees. As a result, these elements will wear out evenly, which will extend the life of the entire tool.

During operation, it is important to constantly monitor the cleanliness of the chainsaw. When sawing wood, the unit quickly becomes clogged with sawdust, which must be removed in a timely manner. Contamination of the technological holes can cause problems with the operation of the fuel system. It is also important to change oil and other consumables on time.

Tools

To adjust, you will need the following tools: tachometer, screwdrivers, and in rare cases, special keys. Let's look at their purpose, necessity of availability and cost.

| Tool | Purpose | Price | Availability |

| Tachometer | Allows you to accurately determine engine speed and adjust them according to the requirements of the manufacturer. You can do without it by tuning by ear, but you need to understand that the tuning will not be done accurately. Therefore, in our tool repair service we use a high-quality and inexpensive tachometer, which can be ordered on Aliexpress using this link. | 900 – 2000 rubles 500 – 600 rubles on Aliexpress | Recommended |

| Screwdriver set (slotted screwdriver) | On most chainsaws, you will need a simple flathead screwdriver to turn the adjustment bolts. | 300 – 700 rubles | Necessarily |

| Special adjustment key | For example, to adjust the carburetor on Husqvarna chainsaws, you will need a special key; it is available only in certified service centers authorized for repairs by the manufacturer. This measure is aimed at reducing breakdowns due to incorrect settings by inexperienced users and those who carry out repairs without official permission to do so. | Out of stock | Depends on the chainsaw |

If possible, setting up a chainsaw should be carried out in official service centers that have a manufacturer’s certificate and appropriate permission to carry out repair work.

Video text

Find out how to fix the most common chainsaw problems using just two standard wrenches!

1. The chainsaw does not start 0:30 1.1. Checking the fuel mixture 1.2. Checking the spark plug of a chainsaw 1.3. Checking chainsaw compression 1.4. Checking the chainsaw carburetor

Read also: Uoni 13 55 GOST characteristics

2. The chainsaw chain does not rotate 5:46 2.1. Removing the chainsaw chain from the brake 2.2. Development of a chainsaw tire sprocket

3. The chainsaw does not cut 6:45 3.1. Checking chainsaw chain teeth 3.2. Checking the sharpening of the chainsaw chain 3.3. Checking chainsaw chain lubrication

What to do if nothing helps 7:58

Stepan Latypov, director of the Belarbo enterprise, says:

A chainsaw is a valuable tool in the household today. For many owners of country houses, this unit has become indispensable. Despite its fairly simple design, the tool sometimes fails. However, almost anyone with a certain amount of knowledge in the field of technology and a set of necessary tools can repair a chainsaw on their own.

How is the carburetor adjusted?

The chainsaw setup algorithm is quite simple and consists of the following steps:

- Warming up the engine to operating temperature ( the adjustment must be carried out only on a warm engine , this will allow for more accurate adjustment).

- Adjusting the engine for smooth operation at low speeds.

- Setting the carburetor to properly supply the fuel mixture at maximum speed.

- Precise adjustment of the carburetor for idle operation.

- Checking the chainsaw in all modes.

Almost all carburetor models have three adjustment screws.

- Screw (T) is responsible for fine adjustment in idle mode.

- Screw (H) adjusts operation at maximum speed.

- Screw (L) regulates mixture formation at low speeds.

By tightening screws (L) and (H), the fuel supply and mixture become leaner, and the speed increases accordingly.

Carburetor adjustment screws L - minimum speed and H - maximum engine speed.

Now let’s look at how to properly adjust a chainsaw carburetor in more detail.

Cylinder-piston group

It happens that the engine does not start or functions poorly due to low pressure in the cylinder. The malfunction may consist of a piston, cylinder or bearings that have become unusable, or piston rings that have sunk. You can look at the problem in general terms; to do this, you need to remove the muffler and inspect the system.

You can measure the compression in the engine by placing a compression gauge in the spark plug hole. After time, you can draw conclusions based on the results of the measurements. The problem can only be resolved by completely disassembling the system. If scratches or chips are visible on the piston, it needs to be replaced. The piston ring must be installed in its correct place, clean and intact.

Process description

- If the chainsaw carburetor is not adjusted and it is not possible to start the chainsaw, then the adjustment begins by installing screws (L) and (H) to the standard setting position. This is 1/5 turn of the screws until they are fully tightened.

- After which, you need to start the engine, let it run a little and warm up.

- The next step is setting the low speed mode. Optimal engine operation at low end can be achieved by adjusting the screw (L) and idle speed (T). To do this, first screw (L) is tightened until maximum engine speed is reached, then released by 1/4, and screw (T) is used to return the idle speed to normal.

- After adjusting the operation at the “lower” range, the traction and maximum engine speed are adjusted. To do this, slowly tighten the screw (H) and check the speed using the readings of the electronic tachometer. It is unacceptable to exceed the maximum engine speed declared by the manufacturer! The ideal option for this would be to use an electronic tachometer, which can be bought at a low price on Aliexpress.

Buy tachometer on Aliexpress

Location of carburetor adjustment screws on a Husqvarna chainsaw.

An important step is to check the saw in all operating modes after adjustment; to do this, you need to let the chainsaw cool, and then start it according to the cold tool starting algorithm. If the saw starts up normally and idles smoothly, you need to check how it cuts. If during the inspection process shortcomings in the power of the chainsaw are discovered, then it is necessary to repeat the adjustment of the screw (H) by unscrewing it and checking the traction in operation.

Loss of traction at the maximum speed recommended by the manufacturer is an indicator of CPG wear or poor fuel quality. Speaking of fuel, 90% of malfunctions are caused by fuel. Which one should I use? 92 or 95? How long can it be stored? We answered all these questions in the article about what kind of gasoline to put in a chainsaw.

We recommend watching a video on how to clean and adjust a chainsaw carburetor, the author of which also talks about the harmful effects of fuel on the components of the carburetor. The example shows how to restore your carburetor using an inexpensive repair kit.

What to do if you have no experience and can’t adjust it yourself?

Due to lack of experience, adjusting the chainsaw may not work the first time, the saw will begin to work unstably, and starting the engine will be difficult. In this case, you need to repeat everything all over again, setting the adjusting screws to the initially recommended position (written at the beginning of the article, immediately after flushing the carburetor) and then follow the steps of the “Step-by-Step Instructions”.

For reference! Chinese carburetors are cheap and cost 1000-1500 rubles (you can look at how much it costs for your saw on Yandex.Market), some people come to the conclusion that it is easier to buy and replace, in the hope that it comes already configured and screwed on factory settings are set. This opinion is erroneous; any carburetor needs to be adjusted after installation.

Adjusting the carburetor of a Chinese chainsaw

Carburetors installed on Chinese-made saws are made similarly to European ones and have the same adjustment screws.

Adjusting the carburetor of a Chinese chainsaw follows the algorithm presented above, and differs in that when initially adjusting the screws (L) and (H), they must be turned out two turns. Next, the carburetors of the Chinese saw are adjusted in the same way as European ones.

Read about how to adjust the carburetor of a Chinese chainsaw in just 3 steps here (a very useful article). As an example, we recommend looking at the article about adjusting the carburetor on a Carver chainsaw.

General principles of disassembly

Basically, all chainsaws have the same components, which are dismantled according to a certain scheme. If the saw assembly is Chinese, then there is nothing to worry about: most often they are made in the likeness of European models. How to disassemble a chainsaw:

- The clutch cover is removed.

- The starter cover is removed. To do this, you need to unscrew the screws and remove the cross handle.

- To remove the handle, you need to remove the cover that covers the air filter.

- The gasoline hose is removed from the fitting cover.

- The saw body is dismantled. You need to unscrew the screws and remove the oil tank cover.

- Before removing the ignition module, you need to disassemble the clutch drum: you need to rotate the crankshaft clockwise until the piston closes the gas outlet.

- Then you need to unscrew the clutch on the chainsaw and remove the clutch: you need to hit it lightly with a hammer.

- The screws are removed, the gas tank with the oil hose is dismantled.

Design and operating principle

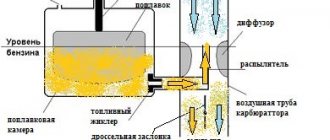

A carburetor is a device in which fuel (gasoline) and air are mixed in specified proportions, followed by supplying the prepared mixture into the engine cylinder. Almost all models of chainsaws have the same type of carburetors, so their design and operating principle are the same.

The main elements of the carburetor design are:

- the body , which is cast from aluminum to reduce weight. Chainsaws constantly have to be moved from place to place; they are held by hand during operation, so reducing the weight of the tool is the primary task of manufacturers;

- diffuser with an air damper, which are located at the inlet;

- jets , which are valves for metered fuel supply;

- atomizer , which ensures the injection of gasoline into the chamber (in the diagrams it is designated as the main jet);

- fuel (float) chamber.

Figure 1 – Diagram of a chainsaw carburetor

The principle of operation of a carburetor can be described as a cycle consisting of the following actions:

- When starting the engine, the air damper opens.

- The stroke of the piston creates a vacuum in the air channel, as a result of which air enters the diffuser, the amount of which is regulated by the position of the air damper.

- Gasoline flows from the gas tank into the float (fuel) chamber. The speed of its flow is regulated by jets.

- In the diffuser, gasoline and air are mixed, resulting in the formation of a fuel-air mixture, which then enters the engine cylinder. The more mixture enters the combustion chamber of the cylinder, the higher the power and speed at the engine shaft will be.

Important ! It should not be assumed that the operation of the carburetor has a cyclical basis, as it may seem from the description. All processes occur constantly and continuously.

When customization is required

Modern “three-screw” carburetors of Carver chainsaws are practically not designed for manual adjustment at home. The screws are provided for factory settings, are securely secured against rotation during vibration by tenacious springs and do not change their position arbitrarily.

But the screws on the carburetors of Carver chainsaws can be adjusted through special holes without removing the casing using a regular screwdriver. This suggests that such models structurally require carburetor adjustment from time to time.

The reason for this cannot be precisely stated from a technical point of view. Only versions are possible:

- The carburetor of the Carver chainsaw is located in an area of high vibration, which causes the screws to unwind spontaneously.

- A rough spring is installed, which cannot fix the screw as on other models.

- Periodic adjustment is required due to the technical features of the carburetor and the internal combustion engine of the Carver chainsaw as a whole.

Saws Shtil and Partner

In chainsaws Shtil 250, 361, as well as Partner 351, 350, the carburetor is adjusted using screws H and L by setting the proportions of gasoline and air. If you release them, a large part of the fuel will be added and therefore the speed will be high, otherwise, on the contrary, it will drop.

The idle speed in Partner chainsaws is regulated using a screw with the letter T, but with Shtil, as a rule, you need to look for the LA marking. Standard adjustment of the chainsaw is carried out during final tests. Basically, after such settings, the percentage of fuel in the working mixture is greater than air, which does not correspond to the optimal parameters. But they must be preserved during the first hours of operation during the running-in of the device. After this, the saw can be adjusted independently, but it will work well even at the factory settings.

But if you decide to regulate yourself, then the actions must be performed in the following sequence:

- adjusting screw L;

- then adjust the jet H;

- after that, proceed to adjusting the idle speed using screw T (if the Shtil chainsaw is LA).

First, screw L must be turned in both directions in order to find the maximum engine speed. If that point is found, then turn the same screw by ¼, thereby slowing down the speed a little. If the chain continues to move at idle, you must immediately turn screw T (LA) until the chain stops completely.

After setting the maximum speed with screw H, you need to check the frequency on the tachometer. In the event that it does not correspond to those specified in the service book, the setting must be repeated. When a lot of smoke comes out of the exhaust pipe at maximum speed, the mixture is too rich in fuel; if noise is heard and the engine gets very hot, then, on the contrary, it is lean. Then you need to adjust the idle speed. With proper settings, the engine should sound smooth at low speeds, and the chain should not move.